Leaderboard

Popular Content

Showing content with the highest reputation on 04/21/24 in all areas

-

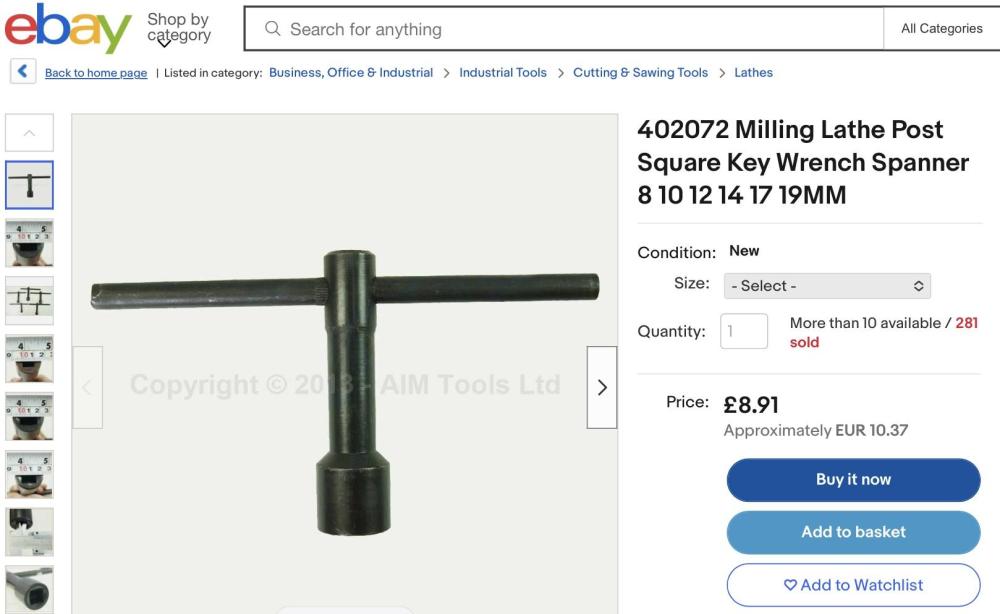

You could use a clock key if you cant find the correct chuck key3 points

-

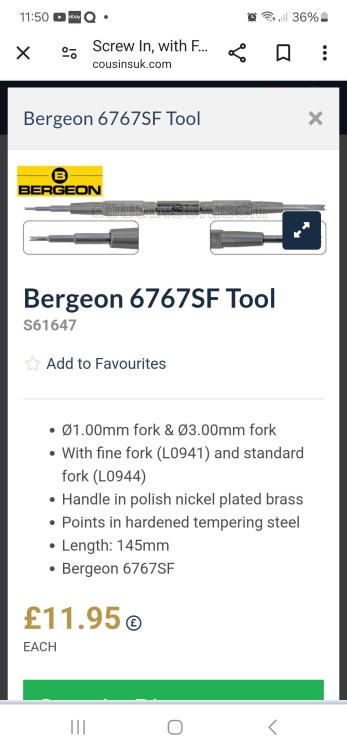

I have a cheap version of this been using it for nearly 3 years now. Works fine, i sometimes reshape the fork and when i past reworking i fit another fork insert. I try to save the pennies with cheap general tools that add up to the pounds for the real goodies. Everything takes time Michael, you take it steady. Bet you cant wait to start setting up, I have a new room planned its been on the gonna list for ages. One day . Watch the recip saw and fibreglass spells , a grinder does the job but you will get covered in fine fibreglass dust if thats what the tub is made of.2 points

-

I have some spring bar removers which I showed in the Some Timelab Tools thread that I started. I will have another look at it all once I get set up in the room that I am removing the spa from. Not doing anything until next weekend to cut the spa up to get it out though. Have spent the last 6 weeks digging rocks up in our gardens, then adding soil where required and then putting all of the stones back to get them back on the surface and not buried in the soil. Hands and wrists are sore. Not the best for hanging onto a reciprocating saw for hours.2 points

-

The key is quite simply called a chuck key. As you can see above, they can be either male or female. Mostly male on larger industrial lathes.2 points

-

I've thought of this too. A photography forum that I have been a member of for 15+ years just shut down recently. They had many millions of posts, members with 80K+ posts, a huge community base with many of us donating to the cost to keep it up and running just because it was a great resource for us all. And it just went away like that; poof. I also used to run a forum that was around for about 15 years. My interests changed over the years and one day I just decided to not renew the hosting costs. I bet the hosting cost for this forum is WAY more expensive than mine ever was. It's all about the storage and bandwidth. Every time someone uploads a PDF that takes storage space, and every time someone downloads that PDF, that takes bandwidth. I try to be mindful and not upload huge files here, or point to a file that can be downloaded elsewhere instead of uploading it here, all that storage space and bandwidth adds up. If it were ever an option I would be happy to contribute to the forum as it's a resource that I highly value.2 points

-

See, what has happen is a normal consequece of the reducing the hammer size and changing it's shape by the removing metal from it. But here the hammer is adjustable and just adjustment is needed to correct, and this is what You have done. There is a rule for the adjustment and it is that the hammer must lay firmly on the seconds counter heart and there should be a litle free play in the same time of the minutes counter heart/hammer which alows counter movement of about 0.5 min on the small dial hand (+/- 0.25). Of course, there is no way to make one hammer to delay from the other, as they are one single part. What has changed too is the slope of the hammer head and thus the orientation of the heart has changed, and thus the switching finger position. This led to need of the finger position correction. The rule here is that switching of the minute counter has to start when the seconds counter hand is on '59'. Of course, the seconds hand must be positioned as so the resetting is at '0' exactly. If switching is earlier than 59, there will be no problem, but it will be wrong as reading can be not correct. If the switching starts later, the problems that You described can happen.2 points

-

I live in north central Ohio, I'm a retired Master Machinist, and watch making is my new found passion1 point

-

Aloha All, I have always been interested in mechanical watches. My first real watch was a new Rolex Sub Date circa 1995 (I was in my 20s), and I got back into watch collecting during COVID-19. My obsession with watches turned into modding watches, and for the past two years, I have been amassing tools and parts in anticipation of taking this hobby to the next level. My goal is to learn how to service a watch movement and get proficient in restoring vintage watches. Making the old new again. I recently signed up for the watchfix.com course and am to the point of having broken down a movement. I look forward to interacting with you all and appreciate your future input. Mahalo, Frank1 point

-

Wound strings can be used too, after removing the coil of brass. They have steel core that is thicker than in unwound strings1 point

-

As longs as the gauge / thickness is OK, it should be fine. You can also use thin piano wire, or non-wound electric guitar strings. You can get those in different gauges to suit what you need, very cheaply from such as ebay or amazon - or music shops, if you have any nearby.1 point

-

You can buy standard 2.5mm endmills, which should fit the 2.5mm reamer holder, if that is a collet fitting? eg. https://www.cutwel.co.uk/2-5mm-4-flute-k2-coated-carbide-end-mill-g9432-series-yg-1-g9432025 Just be sure it's a type like this that has the same shank and cutting diameter - many small ones have 3mm shanks for such as Dremel tools.1 point

-

One thing I would point out here is that, Cousins give the barrel diameter and this is important because when you come to fit the new spring, if the barrel diameter is smaller than the internal diameter of the washer the new spring sits in, you will have to manually unwind it from the washer to fit it in the barrel. If the spring barrel size is correct (or smaller) you will be able to drop the new mainspring straight into the barrel by just pushing it out of the washer. The other thing with barrel sizes is that, if you are really having to make measurement compromises (i.e on both thickness and length) you need to make sure the spring is going to wind into the barrel.1 point

-

The silent lever should be friction tight by the domed washers, so make them more domed or add another. The movement is an 8day smiths enfield westminster Chime1 point

-

Ahhh. Yours is a girl, mine is a boy. The square post is 3mm x 3mm. The body of the tool must have a diameter less than 5mm...maybe less. Clock key is a good idea. However, the body will be too big, so I will have to turn it down.1 point

-

1 point

-

1 point

-

Hello everyone, I'm sharing my latest project, the restoration of a 1944 Waltham A-11 watch. I'm also designing a custom case to store it, as I intend to start a collection of Type A-11 watches not only from Waltham, but also from Elgin and Bulova. Hope you enjoy the video. Bye. .1 point

-

@nevenbekrievVery reassuring, thanks! The minutes counter starts to move at 58 and is finished at 00. If I stop at 59, the minute counter is in between the markers. To me, that's a clear reading so I'm satisfied.1 point

-

1 point

-

Hmm, I am having a hard time visualizing that. The tool needs to have a square recessed region to go around the square post, no?1 point

-

Been there. Worn that Tshirt. 'ping'. Hands and knees. Nothing. Nada. 20 minutes? Ha! I found it 7 month later. How? Well, after advice from a member, I invested in a £4 UV light torch. Hands and knees looking for a 'ping' from a Sekonda, found them both within 30 seconds. UV makes the jewel shine. easy peasy. Could have taken longer. Just lucky on the location of the search. Hope this helps.1 point

-

Naptha appears to be a general name and its content can be varied depending upon what it's specific use is. Lighter fluid as an example can be light or heavier also with other ingredients to help it burn. Try sesrching for benzine ( as opposed to benzene which is linked to causing health issues ) . There are other fluids such as ethanol that you could try and also methylated sprirts, mostly ethanol with a small percentage of methanol added. Experiment with any new chemical to see how quickly schellac dissolves in its presence. I have tried a few things but hexane is not one of them, i understand it does evaporate very quickly. Be sure sure to check out any safety data on chemicals you try. Toxicity of fumes and flash point information, ultrasonic machines can heat up fluids even without a heater function. And of course always ask here for personal opinions when trying a new substance.1 point

-

I would go for the dearer spring. You won't need to remove the spring from the carrier ring and then use a mainspring winder to get it into the barrel, for a start. Also that spring is closer to the needed dimensions, especially the length. The length plays a part in the mainsprings strength. If you double the length you will half the force (strength) of the spring and vice-versa. A spring with 20 mm less length would be about 7% shorter, so technically would be 7% more strength, but I find halving this number is closer to real-world findings, so the spring would be about 3 to 4% more strength/force. On a mainspring that ideally kicks out 300 degrees of amplitude, a 3% increase in amplitude would be 309 degrees. Increasing or decreasing the length of the mainspring will affect the power reserve to a greater or lesser degree. It depends how much shorter or longer it is. I've attached a lesson regarding mainsprings, focussing on the size and strength of the spring within the barrel, you might find helpful. Unfortunately it is a PDF converted from a PowerPoint presentation, but only a slide was lost that was originally a video of fitting a mainspring Lesson 5 The mainspring.pdf1 point