Leaderboard

Popular Content

Showing content with the highest reputation on 09/19/18 in all areas

-

Hi All, Now, to start with I should say that my watch repaires are nowhere near the caliber (......see what i did there?) of some on this forum, but everyone started somehwhere right? Up until now I have been into costmetically restoring watches that run but have been somewhat unloved. Out of that I have started getting into the mechanical side too, I'm currently building up a FL Twin Power movement (one that I did not take apart) using the age old "yep, that seems to fit there" and "hmm that doesn't look quite right" methods! Some resources on this very forum have also been extremely useful. I can get the odd dead watch re-started, but a full strip down, service and rebuild is where i would like to get to. As i say mainly cosmetic work, the interest for me is taking something that looks completely unloved and turning into something that will be cherished. My watches have been bought for birthday presents, wedding presents, something that's being bought specifically to hold onto and pass down to the next generation, and that's what it's all about for me. Anyway, some examples for y'all Hamilton Self-Winding: Stunning Louis Erard Triple Date: Longines: Omega Geneve (never did try to sort that bottom lug out just in case): Oris 15 Jewel: Oris Super: Roamer Popular: Rotary 17 Jewel GP: 70s Seiko Auto: Seiko SeaHorse: Tissot Visodate Seastar Seven: Tudor: Old Timex: Thought I'd leave it there as you're probably getting a bit bored That's probably about 10% of the watches I've done over the past couple of years!! In terms of my own 'keepers', I don't actually have that many. A couple below: Tissot Seastar that I fell in love with the moment i put it on: Oversized Tissot Antimagnetique, which i sold and then pretty much begged the buyer to sell back to me. Which he did.....but failing to mention that hands were fused together. So i wound it not realising, and it's now broken and slightly in bits In the future I'd very much like to aquire a genuine military issued chronograph, that will be my significant investment watch i think. Hope you like! Matt2 points

-

Do not oil the pallet pivots. It will cause complications in time keeping. As you say it causes drag. The pallets have very little movement so oil is not needed.2 points

-

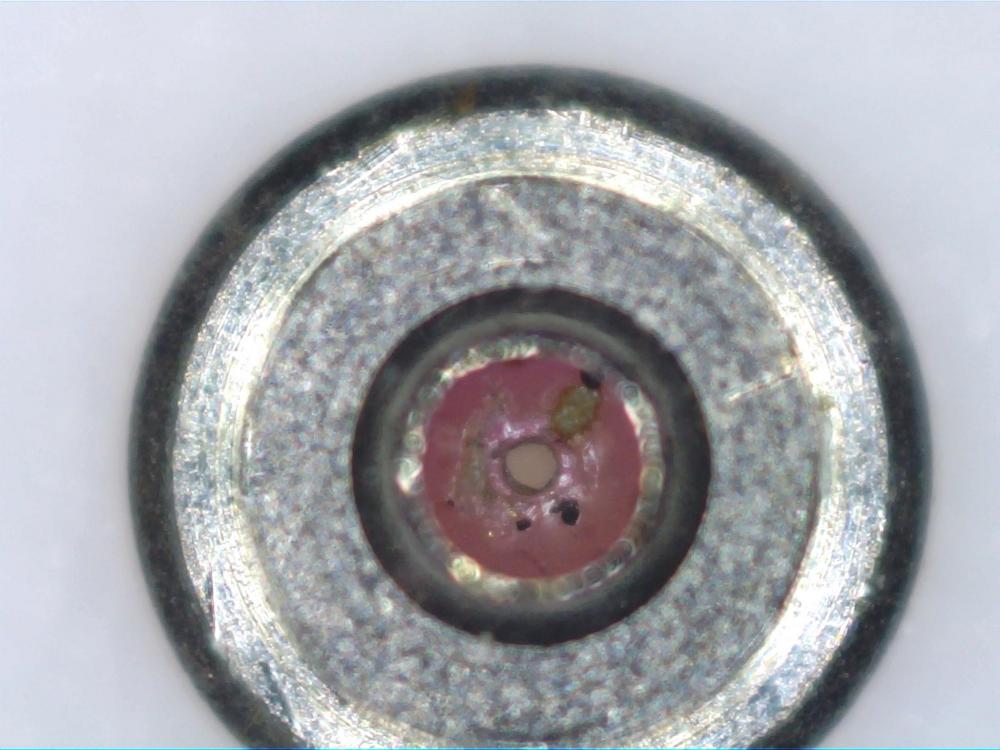

Not a question, but I thought I'd post this for general info. I was really struggling to get the amplitude above 190 deg on an Omega cal 613. I'd fitted a new mainspring, and all the pivots looked straight and clean. Gear train running freely, barrel arbor not sticking, no loose jewels, and jewels looked good under the microscope. Hmmm I always have a good look at the jewels to make sure they are clean and not broken, but have never bothered checking one area - inside the Incabloc hole jewel. The cap jewel and top of the hole jewel looked good, but it was only when I looked underneath I found the problem. I don't know what the black bits are. They had been cleaned twice in my ultrasonic in lighter fluid, then IPA. Obviously not enough, not easy to get a brush in there. I put in new jewels and now have 275-280 deg amplitude Another item for the check list !1 point

-

Here is how I make my custom drills: http://jamesriser.com/Machinery/MakingCustomDrills/Spades.html By starting with HHS I can skip the hardening process and possibly warping when using O-1. I prefer to step down from a standard diameter to the required drill diameter. This makes for a stronger drill and one easier to mount in the lathe or drill press. Jim1 point

-

It's been a good learning experience, for you, and us watching. I never try to give up on these difficult movements, because you can learn so much about what could be wrong. And I've still lots to learn. ....... but there's always a point when you've had enough ! Good luck1 point

-

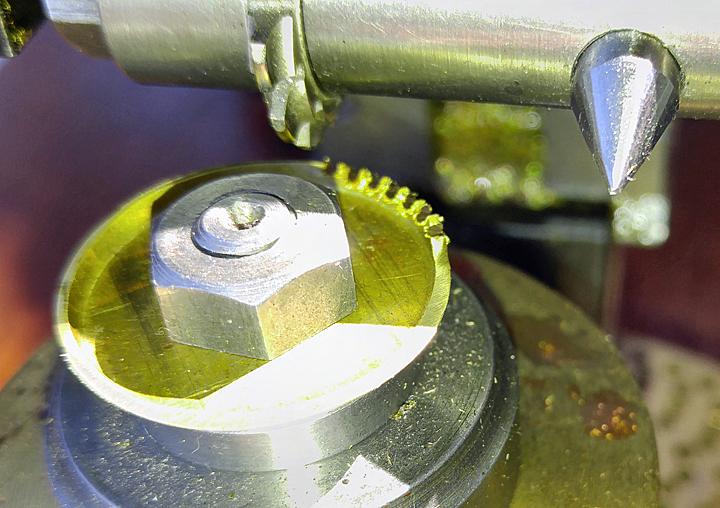

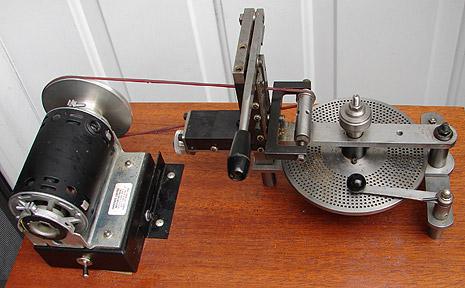

I really do not make nor repair watches. I design, manufacture, and repair apparatus for magicians around the world. Many of the tools and machines that I use would be very familiar to you watch and clock folks. Recently I was working on a design that required an intermittent action driven by a very shallow "crown gear". Here are a few pics. To make these gears I punched out brass discs, added the center hole, raised the rim on a die set I machined, and cut the teeth on my Chronos wheel engine. I have tons of additional projects involving watch and clock scale techniques and tooling/machines - if anyone isinterested. Jim1 point

-

Welcome Dave, enjoy the forum.1 point

-

1 point

-

As Nucejoe says its not a big job but not something I would have attempted as a first project on a quality watch. If you really treasure the watch I would recommend getting professional advice and get a quote for the repair. However if you do attempt it yourself and it is broken dial feet buy some dial dots, tiny dots of sticky which are easy to apply and easy to remove in future. https://www.ebay.co.uk/itm/260-x-Watch-Dial-Foot-Pads-3mm-Sticky-Feet-Sticking-Spots-for-Movement-Repairs/263363518242?hash=item3d51b05f22:g:ZzEAAOSwdx1aNAVO1 point

-

The hands appear to be telling the correct time so it would be just the dial that is revolving. I have a passion for Tissots and have some dating back to the 50's but never known this to happen. Yes the dial feet can break off but both at the same time? and usually when your removing the dial. Tissots usually fit into a grommet in the movement instead of the usual movement edge screw. Are you sure its a Tissot????1 point