Leaderboard

Popular Content

Showing content with the highest reputation on 05/04/16 in all areas

-

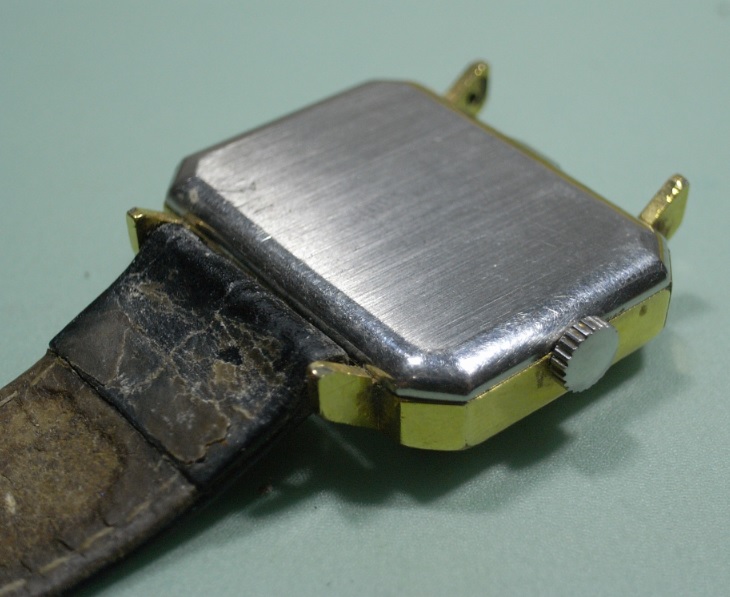

Omega 620 Complete Service I'm servicing a nice vintage Omega DeVille for a friend at work, and I promised her I'd post a walkthough of the service online so she could see the progress. It's an old 2 hand mechanical, which is rare to find in the DeVille range these days, and it has nice patina on the Dial. Along with the service to the movement, it will need a new leather strap, as the original one has succumb to age. I'm glad that the glass is in good condition, as replicating it would be an endeavour to say the least; and fitting a standard flat glass would take away from the elegance of this timepiece. It's only fitted with a dust-proof snap back, so I was expecting to see the normal amounts of corrosion on the stem, and keyless work. But I was pleasantly surprised to find virtually no corrosion on the stem or movement. So this watch has definitely been well looked after, and from the markings inside the Caseback it has also seen it's share of trips to the watchmaker for servicing in it's lifetime. From my initial inspection the first issue I noted was a suspected broken Mainspring, as the Crown spun freely whilst in the winding position with no resistance felt against the Click. Now the watch is open, and can see there is damage to the Crown Wheel and Ratchet Wheel, I am even more confident my first thoughts were correct; but I'll know for sure when I open the Barrel. There are also a couple of fibres inside the case. You can see one here resting on the incabloc setting of the Balance. So a good clean and service, along with a new Mainspring, should see this little 620 movement running nicely for my work colleague. I don't have time to strip the movement and remove the Barrel until the weekend. But in the meantime I will get pre-approval for the purchase of a new Mainspring from the owner, so once I've removed the Barrel and confirmed it's broken I can place the order. Is the Mainspring truly broken? Will the owner agree to spring for a new Mainspring? Does Mark enjoy wearing 70's disco outfits at that Retro Nights more than he lets on? All these questions and more will be answered in the next episode!! So stay tuned .... same Watch Time, same Watch Channel!!2 points

-

One thing about reducing the diameter of the seconds hand tube by 'pinching' is that it will only grip the seconds pinion at the 'pinch' points. This will result in the seconds hand easily moving out of alignment and fouling the minute hand or dragging on the glass. If you have a piece of wire slightly thinner than the seconds pinion, put this in the hole of the seconds hand and gently close the end of a pin-vice around the tube (with the wire inside). The wire will ensure you don't crimp too far. The benefit of doing it this way is a) you have 4 pinch points and b)the force is more controllable. HTH Anil2 points

-

Yes, Watch Repair for Beginners: An Illustrated How-To Guide for the Beginner Watch Repairer by Harold C. Kelly or/and Practical Watch Repairing by Donald De Carle Also check this one out: http://www.clockmaker.com.au/diy_seiko_7s26/ AND don't forget Mark's videos!!!2 points

-

I would leave it as it is. It has obviously been specifically designed that way with a specific mass of metal deliberately distributed and shaped. If you were to remove metal, you will probably speed up the escapement and take it out of the range that the regulator is capable of compensating for.2 points

-

1 point

-

Poised pallets never, don't believe all that is on the Internet.1 point

-

1 point

-

1 point

-

Its a railroad watch with a locomotive on the dial Or i can just remove the guard pin1 point

-

I feel a bit of filing coming on. Remember it ain't no Railroad watch!1 point

-

Found something here: http://people.timezone.com/mdisher/EHElgin/EHElginPt2.htm In short, old heavy weight levers should be poised, modern levers should be as light as possible to decrease gravity effect. Then reducing fork end weight seems a better choice.1 point

-

Well, just imagine both the lever rotation axis and the lever itself are in horizontal position (e.g the watch is in my pocket). There is different push on the balance in the two directions from the fork. Bigger downwards and lower upwards (if the fork end is heavier). Measured that before stripping down the movement, it even stopped sometimes on the position mentioned. There was no problem (not that big difference in rate and amplitude) if the rotation axis or the pallet (or both) were vertical. There must be some weight balance! It has to be mentioned, at that time it has a wobbling balance caused by the untrue balance wheel and the worn balance bushings. But if this would be the problem source then it would have stopped if the pallet fork is vertical and the balance axis is horizontal. I can change the balance spring length, since it is fixed by a pin. Rate adjustment (or shaping the spring if needed) should be no problem. I didnt noticed that the pins have different thickness. Will replace the thinner. Meanwhile, i have found a nice procedure for pin pallet escapement service: https://www.dropbox.com/sh/gukk9my456xi2gt/AAAqpVVbth5uxnTJ_T60YIV5a?dl=01 point

-

I did not know a pin pallet had to be poised. I don,t know if it is the angle of the final picture but the pins look different widths if so that is wrong.1 point

-

1 point

-

you couldn't have picked a better watch for the beach. just hope there's no sand between your wrist and the bracelet. that's as bad as having sand between your.....oh forget it. love the pinstripes on that SAR. nice pick for around town.1 point

-

Oooooo that's funky I like it. I think my things i ordered off thewatchcollector in the good old USA are being delivered by the flashes half brother "The Slow"1 point

-

Excellent advice from members above. I would just add that - as I know to my cost - it's comparatively simple to get a movement to bits, but can be fiendishly difficult to get it back right again and in the proper order. So my advice would be to take notes at every stage, set the disassembled parts out in order of disassembly and, if you can do it, take a photograph at every stage to back up the notes. Then, like setting out on a maze with a long string or a trail of breadcrumbs, you won't get lost on the journey home. Part of your tool kit will be trays or dishes or plastic containers to hold disassembled parts. And - I'm sure you know this - learn the terminology of the mechanism so that, if you ask a question, you're talking parts language that people here can understand. You'll get even more help! Cheers, Will1 point