Leaderboard

Popular Content

Showing content with the highest reputation on 01/22/24 in all areas

-

Thanks for the information, after reading your comments I thought I should get better informed on the subject. To summarise what I found: it appears that the off gassing can only occur when the glue is active [3], or put another way the clouding/blooming/chlorosis can only occur up until the point the glue becomes inert, usually 24 hours [2] or exposed to moisture [1]. I think I did replace the repaired dial/crystal in less than 24 hours, so your concerns are well justified, I think in future I'll leave any superglued product out in the open air for >>24 hours just to be on the safe side and confident it is 100% cured and safe to re-install. Thanks again for the warning, we live and learn , the sources of my research are below: ===== Quotes the above is derived from: " cyanoacrylates ... immediately polymerize and become inert when exposed to moisture."[1] "A quality super glue, such as Loctite Super Glue Liquid Professional (20g bottle), dries and sets in seconds. For full bond strength, the parts should be left undisturbed for at least 10 minutes. The glue will be fully cured in 24 hours." [2] "What is cyanoacrylate frosting or blooming? The technical term for cyanoacrylate frosting or blooming is chlorosis. It refers to when excess cyanoacrylate monomers vaporize or become airborne, reacting with moisture in the air. The monomers then cure into small particles that fall onto the area around the bond line. This is the white residue you often see on darker parts bonded with a cyanoacrylate. What causes cyanoacrylate frosting or blooming? This frosting or bloom residue is a by-product of an instant adhesive cure process and only occurs while the cyanoacrylate is curing. The worst cases of chlorosis happen when a part is packed into a container or plastic bag before the cyanoacrylate is fully cured or polymerized." [3] References [1] https://aronalpha.net/blog/common-misconceptions-about-cyanoacrylate-adhesives-and-what-you-may-not-know-about-them/ [2] https://www.loctiteproducts.com/en/know-how/fix-stuff/super-glue.html [3] https://www.resinlab.com/resources/cyanoacrylate-frosting-or-blooming/ Me either, but I just pulled another out of my bag of horrors, and it is very similar. I am currently challenging myself so see just how bad a watch has to be before I can't restore it, maybe I met my match: This watch would be especially good to restore as it is made on my year AND month of birth, so I am a little extra motivated to make it work.4 points

-

I think that is what is described by the sellers of "Mumbia Specials" as "running nicely, recently serviced", at least if my experience of one or two HMTs is anything to go by.3 points

-

I've been the lectures where people talk about what goes into servicing a Rolex for instance. Your procedure is similar to that where they'll look at it on the timing machine although Rolex gets a little more obsessed with this. in other words Rolex is looking for fully wound up and of course as a reminder fully wound up is not fully wound up you have to wait a little bit like up to an hour 15 minutes after you fully wind up it has to settle for a little bit. Then 24 hours later they compare the numbers. Then it typically goes on auto winder for several days where it records the time and they do an average over the several days. Then comes off the winder and they let it run until it stops just a verified actually run the correct number of hours. Often times people at auto winders think everything is wonderful but the problem is when it's kept fully wound up that's different than if somebody takes it off like overnight where maybe it stops could it won't run overnight for instance. Oh other things to do looking at the watch. For instance I can't remember the light source but with a very very bright light much brighter than you normally use look at the dial look at the crystal look at the hands you're looking for specks of dust. I can't quite remember how many specks of dust per cubic inch I'm joking about that part but there was a criteria of how much was acceptable and what was not acceptable and because you using a really bright light source makes it easier to see problems where you may casually not see the fingerprint or speck of dust or something oh to add your knowledge of things cousins is interesting what happens if we search for the word working for instance? https://www.cousinsuk.com/document/search?SearchString=working acquired it in the days when Swatch group let cousins have an account and they got a few of them there are way more than this by the way. You may find the very last one of interest doesn't cover everything but gives you a few clues about stuff oh and one of things express if you doing other people's watches it be really nice to keep a journal a logbook or something and keep your timing results. Like if you hand the customer receipt of I done all of this keep a copy for yourself. I don't do that I'm lazy at work we do keep notes in the computer but we don't keep timing results etc. so I get a damn watch came back but the timing issue and fingerprints where they shouldn't be because it's a pocket watch were somebody could unscrew the back for instance. These are the times where I keep thinking it be nice when I run a timing cycle at the end is to paste it into the record book or something where when it left here it was doing this I don't understand why it's now looking like crap plus a good picture the movement would've been nice. Oh and if your incoming customer watches always nice to get pictures of whatever comes in just in case somewhere along the line you discover something damaged or broken you can look at the picture to see if you did it or if it came in that way just didn't notice. Also just nice for data fine watches of the end up with lots of them the software we use they photograph everything sword out sometime somebody just photographs the pocket watch case and I don't get the see the movement or somebody writes up a description of the case but not the movement and I'm not sure which watches which was really good the document everything you have to avoid unpleasant confusions that will eventually pop up and be quite annoying. Also if you have an annoying customer make a note of that because they'll be back in the future to bother you again. Especially if it's a pocket watch a take the back off and play with it and it has some of the customers really do like to play with their watches.3 points

-

Well i have serviced 2 movements. I can tell you one thing, If he'd come to me with some vintage swiss family heirloom thing i wouldn't touch it with a ten foot pole. I know the 7s26 and the nh36 and the 7006 inside and out. I dont' even have a service sheet up when i work on these movements now. I'm dipping my toe in and seeing how it goes. A lot of watchmakers just will not work on seikos and that's why this guys come to me. he's given the thing to two watchmakers who threw it in a drawer for a year and did nothing to it which is a weirdly common thing i hear from people desperately looking for a watchmaker. This aint' gonna be my job but i do enjoy it, seem to be pretty good at it now and it can break up the monotony of my art job which i enjoy but i like doing other things too.2 points

-

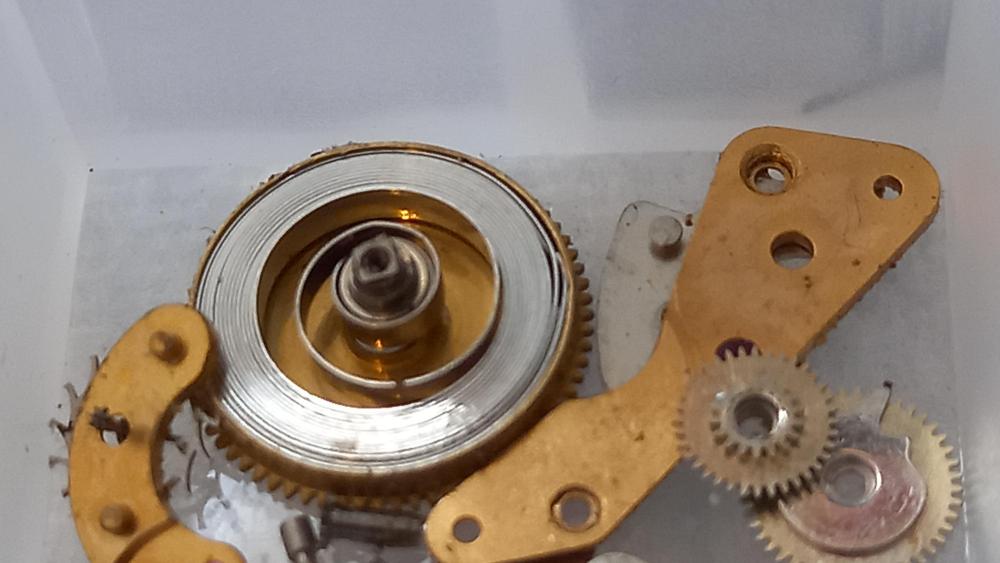

Really pleased with this project. Looks like it will clean well. On the main plate. The two screw threads need to be removed. Not sure I will use the plate, but will be a good exercise. Looking at the photograph of the mainspring I did think it was a break, but in fact is was a substance from the calendar wheel. It is now removed. Phew.2 points

-

2 points

-

Generally what I do is get it running, let it run for a day or two. do a six position timing at full wind, do a timing at half wind, other than amplitude they usually look pretty damn similar if not roughly the same. Then i wear it for about a week, check time with atomic clock every day at the same time and chart average daily deviations, so basically time it to my particular wrist behavior. Then i readjust the rate to compensate as i get very consistent results and then i have a watch as accurate as i could need. But yeah this will be my first time not knowing the behavior of the wrist it will get on.2 points

-

I’m with you all the way. I am working through thoughts myself about how I want to do my testing and quality checks for my own satisfaction, I can be a bit obsessive about getting the “right” result. As @JohnR725 has pointed out on numerous occasions the manufacturer looks at things differently than we generally do. My idea is kinda outlined roughly below, I intend to document it and submit here for opinions and ideas. 1. Watch allowed to settle for 48hrs before commencing testing 2. T+48 full wind watch and rest it for 1hr 3 T+49 timegrapher test recording beat, rate and amplitude in all 6 positions 4 not winding the watch in any way repeat test from 3 5 remediate any issues found from 3 & 4 and retest from 1 6 if watch meets your requirements then wind watch fully and set to the correct time synchronised by hacking if possible to a reliable time source. 7 wind watch every day at the same time or use an automatic winder for the recommended time period to fully wind for the watches power reserve, record the time source time and the time indicated by the watch, this should be the actual time, not the delta 8 at the end of the 7 day test average the daily deltas and assess if this is acceptable to you i know a bit airy fairy but early days with where I want to take it. Having written many acceptance testing documents and procedures my idea is to use spreadsheets for the assessments. What I am not sure of is what the assessment standards should be, I was planning to use the snippets John has given us from Omega and build on that with research and input from all you good folks. sorry for the ramblings Tom2 points

-

This quartz alarm chrono had a nasty crystal incorrectly installed, bent hands and was not running. Replaced with a NOS crystal and advice from the forum went with G-S hypo cement. The hour and or minute wheels were damaged and so sourced a new movement as well. There is some plating loss on the bracelet and on the case and alarm setting crown. The dial suffered a bit of damage as well. Overall though I like it. September 1994 7T32-G640. Other models have "quartz" on the dial but this one does not. Wore it on the golf course yesterday and the crystal stayed in place. Still need to clean the excess cement on the inside of thw crystal.2 points

-

You shouldn't use super glue, it can off gas and cloud up the crystal. I leant that on here.2 points

-

Just thought I would add a side note to my recent restoration, I used some super glue gel instead of regular super glue and found it far better to use on replacing the dial markers, here's how I did it in case anyone is interested Positioned the loose dial marker in its correct position on the front of the dial With the dial marker held in by friction I turned over the dial, so the back was now facing up I then opened up the super glue gel and squeezed a small blob out of the tip of the tube so it was just visible on the tip of the tube I then used a tooth pick to scoop up a small blob of gel from the tip of the tube I then dabbed a small droplet/blob of glue onto the foot of the dial marker that was sticking through the back of the dial with the tooth pick gel Being gel the glue stayed where I put it with little risk of running through to the front of the dial Being gel it has a slightly longer setting time, so you have time to play with it a little before its too late After it dried I moved onto the next one for good measure I also re-glued the markers which hadn't become free, just in case they were thinking about it Hope this helps2 points

-

Hi there all a quick question I've been given a box of stems all mixed up. How can I find out which stem relates to a make or caliber of a watch. William1 point

-

Yeah i would say just a tad more than surface rust there, just a tad. To get the stem out1 point

-

I believe some of the auto winding boxes that people by. Those extremely expensive boxes that have such a cheap circuits inside of them. They look pretty on the outside but are very expensive but they're designed to keep your watch wound up but not wound up continuously because of course continuously winding a watch is not considered good either even though that's was done in the shops so realistically you should probably have a number of conditions running at full winder and then as you said put a timer on turn it off for 10 hours to simulate off the wrist for sleeping or when somebody got home maybe they take their watch off until next day after all the watch should build a run a certain quantity of time after it's been wound up but one of the problems with automatic watches today are is how active are you? Yes I know where all active but are we active enough to have an automatic watch. If you sit at a desk job do you move your arm enough for instance to occasionally get comebacks because people are unhappy the watches are running you put on the timing machine it has practically no amplitude because those people need to manually wind there watch in the morning when I get up to make sure it has enough power to run and the automatic is just there to supplement.1 point

-

Hi. With a great deal of patience and difficulty as any two stems may look alike but have subltle differences. You could try the web site. WINDINGSTEMS.COM to look for similarities. Not an easy job.1 point

-

Yes, my english doesn't make difference between reamer and cutting broach. I try to improve it here...1 point

-

The equivalent of Russian watches from Ukraine. Always sold as "Serviced by Master Watchmaker". That is, dipped in a can of naphtha, blown off with a hair dryer, and then something looking like oil injected here and there.1 point

-

I think that is what nev was meaning, reamer just being another term. I wouldn't be too happy either.1 point

-

The more I look at the movement I'm convinced it's German. That dial is certainly a replacement. You are going to need some clock makers tools if you decide to clean it. Have you any knowledge about clock repairs? I would not recommend starting on such a movement without good experience.1 point

-

Well, there seems to be no other option than purchasing a reamer that I will never need again. I‘m not happy with this idea (yet). Can a cutting broach do the job?1 point

-

Ronda catalog is showing the roller table diameter on staff as 56 maybe roller is too small . Could you measure on a reamer where you need to be with the size ? Stop short and finish with a smoothing broach. Reducing the staff would feel safer for me and normally easier to replace if things go wrong .1 point

-

1 point

-

Hi Ross not looking too bad date wheel is cabbaged almost eaten away nice collection of spares though.1 point

-

1 point

-

One reason a watchrepairer might have ignored the work, the cost to service compared to a new replacement . An example i have , I've been asked to make furniture a few times, i used to do a little of it when i was younger, but still get asked now and then. My answer is always " no sorry, i cannot justify the cost to you for me to make it, buy something off the shelf already pre-made ". Unless someone had a real love of the watch to be repaired most will turn a price down. Old Hippy quoted around £150 which i thought was very cheap liability cover. There must be a payout limit on that and an excess as well.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Looking at the dial at 6 looks like Made in England. Could you post a close up photo please. The barrels can be removed without taking the movement to pieces. Pendulums in that shape I have seen many times on Smiths Grandmother clocks. Grand mother/ Grand daughter clocks are the same, height 4 to 5 foot.1 point

-

It is funny the situation with watchmakers out there. I get it if the service costs more than the watch is worth and they tell the customer straight up. I don’t get that they then still turn the customer away even when they have said they are happy to pay. My best friend from Army days in in the same boat you describe Col, seiko 5 with 4912 movement, no one will touch it including seiko. He is muttering about sending it to me to look at for him though the postage from Australia to Scotland and back probably covers the value of the watch. i hope it works out, if it does look like it’s going ok look at getting some sort of liability insurance though. Probably not going to be an issue doing a couple of watches a year but by the sounds of it you could get busy very quickly, especially when the word gets around. Tom1 point

-

My glass supplier has the same problem with double glazed units, once they are sealed up there is no getting to any dust or marks inbetween. Only way is a visual inspection under florescent lights. There is a criteria that is acceptable but that is much less strict than any dial inspection. Mostly from edge and size restrictions . I once had customer that went around with a torch looking for marks on a full house of windows, she pulled every single piece of glass. So i took the torch out of her hand and then told her to find them again, she couldn't, the few that she did find she had to look very hard to find them . Yeah another not wanting to pay full pops, you get them.1 point

-

I get it. I actually love that. that is so much easier than the barrels i usually work with which just have a barely perceptible slit halfway down the side so you get to trash your thumbnails trying to pry it open. Thanks bud!1 point

-

Yes Rich, I agree with you. The way I see the timegrapher is it’s an imperfect tool, useful nonetheless especially for diagnostic reasons. It means we have something objective to work with and can show what we are concerned about to our friends here when we ask advice. I have dropped from a lot of specialists/collectors forums one of the reasons is the crazy expectation some of them have of their 50 year old recently serviced watch which wasn’t even a chronometer in the first place. Another funny thing, none (as far as I can find out) of the observatory’s or COSC use timegrapher for any of the certification process. Tom That’s why I included in my brief process outline above that if auto then it should be only on for the max time to hit power reserve each day which would probably equate to the design case for the watch. Tom1 point

-

Your barrel looks more like something I would see in a Swiss (or non-seiko) watch. To open it in your case I would place the closed side of the arbour on my riveting anvil and then press down on the teeth at 6 and 12 o'clock and try and use a spare finger to stop the lid popping off when it becomes loose. The Arbor should force lid off as you press down. The start of this video may explain better1 point

-

I have a height adjustable desk, and it made a world of difference. My wife insisted I get one about 2 years ago as I was constantly complaining about neck ache. Should always listen to the wife! Gone are 99% of all watch related aches and pains. I also found that using a scope for most of my work instead of a loupe or visor also forced me to sit upright with good posture instead of hunching and causing neck/back strain. The desks aren't too much more than an ordinary one, I was surprised at how little the cost difference was +25% (ish) In short I would highly recommend.1 point

-

Its good Col, as John always reminds its 24 hours after being fully wound thats more important. Most often a watch is wound once a day , from a friday to a Saturday morning after a lay in that might extend to 30 hours possibly a little more if lazing around. As the mainspring is coming to an end isochronism will start to be lost through lack of amplitude so to prevent having to reset the time 24 hour timekeeping becomes important. I have a few new 7s26 models, the end tail of their final production and the quoted manufacture specs are quite grim but i understand covering their backs. Without looking i think it was -25 to + 40ish , i might have that backwards but its something like that. The ones i have are far better. Haha it was , i think most of us were " whhhoooa hold up " its not only what you can achieve on the bench its as much if not more how someone cares for their timepiece. We all are so careful because we love what we can do. If i take mine off the wrist to do chores then i put it somewhere dry and safe, if i cant it goes in my pocket, i check that pocket for loose change or anything that can scratch. I check it every ten minutes for condensation in that case . Hows Scotland matey ? We have a storm coming, keep safe and dry1 point

-

I have wondered the same thing about removing the spring. But I came to the conclusion that removing it is probably less stressful as the spring is leaving the barrel under its own action. Unlike inserting a spring which can be pushed too hard resulting in kinking or backwards (not the first time I have coiled a spring only to notice I coiled it left handed instead of right handed) or...? I think it's just one of those situations where you just have to do the best you can and live with the risk that you may have to replace it. I am sure if there was a market for it, and it was technically possible to mechanically un-wind a watch mainspring our friendly Swiss tool manufacturer would be selling it by now for crazy money1 point

-

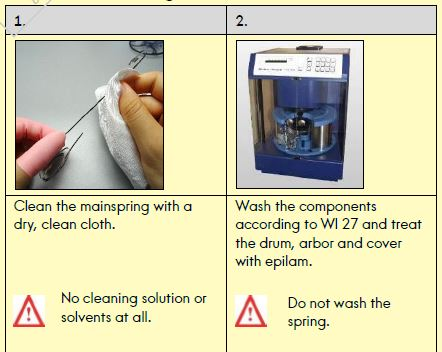

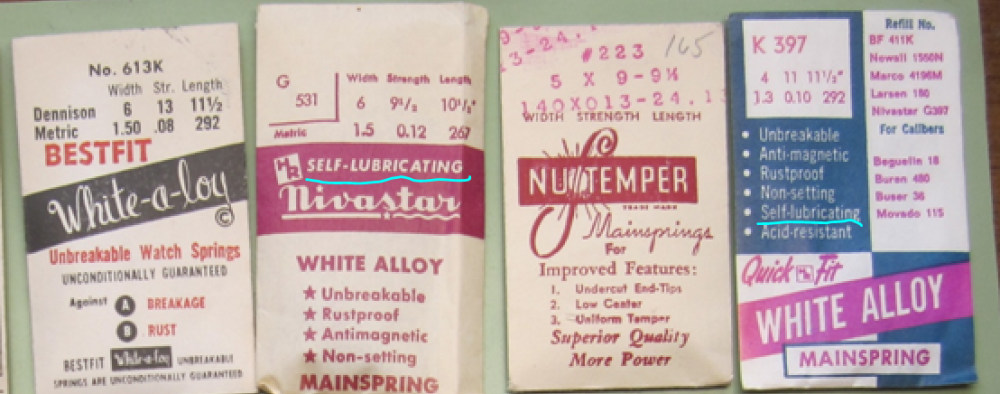

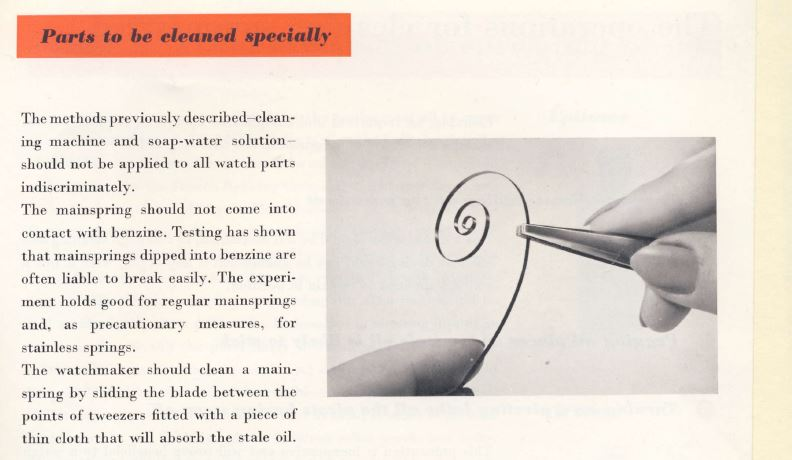

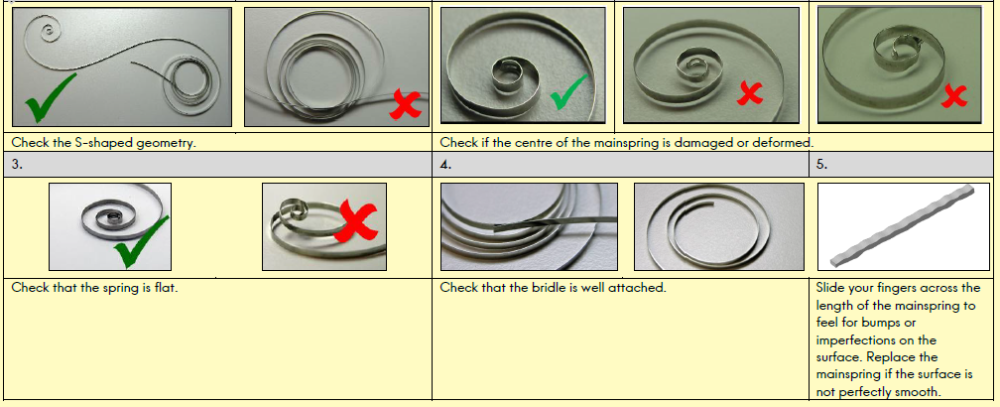

in clock repair is the only place I know of where the mainspring can be removed with tools rather than by just pulling out. But that's because clock mainsprings are so much bigger than watches and if things get out a hand it can be very very bad because of all that force. that's a common method you do have to be careful though that the whole thing doesn't get away from you and everything goes flying away possibly to never be seen again. this is the usual recommendation if you are thinking of reusing the mainspring. typically in fact that's never been the method that I used I just pull the spring out from the center. This safe method of doing this is under a cloth towel or wrapped in a towel for instance. Your hands are under the towel you can't see what you're doing but you can tell by feel and nothing's going to fly away. I usually do it by holding the barrel in my left hand and pulling with my right hand but I'm dealing with pocket watch barrels which are really easy to hold onto versus wristwatch which are a lot smaller a be better to do this under a towel. the concern with hand insertion and improper use of the mainspring winders is distorting the mainspring. Typically in the case of vintage blued steel spring as they come out they have a nice cone shaped to them. That is believed caused by hand insertion of the spring. in general I don't think I've ever seen a recommendation of cleaning a mainspring in the cleaning machine. For instance modern Omega recommends dry cloth no solvents and definitely no cleaning machine for the mainspring itself. here's an example from Omega from the late 50s where they do give us a clue about solvents why they're bad. so typically should build just wipe the spring off you might still get stuck with some form of a solvent if the prior lubrication is nasty and sticky. Although it Omega's case especially the newer version they are not worried about sticky lubrication because there shouldn't be any visible lubrication out all. Here's a for instance mainspring packages are quite amusing especially the newer ones with the non-blued steel Springs. Notice basically the perfect they will last forever they will not break they will not well actually they will break and it will shatter and they can get rusty. But noticed two of the packages say something interesting or self lubricating? This is one of those horological mysteries of the universe of it says that it's lubricated but I can't see the lubrication? So watchmakers have had theories that the particular steel doesn't actually need lubrication it will slide on itself. Others are various forms of dry lubrication. Or Omega document attached which tells you what they were using at least initially they may not be using this anymore. you should open up a modern Seiko watch and look at its mainspring barrel it is filled with Greece usually a peculiar grayish substance. Fortunately the barrel is sealed up nice and tight there are no little openings like you typically find on older watches so it doesn't go losing out across the universe. Basically this at the extremely stringent with your lubrication on the mainspring otherwise it will escape. This is where anyone new to watch repair once they complete a watch they should have it for at least a year and six months or year from now taken apart and see how things look. like put it on the timing machine see if it still performing like it did a year ago see if your lubrication is wherever you originally placed it and see if the mainspring lubrication is leaked out across the universe. Unfortunately with watch repair you can see some instant effects of poor lubrication choices but it really takes at least a year or more to see the effect of bad lubrication choices. then here's Omega's recommendations if you're reusing a mainspring then I can't always follow these recommendations like the first part the beautiful S curve. I've taken a mainspring is out of packages vintage Elgin Hamilton as they both had alloys that wouldn't set and they had beautiful back curse vintage new old stock. But modern spring is made in modern Swiss factories for pocket watches often times do not have beautiful back curves. One of them in particular basically had a curve for the harbor and more or less went straight out with basically almost no curve at all. Brand-new unit sealed package you get a lot of quality variations. Typically have wristwatches you'll never noticed this because if it's a new spring you're just going to push it in from the ring. The typically a pocket watches they have to come out of the ring and go in either by hand which I do not prefer or with the main spring Winder as you have to get the end to catch. Then when you take the spring out that's when you make the observation of the poor quality of your spring otherwise you would never know. Omega technical guide number 30 1963 self lubricating mainsprings.pdf1 point

-

I recently did one and the comments are on watch of today: I think the secret is to glue the feet on the back where they poke through the dial, not the marker to the front of the dial. If the feet are already loose I would gently push the marker back in place and then flip over the dial and add a spot of glue to the feet to stop them pulling out again. I found using super glue gel for this much better than regular superglue (see details in the thread in the link above), but the 2 part epoxy would also work. IMPORTANT: There was a discussion further down on the same thread about using super glue and I advise you read that also, but I think the bottom line is that if you leave it to fully cure (>24 hours) before re-installing you are OK.1 point

-

It is nor pure nickel, if it was, then why would You put a new nickel layer on it? It is 'nickel silver', or 'neuezilber', or 'coin silver' with chrome plating.1 point

-

Thanks Razz. I have access to the Matsys best-fit database, but not Boley. I did find some replacement springs on Cousins UK, but not sure of the dimensions I need. I will have to do more research but thank you for the jump start. J1 point

-

That's pretty wild. The caseback reminds me of those awful mumbai specials, they use that same font and logo for their fakes yet weirdly, the dial on that cheap fake is pad printed and of pretty decent quality compared to any fake seiko i've ever seen. To pair it with that oddball quartz movement, that's pretty fascinating.1 point

-

I've noticed others posting in here some of their experience so here is mine: I started developing my skills by taking apart cheap HMT movements from several HMT watches I scored on Ebay. I guess I shouldn't have started with such small watches, but I've successfully taken a few apart and got one back together and working. Learning from that experience, I purchased a G.S.T.P. Pocket Watch (WWII) to practice on a larger movement. That's where I'm at now, and hopefully, I will get this one working, but then I learned my second lesson, and that is, maybe not start with a movement that it will be hard to get donor parts for. I have all the basic tools, good screwdrivers, several Moebius oils and greases, a timegrapher, a movement holder, and lots of stuff, but I have learned the most important thing to have is magnification in different levels and PATIENCE.1 point

-

Seikos are not crap! This is crap (see below). I picked this at a car boot (swap meet or flea market here in the states) for $5. I showed the seller that it was fake and we had a brief conversation about why would someone fake a Seiko? I could not help but posting it here because I think the OP's watch is what this watch is trying to be. An interesting aside is that the quartz movement is a Sunon SP28 and has 4 beats per second and so kind of looks like it "sweeps" like a mechanical. I may cross this into another case as the movement is worth more than the $5 as is the case...1 point

-

I don’t think I’ve ever seen a dial lose the markers en masse like that. The conditions to bring that about must be interesting… Well done as always Waggy! …a good point but for a watch literally rescued from the bin I’ll allow it…1 point

-

1 point

-

You could use them to remove the cannon pinon. I always recommend use the right tool for the job, there are many tools for the removal of cannon pinons. nevenbekriev, what has your video got to do with the original question? Please do not hijack a thread just to post something. You can start a new thread. I might remove it.1 point

-

Managed to rescue this Seiko 7009A (August 1978), it needed a new crystal and date change return spring (the huge banana shaped one), the bracelet needed some TLC on the bufing machine and re-shape some of the bent links, and the rest is original. I had to do a lot of gluing on the dial to replace all those markers, fortunately they were all still there , then re-lumed the hands, Before, lots of : After: 250 degrees amplitude and 0.0 beat error + 5 seconds/day face up and -5 seconds/day face down so very respectable for this old timer.1 point

-

1 point

-

1 point

-

1 point