Leaderboard

Popular Content

Showing content with the highest reputation since 04/27/24 in Posts

-

I should have done this a long time ago. I would like to say a big thank you to all my followers new and old. If I can help in any way just message me and I will do my very best for you.10 points

-

6 points

-

4 points

-

4 points

-

For those of you who are looking for a Seitz jewel gauge, I just want to make you aware that there may be a good opportunity right now at Tradera.com (Swedish eBay). The site has significantly fewer visitors than eBay and I have made several fantastic deals there. 1500 SEK corresponds to approx. £110/€128/$137 https://www.tradera.com/item/1922/631487681/seitz-urmakarverktyg-matare Just to make sure, I'm not associated with this listing in any way!4 points

-

4 points

-

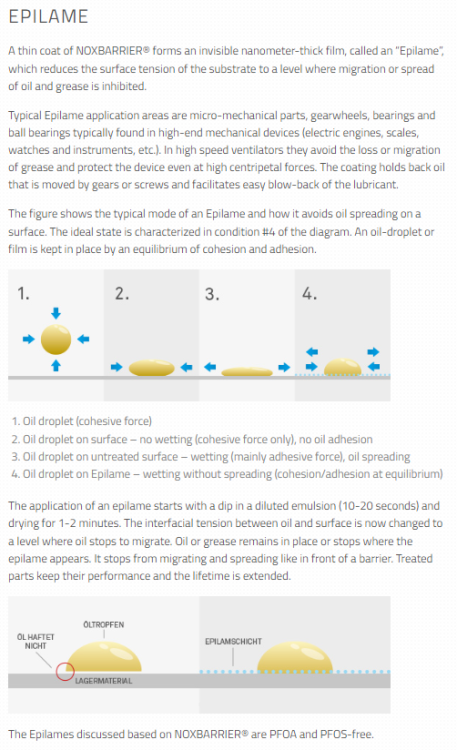

According to these guys "Coating watch parts with a thin, even monolayer of epilame provides an effective oleophobic barrier that halts oil spread in its tracks." Which is exactly the same process that causes water beading on a waxed car. An oleophilic treatment would actually cause the oil to spread out to as thin a layer as possible as every oil molecule would try and come into contact with the oleophilic surface. The reason an oleophobic surface prevents spreading is because the oil behaves in such a way as to have as little contact with the treated surface as possible.4 points

-

Picking up this side-tracked post again as I just removed a balance staff of a 1920's Omega (35,5L-T1) I was impressed by the way @Delgetti had his setup when he had to change out a balance-staff (https://www.watchrepairtalk.com/topic/28854-new-balance-staff-not-riveting-to-balance/page/2/#comment-244054 Not only that, but also the idea of removing the seat first before punching the staff out from the seat-side, avoiding the whole discussion of the rivet yes/no enlarging the hole. I didn't have the fancy clamps & tools Delgetti has, so I used my screw-head polishing tool. Initially I used #1500 grit diamond paste on the steel wheel, which kinda worked, but very slow. I changed to #800 grit diamond paste, which worked better, but still slow. Then I glued #240 sanding paper to the steel disk; That worked and the disk was hand-driven. Once close to the balance wheel, I took the sanding paper off and continued with #800 diamond paste. One can only do this when the balance wheel sits true on the staff and has no "wobble". I went on grinding until I saw some diamond paste on the rim of the balance wheel. This was as far as I could grind and it seemed that at that point there wasn't much left of the seat. Carefully, with my staking set, I knocked the staff from the seat-side out. Turns out that the thickness of the seat left, now a small ring, was only 0.1mm. The balance wheel hole is in perfect shape and no damage done to the wheel at all. Of course, if the wheel has a "wobble" or isn't seated true on the balance staff, you can't get as close and there will be more left of the seat. In my case, it worked perfect I'm very happy how this method worked out !4 points

-

3 points

-

Yep, that's exactly how it should fit. The reamer shank is tapered and the socket in the spindle is also tapered so that the one centers in the other and is gripped tightly. If there is any wobble when the reamer is seated as far it will go then there is a problem. The cross hole in the spindle is to allow you the push the reamer back out again. If the reamer seated much deeper then it would limit the access for pushing it back out again. Here is one of mine for comparison.3 points

-

[SBGA405] Grand Seiko “Godzilla” Spring DriveI always enjoy coming back at the end of the week to my first Spring Drive watch which is a combined automatic mechanical watch and a high quality quartz — a Spring Drive.Impressive accuracy (10 seconds per month) and wears remarkably comfortable at 44.5 mm in diameter and 95 gm.Love the power reserve indicator, and the colour of the dial amd the watch band.One of my “perfect” watches!!3 points

-

Not a family member, and yes, it no way near as good, as some information got lost from original site and some information got incorrectly copied. The original site is available as iOS app here: https://apps.apple.com/fi/app/ranfft-watch-movements-archive/id65020089393 points

-

Even the amount picked up by the smallest oiler can be too much. I made my own oiler with a 0.2mm wire. And I use the amount picked up by the smallest black oiler and use that to transfer an appropriate size droplet to the tip of my homemade oiler. The final amount of 9415 used is so small that it seems ridiculous.3 points

-

I assume you're using 9415? the concerned with 9415 and I'm attaching a PDF from Omega is too much can cause a decrease in amplitude. This is why you look at what they do they go to extreme lengths to put extremely tiny quantities. so as you've discovered proper lubrication of the escapement increases the amplitude. We've seen it on this group where people are having typically newbies issues and I will ask if they lubricated the escapement the usual answer is no they had not because and once they did they saw spectacular improvement. one of the amusements with lubrication tends to be so many variations. For instance I was in a classroom once and the students all came from for the most part accredited schools in watch repair. So the instructor asked how did we lubricate our escapement's and I don't remember the actual quantity but it's really quite amazing how many people can interpret slightly different ways of doing the same ask. Of course the instructors method was the approved one. This was the place a drop of oil on the impulse face of the exit stone. Allow one third of the teeth to go by and place another drop then another third and your escapement should be lubricated. But sometimes and yes it will show up in the timing machine you'll see in your regular line because if the oil didn't transfer all the way around to the other stone that does cause a issue with the timing machine. Oh but when I was in school we were using 9010 as 9415 did not exist yet although 941 did which is an oil recommended for escapement's. it has to be dissolved in a proper solvent with the right amount of concentration as you want a microscopic layer on whatever your treating. My understanding is the vapor process is the very best but the vapors are not good for human consumption. The reason why the vapor process is nice is that it puts a very very thin coating on versus dipping in a solvent which can vary depending upon the concentration. 8645_WI_40_rules for lubrication cousins.pdf3 points

-

Used with the correct fitting staking punch it will remove the roller.3 points

-

They don't seem especially clogged not like teeth on a file, maybe a little but a good clean up will certainly improve them. That one in particular is unnamed but still seems fair condition, the others are really good quality, i think the seller was hoping for higher bids. No thats just staining Rich , the surface i would say are pretty even. Probably some discolouration from a metal it was used on. They all bite into spring steel nicely, better than buggering up a toothed file. The brands are from two reputable manufacturers. Thats a really good price . See how the bidding goes.3 points

-

I was considering just building a watch from scratch, I've heard the nh35 movements have a lot of case and dial choices and apparently they run poorly when you buy them new so a good service is required. But honestly building a watch like that doesn't interest me. I love fixing things. There's nothing more satisfying to me than taking something broken and making it work again. Plus watches are cool and easier to store than a car engine! I only had one engine in the dining room and my wife complained. Hopefully the watches will go unnoticed.3 points

-

I think we all get a lot out of this group, and it has been pivotal in my development by the sharing of knowledge, experience and learning from more seasoned experts such as @JohnR725 and others (you know who you are!) as well as fellow novices. I think that having a backup communication plan in reserve so that if there is a future problem just makes good sense. I don't think anyone is trying to undermine the forum, but if something unthinkable happens, like the Ranfft website for example, then it would be good if those who are willing can still keep in contact. Speaking personally, and I know I risk a charge of heresy, it would be good if Mark could be a little more visible in this forum, and maybe give any insight from time to time on the future/progress of forum and instructional videos etc. even if its just to confirm the status quo. I appreciate he is a busy man with a full time job, but so are most of the rest of us and to post a few lines every now and then shouldn't be too much to ask to reassure the restless villagers. Best outcome for me would be a message saying something along the lines of: "Hi guys, all good, no planned changes... enjoy the forum, will message again next month!" Just my two cents.3 points

-

Knocked out another 404 last night...when you are in the zone! This watch was a non-runner which I picked up as part of a lot of 8 watches, so works out to be $3.12 per watch. Before: And the finished watch, new crown and stem and the crystal was cracked so was replaced. I also replaced the mainspring as the original was the old steel type spiral and very 'set' - all else is original: The Movement was a AS 1686, but in reading around a little the ACCRO watch company were sued for their use of the five point crown on their Jacques Pere range as it resembled Rolex, see below: ACCRO then reverted to just ACCRO on their watches - I have done some sniffing around the internet and haven't seen another example of ACCRO and the crown together on a dial so maybe I have something unusual, or maybe I was looking in the wrong places .3 points

-

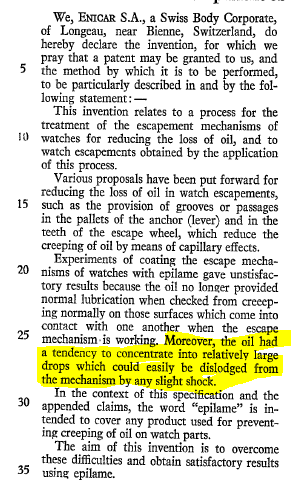

one little minor problem with your chemistry experiment here which is what exactly is epilam? In other words is it an exact substance with the chemical you specify or is it a term? For instance originally it was steric acid either dissolved in some sort of solvent or it was applied by vaporizing it. Then now it's all kinds of different things the watch companies all have different ideas there's a whole bunch of patents. So is not always an exact substance. let me snip out a image from the patent that I attached up above. Notice I highlighted something it seems to disagree with your evaluation.3 points

-

can I ask why you're not happy? did you notice that the acceptable low 24 hour amplitude of this watch is 160°? is there any possibility that a watch company could manufacture a watch that could actually run at a low amplitude and keep time? so if they can run at 160° at 24 hours and keep time then they probably would keep time at 240° which yours seems to be doing? then if you're really unhappy with this I would recommend purchasing an original Omega mainspring. Just because the aftermarket have numbers like an Omega mainspring it doesn't mean it's the same thing. Then I would also recommend replacing the escape wheel and the pallet fork. This is what they do in the Swatch group service center if they are unhappy with anything on the other hand they have an infinite supply of spare parts.3 points

-

Maybe I'm over simplifying this and I'm a little late to the discussion, but just by my looking at oil when I use it on a treated cap jewel the oil stays in one nice bubble, but when I don't it spreads out to the edges of the jewel. I'm not sure (but could well be wrong) but the analogy of a waxed car and rain is inaccurate in this case, the wax is very hydrophobic and repels the water, however, the process epilame works by is a different physical process based upon cohesion/adhesion (oleophilic) not repulsion (oleophobic) at least as far as I have read/observed. If one were to use a oleophobic substance equivalent to wax (hydrophobic) then one would need to create a donut shape to fence in the oil, however if one used such a strategy with a epilame which is oleophilic then the oil would sit on the ring of the donut and not in the 'donut hole', exactly where you don't want it. Even if the oil is smeared then the oleophilic epilame should pull it back to the center (see diagram below). Reference For interest the chemical in epilame is 2-(PERFLUOROHEXYL) ETHYL METHACRYLATE, CAS NO: 2144-53-8 Out of curiosity I looked at the price of buying this in the real world i.e. from a bulk chemical supplier, and for once it is about the same price as buying in the watch world.3 points

-

3 points

-

3 points

-

I recently helped my mentor to service 7 Seikos and he told me not to lubricate the pallets. His reason was from his experience from the advanced classes that he conducted, his students all ended up with worse amplitudes after oiling the pallets. I have to admit that I had the same problem when I oiled the exit jewel, like so many videos on YouTube show. I actually ended up with worse amplitude. But now I oil the escapement by oiling the teeth of the escape wheel. I think Rolex used to train their technicians this way. I find that I get about 20° -40° increase in amplitude oiling the escapement this way. I've only started playing with epilame recently. I got a bottle from a Chinese seller on AliExpress. It's supposed to be Episurf Neo but everything on the bottle is in Chinese. When the bottle arrived, half of it had evaporated or leaked. And when I brushed on a thin layer on a mirror, it dries rather slowly and even feels a bit tacky. When I did the oil spread test, like my experience with stearic acid, the treated and untreated surface of the mirror yielded similar results. The contact angle of the oil drop looked about the same for both the treated and untreated surface. When I epilamed an actual pallet fork, the escapement was so sluggish that I couldn't even get 180° amplitude. I dunno if I got conned by the seller but the results are just not convincing.2 points

-

2 points

-

More eloquently put than i Stephen, although i dont think i was too far behind you . I received an email from Episurf, they dont provide specfic instructions for its application, but did tell me that some watchmakers use a dry rub method and others do not, also in their literature they provide a surface tension measurement of Epilame.2 points

-

OK, let me try and expand on why I think this is right (but maybe misleading at the same time). Wikipedia has a good explanation of surface tension, which is where I got most of the ideas below. The cohesion of the liquid molecules binds them together into the most compact form possible. If there are no external forces acting, this is a sphere. Surface tension is the combined effect of the cohesion between molecules on the surface with others on the surface, as well as the cohesion to molecules just under the surface, causing contraction and the formation of a denser "skin". The way a droplet of a liquid forms on a solid surface is determined by the strength of this cohesive force relative to the adhesive force between the liquid molecules and the surface material. If cohesion >> adhesion, you get a droplet. If cohesion is similar to adhesion, the liquid tends to spread out on the surface and creep away from its original location. Oil doesn't have the same high surface tension that water does, so it is not going to form a really rounded droplet on any surface in the way that water will "bead" on wax. This is where my earlier statement is misleading, but it is still exactly the same principles at work. Drops of oil on an epilamed surface are not going to run off in all directions at the lightest provocation. What the epilame does, I think, is reduce the adhesive force to the surface somewhat, making the weak cohesive force of the oil molecules more effective. The result is less tendency of the oil to spread out and creep, and more tendency to stick together as a cohesive mass. I don't think epilame has any effect on surface tension. That is a property of the liquid and is determined solely by the cohesive forces between the liquid molecules. I also don't think the epilame makes the liquid "stick" to where it is applied. The oil adheres ("sticks") more strongly to a non-treated surface than to a surface treated with epilame. This is why the epilame needs to be removed from the contact surfaces by running dry for a short period. The oil then sticks more readily to the local contact surfaces, where the epilame layer is worn away, than to the surrounding area. The oil sticks together, and is thereby anchored in place as a single body. Interestingly, reducing the adhesion of the oil to the solid surfaces will also reduce capillary action, which is what we rely on if we don't use epilame. Another reason to make sure the epilame is worn away from the spot you want the oil to stay put.2 points

-

That is the reason why. I think it is better then have them all over the place. Regarding unmerged I can't see the sense.2 points

-

I tried the Moebius 9415 from any sensible amount, down to a microscopic drop (or "super minimalistic"); the size of droplet which makes you really wonder why one would/should apply anything at all? But to no avail, consistently a lower amplitude compared to my Dr.Tillwich 1-3. Of course, as John mentioned above, the Dr.Tillwich 1-3, just like the Moebius 9010, likes to go somewhere else. Since short however, I'm the (proud?) owner of a bottle of Moebius Fixodrop. Can't say that I'm a proud owner of the 9415. So far, I haven't seen or discovered the "magic" of the 9415. Meanwhile, Moebius () has my money though.........2 points

-

I used to be quite active on The Lotus Forum when I owned my Esprit. I was there for so long, Bibs asked me to be a moderator. I'm not sure how long I did that for, but I think I turned into the second longest serving moderator. When I 'handed back my keys', Bibs made me a Full Forum Member. Normally this is a paid membership. My reward I suppose for helping out for many years. Bibs (forum owner) is quite active on there and if I am not wrong, don't quote me in other words, I think he once said that the money from memberships didn't cover the running cost. He adds money himself to keep it going. Does Mark have any sort of subscription scheme on here? I'll admit that I never paid to be a member on TLF. I should have. I never did. I agree that it would be a good idea that there is some sort of contingency plan for this forum. I intend on becoming more active on here. Life has just been getting in the way recently. I enrolled on Mark's watch course and was keenly doing that, but even that has had to take a back seat for a while. I am looking forward to getting back into that and also starting to do work on the clocks that I have been amassing. To do that successfully, I see myself needing to lean on the other members here. If for whatever reason this forum was to close, I think a great many of us would struggle.2 points

-

Even for myself who only started getting into watch repair/servicing during COVID I have seen a huge jump in watch prices - we have a 404 channel on this forum. When I started you could relatively easily find a watch on eBay to restore and put onto the channel, however this is now almost impossible and the only feasible solution is to buy a job lot with an average price <4.04. Even watches sold for parts/spares are 3 or four times the price of only a few years ago. Why - Either Demand must have increased in order to push up the price, or supply is reduced. I think it is a little of both, I think that most watches in the UK/US may have been picked over, which agrees with most of what @Neverenoughwatches says so supply of all kinds of vintage watches, including tat is dwindling. As a double whammy I think that more people are wanting watches, either to work on, or as a way to differentiate themselves from the Apple Watch and FitBit crowd. The upshot is that half decent watches that require restoration are now $500 instead of $100 and cheaper watches (Seiko 5 etc) are now $50 instead of $10, and even Mumbai Specials and garbage are now pushing $50 each. When - how long will this last, I think that most of the people who are returning to mechanical watches are those that have previously experienced life without them and want to return to something with a bit of personality that doesn't buzz every 10 seconds on your wrist and tell you how many steps you have done today. i.e. the 30-40+ generation. My son who is 17 has several mechanical watches but only wears one on a special occasion and is obviously only aware of them at all in part due to my hobby. I asked him the other day how many of his friends wear a watch and he told me that some use a smart watch but most just use their phones. So as I see it, demand will start to fall once the sub-thirty crowd start becoming the majority and/or the older amongst us stop buying watches and switch our attention to mobility scooters and trying to remember our bank password. Price - I think this is here to stay, even if demand does start to drop as the older generation becomes to decrepit and stops buying and the younger generation isn't interested in buying, supply will become progressively less as time goes on as more vintage watches become lost or broken beyond repair. I think the prices will plateau at some point as an equilibrium is reached as reduced demand is balanced with reduced supply, i.e. less and less people buying less and less watches. Sorry for the long ramble!2 points

-

I usually don't read new introductions but when you came to the group did you want to learn watch repair? The reason I ask is your watch seems so suffered some damage under your hands. And now you're ready to move on to a new patient and have you learned? I often relate watch repair like learning to be a doctor lots of practicing. Even though this is a damaged watch have you practice taking it apart and putting it together a whole bunch at times so you feel confident that the next watch you probably won't break anything? Then when watches were invented specifically pallet forks they didn't have epoxy glue which even if they did they wouldn't you used anyway because the pallet stones need to be moved around they need to be adjusted. so the substance of choice for holding pallet stones and roller jewel's in is shellac. It's a really interesting substance were if it's warmed up at melts the palace on can be moved around hopefully the correct position when it cools shellac hardens back up in the pallet stone will be held in place. If you're carefully could probably put your pallet stone back just warm up the fork carefully ideally there's a tool for this and your pallet stone would be fine.2 points

-

No John, we don't want Mark to change anything, we are just scared of losing a brilliant forum and losing contact with each other. As pointed out, this forum is full of knowledge and I for one, consider the regulars friends. I would hate to lose contact with you and the others. PS, this forum is really important to me.2 points

-

I'm not sentimental, I see it this way. I inherit something I don't like, I could sell it, buy something I do like and remember the person with the new item. For example, I inherit a watch ( I haven't), I don't like it, I buy a watch I do like, every time I look at the watch, I think of the person.2 points

-

@JohnR725 has pointed out many times that the Swiss don't care about amplitude, the timekeeping is the most important. Give yourself a pat on the back, great beat error and timekeeping, nothing to be disappointed about.2 points

-

Imm going to close the discussion by attaching the photo of my super-titanium after several vicissitudes finally working. Purchased as not working I replaced the battery and for a stroke of luck I found its semi-new solar panel which, having verified its operation, seems to recharge the accumulator perfectly. I had taken this watch almost by bet, with 40 euros I brought it back to life. The initial half idea was to resell it to finance another purchase, but.. it's definitely a nice item. It would need to check the impermeability but it's a pleasure to see it on the wrist2 points

-

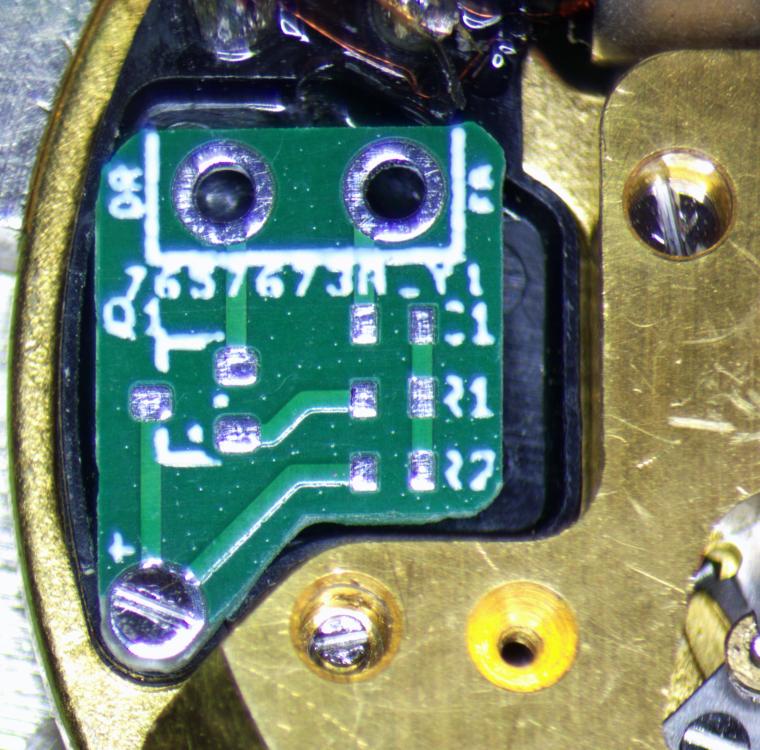

Murks, The rate and amplitude look OK, and the amplitude should improve once the oils you have used get a chance to move bed-in, also I notice that you are using default 52 degrees for the lift angle, if you get the real lift angle (assuming it's not actually 52) this will change your amplitude - maybe higher, maybe lower. I notice that the beat error is a little high, but not crazy high. At the risk of upsetting the purists, if the balance has an adjustment arm I would go ahead and try and get this <0.3 ms, but if it does not have an adjustable arm then I would probably leave well alone. Just my opinion.2 points

-

2 points

-

I've never done it, however just today I was reading about it! P.24 - P.38 of this explains the truing procedure for damaged balance wheels. I have no idea if this is still the accepted way of doing it, the learning material is rather old . Hopefully one of the veterans will be along to give you an easier solution. Good luck Joseph Bulova School of Watch Making.pdf2 points

-

have you ever noticed a nicely waxed car when water droplets hit they literally just run off. That's what you would have with epilam. The whole purpose is to keep the oil from spreading and if you put directly on top of the epilam it might not form a nice round ball but it has nothing to stick to which is exactly what is supposed to happen.2 points

-

2 points

-

If you tend to be a little heavy handed then heres something that might help you to prevent cap jewel loses if you have some spare tweezers. File a round into each of the tips so you can grip a capstone or chaton while oiling or moving them around. Instead of filing along the length, angle file the tips first then file the rounds perpendicular to the angle. This way the tweezers wont get in the way of the oiler. Choose an angle that suits your natural hand grip position. The tweezers can now grip round parts on four sides Instead of two that often flip that part away.2 points

-

2 points

-

2 points

-

Thanks everyone for your helpful replies. I think between us we’ve worked out what’s going on. Next job is to have a proper look at this great wheel assembly, see if I can remove the clip and the friction fit pinion, give the bits a good clean, then put it back together with a bit of blue grease. I’ll also get the pallet fork under the microscope to see if it’s ok or been damaged.2 points

-

It's a little circlip style retaining clip to keep the pinion from riding up out of position.2 points

-

Doctor, If the train turns when hands setting, this means that the train is not blocked. And this is true for all kinds of trains design. The train is normally blocked by the lever. So, put the lever in place and try again. If the train turns again, search where You have placed some wheel upside down and it is not meshed with the next one in the chain. The other thing is the amount of friction that is needed to overcome when setting hands. Yes, the friction part here is in the great wheel, and it needs lubrication. If the parts are dry, then friction will arise, seizing will happen and thus risk of breaking of teeth in the train or breaking of joint wheel/pinion. I don't know this calibre, but I guess the clip is part of the friction device. But for sure it stays tilted, which is not normal. So, pay attention to it and see what is wrong there2 points

-

2 points

-

As I'm only cleaning watches in small numbers at home, I pre-clean any significant deposits of old grease and oil before using the cleaning solutions. I scrape off deposits with pegwood and Rodico, and if really dirty, wash parts in naphtha with a brush. So I'm happy using DX, but can understand why it's avoided by the pros.2 points