Leaderboard

Popular Content

Showing content with the highest reputation on 01/01/24 in all areas

-

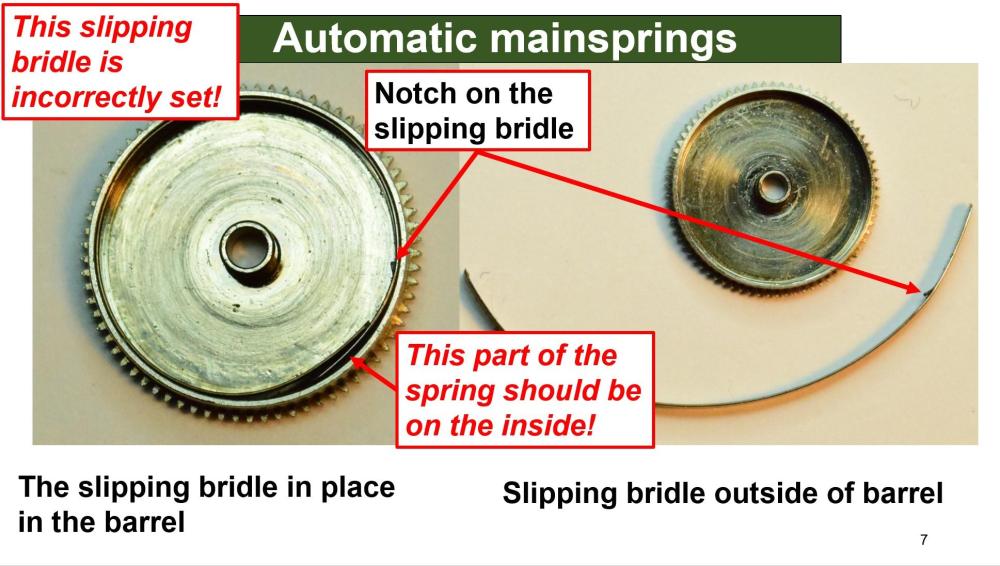

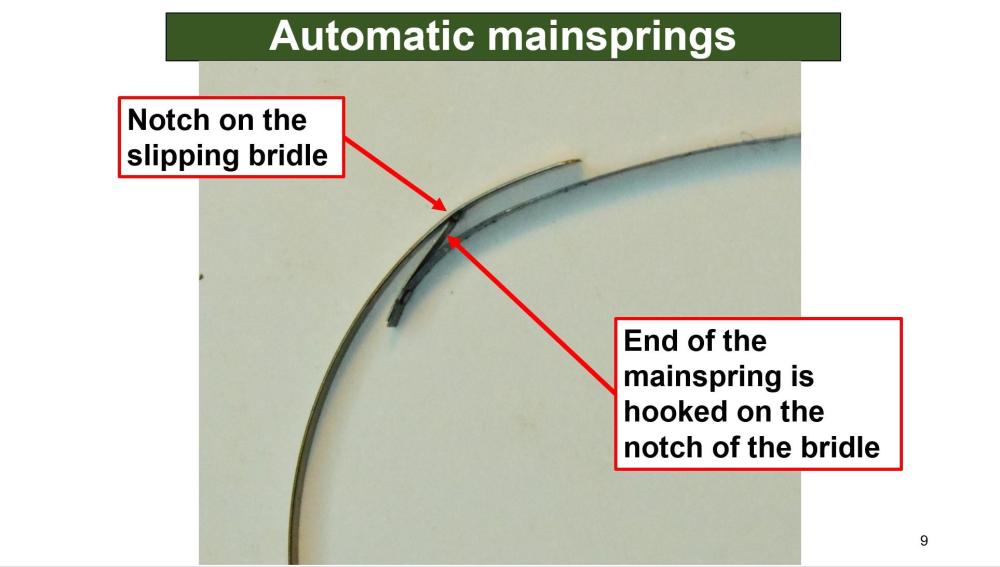

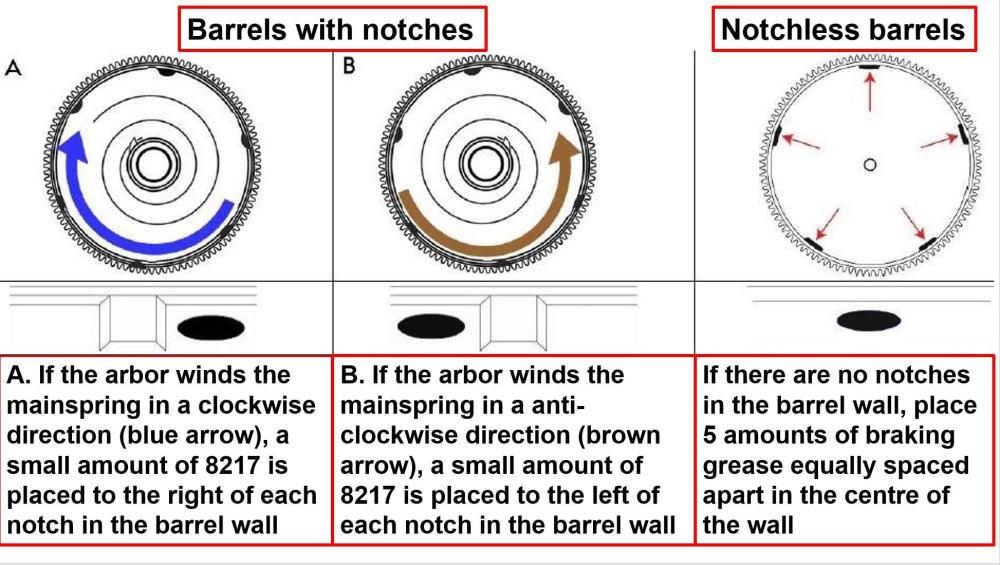

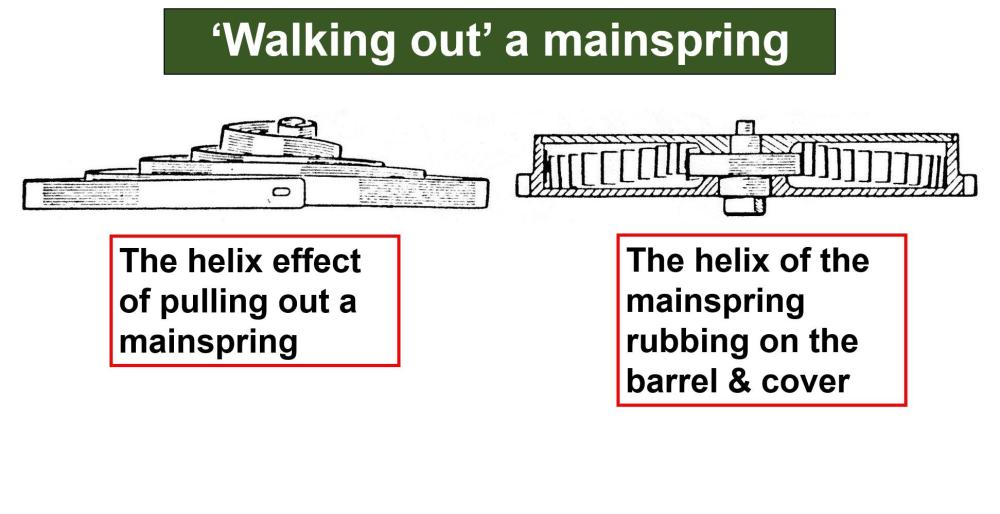

Undergreasing the actual spring, not the barrel wall. So, when the mainspring has been cleaned it is greased. If the entire length of the mainspring hasn't been greased enough or not at all, (the spring has to be able to slide coil over coil) then when winding the watch manually there might be a scratchy feeling with the coils not sliding over each other because of the lack of grease and too much friction of the coils over coils. The scratchy feeling may also be because the spring has a slight helix and scrapes on the barrel and/or cover when winding, which can also fluctuate power output, therefore a loss of amplitude. There are generally three types of braking grease for the barrel walls depending on what the barrel is made of. Moebius 8212 is meant to be used on aluminum barrels. This grease has a moderate braking effect. Moebius 8213 is meant for brass barrel walls and isn't quite as thixotropic as 8212, but is more viscous than all of them so provides slightly more braking. The goldilocks of them all is Moebius 8217 which can be used on all barrel types, This grease is the least viscous but still has a fairly good thixotropic effect. The thixotropic effect is when the grease is under load or pressure it changes from a viscous grease to more fluid like an oil. Moebius 9415 is a thixotropic grease for pallet stones because of this effect; it is better than 9010 which used to be used. Oils and greases have developed a lot in the last decade On old-style automatics, the 'slipping bridle' was a separate piece of spring that had to have the correct springiness to dictate when the bridle slipped and therefore the mainspring. This still had to have braking grease on the barrel wall. The mainspring looked like any manual spring with a hook on the end that caught the hook of the slipping bridle. It was more the shape of the bridle that determined when the bridle and spring slipped rather than relying on how much braking grease was on the barrel wall. The flatter the spring (when out of the barrel) the slip will happen later, also creating the most amplitude, the more curved the slipping bridle, the spring will slip earlier which may result in not enough torque being generated and a loss of amplitude. On modern automatic mainsprings, it is the bridle that pushes the mainspring against the barrel wall and creates that force so the end of the spring will jump from indentation to indentation in the barrel wall. On old-style automatics, a lot of the time the slipping bridle has been removed and a modern spring has been used, but there aren't any indentations on the barrel wall, just a smooth wall. Depending on how much and which type of grease is used on the barrel wall, as well as the state of the wall will determine when the spring will slip. Also, some older automatics will look like having quite a low amplitude fully wound and after 48 hours after oiling and greasing, let's say 250 degrees, once the auto module and rotor are replaced and the watch is fully wound and the rotor is spun a little, because the spring has total full torque now you can see the amplitude increase as much as 30 or so degrees. Here are some slides from a lesson I wrote for my students. As you can see the slipping bridle was set incorrectly which I found when taking the movement apart. It is important the bridle has room to close up properly, which highlights the point that "just because you found it that way doesn't make it the correct way" So, don't ever assume how you found it is how it should be!5 points

-

Happy New Year everyone! Using a sharpened pin and cycles of 10 min heated ultrasonic cleaning baths, I was able to clear the immediate pivot hole of debris. I don't own a Seitz tool or equivalent so I did not want to risk removing and breaking the jewels. Fibers remain in the gap between the jewels adjacent to the pivot hole but no significant drops of amplitude were noted on the initial timegrapher readings in multiple positions with a healthy amplitude above 225 degrees. Using the sharpened pin and capillary action, I was able to oil the balance jewels without an automatic oiler. All in all it turned out to be a great little timepiece and a huge lesson learned: Don't peg jewels unless both ends are open! Will attempt for final regulation after wearing for a few days. Enjoy the pics and have fun tonight! Dan4 points

-

My mentor warned me not put my watch repair bench in the bedroom. He often gets ready for bed, then decides to fiddle a little more and before he knows it, it's 3am. I sometimes get up to go to the bathroom, then end up in my workshop assembling a movement.4 points

-

I know something that almost everyone here is terrible at. # not spending money on watches and watch repair tools #3 points

-

I have pondered this term "breaking grease" because it has never made sense to me. My research indicates that the primary component of such grease is molybdenum disulfide. It is very slippery! It maintains it's slipperiness even under high pressure and thus continues to protect the metal. The proper shape of an automatic mainspring will result in high pressure against the barrel wall. If I understand correctly, a common grease would be "squished" away while moly, will remain...will be slippery, and protect. What makes an automatic mainspring work is its shape (as @Kalanagnoted) and the grease creates a sliding surface that remains in place.3 points

-

I'll tell you what i love about this forum, there is no bullshit, we are all genuine and honest, we say it as we see it, if we dont know we say so, if we get it wrong we apologise, we try to be diplomatic when its called for, and when we criticise its constructive, but we also have a laugh,banter and take the pee out of each other with no hard feelings. I belong to a couple of other groups that specialise in different aspects of repair, tools in particular. One of them has a lot of pretend professionals, its like listening to those youtube bullshitters. They get tetchy when questioned and are often full of excuses, like to argue and rarely admit fault. I think we get along just great.2 points

-

2 points

-

If you have a crown (button) and the tap size is right and the colour also, but the crown doesn't fit over the pendant tube, these tools are to make the inside diameter of the crown fit the pendant tube. You could also, reduce the size of the pendant tube on your lathe after pressing it out2 points

-

I'm really bad at wrapping presents, to the point that I just put them in a bag and the job's done, which is strange because when I was a mechanical engineer/tinsmith I used to clad MDF kitchen units with stainless steel after shaping the stainless using a press brake. Maybe it's not having the patience to wrap them, but again that's strange as I have loads of patience when servicing watches.2 points

-

These are handy if you don't get a good result by hand https://www.cousinsuk.com/sku/details/gravers-scorpers-scrapers-deburring/g34925 Finish on Arkansas stone after a 2000 wet and dry to 4000 grit film on a lapping plate. I use a glass lapping plate to get the initial shape and angle. Use plenty of water to make the lapping film last2 points

-

Yes, I use one. They take the ball ache out of using a file and burnisher, although using a Jacot tool on its own is quite cathartic and good to learn the hard way. Best to have two grades of wheel. I use a wheel that is very much the coarseness of a file/burnisher, maybe 1000 to 2000 grit that takes out the scores on the pivot and can shape the pivot flat rather than tapered, and a fine wheel that gives the pivot a good polish. I bought mine from this guy who makes them at a fraction of the price of a Pivotfix: https://www.ebay.co.uk/itm/225939944659?hash=item349b11f4d3:g:pJoAAOSwExZlTmMs This one comes with both wheels. Course and fine. It just needs a decent Jacot tool if you already have one. Result!2 points

-

The way I remove bezels is with a Stanley blade and a brass hammer like @Kalanaghas shown. Start where the indentation is on the bezel, if there is one, and work your way around. try not to twist the blade, as this might bruise the case and bezel. Go slow and it will work a treat. I do this with all Rolex bezels as well. The four-bladed bezel removal tools are rubbish and most watchmakers I know never use them. They use the blade and hammer method.2 points

-

The same to you Happy New Year. Oh yes I really enjoy being on here still learning and I so much like helping. The difference for me there is no pressure in getting work finished I can relax and I do.2 points

-

Have you noticed that everything you are crap at you actually hate doing . Making the bed, washing the dishes, hanging out washing, ironing and folding clothes, hoovering, tidying up after yourself, washing the car, cleaning the bathroom, dusting . Strange that2 points

-

Happy new year OH. But it must have surely in your earlier years, and you are here with us every day bantering and helping us learn. I know you get something out of that.2 points

-

I think that was jon's meaning, detrimental in the regard that it is too high if there is not enough breaking grease. Is the scratchy feel the spring sliding dry on the barrel wall ?2 points

-

Handwriting. My handwriting is terrible. Always has been. I don't think it has improved since primary school. And if you think Chinese words look like chicken scrawlings, you haven't seen me write in Chinese.2 points

-

...it's New Year's Eve and you're sitting reading and writing on WRT. ...you start your timing machine before you start the coffee maker. I guess there are many other ways to know, so please fill in with more signs that you are stuck in the repair quagmire1 point

-

Hey all watch peeps, well happy new year to you all, heres hoping for a wonderful year ahead in the world of watch repair. Great tool and watch finds and even better fixing times to be seen by everyone in our community. I'd like to kick it off with this ingenious device and go ask if anyone has any experience with it. I think its also known by the brand of pivotfix ? . Used in conjunction with a Jacot it burnishes pivots by way of a hardened roller bearing.1 point

-

Fantastic post @Jon, it straightened out a lot of question marks! I read it through quickly (getting ready for the night), so I'll probably have additional questions once I've read it thoroughly. Thank you!1 point

-

That's why this forum is so brilliant. I posted a question, @Jonreplied and @oldhippywho knows more than I ever will, leant something and so did I. Brilliant, just Brilliant. I think what connects us is we love learning.1 point

-

Ah ha that is why i feel so at home. In some very strange way we could all be related, descended from a cast out caveman that had an obsession with tracking shadows cast by the sun. And if that's not a crazy idea i dont know what is , anyone else have anything? Now come on OH, I've been here for at least 18 months now.1 point

-

I keep saying I'm still learning after all these years. This tool is a new one on me.1 point

-

Useless is not a word to describe any of the regular members on here. Stark raving mad, maybe. Hehe.1 point

-

Useful tool. Something I've been called many times, actually i might have that wrong and the description used the word useless.1 point

-

I have read elsewhere that pith wood is used for this. I have a bunch of old pith wood that came with a watch I purchased several years ago. Pretty beat up. But when I cut it with a razor blade, it is nice and pretty!! I will use that.1 point

-

1 point

-

Yes This is better as it has more tips https://www.ebay.co.uk/itm/375149585076?hash=item5758a862b4%3Ag%3ACt0AAOSw71ZljV-C&amdata=enc%3AAQAIAAAA0AtIVPLP67Yqwz2UcYhdWtS42kIebQUGQJl5CUzBMA1S4He7gxaSIOd1EPEzhFQO3kcVSdP4lyisHH6GNU4%2BcXvOBmvVoWS17mdGU3gNDb6B1Mtml78aECeFNO5X%2BxSLBfmPtbGA5fv6DaxUgdRs2d%2B%2FpOGwHWXTJOd%2FXGPedjyx8W%2F%2FKjyLJoh%2BvQfT%2BeeMINkPqb080gK6q167CHcT33NlamIxorLEhg8vsxR08PYe01FLVeTBmQoLZ6%2F8iJFGZS9vFItA7gHw%2BJnR3NTnGcs%3D|tkp%3ABk9SR4i0wueYYw&LH_ItemCondition=30001 point

-

Thanks Jon, i have a glass supplier that will freebie me pieces of 6 or 10mm plate glass or toughen it for just a few quid.1 point

-

I would always go for a dedicated case back opening tool rather than the Jaxa type, as they are less likely to slip and damage the case back. You can pick up some really good quality case back opening tools off eBay like this one https://www.ebay.co.uk/itm/375149559027?hash=item5758a7fcf3%3Ag%3AgaIAAOSwZtdljV2F&amdata=enc%3AAQAIAAAA0OpyV44AlBZJgYrd6Tjmi5iqyTxuj0XSEoOQwDZwR%2FIMK1nxBisP0dyypUwQOBj1b9QGPyimmBQ0kKS1i%2BPb2XMm3LIGlmUs7NODM0rMRBYUGdlUtiD3t%2F8u9xWvyLS5jLniODxhfIGoY%2B2swW1ibRkK0WK8LCypHGmb8nnyh0QDOHIHPGzpXTlyX9lxrRqxwHf2SFKENwuSTRcHOtTER0vTl4OE3sEJru1i%2F04ltF2uvZzzRxP7lVGp0kPT3LYXMzPmYjenDiKa9cwsI5TxJVE%3D|tkp%3ABk9SR4i0wueYYw&LH_ItemCondition=3000 It's best to get as many holders with the tool as possible though. I have one of these MKS tools made in Japan, as well as the Bergeon copy and prefer this, although when opening Rolex cases I go for the Beregeon copy with Horotec suction cups top and bottom1 point

-

That'll do. Here's a cheap lapping glass plate which will be a lot flatter and give better results. https://www.amazon.co.uk/Veritas-Glass-Lapping-Plate/dp/B07Q58JFV9 You can spend a lot of money on really good quality lapping plates1 point

-

I find that kind of strange, a logical mechanical mind such as yours. I know that certain aspects of my experience in construction directly transfers into watch repair. My missus is the same with numbers, crap at maths but can remember my first car number plate 40 years ago and dozens of old phone numbers. It begins with S and ends in apphire Thats me, my writing is appalling. I haven't done grown up joined up writing since school. I write everything in capitals, any other way seems unnatural to me.1 point

-

I do exactly the same , my watchroom is in the room next to my bedroom, I've often stayed up till 2 and 3am then finally toddle off to bed . Its an addiction, a good addiction mentally but can get out of hand. We are just guys that love to fix stuff and proudly show off what we can achieve, its that recognition thing we get a buzz from positive feedback, who doesnt ?1 point

-

1 point

-

...remembering the names of people, even those I easily recognise. It can be extremely embarrassing. ...remembering the name of a certain very hard watch crystal. Every time I try to explain to someone that there are three types of watch crystals, acrylic, mineral, and... and... and... sorry can't remember it now. It naturally exposes me as a liar after declaring myself deeply interested in horology.1 point

-

We are, we don't have a life? But who gives a f£^k? Hehe. Posted before, we're probably not normal. I'm no way sober. Happy New year to all.1 point

-

I use almost only tungsten carbide gravers for lathe turning. I form and sharpen them only by diamond disk, dry, mounted on usual bench grinder motor. The disk is 800 grit, the diam. is reduced to 80mm. No aditional finish needed, good and clean surface and edges acheeved. It is important that the disk rotates true in plane, which needs some adjustment as the disks are soft and can be bent in needed direction. For HSS gravers - after grinding by bench grinder with small red color disk for sharpening cainsaw chains ( I don't know what the grit is) I use arcanzas stone for polishing the edges1 point

-

Carrying any extra muscle mass you can into old age seriously has real benefits. Toned muscles support joints, absorb joint impacts that can otherwise cause trauma injuries that never get better. What is gained mentally from this kind of exercise or any exercise for that matter is huge compared to the effort involved of working out. I'm not just talking about sweating it out in the gym but if you can safely then that's great. If all that can be managed is sat in a chair and raising tins of beans in front of yourself and above your head that has exactly the same effect. Folk just need to find the right level of intensity that benefits them without overdoing it. The body is a series of motors doing different things in everyday life, sometimes individually, sometimes combining to work in synergy with each other to complete a set task. A 2 horse power mechcanical motor is always a 2 horse power motor that eventually mechanically breaks down through overload. A body's 2 horse power motor can become a 3 horse power motor with overload, and rebuild from good nutrition and rest. That newly built 3 horse power motor can then do 2 horsepower work, faster and with less effort. Resistance training overload 101.1 point

-

For a moment it was like the cartoon where the chair had a shorter leg and I cut the longer ones and end up with another leg longer. But happy to report that the basket trued up nicely. I also noticed that the stirrer motor has a collet chuck. I could remove that and fit a fixed coupling to reduce some more wobble.1 point

-

1 point

-

You sure like to make life hard. Why don't you buy them already sharpened.1 point

-

Hi DNIC. welcome to the forum plenty of info to be gleaned from the members on here. As mentioned pictures with questions help enormously.1 point

-

I usually use a butane microtorch for heating seized screws. Depending on the type of threadlocker used, sometimes the parts need to be heated to 150°C before the bond is weakened. Before applying heat, make sure that any heat sensitive parts are removed, like orings, gaskets, etc. Although it might have a right hand thread, it usually helps to turn the part in both directions to break the adhesive bonds.1 point

-

I believe it’s like anything else we do, practice enables flexibility in approach. Like @RichardHarris123 I’m not truly ambidextrous but have fine motor skills with my non-dominant hand. Tom1 point

-

1 point

-

I do the opposite, but it brings up the point that one needs to develop some skill with the non-dominant hand. Oiling cap jewels is a perfect case for that.1 point

-

Linux. Been down that road. Best to do everything Nucejoe and eccentric59 says. However if I may offer one piece of assistance. Use Rodico. Place it over the shock jewel spring. Replacements are not available. New movement will be needed. Trying to obtain replacement shock jewel spring is not the thing to have to do. Course is great.1 point

-

Okay. Got it. I have new hands for this movement anyway so I'll see about prying off the hand pipe off the minute recording wheel and any other wheels if necessary. Thanks to everyone for their responses as I learned something today.1 point

-

I know this may be a long shot, but would you be able to share the file for the label you printed? I am currently restoring the same model and struggling since the lettering is not raised. Thanks!1 point

-

Ok but if you look at the pictures the case opens from the front, unless the OP has missed that the back does come off. I like you have to work with what we have presented with by the OP. If the back does come off then fine it's a standard movement and the lever is pushed from the back towards the dial, but, if the back does not come off for whatever reason the OP will only have access as shown in his photographs, then the issue is one of is the movement a standard design where the lever is pressed when the back is removed , if so in this case the lever needs to be pulled towards the dial as it cannot be pushed because it cannot be accessed from the back. If the lever needs to be pushed from the front then the movement has been made different to all their other movement which I doubt is the case. I still think this needs the OP to respond to the suggestion given to settle this one way or another and until he does I will keep my thoughts to myself, as it's clear I cannot get my thoughts down in a way you all can understand, that's down to me and my issues I know so sorry about that. Bye1 point