Leaderboard

Popular Content

Showing content with the highest reputation on 12/03/22 in all areas

-

Radiation (although a more serious situation) is a bit like lubrication in that there can be many opinions along a spectrum with no true right answer. On one hand there is no absolute "safe" level of radiation exposure, but on the other hand a risk/benefit analysis can be done so as not to simply turn our backs on anything involving radiation that has benefits for our lives. (Sorry if that came out preachy!) In industry and medicine, when we need to work with radiation the guiding concept for exposure is "ALARA" which stands for As Low As Reasonably Achievable. The tools to accomplish this are Time, Distance and Shielding. So for those that want to minimize their exposure to the (sometimes quite significant) radiation coming from old lumed hands and dials, those concepts can be used. Keeping it outside of your body is the first concern (there would then be zero distance) so masks, gloves, disposable plastic drapes, etc. are useful as mentioned in posts above. Keeping things damp can minimize contaminated dust generation, so if you are sanding or scraping off old lume, keep the tools and parts wet. But even then, there is radiation being emanated from lume even in a closed watch or a sealed bag of hands, so precautions shouldn't stop there. Doing things quickly, and maybe not using your "hottest" vintage watch as a daily wear item can leverage the time aspect. Thought of in this way, you can find other ways to avoid prolonged exposure, such as not storing your stash of old hands in the drawer right below the working surface you spend hours hovering over. I do think it's a good idea for everyone working in this area to have one of the inexpensive radiation meters - you can't balance the risks if you don't know the relative magnitude of what you are working with. There is another wrinkle - Radon (a radioactive gas) is generated as radium decays, and one study found that a collection of a dozen or so radioactive watches in a poorly ventilated area could lead to elevated radon levels, so how and where you store hot materials can also take that into consideration.4 points

-

Hi, not sure video links are allowed here, please delete if not appropriate. Here is a DIY/hack which allows you to hear full watch beat sound from a simple No. 1000 device.3 points

-

2 points

-

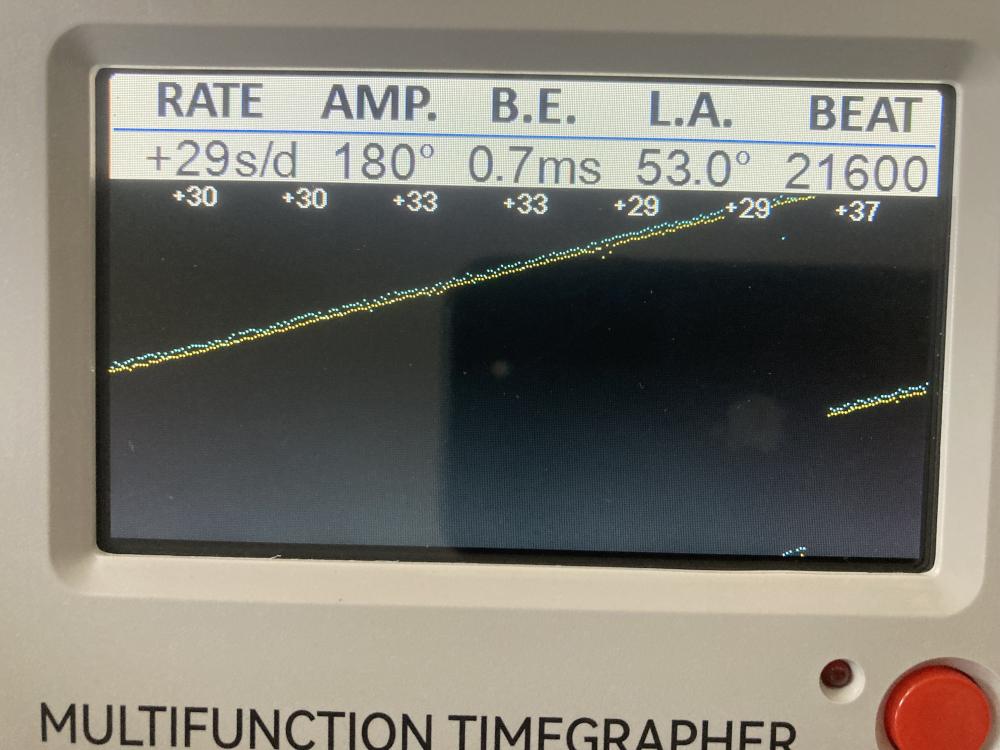

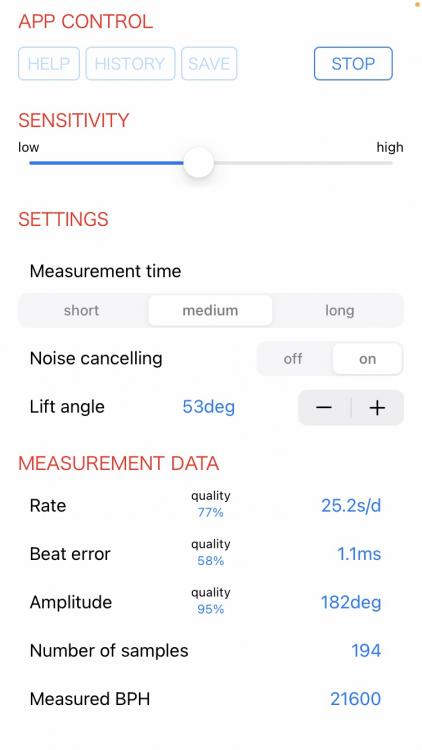

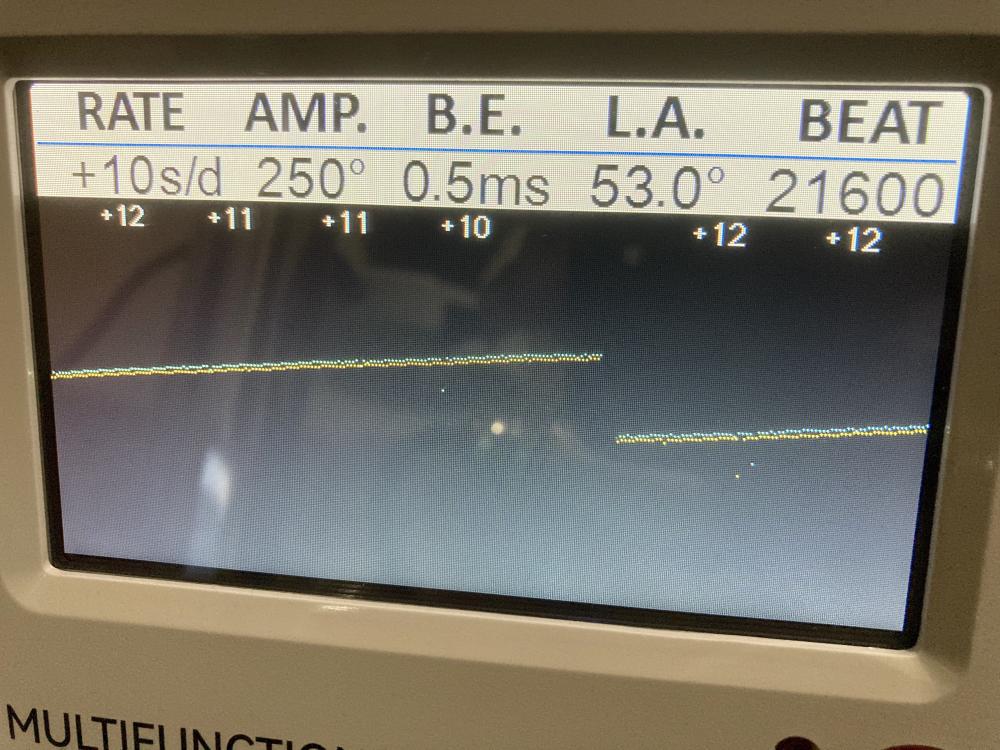

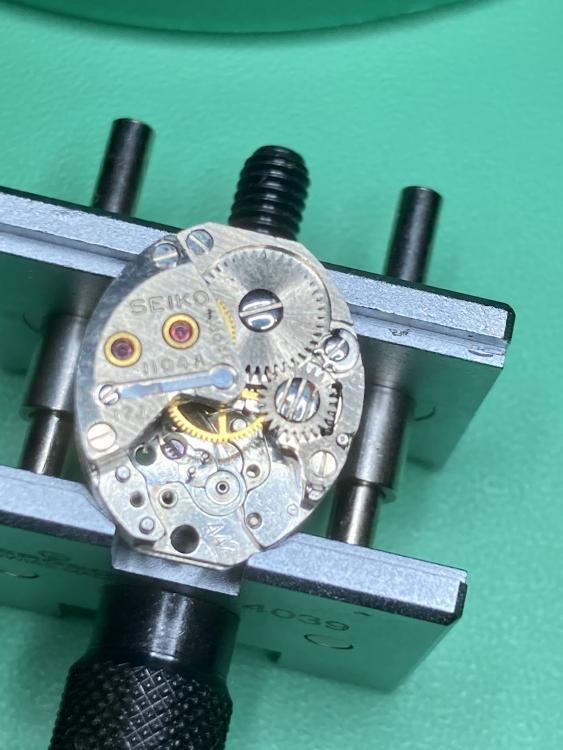

Good day everyone So, after practicing reassembly on a non working Seiko 7S26A with a dial foot lodged in the centre wheel, including rewinding (and breaking) a kinked mainspring, losing diafix cap jewels, and reinstalling a balance complete, I obtained two working movements from speedtimerkollektion., both 7S26A. The first was advertised as "the movement runs and stops." Turns out the hands were bent downwards and the second hand was blocked by a dial index. Once that was popped off, the balance wheel swung back into life. I put it on my newly acquired timegrapher: Found the readings varied somewhat depending on gain setting. Compared it with the app WatchTuner so decided to settle on this reading. Decided to attempt my first ever service. The parts were in worse shape than the previous non working 7S26 with crud and rusted areas. Cleaned the parts with rodico, pegwood, and pithwood before ultrasonic cleaning in jars with Petroleum Ether, Propanol, and 2nd rinse Propanol (3 min each). Cleaned the pallet fork and balance by soaking in a jar of Hexane. My little 1L 55W cleaner struggles to remove all the gunk and rust. Placed a few parts in white vinegar for a few hours to remove the worst of the rust. Definitely have to work on my cleaning technique given what I'm seeing under the microscope. Some screws are still discoloured. Reassembled and oiled using 9010, 9104, 9415 and 9504. Used S-4 on the first reduction wheel and pawl lever. Used notched pegwood to reinstall the diafix springs and a balance taper pin to oil the assembled diafix setting from the other side. My Chinese automatic oiler arrived with a bent needle that promptly broke so I am awaiting a new needle. I left the mainspring barrel well alone since it was winding and unwinding normally (unlike the previous practice movement). So this is the result without any regulation (which I have yet to delve into). I've got the second working 7S26A to practice on then a complete Seiko 5 7S26A watch I picked up on Yahoo Japan auctions. Will work on these before any of my own 7S26 or 6R15 watches. So after the Chinese ST36 (6497 clone) (a true victim) and two 7S26As, I wanted to try my hand at hairspring manipulation, balance staff replacement, jewel adjustment etc. Turns out Seiko Ladies tiny form movements are not popular with collectors. I obtained two working 1104A watches on Yahoo Japan Auction (for just 639 yen each) and nine non working 1104A movements from speedtimerkollektion (for about 1.50 to 2.50 USD each). Got some NOS spare parts so have some good practice material to work with. This is the first one I've started to disassemble. About the size of an American dime and older than I am.1 point

-

Radon membranes and dpcs have been used in modern house building and extensions for quite a few years now. Similar to visqueen sheet barriers with added polymer layers. Areas known to have a certain percentage of house contamination of ground radon gas the building regs require these barriers to be installed. Traditional vented sub floors once used didnt require these measures ( my much prefered method of house building also ) Apparently around 1000 deaths a year are estimated due to lung cancer caused by radon gas. Next time you're passing a new building site, drop by and ask if they have some radon membrane going spare, used to be green , i assume it still is. Make a few small baggies for containing anything that has lume and seal with radon tape, when opening do it outside. Over the top ? , does it matter if it is ? I know that my health is worth a lot more than any small amount of effort to preserve it.1 point

-

Good video, thanks. I think even I could do that. But, what I would really like, is a simple (ideally ready made) interface to connect the Weishi microphone to my PC. I know there's a thread on this, but I'm not knowledgeable on electronics. ( @JohnR725 and @praezis seem to have no limit to their knowledge!) If someone could make a box with a socket on one side for the microphone, and a USB plug on the other - I'd put it on my xmas list (They'd probably sell quite a few).1 point

-

A lot of the danger is blown out of proportion as people panic when they hear "radiation". Not realising that even bananas (and us) are radioactive to some degree. The bottom line is, you are probably safe unless you ingest some radium - which you definitely don't want. The body treats it as calcium and deposits it in bone, where it will stay for the rest of you life, emitting alpha, beta, gamma particles. Alpha particles are the most damaging inside the body (Litvinenko was killed by an alpha emitter). That's why, when working on radium dials and hands, I wear a mask and gloves, use cling film on the work surface, and use water to remove any radium.1 point

-

Watch repair is a lot like learning to become a doctor it involves a lot of practicing. So like learning to become a doctor it's best not to practice on live patients as well our expenses are less than real patients if they should die. But replacement balance completes expensive. To get good at hairsprings you need lots of practice need to find something cheap and disposable because bad things can happen when you're learning with hairsprings.1 point

-

I can't remember where but I do know that there are some people using acetone. I think it might've been a school was using it but I just can't remember where and why think that. Then in this fuzzy memory I'm not quite sure if I remember whether it dissolves the shellac or not. So probably fine for a quick rinse but if you leave it for a long time just check anything with shellac.1 point

-

1 point

-

1 point

-

The hairspring is twisted at the stud. You need to twist it in a manner that will bring it down 180 degrees from the stud. You will have the tweezers in position, like if you were about to grab the hairspring, but not squeezing yet. They will be tilted in the direction you want the hairspring to go down, then when you close them, the spring will twist. Sorry I don't have any photos or images to show.1 point

-

Yes the purpose of that was to tell the watchmaker not to drive it out. But sometimes people have driven them out. There is at least one or watch.org which one that they actually had updated the staff to include a blued hobby that you can put in and then user friction staff I don't think it was Waltham I think it might've been Elgin but that was an upgrade I'm attaching a handbook that should come with your Jewel tool depending upon which one you have. What makes a handout interesting is it does show pictures of burnished in jewels and unfitting modern jewels in their place so for instance if you broke the old one you may build a ream out the fitting and fit a modern jewel but sometimes there isn't enough clearance or won't be enough material left. Just in case you don't have it I also have a link to a Waltham material guide you go through and begin the grass the problem of getting a jewel. Yes at one time a very long time ago they were replaceable. But when the problem with American watch companies is they can end up with variations especially Waltham has lots of variations for the same market. Or some of the watch companies will have variations for the balance staff even this one has some variations even though the size is all appear to be identical so not sure why they're actually categorized as different staffs on the hand out I was looking at. But other companies like Elgin one staff comes in 12 different variations yes a lot of them were pivot variations but their separate different staffs where you can't use one in the place of the other even though they have the same part number. Then because I'm not finding it in the catalog but I'm attaching it should be there I snipped out an image from the slightly earlier one it shows what the settings look like. So in the parts list it says there in a setting and peers with the settings are as you can see there's not a lot of material so if you listen mash out the old jewel which is usually the easiest way if you're going to replace it with a modern jewel you can agreement out and then possibly fit a modern friction jewel into the setting.Or if you in a unset jewel you could just open up the setting and replace what's in their. But you'll notice when you look at the catalog I don't think they actually specify the size of the jewel. Then yes if you had a watchmaker's lathe which is the easiest way there is a simple way of changing a modern plate jewel to be able vote burnished in. https://archive.org/details/catalogueofwalth00walt Seitz book.pdf1 point

-

For hole jewels, there are ones with straight sided holes and ones with olive holes as you have seen. Olive holes have curved hole walls, straight are self explanatory. Olive hole jewels reduce contact area and thus friction, and are generally used in areas that are most sensitive, like balance/ fork/ escape wheel. They also generally (not always) have a convex face opposite the oil sink. The convex face further reduces friction when used with a shouldered pivot, and when used with a cap jewel (oil sink facing the arbor/staff) promotes capillary attraction of the oil between the jewel face and the cap jewel. Many old high grade watches have convex faces on all the jewels. Some may also have olive hole jewels up to the escape wheel or further. If replacing a jewel, certainly go for olive hole with convex face for a balance, and it's a better choice for other places if the size is available.1 point

-

Those special pinvices are rather costly and rare, and different sizes will be needed. You could make (I did once) your own one with low cost. Take a cheap indian sliding pinvice (#330, its opening is zero) and a jewellers burr with ball shaped tip of appropriate diameter. Then mill the center of the pinvice to the needed depth. The mouth of the pinvice is mild steel. It will last and keep its shape for very long. Frank1 point

-

1 point