Leaderboard

Popular Content

Showing content with the highest reputation on 04/23/17 in Posts

-

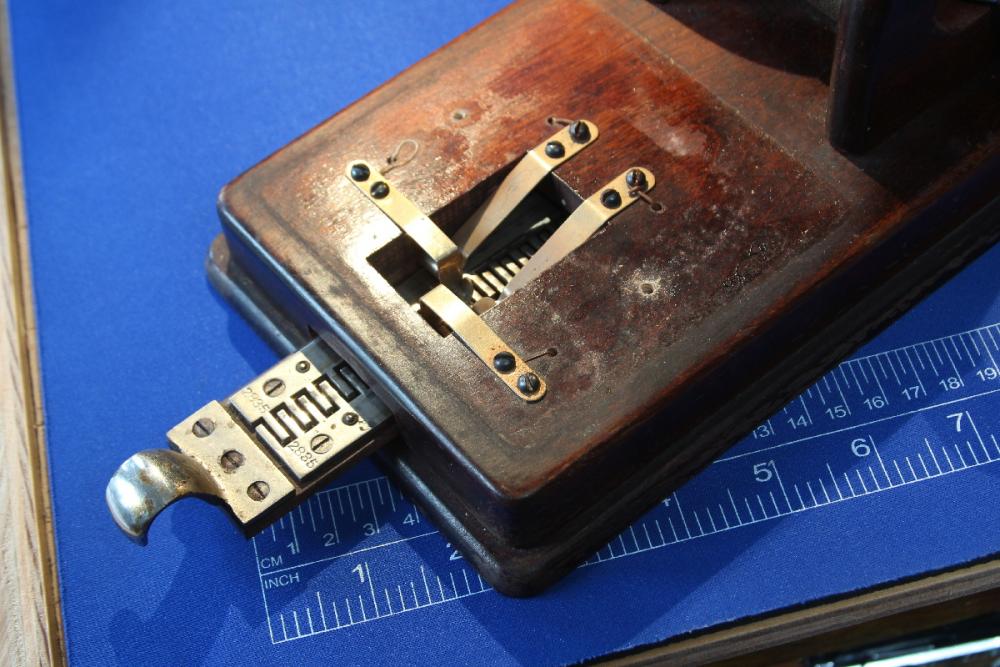

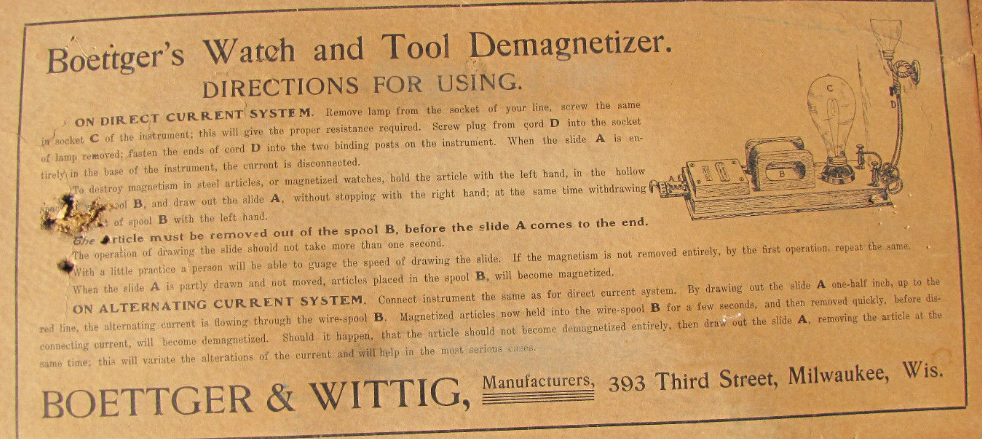

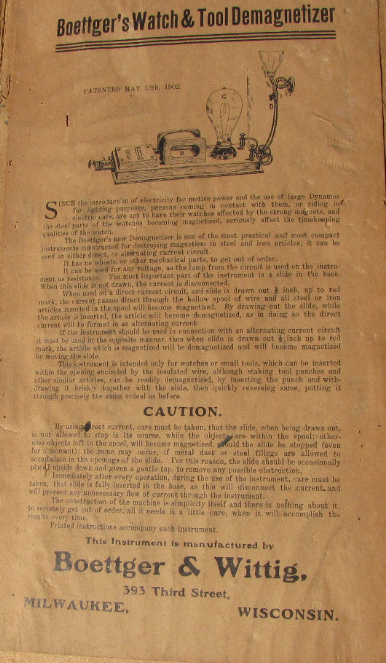

No wimpy ebay/made in China, blue plastic. $6 dollar watch demagnetizer here. I got me a badass demagnetizer—a 1902 Boettger & Wittig machine made in the U.S.A (Milwaukee WI). I did find it on ebay and bid $35 to win the auction. I didn’t care if it worked as I could make a steam-punk lamp out of it—If I could also use it to demagnetize watches/tools that would be a bonus. I finally got up the nerve to plug it in and after some trial and error I found that it does work. The tool is not UL listed (to say the least) and if the operator touches the terminals where the vintage lamp cord is connected, or the metal on the draw bar it presumably causes instant electrocution as these parts have 120 volts present. In 1902 electricity was still new and I am guessing that anyone that purchased one of these machines had enough education/common sense to not touch the metal parts with it plugged in. I had a question about its operation as the original instructions really don’t explain the finer points of how it works. The tools can be powered by either direct current (D.C.) or alternating current (A.C.) and both were available in 1902 for consumer use. At the time Westinghouse (A.C.) and Edison (D.C) were battling it out over which one was better—Westinghouse won.I drew arrows to show the flow of current. 120 volts is connected to the screw terminals. The light bulb is in series in the circuit and adds resistance to lower the amount of current flowing to the coil. From the light bulb the wires are connected to a wiper that touches one side of the draw bar (pulled out part way at left—yellow arrows indicate 120v). The other 120v terminal connects to the other side of the drawbar. The coil has two wipers that touch each side of the draw bar. When the drawbar is pulled out the coil wipers alternate between each side of the drawbar (you can see the interlocking pattern of the metal on the drawbar) and thus the coil reverses magnetic polarity as the wiper arms touch the different sides of the drawbar. When plugged in the circuit is in one of three states depending on the position of the drawbar: 1) the light is bright and the coil is not receiving current, 2) the light dims indicating that the bulb is in series with the coil with is now an electro magnet, and 3) the coil 120v supply is reversed and swaps north and south magnetic poles.With a screwdriver inside the coil If I pull the drawbar out so the light is dim (coil is on) and leave it for 4 seconds, then shut the tool off the screwdriver becomes magnetic. If I do the same thing but slowly remove the screwdriver from the coil about 2 ft. then shut the current off the screwdriver becomes demagnetized. The same thing happens when I slide the drawbar in/out but the light flickers as it is intermittent to the circuit. So my question is (finally got there) what advantage does sliding the drawbar out to either magnetize or demagnetize watches/tools have. The tool works the same either way—using the drawbar or just turning on the coil.I included the instructions for reference. They are written in the formal language of 1902 and it is difficult to understand what they are trying to convey.3 points

-

I am 100% sure as the drawing is not that clear but looking at my "bestfit" book it could be caliber 922. There is no caliber 416.9. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&AS_922&2 points

-

1 point

-

Hi I own a Seiko Sealion Automatic which I had bought for my 21st by my parents, its still going and I am now 69. Seiko make great watches. I also own a Baume & Mercia Clifton and more recently an Omega Quartz on an impulse at an auction. I have removed the movement (1310) and it looks like it needs some tlc. I have ordered a new battery for it but I have my doubts if it will run. I wondered should it live up to my expectations and not work if there are any diagrams or instructions on how to dismantle and repair or tests that can be carried out.1 point

-

Think there could very well be a model with that number. AS 416.9 but it's not easy to find them on google? Even the prima primarosa is close? But from there to find a stem that works? Maybe it would be easier to measure the clutch wheel and the movement plate and from there try to find a stem that could fit? If you go to windingstem.com you can type in the measurements and see if there is a stem available?1 point

-

Yes I agree thank you, it certainly does appear to be close it makes me wonder that if the numbers jump between calibres if there are models in between that are not listed but closely related appreciate your help my friend1 point

-

Have you search here? The 437 looks like it could be close? https://watch-wiki.org/index.php?title=Kategorie:Bildgalerie_Uhrwerke_Adolph_Schild_S.A.1 point

-

Thanks Stuart - if I knew I would tell you i will follow your advice, maybe send it in to Ranfft also much appreciated1 point

-

Looks like similar to.hublot screwdriver set Sent from my SM-A720F using Tapatalk1 point

-

Ok, I give up, quiz over, you can tell us now! I understand why clockboy went for the 922, but this appears to be a cylinder movement. Ernst Westphal has a great selection of vintage catalogues, including one that shows pages of 10.5'" rocker bar cylinder movements all together, but I can't spot this one anywhere. AS movements in this category are 175, 467, 740, 760, 937, 960, 1086 My advice would be to look at the drawings for AS on windingstems.com and pick the one that appears to be the closest fit to the other parts you have You may be able to find some older movement catalogues, but yours definitely isn't in any of the ones I know of on-line1 point

-

1 point

-

I had a similar experience with a customer who kept magnetising her watch. I found that she had a magnetic bracelet and was wearing it on the same wrist as the watch. It took a few weeks before I resolved this issue. The other issue to be aware of is how the customer wears the watch. Some wear the watch with the crown facing away from the hand some even wear it on the reverse side of the wrist. This knowledge is useful when regulating the watch i.e. getting the best setting for how they will use/wear the watch.1 point

-

There is only one hand - the second one. You need to post pictures of the mov.t for questions related to it. You can find many threads on buffing and polishing using the search box on the top right. BTW, your watch has a lapped "sunburst" finishing, which can't be really be done manually.1 point

-

1 point

-

1 point

-

Thank you! Yes it was quite an investment in time and energy, but one that is well worth it. The GP's have a vintage look and great quality without the premium that similar Omega and Longines watches command. J1 point

-

1 point

-

To understand adjusting a watch I have some links below reading material. Plus image from Omega's technical documentation's on what they expect. So Omega publishes the timing specifications for just about everything they make but this section is for watch is older which works nice for us as it's more generic. Even though their listing physical sizes of watches the other thing there showing is the running time. So modern watches tend to run much longer than their predecessors. Modern watches that may run 48 to longer at the end of 24 hours still have really decent amplitudes and their timekeeping is going to be much better than a watch that runs a little over 24 hours. Then interesting terminology things. Notice on the Hamilton pocket watch it says adjusted. What exactly does that mean? So on American pocket watches it may include things like temperature.. Where is modern watches there is nothing we can do about temperature.. Then the number of positions is an interesting question is what exactly does it mean? So for pocket watches the positions are slightly different than wristwatches such as normally pocket watches never run crown down. So another image from Omega showing their various positions. Note Rolex only times their watches in five positions. Then the attached PDF from ETA 6497 Showing the number positions is basically based on quality standard grade 2 positions something better three positions. So for the original question of confusing terminology of what exactly " regulated to 5 positions " We need to look at the pdf Link below labeled labeled X-D-DVH-Di-Im-N_EN. Looking at the very beginning X = mean value rate. So for X the more positions we add in the more closely they have to be if we want to meet whatever timing specifications were trying to achieve. Basically timing in positions regulated in positions just means watch was verified the various positions. Then a problem. Ever noticed how tech sheets don't really explain everything? Specifically tech sheets for watch repair? This is because it's assumed that the reader of the tech sheet has basic knowledge of watch repair. Then run down to your local bookstore how many books on how to repair an automobile versus how many books on repairing a watch? Repairing watches isn't exactly a dying art but the number of people doing it versus other things is considerably less so the amount of information available is less. Then conceivably at one time especially before timing machines this statement may have been correct " I mean is it a big secret passed down only to the next generation? " This is because whoever was adjusting the watches before timing machines existed was at the absolute top of the food chain in the watch shop because it did require full knowledge of everything and considerable skill which probably was passed down to the generations. http://www.witschi.com X-D-DVH-Di-Im-N_EN SCOPE / BEAT NUMBERS Test and measuring technology mechanical watches Witschi Training Course ETA 6497-1 Manufacturing Information.pdf1 point