Leaderboard

Popular Content

Showing content with the highest reputation on 10/14/16 in Posts

-

I picked it up at the swap meet for $75 . They were asking for more , but I had helped the seller out with some other of his watches in the past so he dropped the price . It's NOS , came in it's packing box from Russia . The key also locks the front glass panel for a water- tite seal and has an 8 day power reserve on a full wind . This bugger's heavy .2 points

-

I use the same method as George Clarkson minus the rodico . It stabilizes the clip against the case .2 points

-

Hi everyone, I've been interested in Horology for a long time, I'm guessing a big push in that direction was when I was 13 I was given my great grandfathers BTM watchmakers lathe. My grandfather and great grandfather were both watchmakers, so I guess it was only a matter of time until I caught the bug. Where I live they stopped running formal training on watch and clock repair over 10 years ago until the Master Clock and Watch Makers of Western Australia started running night classes staffed by volunteers 3 years ago which I've been attending since January this year. I've still got a while to go before I reach the point of being able to service and repair other peoples watches and clocks, but at least I've got a path to my end goal now. I have all the tools now to carry out basic servicing and repairs on clocks and almost everything I need for basic servicing of watches which was helped along the way by an out of the blue call by my step uncle offering me my grandfathers watch repair toolkit which was even more amazing because at the time he did not know I was studying watch and clock repair. I also have a workshop set up for model engineering complete with a Chinese lathe, Mill, drill press, cold cut saw etc which will prove it use especially with clock repair. I still haven't set up a dedicated service area as I've yet to convince the wife I need a space in the house as my workshop is not suitable as its full of a dismantled vintage BSA motorcycle, but I'm sure I will get over that hurdle within the next 6 months. I stumbled across this forum a few months back and figure now is about the right time to join as I'm hoping over time besides asking for help I may be able to provide some too. Attached below are a couple of photos of my BTM lathe, for those that dont know it was made in England during WWII for the military as obviously the German lathes were not exactly available. Tony1 point

-

As I see it you have 2 choices...leave it sticking up slightly away from the movement which will convince you you've made the wrong choice every time you look at it OR as clockboy says use a pin vice and gently straighten it so that would mean success. if it breaks you also have 2 choices. Attach it to the movement with one foot only or use a little sticky pad. Go For It....You know you want too !!!1 point

-

1 point

-

Really nice job. I buy my crystals from Dave"s he is great. http://www.watchpartsandtools.com/index.html you can even send him the bezel and he will fit it. I like to do my own but it's an option1 point

-

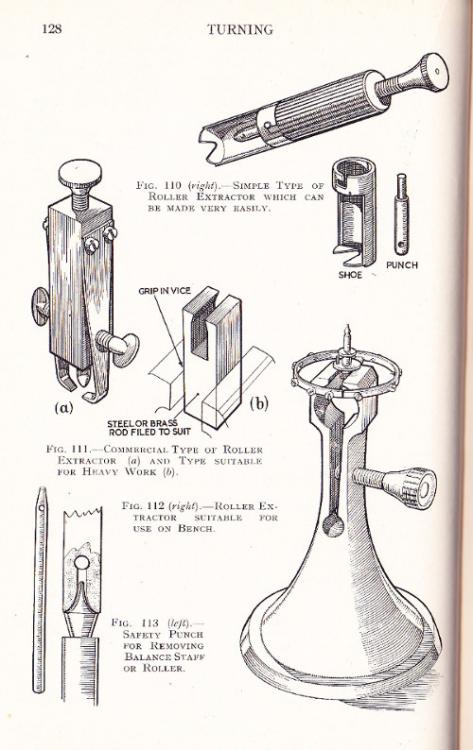

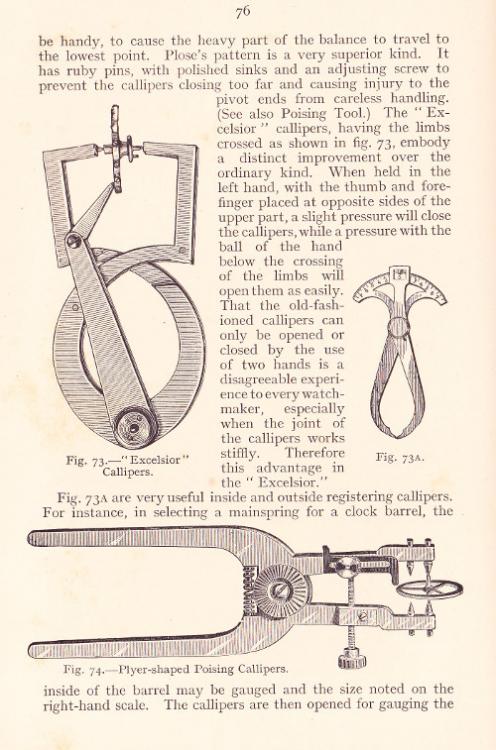

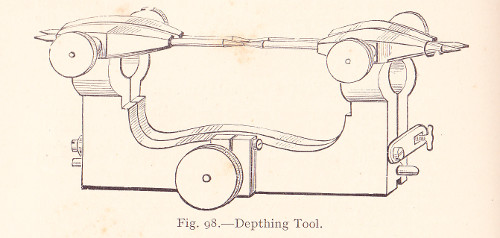

I would go with Watch Depthing tool which is used to work out the correct distance from a wheel to a pinion and then to transfer this measurement to the plate for drilling the pivot holes. Plyer shaped Poising Calipers as rodabod has stated for checking the true of a balance wheel The last tool I thought was for removing cannon pinions, but my book tells me its for removing rollers, but I guess it would work for hands and cannon pinions too. Depthing tool and truing pliers pictures are from 'Watch and Clockmakers Handbook Dictionary and Guide by Britten, other is from Watch and Clock Making and Repairing by W J Gazeley, both very useful books for identifiying tools and how to use them.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Thanks folks for your comments. Happy to let you know as much as I do Roland. They take around 4-5 hours to make and so I really could not sell them and keep everything fair, but there is a large amount of satisfaction once a watch repair/service is done and in the making one of these. There is a lot of subtlety to making them as I am sure those of you who have done this will agree. Firstly examine the watch, you need to evaluate the lugs carefully. How thick are they, what is the distance from the hole to the case. These are factors that need to be considered for thickness of the bands leather. You need to use strong leather that will last. I tend to use kid leather for the lining, suede side out as this is very comfortable. I also use leather for padding if I need to. Consider stiching colour and length of the band. Try to get the buckle to lie on exactly the opposite side to the watch once the band is on your wrist. I have made up some simple templates for the bands depending on lug width. You may have a lot of tools already, but these are readily available and cheap from eBay etc. In my view the glue is critical as you need the band to be flexible, so I use Japanese Seiwa glue. It has a long shelf life, dries at the right rate remains flexible and locks on. For a long time I used a hand awl for the stiching holes, but now use the prongs you can get from eBay. Get a 10 and a 2 one. You will need the small one for curves. Think how you use the leather, I try to get matching patterns for both sides, if it has these. I use scalpels rather than knives etc. These are just my ideas, the rest you will pick up easy enough. You sure won't have any problem with Christmas presents...In my view nothing sets off an old watch like the band. Here are a couple more. I like the orange ostrich, but I think I am alone here. And thanks again for the kind words.1 point

-

I had a bad day yesterday. My sodding computer went stupid and it took me nearly the whole day to sort out. That's Microsoft Windows 10 64bit for you. I don't have much hair to pull out.1 point

-

1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)