Leaderboard

Popular Content

Showing content with the highest reputation on 02/09/16 in all areas

-

Sometimes with old movements after you go through the normal cleaning cycles including pegging the jewels, you still find old oil that has turned to hard varnish left in the oil sinks. This has happened to me on a few occasions and I started thinking there has to be an easier way than soaking in acetone and going through the pegging process again. A couple of weeks ago I was at the dentist and found the answer in my mouth............the ultrasonic probe. When returned home, I fired up my iPad and started searching eBay for a second hand dental unit and got lucky. I managed to get the unit for my initial bid of £40 complete with five new sterile probes. It was only after buying it I realised it had to be plumbed into a water supply, and I didn't think my good lady would fancy a hose connection in the kitchen, and I certainly didn't fancy cleaning watch movements in the garden. The problem was solved by purchasing a 5ltr garden sprayer for £8. Now that I had all the kit it was time to try it out, so an old movement plate was found with the necessary hard residue in the jewel. The result to say the least was staging, a gentle clean lasting about 10-20 seconds per side and the jewels were spotless. I just love lateral thinking! Below are some pictures to let you see the setup and the results. I only cleaned two of the jewels in the plate. The complete setup. The control box. Water must be flowing when in use, and don't touch the brass with the probe. Two jewels cleaned. Spotless!3 points

-

3 points

-

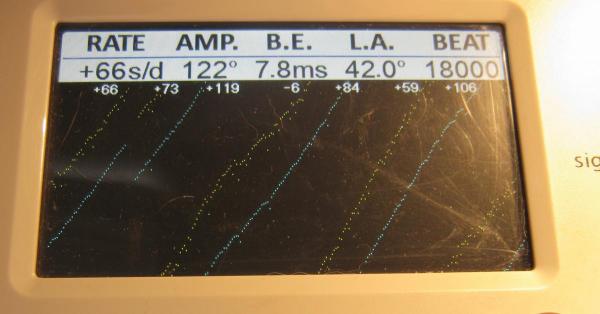

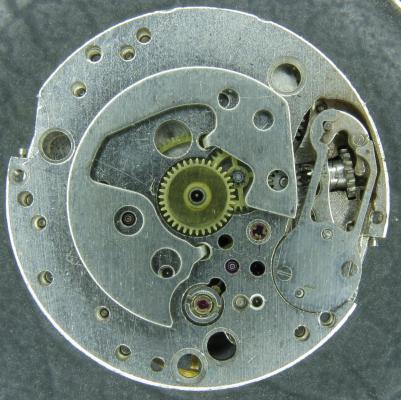

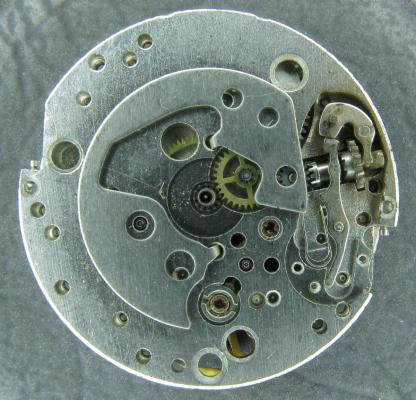

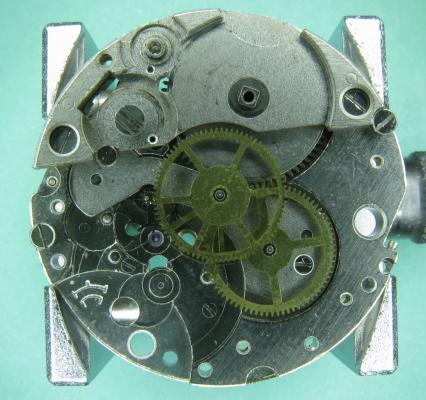

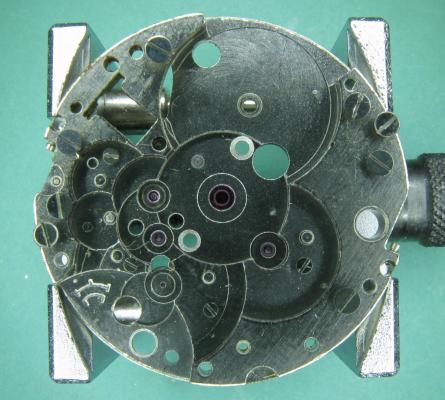

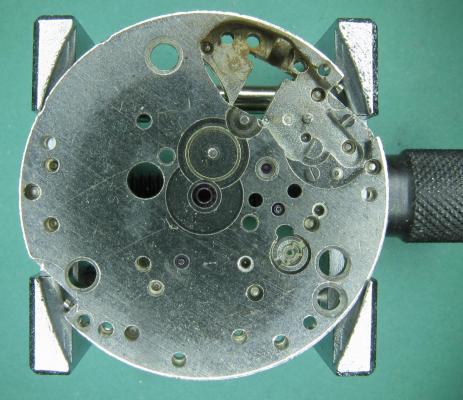

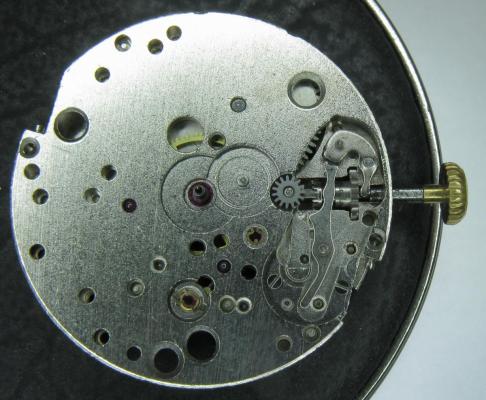

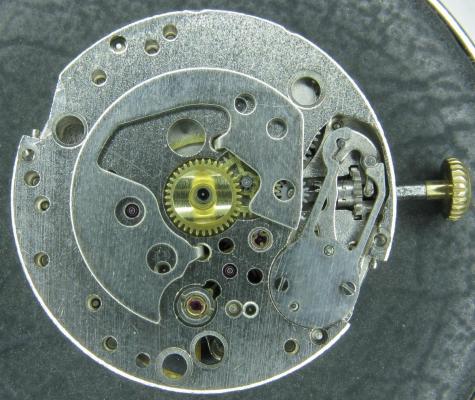

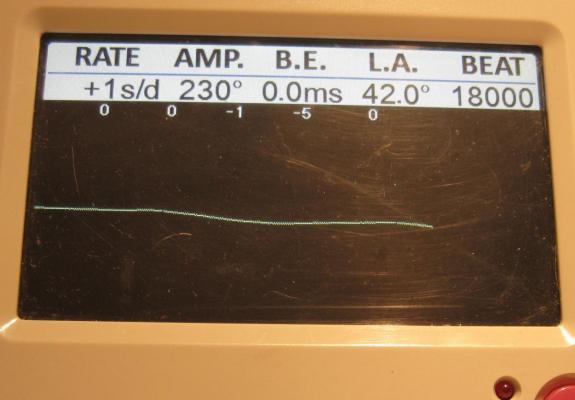

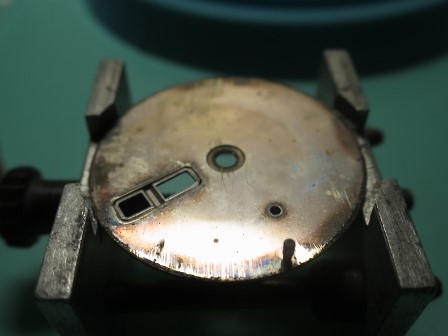

Just before Christmas I sold (through the good offices of eBay) an absolutely immaculate example of a 19 jewel Sekonda hand winder. I was a little sad to see it go as I don't think I am likely to see another in as good order for some time, and having just serviced it it was running like a champ but I couldn't justify holding on to it. Well, shortly after it had arrived with its new owner I received a message through eBay from the buyer. Huw had contacted me to say how pleased he was with his new acquisition, and did I service watches? as he had another example of one of these that was a little stiff in the winder and gained about a minute per day, and he felt that it maybe could benefit from a bit of a spruce up. I have done quite a few of these so am reasonably comfortable with them so I quoted a price and accepted the commission. A couple of weeks ago Huw's watch arrived so I thought I'd do this as a walk through. Looking well used but not abused, Huw had explained that he bought this not too long ago as a stop gap whilst his other watch (a Sekonda quartz chrono) was out of action with battery issues. First impressions are of a watch that has seen a lot of wrist time in its (probably) 40 years. The Timegrapher trace confirms the rate at roughly +60s/day, and confirms that a service is long over due. With the crystal out of the way the condition of the dial is actually rather good. The shadow to the right of the 7 is a lens fault on my camera, not the dial. With the back removed there is plenty of dirt speckled around the whole movement and everything is bone dry. The good news though is that it doesn't look like anyone has messed anything up inside. You can see the spring clip retainer on the escape wheel end stone (a bit like Seiko Diafix but not quite as clever). You can also see corrosion to the back of the bezel, this watch spent a lot of time on some ones wrist. With the movement out of the case the reason for the stiff winder and all of the dusty crud in the movement is brutally apparent. The outer end of the stem has started to rust causing it to bind in the case, and the resulting rust powder is thick on the inside of the case. These cases are a bit prone to this kind of problem as there is absolutely no attempt to seal them even against dust, let alone water, so even sweat on a hot day can seed the beginnings of a corrosion problem. With the dial off the press fit retaining plate for the motion works is exposed along with the keyless works. There's that little end stone retaining clip again, and the Raketa version of Incabloc on the balance. The rust doesn't seem to have got this far. With the set bridge out of the way though there is a hint of rust in the keyless works. Ouch!!! Just in time me thinks!! Balance and cock removed and the hairspring looks to be in good shape apart from the terminal curve which is off concentric. That will need to be sorted or the regulator will distort the hair spring as it is moved. Here also is the shim that Raketa are fond of using under the balance cock to adjust the balance end shake. A bit further in and plenty of gunge under the ratchet and crown wheels. Train bridge removed to reveal the train layout and a sub-bridge for the 2nd wheel. The main plate stripped with the screws put back in their respective holes. I do this so that screws don't go missing in the cleaning machine and I always know which screw goes where. The stripped main plate dial side. And then with the balance reinstalled (minus jewels) ready for the Elma. After a thorough clean everything is ready for inspection and reassembly..... ....starting with the balance jewels. This is when I check and adjust the hair spring for flatness and concentricity, eyeball the beat, check the end and side shake on the balance, and that everything swings freely. If you leave it until later there is too much other stuff in the way. Once I'm happy with it the balance/cock assembly comes back off until later. There is still a little work to do in this pic as the coils are still not quite concentric. The main spring re-lubricated and back in the barrel. This maybe could have been replaced but it wasn't too bad so went back in to help keep the cost down. Barrel, barrel bridge, 2nd wheel sub-bridge, and train back in place. Pallet fork and bridge installed. You can see the exit pallet poised ready to receive a drop of 941 on its impulse face. Walking the pallet too and fro then distributes the oil to the escape wheel teeth. Drop in the balance and away she goes. The cleaned up and de-rusted keyless works go back in.... ...and then the motion works and cover plate. Dial and hands back on, and ready to re-case. Again, to help keep the cost down I didn't replace the crystal with a new one, however, the original was just a little too deeply scored to easily polish out and there was what looked like a very small fracture. So a quick scout through my spares box and I found a second hand replacement which has cleaned up nicely. And the proof of the pudding ... as they say!! At 230 degrees the amplitude isn't anything to write home about but it is a significant improvement on the starting point. A new mainspring would almost certainly help this up into the high 200's (on the watch Huw bought from me I seem to remember it was 300+), but 230 is certainly usable. It is otherwise a nice clean trace with minimal beat error. It has been running for a week now in which it has gained just under a minute, so after a final tweak to the regulator it will be ready to return to Huw. I like these movements a lot. They are well designed and well executed, and capable of excellent results if looked after. They also seem to turn up quite frequently at the boot fairs. Unfortunately though, the lack of any attempt to keep moisture out of the case does mean that they quite often suffer from corrosion issues, and the relatively low cost (both when they were new, and when they turn up second hand) means that they are often used as a beginner watch smiths practice or learning watch, with the resultant butchery that many of us have dealt out as part of our learning curve. It's a shame in many respects, but then we all have to learn somehow. When you do find one that has survived unmolested though they are very well worth looking after. My thanks to Huw firstly for buying my watch, secondly for asking me to help this one to keep going for a few more years, and finally for allowing me to post his watch on here.2 points

-

When fitting new stems to watches I use these tools :- Digital calipers, Fine grade diamond lap Wire cutter Pin vice Now for fitting. (1) Hold the stem in the pin vice and screw on the crown tightly by hand. (2) With the movement fitted correctly in the case, insert the stem until it locks in place. Now measure the gap between the case and the underside of the stem. In this case it is 2.16mm. (3) Subtract 0.2mm from this size and this will give the amount to remove from the stem. In this case it will be 1.96mm which will give 0.2mm clearance below the crown when fitted to the watch. (4) Now remove the crown from the stem and hold the stem very tightly in the pin vice, then place the pin vice and stem between the jaws of the digital calipers then zero the calipers. (5) Remove the calipers and without touching the zero button set them to minus 1.96mm. THEN RE-ZERO THE CALIPERS AT THIS LENGTH The wire cutters are now used cut off the excess thread leaving a small amount to be filed to the exact length. (6) All that is required now is to dress the stem with the diamond lap a little at a time until the calipers read zero. (7) Finally screw the crown on tightly and it should be ready to fit to the watch without further adjustment. I find that this method cuts down on trial and error. FOR SCREW DOWN CROWNS. A) Screw down the crown tightly onto the case without the stem and measure the distance nbetween the bottom of the crown and the case. B ) Screw the new stem tightly into the crown, then insert into the watch until it engages and locks into the movement. C) Press the crown down firmly as far as it will go and hold it there. D) Using the vernier callipers, measure the distance between the bottom of the crown and the case. E) Subtract the size determined in (D) from the size measured in (A) then subtract a further 0.15mm from this size. This is the amount to shorten the stem by. This should allow the crown to screw full home without compressing the stem too tightly between the movement and the inside of the crown. F) Cut the stem leaving it slightly longer than the size determined in (E), and dress down to size using the diamond lap and vernier callipers as described in the original post. G) Screw the crown onto the shortened stem and check fit and function, before using a tiny spot of Loctite 221 to secure. Click here to view the article1 point

-

Well after absconding to a friends beach house on 23 of December, and not getting back until this weekend I've been devoid of watch talk and only a wardrobe of three watches. My Suunto Core Black, the Citizen Airwave and my Junkers "Iron Annie". I still haven't got my other 50 or so out of the safe yet, it takes longer to unpack and get re-organised from a holiday than it does to get ready for it! I have a couple of projects I need to tackle, one is a simple little mechanical based on an AS movement, the next is "The Pogue". I have the replacement bits for that but being my first chrono I'm going to tread very carefully. Good to see we are all enjoying this fascinating/frustrating little hobby and I'll be back with some input soon. Cheers Jim (A pic from the holiday)1 point

-

Here are some a few of the Dueber Hampden pocketwatches I have collected or were handed down. Mostly 12s and a few 16s, 4 are 21j. Also have some wristers in the bags. In the box are some of my wearers, including: Longines 25j 994.1 cal, (last of the thins), some 4 & 5 jeweled Seiko quartz, Seiko 27j bellmatic, couple Seiko 5 Actus 21j autos, these are daily wearers. I do have a penchant for Seikos! Hey, how did that junky old Rolex get in there?!?! Now you know why I started repairing. :D1 point

-

It is very satisfying. Just remember to never use wd40 on any watch you actually care about [emoji16] No gasket because none of these cheap watches are waterproof/resistant. Some sellers even warn you not to wear them while washing your hands.1 point

-

Thanks, One day I'll find a real one, but just knowing the difference is worth the price of admission. Hell I'd take a 7750 movement in a plastic case! If I do wear mine, and someone notices it, I always take it off and hand it to them and ask, "Do you think it's real?". Thanks for the dial offer...since I only have Hampdens, they are still avail in quantity. My problem is on the bay, which is where I do most of my fishin', sellers have figured out how to get rid of, well, for lack of a better word, "junk" by putting it with a desirable movement, more or less forcing you to buy what you don't want or need. I just recycle, problem with that is you can't fetch anything for elgin, walthams and the like, unless it's complete and working. Good luck getting your stuff in order and do post a pic when you are done. Dave1 point

-

Kind agree there Oldhip, as you can see I'm just starting and my bench looks like someone hit it with a lb of c4! Most of what you see is in timing or waiting for parts. I am jealous of some setups, just don't have the space. You might recognize this as a 'jewelers' bench, real watch benches are out of budget, actually works well for me, arm rests hold things steady and located next to window for really good natural light.1 point

-

Thanks Jeff for the compliment, that's why I didn't reference model or cal, it is a knockoff, but I know how purists feel about them, (rather not wear it at all... than a fake). I took it to a pro and he said it was a good fake, (if there is such a thing) you can tell by the dial, not really crisp lettering, no lum. Everything else looks and feels right and it does keep good time. (35+hours). I got it in a bag o' watches from an estate for $25, sold two of the watches, an old elgin and a swiss auto for $40, so WTH. I suppose I could throw it in a pile of junk and put it on the bay, but that wouldn't be right. Besides, I don't think there are too many who'd admit to buying something that turned out to be something else. Anyways congrats, you get the paying close attention award. Like Dad used to say: "The punishment for lying is always greater than telling the truth". Thanks again, Dave1 point

-

Hi - allow me to introduce myself. I live in Germany (but am a US expat) and, living on the border with Switzerland (and actually working in Basel) I have spent a lot of time over the last 25 years looking in shop windows while my wife looks for shoes. When I moved here, I was wearing a Timex Ironman. Eventually I saw an IWC Portofino and fell in love with it. Unfortunately it was way out of my price class. However, I started paying more attention to watches. Shortly afterwards, Nomos came out with the first Tangente, and I fell in love with that. Still out of my range. I muddled through the years with various watches, including a fairly nice Cito (minor German brand) with an ETA 2892 that I stupidly left in a restroom in Switzerland and never saw again. Four years ago I finally bought my Tangente and thought I was set. But I also started acquiring other watches, especially Gruens (I grew up near Cincinnati). I have a handful of watches from the 50s/60s. And this year I was fortunate enough to buy an IWC Portuguese Chrono, which is pretty much the only chrono I would consider wearing and for my taste is about as close to a perfect watch as there is. It is most likely the only watch in this class I will ever own. But I still have a fondness for these 'other' watches, including a 50s Lacorda I bought a few months ago. Lacorda is a French manufacturer. This one is in nearly perfect condition, I was the only person interested in it, and there was something about the dial I liked. Unfortunately it runs very fast. Which brought me to Mark's video on regulating a watch (easy enough, as it turns out, and I have some basic watchmaking tools), which in turn brought me to this forum, which looks very interesting. So there you go, and there I am, thank you for your kindness, and here's a picture of the little Lacorda. I'll know tomorrow how it's running, but I assume it will take a week or two to really get it right. Steven1 point

-

Thx. It actually looks better in the flesh than in that ridiculously enlarged photo. I was never interested in Omegas. For me Omega meant diver's watches and Speedmasters, and that just isn't my style. I've always been a fan of IWC. I had been putting money aside for a Cal 88 or 89 IWC. I still am, as a matter of fact. This one though opened my eyes to the 600/601/602 movements. I like handwound, dateless movements. These seem to be approaching the quality of the IWCs at only half the price. I discovered there are a lot of 60s Seamasters and Geneves with these movements that appeal to me. It helps that my 6-1/4" girly-girl toothpick wrist doesn't look ridiculous wearing a 34mm watch. So, I'll probably pick up another Omega or two before I depart this grey earth. steven1 point

-

There is a YouTuber that goes by Ratfaced Git who does a lot of walkthroughs of Russian movement disassembly and reassembly. And he has done the Poljot 3133. He's an amateur but it is a good introduction to the anatomy and function of the movement.1 point

-

Also welcome from me as well Justin. Good to have a Dealer on the forum as your advice would no doubt be useful and reciprocated with watch repair advice by the forums greybeards and elders if needed. Great place this and not too starchy either. Cheers, Vic1 point

-

Hello George, Wondered if you are taking on guvvy jobs. Went to the dentist on Monday and have paid £225.00 to get a molar crowned in a couple of days but I think it would be £17.50 for a clean and polish - surely you could manage that - God knows my mouth is big enough ! :D Cheers, Vic1 point

-

I've got my setup about how I want it - for the time being. Having no dedicated space, I've organized my desktop bench with the tools I use the most. The less frequently used tools are in plastic ammo boxes in the closet. When set up, my kids' homework desk becomes my work area. Right top drawer Left top drawer Bottom drawer I've still got some extra room, but I don't want to overload my bench, since it still has to be portable. When I'm done working it gets moved to the credenza and covered with a dust cover. I need to get an adjustable chair, better lighting, and figure out a more permanent storage spot for my bench when I'm not using it. Other than that, I'm good until the kids move out and I get a proper bench - something I'm in no hurry for. :mellow:1 point

-

1 point

-

Chronometer performance is -4 to +6 seconds within a 24 hour period, so if he is getting +30 per week that's still well in at +4.2 seconds a day!1 point

-

1 point

-

Thanks for the introduction Justin and welcome to the forum. You should get any help you require here should you require it.1 point

-

Hi Mark - good to see you here. I guessed you'd been very busy. Sorry to hear your balls are in the air, though. Anything we can do? :startle:1 point

-

Not at all ash. I don't use this forum as a means to gain business. However, Geo is correct, I have been incredibly busy on the bench taking on more work than usual due to an unexpected loss of earnings in another area. Regretfully, I have quite a few balls in the air currently but I'm hoping things will calm down soon for me lol. Sent from my iPhone using Tapatalk1 point

-

As I mentioned, the watch has many minor issues: It has a missing sub-dial hand. I was able to purchase an after-market set of hands. The after-market hands are difficult to find and I was lucky to find a supplier here in the Philippines who has several sets as samples. Apparently, he had a Chinese company replicate them and they are still in the process of testing the batch. The minute hand is actually a bit loose and the sub-dial hand got removed after a few chrono resets. I had to tighten them a little. It did not come with a crown and a stem. The stem used in the Seiko pogue is different from the one readily available, so I have to settle on one that is used with those without a rotating inner bezel. One of the chrono pushers is bent. Again, I used after-market replacements. The dial has a missing foot. I still plan on reusing the original dial but I would have to build my own resistance soldering machine to attach a foot. So for the meantime, I used the after-market dial shown in my original post. The intermediate date wheel is damaged. Here's a picture comparing it with a good one (right). The cannon pinion is loose. I have a spare 6309 and luckily, the 6139 uses the same cannon pinion. The crystal is all scratched. I could have removed the scratches but a replacement crystal is also readily available. Here is a comparison of the replacement crystal (right) and the original one (left). The original bezel is scratched and faded. Again, an after-market replacement was used. but the new bezel is a bit big so I had to trim it a bit. As expected, the oil and grease inside the barrel are all dried up. Fortunately, outside the issues described above, I did not find other problems with the watch. As you can see, I can't really claim that this was a real "restoration" as I used a lot of after-market parts. Many watch collectors will frown upon this but as a watch repair hobbyist, I put more weight on the integrity of the movement. In my next posts, I will describe how I serviced the movement. Cheers! Joel1 point