Leaderboard

Popular Content

Showing content with the highest reputation on 05/20/16 in Posts

-

Wot larks! Got this in a charity shop yesterday afternoon for £35. It's a Decca "Crescendo" portable wind-up gramophone from around 1930 or so - came with some rather battered but playable 78s. I must dig out the ones I have in the upstairs cupboard. Works a treat and is unbelievably loud. Beats an iPod hands down. Perfect for annoying the neighbours on a sunny afternoon while sitting out in the garden in my white suit, straw hat, drinking Pimms... don'cha know. Cheers, Will1 point

-

1 point

-

The most important is the termination, modern mainspring don't used T-End style; don't think you can find that on cousins uk. Hamilton #318 mainspring are easy to find on ebay us.1 point

-

Yes that is correct. For main plates and and other parts that are dirty, I use an ultrasonic solution in hot water and brush gently with a toothbrush, rinse, and finish in naptha to displace any hidden water and let dry. Super spiffy clean. Sent from my SM-G925T using Tapatalk1 point

-

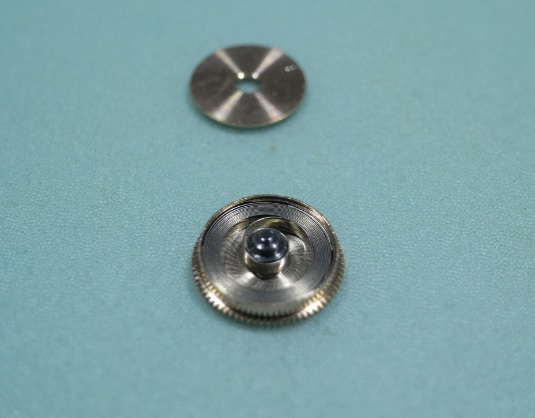

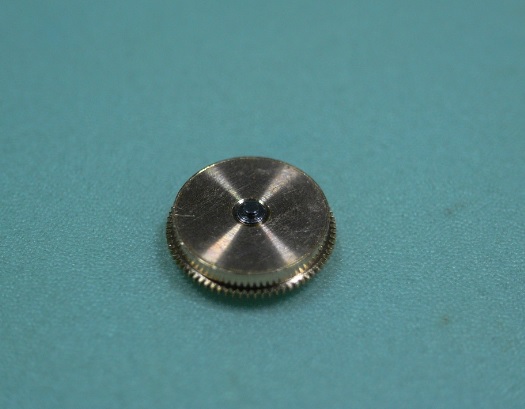

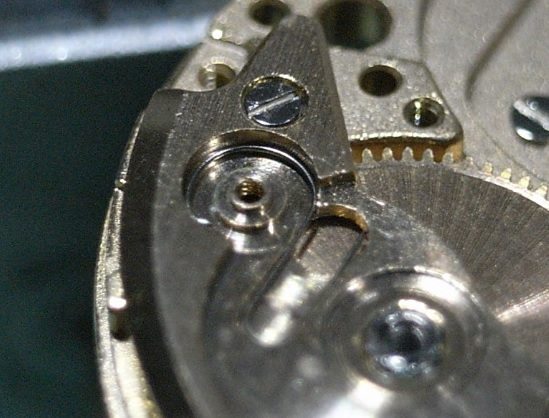

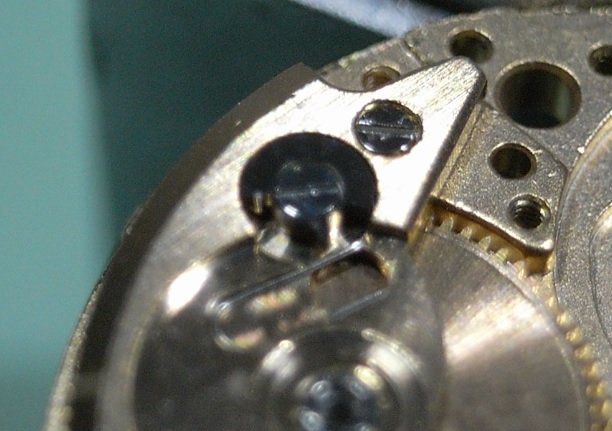

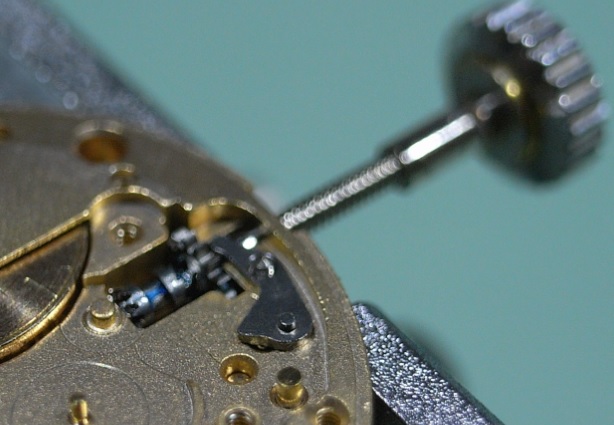

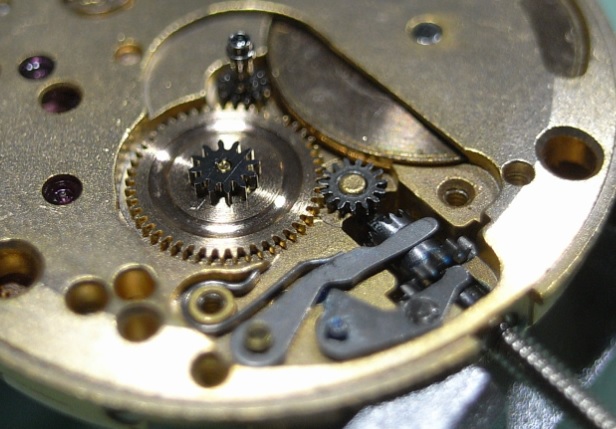

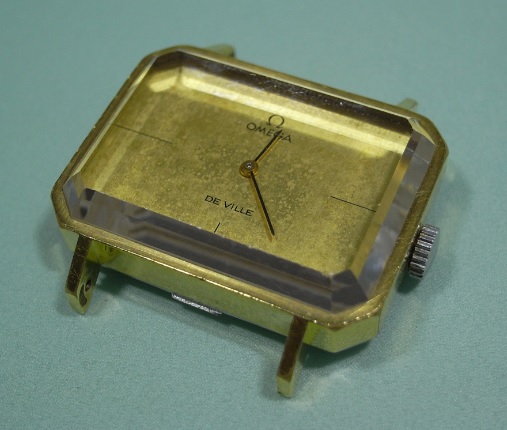

The replacement mainspring arrived at last, so it's time to assemble the movement. To install the new Mainspring, keep the coloured side of the keeper up and press gently into the Barrel with Brass Tweezers. Then install the Arbor . Then replace the Barrel Cover. After discussing this movement with a master watchmaker and good friend, he recommended using Jizma Green to lubricate the Arbor. Install the Barrel and Setting Lever Screw. Then replace the Mainspring Bridge. Install the Click Spring. Then the Click. Now install the Escape Wheel. Next install the Fourth Wheel. Then the Third Wheel. Lastly the Center Wheel. Carefully place the Train Bridge over the wheels, align the pivots and secure. Be sure to always test the free running of the train before completely tightening down the bridge. Now install the Ratchet Wheel. And then the Crown Wheel and Crown Wheel Core. Flip over the movement and place the Clutch Wheel and Winding Pinion. Insert the Stem and then install the Setting Lever. Replace the Yoke and Yoke Spring. Press the Canon Pinion in place. Now install the Minute Wheel and Setting Wheel. Then replace the Setting Lever Spring and Hour Wheel and check it's function, then remove the Hour Wheel to avoid it falling out as the movement is flipped. Flip the movement over and install the Pallet and Pallet Cock. Give the Crown a few winds and test the Pallet's action is free. Then install the Balance, remove the incablocs, lubricate and re-install. Turn the movement over again and after replacing the Hour Wheel secure the Dial. Fit the Hands. Place the movement in the Caseback. Then snap the Top Case in place, and fully test the watch's functions. Check and calibrate the movement on a Timegrapher, and the service is complete. This has been an extremely satisfying movement to service, and I'm sure it will give it's owner many years of pleasure to wear I also trust it helps others and gives them the confidence to tackle the service of this movement.1 point

-

Roller table is the complete, correct definition. Making a Vacheron Roller Table http://www.historictimekeepers.com/Vacheron%20Roller%20Table.htm1 point

-

Hello and welcome to a great place to learn. I would say some work area that you can sit at that's about shoulder height it doesn't half save your back from aching from bending. Also I cant stress how much good tweezers and screwdrivers are to cheap ones. As oldhippy said pocket watches are also great for learning how parts go together and interact with each other and once you've taken it apart and put it back together a few times it all starts to fall into place where parts go. Mick1 point

-

I've uploaded image with the specifications for your mainspring. Just remember when you're looking for a generic spring it has to have the right end to fit American pocket watch. Then typically the modern White Springs for the same thickness are stronger than the original ones. Personally I always like to remove the old spring and measure that just to verify it does actually meet the specifications that you find the reference books because occasionally there's variations.1 point

-

Hey Nello, Welcome to the forum. If you're into mechanical watches, this is the place to learn! I started here with knowing only how to change a battery in a quartz watch, and I've just finished my first chronograph valjoux 7750. In between? Well, a LOT of maimed watches, flying springs, screws, levers, hands. mainsprings. But also I've succesfully overhauled my ENTIRE collection of watches: 5 vintage Omega constellations, 3 Bulovas (a 333 Oceanograper, a 666 Oceanographer, and a Jet Stream), 1 Jules Jurgensen transistorized+balance wheel, 5 Sicura Jumphours (3 manual and 2 automatic winding), 4 Cordura watches (including 2 mechanical alarms), a Boctok Russian divers watch.....you get the idea. I started out with crappy tools and very quickly learned that the minimum you need is a good pair of steel tweezers and brass tweezers, a movement holder (bergeon 4040) a set of screwdrivers (these don't have to be swiss, I've used French-made just fine, but they have to be precision--i.e for watches), and lastly, a 4x head band magnifier and a 10x loupe (bausch&lomb not chinese). This is what you'll need just to dissasmble, and I haven't gotten into tray storage for parts, rodico, peg wood, oils/oilers, crystal press, hand remover, cannon pinion tightener, one-dip cleaner or naptha for removing old oil, lighting, and a work mat to minimuze eye strain. I love this hobby and its been very rewarding. These things are just to give you a heads up, not to dissuade you ok? There are many, many knowledgeable and friendly like-minded fellows here (no gals that I know of) that will help you along the way as you learn. If you lose a part or need help with suggestions on something your working on, you will also discover a wealth of information from the members, and maybe even someone has that part. Look around, have fun check out the overhaul videos done by mark and last but not least, post pictures! Regards, JC1 point

-

1 point

-

Use the other side of your micrometer, that way you can get right inside the bezel and measure up as far as you can go to the shoulders of the bezel, measure from say 12 to 6 or 9 to 3. Here is a video I found to help you.1 point

-

de magnetize / de GAUSS : I have a couple old watchmakers de magnetizers. there is a button to hold down when passing AN ITEM thru (in and out) of the coil. this means there is no power on when left un attended. I like that GAUSS meter. vlnn1 point

-

This is what you need. If you get anything that is to powerful it can distort the hairspring which is the main part that needs demagnetizing. http://www.ebay.co.uk/itm/like/161822826949?limghlpsr=true&hlpv=2&ops=true&viphx=1&hlpht=true&lpid=122&chn=ps&googleloc=9045125&poi=&campaignid=207297426&device=c&adgroupid=13585920426&rlsatarget=aud-133395220866%3Apla-131843272146&adtype=pla&crdt=0&ff3=1&ff11=ICEP3.0.0-L&ff12=67&ff13=80&ff14=122&ff19=01 point

-

That looks awfully like an old citizen movement with the parashock shock protection system...like a 7210...ish sort of movement. I hope someone familiar with this can really identify it.1 point

-

I use elma 1:9 as cleaning solution and Elma Suprol as rinse, set it universal as it can be used in both ultrasonic and normal cleaning machines. Most of cleaning solutions are water based so you need rinse bath with something which repel water.1 point

-

This was a mod I did a few years ago. Seiko 6309 7040. Check out the second hand you aviators. It was one of those bits and pieces, junkyard builds. I actually wear it a lot as its a bit of a favorite, fits good and is very comfortable to wear. I just serviced it recently and it's running very nicely. Not bad for a watch that serials from 1980.1 point