Leaderboard

Popular Content

Showing content with the highest reputation since 04/20/24 in all areas

-

Its 4 o'clock in the morning here in the Uk, i cant sleep, i dont sleep, not much ever really. My brain never shuts off to rest, I'm just a constant thinker, i have to be very tired to be able to sleep, i guess eventually it will be my undoing and my health will suffer because of it I'm sure. But while I'm here i want to get as much out of life as i can, and give as much as i can, to help,maybe to make a difference to someone's life if that is within my capability,recent events have made that need even more clear to me. I'm not sure where I'm going with this or why i bring it up , or if its relevant to want i want to talk about its just in my head right now. What i do want to talk about is something thats been on my mind for ages. I like to be prepared, I'm not fond of surprises because surprises take control away and i am a bit of a control freak at times. This forum, Our Forum if i can call it that, is here because of two reasons. The guy that created it and keeps it funded and the people that joined it. Without either, it would not exist, and lets face it one day it won't ( I'm a realist and i talk about things others dont or who are afraid to in other words folk that dont particularly prepare for the inevitable). How many of us visit here regularly ? How many among us almost depend on the forum as a way of socialising because they are stuck at home and how many of us has it become part of a daily routine to check in and see if they can offer advice or get help with something they are working on or just to have a chat and engage in some banter. The members here are in the thousands and thousands have disappeared over the years many had just a fleeting visit. But there are a good few of us that know each other quite well and visit regularly. I dont know about you but i wouldnt want to lose that communication with you all, in all honesty it has become an important part of that side of my life and helps to feed my passion for all things watches. Some of you may think differently and thats ok, some of may stop and think # what would i do " Without Our Forum " #7 points

-

Double Oooooo Removal tool? Dreamed of one of these. However, Kalle on Chronoglide showed everyone my system with the pegwood. Worked a treat. Felt so chuffed to be mentioned. https://www.youtube.com/watch?v=tTFrXjiyGKc 46:40 for the wheel removal. Mentions me at 50:00 and does the removal with the pegwood. Felt like my 15 minutes of fame.7 points

-

Like losing Ranfft. That was a wake up call. We took his website for granted. Miss him terribly.7 points

-

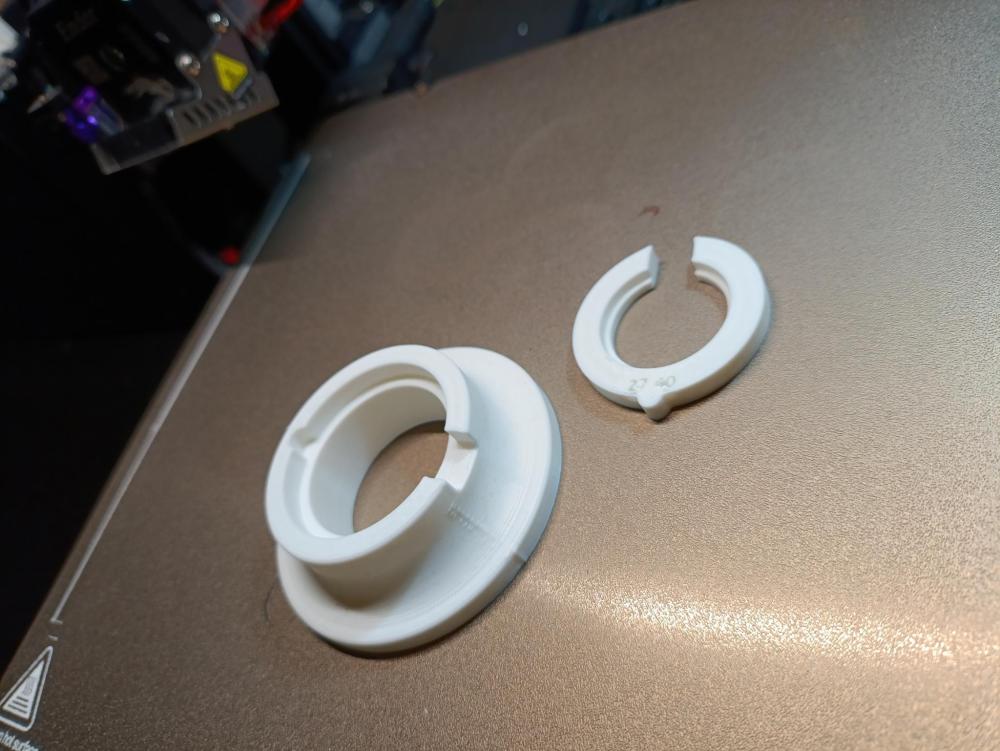

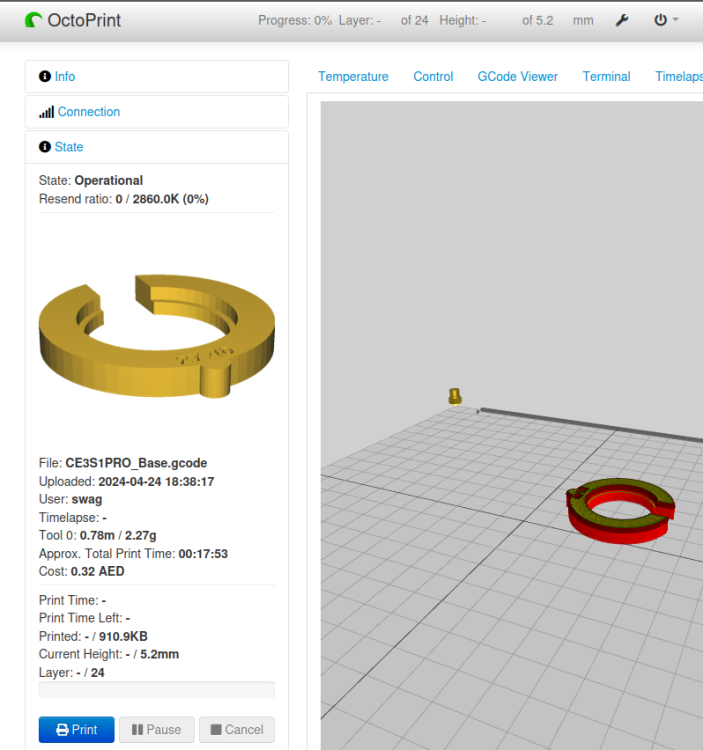

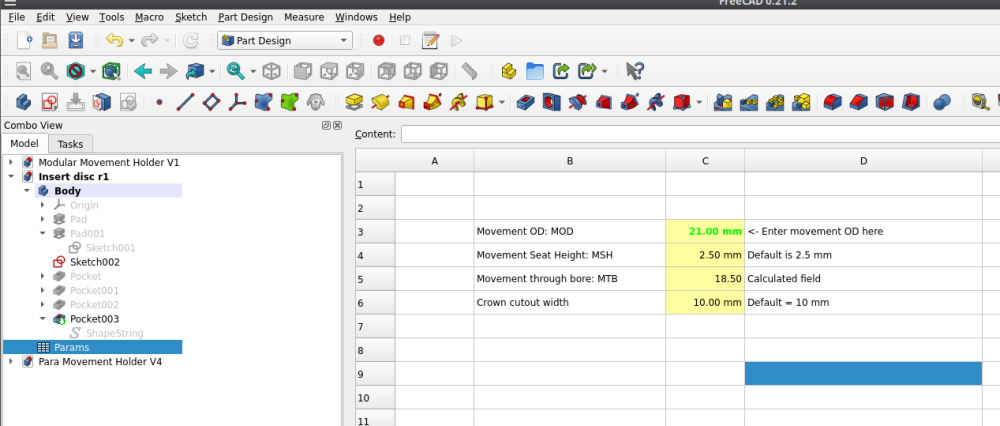

All Done, Here are the finished pictures: This one shows the generic "one-size-fits-all" base which accepts the bespoke rings - notice that the parametric movement OD (27.40 mm) automatically prints on the ring From another angle: Here is the ring about to go into the base: And finally the base and ring together: Here it is next to a pen for scale: On my system with 20% fill each ring will take about 18 mins to print, but I am sure this could be optimised: Here is the screenshot of the spreadsheet in FreeCAD, you just need to change one value to create the ring in cell C3, (the base doesn't need any changes). I just uploaded the files to printables link here, but also include here as a fake pdf, please change the .pdf to .zip to make the file work once downloaded: Modular Movement Holder.pdf Any feedback welcome! I'm also going to make a parametric ring insert for rectangular/oval movements - but I just finished a parent teacher evening so too tired now6 points

-

This forum is a big part of my life. When I retired from horology many years ago due to poor health I missed what I had trained for. On here I can still do my bit in helping and advising others and have a little fun as well.6 points

-

Hello everybody, sorry for the late reply. Thank you all so much for your help and your tips. I got lucky and found a replacement wheel bridge for cheap which actually ended up being in decent condition. I decided not to do anything about the mainspring barrel pivot since I didn't have the right tools and the barrel didn't have much endshake anyhow. I am happy to report that the watch now runs great, I have regulated it to about +-10/s day which is fine by my standards. The timegrapher result looks decent as well, although beat error is around 0.6ms which could be better I suppose. Amplitude reaches over 230 quite consistently which I'm happy with also. My lighter fluid has also been replaced by balance spring cleaning solution and now the springs don't stick to themselves anymore - who would have thought. I'm super happy with this watch, it might not be worth a whole lot but it's awesome that I could restore it and it makes me wear it with pride. To me it's a genuinely good lucking watch, it'll be my daily driver for a while. Thanks again to everybody for their input! I couldn't have done the repair without your help. Here are some images for those interested, the bracelet isn't original but I don't really mind:5 points

-

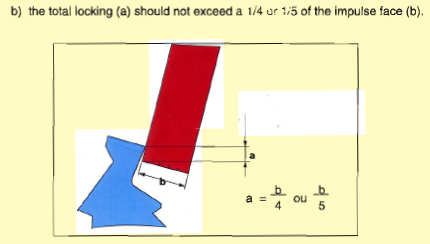

Hi guys, I wrote a set of five lessons for my second year students regarding the Landeron 248 chronograph watch, which incidentally we are meeting tonight. They are going to be polishing pivots and pinion leaves of their 248s, before putting the movements through the cleaning machines. This is number one of five. I posted number two of five the other day HERE There are seven eccentric studs on this movement, so understanding what the studs do, how to set them, their actions and interactions with other parts of the chronograph mechanism is vitally important. I found there is very little out there on the internet to help understand the principles of these eccentric studs, especially video content to show various faults and alleviations, so I put together quite detailed walkthroughs of various complicated movements usually consisting of 15 to 18 hours of learning/servicing in the workshop per movement/module With any watchmaking, especially with complicated work, only make one adjustment and measure the results, if any. Be methodical in your approach. The lesson was originally in PowerPoint and I had to convert it to PDF to post here, so a lot of the video content won't play, but the PowerPoint version is in my cloud storage here. https://docs.google.com/presentation/d/10KJJ58P0v2BglKZSilIv9o69xBsbrQPI/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true You'll need quite a newer version of Microsoft Office (PowerPoint) so the video content will play, otherwise it won't. I hope you find this lesson useful and begin to get a better understanding of how to set eccentric studs. Sometimes you'll come across a stud that is too loose, or even too tight. Usually if one is problematic it will be because it is loose. This can't be left, as the stud will turn whilst the chronograph is stopped, started and reset, throwing the chrono mechanism setting off which could lead to the movement grinding to a halt. Don't fool yourself in thinking it will hold. Either a replacement stud is fabricated to suit the enlarged hole, or the hole can be closed up. In turning and setting the eccentric studs prior to disassembly of the movement, we are able to set the chronograph mechanism, especially the minute register mechanism correctly and test for any faults, such as a bent wheel over fourth arbor, or incorrect depth of the dart tooth with the sliding gear, or a mis-set minute runner jumper spring, to name a few possible faults and mis-settings. Also in turning these eccentric studs we can gain a 'feel' for how tight they are in the mainplate or bridge. The more they are turned the more the chance of the stud becoming looser increases. So once set correctly prior to cleaning, the less chance they will need setting once the chrono mechanism is assembled, only if a stud isn't tight enough in its setting in the first place. This is for setting Landeron 248 eccentric studs, but once an understanding of their uses and actions is gained through theoretical aspects together with practical application, then this skill and knowledge can be used in most vintage chronographs to set their eccentric studs and even in modern timepieces where you'll find very few eccentric studs, such as an Omega Speedmaster or Tag Heuer Calibre 01 chronographs Enjoy! Lesson 22. Landeron 248 Chronograph.pdf5 points

-

Never and others. Yes, like you I do spend a fair amount of time reading the contents of this forum. I find it better that any other. Clear, lucid, no Prima Donas, and most of all an easy access without adverts. All thanks to Mark. God bless you mate. You give so much to many of us. What if? No Mark? Hypothetically. A forum. I did run a forum for a few years. Really enjoyed it, but became so engrossed that it did affect my health. I gave to to others to run. Not been back. It was very successful and rivalled a number of large paying sites. No adverts, no others but me. I did ask and listen to members comments and it worked well. Costs Having a domain name, £10 annually. Register the site with a forum company, free. Build the site using the forum company guide lines, free. It looked and ran almost the same a Mark's. All the same facilities. The cost was only £5 per month, but counted visits (views). If I recall, it was that price for 5,000 views. Each extra 5,000 views increased the price by £2 per month. Success was my own personal undoing. From £5 per month initially, it rose to £60 a month and looked like increasing. This was 10 years ago. I could not afford that, and asked it anyone would like to take over and someone did. I would assume that this is the price that Mark is funding for us all. His return is our continued comments on the internet about his course, and the fact that many of the big names on YouTube mention him as their Tutor. Those of us who have done, and are still using, his course, benefit. In comparison to other courses, I can't believe how cheap it is, and the value is exceptional. It is the structure that gives the value. Long may Mark reign. Ross5 points

-

Hi guys, the question is what is a forum, a place for discussion and passing on information, idle chat and a bit of fun and I for one are the richer for it. When in Hospital last year with the Covid being force fed oxygen and feeling total sh1t and close to the pearly gates a daily look on the forum to see what was going down helped to keep me focused on the job in hand took my mind off the problem for a short while but it was a lifeline for sure. We chat to friends for that is what they become around the world read their posts help where we can post information where we can. I like @Neverenoughwatches some times think of members past and wonder if they are still at the watches or given up, some drop in for advise and drop out again never to be heard of again. The forum reminds me of Yorkshire hospitality, The door is always open and the kettle on the stove. Long may it continue. My two bobs worth.5 points

-

4 points

-

Yes, I was so chuffed when he acknowledged me. I'd heard him talk about it and I had tried it by gentle pressure under the wheel and rolling the Pegwood in my fingers. The wheel rose. His way was to rotate the whole wheel in reverse. Learn something every time from Kalle.4 points

-

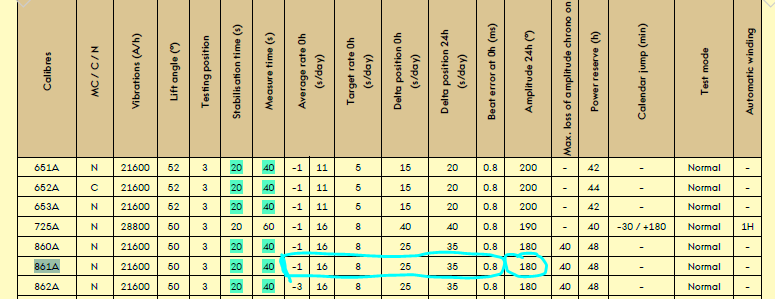

Funny enough, I'm working on an Omega pocket watch which has an amplitude of over 300 and I'm planning to use 9415 to bring it down. So far, my experience with this "wonder-grease" 9415 has been rather poor, especially on older movements. When changed the oil on the pallet jewels / escape-wheel to Dr.Tillwich 1-3, which would be about the equivalent of Moebius 9010, the amplitude gain is remarkable. Try that ..... And as JohnR725 asked, what is the amplitude after 24hrs? My 50-years old Omega 861 runs 250-255 at best when fully wound, around 215-220 after 24hrs. It gains every day 1 second, day after day, week in, week out. Perhaps not an amplitude "high-flyer", but It's the best time-keeper I ever had!4 points

-

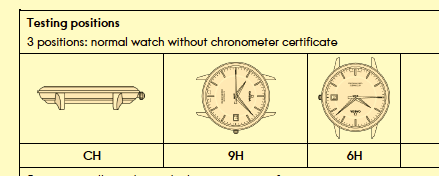

Just a heads up that the CousinsUK branded replacement forks and pins fit the Bergeon tool and look/feel exactly the same. I damaged my Bergeon one and found that the replacement Bergeon parts were almost the same price as a complete new tool, so I decided to try the cousins own brand version. Out of curiosity I tried the fork and pin in my Bergeon tool and found they were exactly the same, and to buy the CousinsUK replacement parts individually is far cheaper than the buying a whole new tool. Hopefully is will save someone some pennies!4 points

-

Funny that you should bring this up. I was thinking about it just the other day. What happens if something happens to @Mark? The social bit is fantastic and I would miss it dearly, but I worry even more about the content. Together we have created a gold mine of information which would be more or less irreplaceable if the site should disappear. People (often with a lot of knowledge) come and go. I sometimes wonder what happened to them and miss them. We have no idea unless we have some private contact information. When I was new here I saw a lot of posts by @Lawson. He had a true fire in his heart for horology and was asking for an apprenticeship in his signature. I found that very inspiring and often wondered what happened. Is the fire still burning? Did he get an apprenticeship?4 points

-

Hello everyone, for what it's worth, here is my approach: 1. Escape wheel submerged in Epilame, then dried quickly with a hairdryer. Then the final tip of the pivots are cleaned by poking into pithwood. The logic being that the Epilame is removed at the intended contact point (to avoid any residue that may mix with the oil), but remains in the areas where oil is not supposed to spread to (further down the pivot towards the wheel). The escape wheel teeth also benefit from having Epilame to keep the 9415 in place. 2. I use a syringe to treat only the pallet stones. I suspend the pallet fork with some Rodico so that the stones hang downwards. I notably use a rather thick needle where a drop WON'T form, but rather where the Epilame liquid stays in the needle tip, which I then dip into the pallet stones. It requires some practice to get the right amount of Epilame into the needle tip, but it works for me now. This way, no drop will "jump" onto the pallet fork and potentially go all the way to the pivots. 3. I let the movement run for a few minutes without lubricating the pallet stones... to scrape off the Epilame in the intended contact "channel". Then I remove the balance again and lubricate the exit pallet stone with 3-4 successive drops. See the "channel" that forms on the pallet stone in the picture -- not so easy to see, but it's visible. I am conflicted about the use of Epliame in balance jewel settings. My impression is that the two jewels sufficiently suspend the oil (even 9010). Apparently Rolex recommends NOT to use Epliame there (heard from a former Rolex service center watchmaker), as it could cause additional wear. Apart from that, I follow specific instructions where I can find them. E.g. the infamous Rolex reverser wheels or sometimes (parts of) the seconds wheel. Exception: I'm currently servicing an Eta 2824 and will probably ignore the service sheet that recommends treating the whole keyless works with Epilame and then using HP1300... I'll skip the Epilame and use 9504 grease.3 points

-

The movement is so called 'Tongji', standard chinese movement. The stem can still be used with the help of extender.3 points

-

To identify movements the standard practice is the actual diameter of the movement, and a front on image of both the movement side and the dial side- minus the dial. The setting mechanism (under the dial) is considered the "fingerprint" of the movement and 9/10 leads to full identification.3 points

-

3 points

-

3 points

-

3 points

-

I have a cheap version of this been using it for nearly 3 years now. Works fine, i sometimes reshape the fork and when i past reworking i fit another fork insert. I try to save the pennies with cheap general tools that add up to the pounds for the real goodies. Everything takes time Michael, you take it steady. Bet you cant wait to start setting up, I have a new room planned its been on the gonna list for ages. One day . Watch the recip saw and fibreglass spells , a grinder does the job but you will get covered in fine fibreglass dust if thats what the tub is made of.3 points

-

You could use a clock key if you cant find the correct chuck key3 points

-

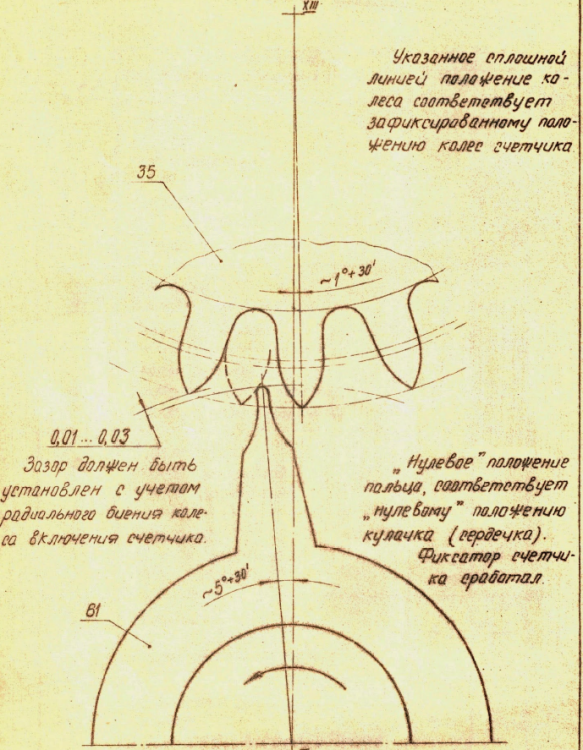

See, what has happen is a normal consequece of the reducing the hammer size and changing it's shape by the removing metal from it. But here the hammer is adjustable and just adjustment is needed to correct, and this is what You have done. There is a rule for the adjustment and it is that the hammer must lay firmly on the seconds counter heart and there should be a litle free play in the same time of the minutes counter heart/hammer which alows counter movement of about 0.5 min on the small dial hand (+/- 0.25). Of course, there is no way to make one hammer to delay from the other, as they are one single part. What has changed too is the slope of the hammer head and thus the orientation of the heart has changed, and thus the switching finger position. This led to need of the finger position correction. The rule here is that switching of the minute counter has to start when the seconds counter hand is on '59'. Of course, the seconds hand must be positioned as so the resetting is at '0' exactly. If switching is earlier than 59, there will be no problem, but it will be wrong as reading can be not correct. If the switching starts later, the problems that You described can happen.3 points

-

Been there. Worn that Tshirt. 'ping'. Hands and knees. Nothing. Nada. 20 minutes? Ha! I found it 7 month later. How? Well, after advice from a member, I invested in a £4 UV light torch. Hands and knees looking for a 'ping' from a Sekonda, found them both within 30 seconds. UV makes the jewel shine. easy peasy. Could have taken longer. Just lucky on the location of the search. Hope this helps.3 points

-

Get someone local to tig it ,very easy fix and should only take a few minutes so probably wouldn’t cost much ,or failing that get it very clean and silver solder it. Dell3 points

-

3 points

-

Hi all Thought I'd show my small and trying to keep under control watch collection! Apart from the Enicar all were under £12! At least if I destroy them in the process then I won't be too worse off. A few pics to start off with First of all my first attempt. A Thuya pocket watch. It was only running face down and would stop when vertical. So now it still works face down and only slows down when vertical so at least an improvement! I only have a generic watch oil at the mo so that won't help but I'm hoping to get some more appropriate oils in a couple of months for my birthday. I did have to get a crystal for it since it didn't come with one. It didn't look as though it would friction fit (and I don't have a crystal press in any case) so I glued it to the case with PVA. So far so good. Next up above are a sekonda and citizen automatic. Both non runners. Both with broken balance wheels amongst other things. I'm hopeful the citizen will start when I get the new one I ordered but the sekonda is being kept for spares and trial of new techniques. And finally the Enicar and the timemaster. Both running when I got them. I wanted to get running watches so that at least I stood a fighting chance of still having a running watch after the service! It was all going well on the Enicar until I dropped the balance wheel during reassembly.... Unfortunately they are quite expensive to get so for now I'll won't do anything with it but I would like to fix it at one point. The timemaster is still running (yeah!) but I managed to break a dial foot during the deassembly. First repair attempt failed so now I am looking at soldering it back on... So there we go. My initial foray into this great hobby. Thanks for sticking with this tale so far. I'm hoping that once the balance wheel arrives for the citizen I will be able to say I bought a non runner and fixed it! So fingers crossed. Thanks for looking, Nick3 points

-

Yup watchie you are entirely on my wavelength with this , you actually said what i was hinting at, what if something happens to mark ? Will someone be able to take over ? Its not that long ago that the forum was down and Mark had to step in and fix it. And you are right a wealth of information that does not exist as a whole anywhere on the planet will be lost. Can that be archived elsewhere? It would be an absolute shame if the plug was pulled without warning, i would like to think Mark wouldn't do that to us. And like i said in my first post i talk about things other folk might be affraid to. So lets not skirt around anything. It might be nice to have a place where we can all drop our emails just in case so we always have that contact. Can you make that happen Old Hippy ? i kind of think of you as the pops of the forum3 points

-

I dont like to give up things that i enjoy Tom. So my next question is how are we going to prepare for that inevitability and what are we going to do about it. Its not just about funding it but I did pick up on something that Mark said once. It doesnt run on fresh air , what if it becomes a burden or an unnecessary cost or for any other reason that i wont get into. We all know life can change in an instant, my life has been so up and down for about 8 years and was only just beginning to level itself out.3 points

-

What I especially like is that this forum is not full of ads. There are some but they're not interfering. No ads between posts like one certain big watch forum. Browsing is also very easy and light for a mobile device. I'm glad there's still room for old school forums like this. I'm a member in many facebook groups but there's really no long term discussion and if you see an interesting post you might never find it again if needed.3 points

-

@Neverenoughwatches Rich, I can only agree with you wholeheartedly. I spend a lot of time here learning all sorts and trying to make any little contribution to help others I can. Nothing can last forever and I wish I could do more to contribute to the forum financially and any other support I could. Tom3 points

-

First thing this morning, make coffee, second, check the forum. I would really miss the forum, not on any social media, not interested in telling the world what I had for breakfast!!! I do consider most of the regulars friends and would wonder what had happened if they stopped posting.3 points

-

That endshake of the barrel arbor is huge! That needs closing up. I'm assuming the barrel cover has been bent in a convex way to create that excessive shake. Put the barrel cover on a staking block and check how flat it is then bend it to suit a better endshake2 points

-

I opened it too, and can asure that it is good and thorough. I can add something little for the minutes counter adjustment (will use the terms from this presentation) - sometimes is prefferdd that the T-line will be slightly tilted as to alow little bigger gap between the the tooth A and the dart tip, and the gap of C tooth is reduced to almost 0, as shown on the picture (from manual for 3133) Also, there is one more option, offering the same result as the changing lenght of the dart or slope of the hammer head - this is changing the position of the heart on the minutes counter wheel. Sometimes just turning hte heart upside down changes slightly the wheel position and thus one can choose the better between the two. Then, the heart position can be totally changed by making new hole for the screw that fixes the heart2 points

-

It's actually quite amazing how much amplitude you can lose if you walk is too much like yours is in the picture. Technically the pallet fork should be light as possible to move really fast. But shellac isn't overly heavy. I would be more concerned if you had too much shellac and it was rubbing on something. The problem with rules are there so many of them and it also depends upon the construction of the watch. Then we have other rules like this The problem with your image is if you measure carefully it looks like your lock is about 50% which is much greater than it's supposed to be. How does it compare to the other side? Then out of curiosity how did you lubricate the escapement?2 points

-

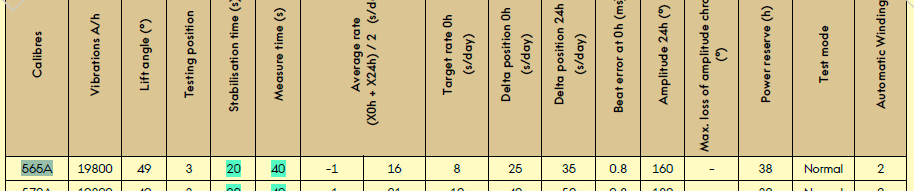

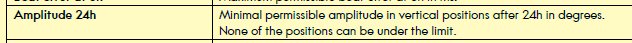

Typically for this group anything less than 300° is unacceptable. What's interesting is the Swiss Do not pay attention to this group at all. Swiss are more concerned about timekeeping than they are amplitude. Then thinking about timekeeping I don't suppose you can show us the watch in perhaps three positions on the timing machine? Like dial-up and dial down And crown down would be nice it often helps for diagnostics Oh and thinking about amplitude I see your timing machine is 52° and according to the specs you're supposed to have 49° so that will cause a minor change of the amplitude. Than very very disturbing for this group so I would suggest the old-timers run away and don't even look but amplitude at 24 hours for this watch is 160°. As I said the Swiss are only concerned about timekeeping. So at the end of 24 hours you have 160°. Then the definition of amplitude at 24 hours is Then they three position as an Omega uses for timing for three position watches like yours is found in the image below although I would still make sure you do dial-up and dial down because those should be identical and other good diagnostics do that Then thinking of lubrication what sort of lubrication's did you use and how did you lubricate the escapement?2 points

-

I started 2 1/2 years ago. Watched Mike on Myretrowatches to learn about Seiko and tried Sekonda on my own. Mike and others, including Wristwatch revival who even this week, recommended Mark Lovick's course. I Obtained 1,2,and 3. Not looked back. See my posts. (6 month, 12 month, 18 month and 2 years) I still consider myself a novice but can do a basic service. Chronographs are still on my horizon. The best thing I did was join Mark. It was after a short time of doing the course that I joined this forum. I did not feel that I was good enough, or could converse well. I have dyslexia. This forum was the next best thing. Whilst I still do not feel able to to stand with the greats, they actually spend their time and speak to me, offer advise, very rarely criticise, and even then offer constructive comments without rancour. Oh! believe it or not, I am still on level 3. I have done level 2 a number of times and will do the same with level 3. I can now understand what level 3 means. Watchmaking. WatchFix. Good to go. Value for money. In my opinion. Yes. Will I do level 5? Yes, but I've given myself to the end of my self imposed apprenticeship of 5 years. Same as my engineering apprenticeship in 1964.2 points

-

2 points

-

You can buy standard 2.5mm endmills, which should fit the 2.5mm reamer holder, if that is a collet fitting? eg. https://www.cutwel.co.uk/2-5mm-4-flute-k2-coated-carbide-end-mill-g9432-series-yg-1-g9432025 Just be sure it's a type like this that has the same shank and cutting diameter - many small ones have 3mm shanks for such as Dremel tools.2 points

-

I have some spring bar removers which I showed in the Some Timelab Tools thread that I started. I will have another look at it all once I get set up in the room that I am removing the spa from. Not doing anything until next weekend to cut the spa up to get it out though. Have spent the last 6 weeks digging rocks up in our gardens, then adding soil where required and then putting all of the stones back to get them back on the surface and not buried in the soil. Hands and wrists are sore. Not the best for hanging onto a reciprocating saw for hours.2 points

-

2 points

-

2 points

-

The key is quite simply called a chuck key. As you can see above, they can be either male or female. Mostly male on larger industrial lathes.2 points

-

I've thought of this too. A photography forum that I have been a member of for 15+ years just shut down recently. They had many millions of posts, members with 80K+ posts, a huge community base with many of us donating to the cost to keep it up and running just because it was a great resource for us all. And it just went away like that; poof. I also used to run a forum that was around for about 15 years. My interests changed over the years and one day I just decided to not renew the hosting costs. I bet the hosting cost for this forum is WAY more expensive than mine ever was. It's all about the storage and bandwidth. Every time someone uploads a PDF that takes storage space, and every time someone downloads that PDF, that takes bandwidth. I try to be mindful and not upload huge files here, or point to a file that can be downloaded elsewhere instead of uploading it here, all that storage space and bandwidth adds up. If it were ever an option I would be happy to contribute to the forum as it's a resource that I highly value.2 points

-

The watch is automatic, but hte automatic module on the picture is missing. All the problems that You are afraid of actually are not problems at all. The only thing that You must take care is when pressing the seconds hand in place. You must then support the movement by the stone of the 4th wheel (in the center of the movement) in order to prevent shifting of the stone.2 points

-

I dont think mine is. Its an idea to have them all in one place if possible, then a quick screenshot will have them saved. Unless anyone has any other ideas of how to reconnect2 points

-

A perfect example Hector, with the forum we would lose so much more My sentiments exactly Richard, i have experienced that loss already, Tiny, Gert, Galilea to name but a few all of which i enjoyed conversations with. I imagine it keeps a lot us sane OH.2 points

-

Naptha appears to be a general name and its content can be varied depending upon what it's specific use is. Lighter fluid as an example can be light or heavier also with other ingredients to help it burn. Try sesrching for benzine ( as opposed to benzene which is linked to causing health issues ) . There are other fluids such as ethanol that you could try and also methylated sprirts, mostly ethanol with a small percentage of methanol added. Experiment with any new chemical to see how quickly schellac dissolves in its presence. I have tried a few things but hexane is not one of them, i understand it does evaporate very quickly. Be sure sure to check out any safety data on chemicals you try. Toxicity of fumes and flash point information, ultrasonic machines can heat up fluids even without a heater function. And of course always ask here for personal opinions when trying a new substance.2 points

-

I would go for the dearer spring. You won't need to remove the spring from the carrier ring and then use a mainspring winder to get it into the barrel, for a start. Also that spring is closer to the needed dimensions, especially the length. The length plays a part in the mainsprings strength. If you double the length you will half the force (strength) of the spring and vice-versa. A spring with 20 mm less length would be about 7% shorter, so technically would be 7% more strength, but I find halving this number is closer to real-world findings, so the spring would be about 3 to 4% more strength/force. On a mainspring that ideally kicks out 300 degrees of amplitude, a 3% increase in amplitude would be 309 degrees. Increasing or decreasing the length of the mainspring will affect the power reserve to a greater or lesser degree. It depends how much shorter or longer it is. I've attached a lesson regarding mainsprings, focussing on the size and strength of the spring within the barrel, you might find helpful. Unfortunately it is a PDF converted from a PowerPoint presentation, but only a slide was lost that was originally a video of fitting a mainspring Lesson 5 The mainspring.pdf2 points

-

2 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.9bb1d20ca71162225b2e652ed4cfed34.jpg)