Leaderboard

Popular Content

Showing content with the highest reputation on 02/02/16 in all areas

-

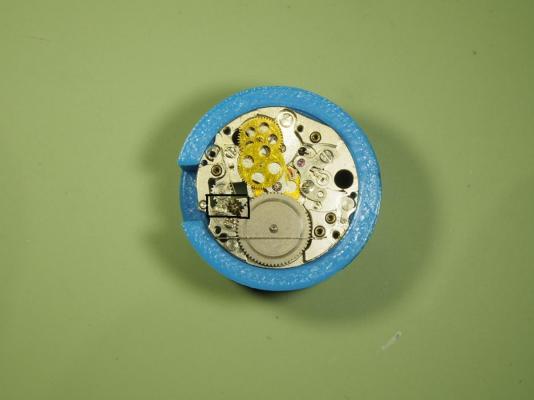

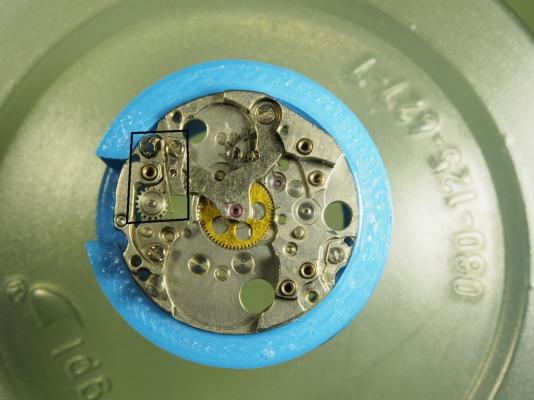

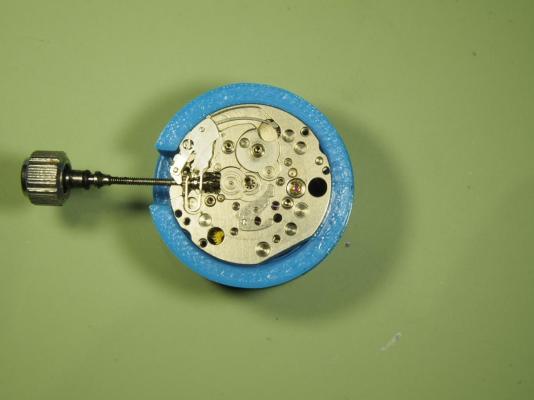

Flipping it over and the three train bridge retaining screws are removed. One of them holds a small friction spring in contact with the centre seconds pinion, meant to show that sorry. Lift the bridge clear but watch out for the transmission wheel pinion that is left behind. It can stick to the underside of the bridge and drop out when you aren’t looking, the small intermediate wheel next to it in the black box is also free to fall off. I am beginning to think that instead of removing the left handed screw and removing the transmission wheel you could leave it attached and then there would be no danger of losing the pinion below it. Removing the pawl lever as described above would still allow the mainspring to be wound down. In 4205B movements this is one unit anyway so not to worry. Barrel,train wheels and the centre seconds pinion are next. Then the pallet bridge and fork. At the beginning I mentioned that sometimes the winding mechanism might not feel right, you might get a few turns of the crown and then it goes loose then winds again. Given the age of these things by now there must be considerable wear and some of the gears in the winding mechanism are well worn I found that the winding pinion on the stem was not contacting the sliding crown on the winding bridge very well, it was tending to lie to one side and flop about. So what I did was to bend the spring that you can see inside the black box so that it puts more tension on the sliding crown and it seemed to keep things engaged a bit more positively. It’s easier to do this once spring has been removed. Take off the winding bridge and it’s almost there. Remove the centre wheel bridge and take out the escape wheel. Pull off the cannon pinion and remove the centre wheel. The barrel and spring. And the spring is removed. All the parts ready for cleaning. And that's it. Once everything is cleaned and ready, reassembly is just the reverse procedure. I will be quite happy to post the pictures of it going back together if you wish. Either way I hope it has been of help and that I have made things easy to understand. It’s difficult to know exactly how much detail to include or omit. If anything is unclear or just plain wrong please let me know and I will try to explain things or make some edits to the post.4 points

-

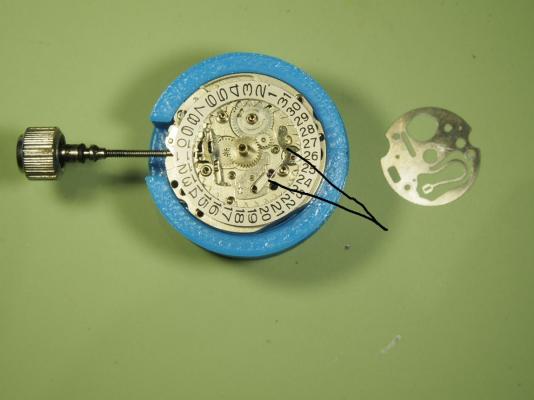

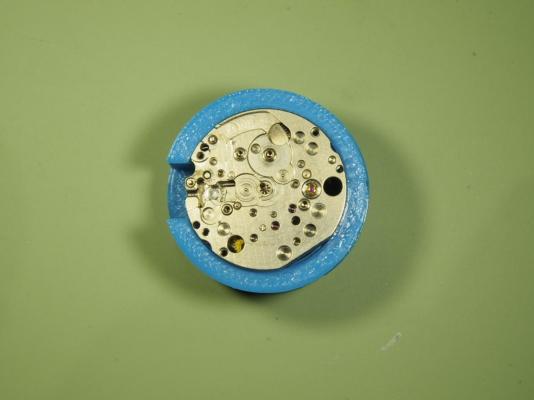

I have done a few of these 4205's now and although I am by no means an expert, I have learned a few things about them that might be helpful should anyone fancy having a go. This is my first walk through and guide, some of the photos are not as good as I would have liked. I have bought a mini tripod which has helped a lot but the lighting is not the best, something to look into for the future. I will try and explain things as clearly as I can as we go along, if anything is unclear please just ask. So, here is the little devil. No guesses as to where it came from. It is a bit tatty but they do scrub up well. This one is actually trying to run so hopefully all it will need is a clean and service. Keeping my fingers crossed as you never know what you might find once you begin. Before I start taking it apart I now check that everything works as it should. It’s good practice I know, but the first couple I did I was a bit lax and I had to strip the whole thing down again when “faults” appeared. In particular, make sure that the winding mechanism feels ok, they have a habit of skipping when trying to wind it up, you might feel it wind for a turn or two and then will just turn freely without resistance. Next, make sure the date rolls over around midnight and the quickset works ok. Never had a problem with the quickset yet but sometimes depending on the version of the movement the date change can be problematic. I will make a point of mentioning these problems and what goes wrong as we proceed. This watch is a 4205-0156 and is fitted with the earlier 4205A movement. The 4205B is slightly different. I tell them apart by the fact that the A has two retaining screws in the balance cock whereas the B is single screw. Now, I can’t swear that there might be versions of the A that have single screw balance cocks or vise versa, sometimes things are never that straightforward it seems. The bezel on this one is free so it will come off no problem. I have freed stuck bezels by simply dropping out the movement and dumping the whole case in some releasing oil for a day or so. Then I dry it a bit and lay it bezel side down onto a nice piece of “grippy rubber that I have, lay some weight on it through the heel of your hand and twist it in jerking movements to and fro. The lugs are quite sharp so protect your hand with a glove or something Really stubborn ones can be a pain but you just have to be a bit more brutal in your method. There is a notch in the case to allow you to prise the bezel off. With the bezel off you can remove the bezel insert, shim and o ring. Hard to tell through the scratches but the dial might be ok. Unless the crystal is cracked I would leave it in the case as there is a dial retaining ring that holds the glass in and they can be awkward to refit and do sometimes crack. Try as I might I couldn’t get the picture the right way round for some reason. Depress the little button and remove the stem. There might be screws holding the movement ring but usually they are missing. Looks as if someone has fitted a new dial and hands which is a bonus. One of the dial feet is a screwhead that needs to be turned until it is clear and the other is a small lever that needs to be swung out. You can see it sticking out near the 28 on the date wheel. Take care not to lose the washer that sits behind the dial. Some of the ones I have done , there was no washer. So either someone before me lost it or it was not necessary. All seemed well when there was no washer fitted so I didn’t worry about it. Well worth getting is a holder like this. I had difficulty securing the movement in my holder. I was recommended to use these as made by Halo8. He is on the bay and made one specially to fit the 4205 when I asked him about it. I bought a few more of the most popular sizes while I was at it and they are great.2 points

-

It was a busy weekend , but I managed to give the Seikomatic a Spa treatment . I also installed a watch-strap I had that was too tight so I put a spring-loaded extension link on it . When I took off the case back it had 3 service markings in the inside that were ink stamps . I tried to preserve them but the acetone got to them , probably from my fingers , and they washed off...[darn ]. In saying that I am saying that I haven't done my own service yet , but the movement is running great and keeping good time . I serviced and cleaned another Seiko 5 Sportmatic with a crosshair black dial and got my first non-running Accutron running by taking out the teeney tiny bent index and pawl fingers , straightening them out [similar to a hairspring , only smaller ] , reinstalling and aligning the fingers , putting a new battery in and pushing in the crown to cancel the hack , and did a couple of back-flips when the thing started running . Oh what a feeling .....oh yeah , I also put a new movement in my Seiko Flightmaster chronograph. But back to the 39 jewel Sportsmatic ,...I took a few pics to share .2 points

-

Movements of the fifties and sixties are in the 10, 11 12 lines ranges. For example a typical Bulova caliber of the 50s is the 10BPAC which is a 10.5 line;1 point

-

If there is rust (iron oxide) on the case it's not gunmetal. Gunmetal is a form of bronze/brass/copper (a number of variations) so it will not display normal rust symptoms as you have shown. If the case is iron steel, it will take to cleaning and blueing as the same as a rifle barrel. Be sure to remove the movement and strip all case parts apart before cleaning and blueing. Cheers Jim1 point

-

I haven't heard of any... I don't think there is one. I use a pair of tweezers and a pin made from a broken oiler sharpened to 0.2mm like in the video below (thanks again perplxr for the tip :) )... and lots of prayers, sweaty palms and searching the net for movement donors :)) p.s. the video doesn't present a diafix but only the pin ;)1 point

-

Here it is in the holder, it does make a big difference. I like to leave the stem in place to check things as it comes apart. The first thing I take out of harms way is the balance, just one of the lessons I learned the hard way. It is worth checking that the autowind works ok before taking off the rotor, I just spin it around a few times with a cocktail stick and make sure the ratchet wheel is turning. Do take the balance out first, as if you do slip while turning the rotor you can bet the first thing that get’s it is the balance. So better safe than sorry. In order to let the mainspring down you need to remove the three small screws that secure the rotor bearing assembly, keep an eye on the pawl lever as you lift things away as they can spring off. The pawl lever grips the transmission wheel and you can’t let the spring down until it is removed. The screw that hold the transmission wheel is left hand thread. The mainspring can now be let down. I gently ease the ratchet wheel back slightly with my finger and then carefully hold the click out with my trusty needle and slowly allow the spring to unwind. I am pointing out the date wheel finger. If you find that the date will not change as you wind the hands through past midnight this finger can be the culprit. If you see the date wheel trying to move but not quite making it, you might find that this is worn. The little finger on the right wears and is then not quite long enough to flick the date ring around. It’s a poor idea if you ask me, there is not much of it to start with. What I decided to do was just to try and nip the end with a pair of strongish tweezers and tease a bit more length out of the plastic. It did work, but obviously it will fail again sometime. But unless you have the luxury of a spare movement there is little else you can do. Remove the screws that hold the date wheel retaining plate and carefully lift it off. Have a good look where it sits and where the locating points are. With that out of the way I have highlighted two potential flyers, the tiny date jumper and spring. Be ever so careful as you remove the date ring so as not to disturb them. I am pointing out the intermediate date wheel and pinion here. I have found that the 4205A has a metal one which is good, the B has a plastic one which is not so good. The teeth are very very tiny on the plastic ones and I have come across some that have been crushed. This is another reason for your datewheel not turning. This has nothing to do with the quickset by the way. Now, maybe I have just got the patience of a saint or something, but I have rescued a couple of these poor crushed wheels by carefully opening up each and every tooth with the tip of a scalpel. It’s not a lot of fun as you can imagine but again, if you don’t have a replacement what are you going to do. I did once bite the bullet and ordered another similar movement from Ramon, but guess what? Yep, that one was exactly the same! Deary me, said I on discovering that. Here is the metalwheel removed. The minute wheel, hour wheel and date indicator driving wheel are and date corrector finger have been removed. Notice the small plate still attached just below the cannon pinion, there is nothing holding it on other than being a tight fit on the locating pins. Never had one drop off but I prise it off anyway just in case. Next is the setting lever, spring and yoke and the dial side is stripped.1 point

-

1 point

-

My first thought was the centre second friction spring, it's well distorted and looks like it is resting on the pinion and not the end of the pivot.1 point

-

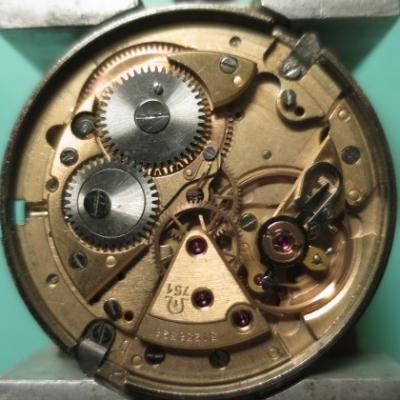

I'll give it a shot. But since I am such an amateur watch repair hobbyist, this case might be a no-brainer for many of you who are already experts. Early last year, I received a non-working 1969 Omega Constellation featuring the venerable Omega 751 movement. After replacing many parts, I was able to restore the watch. The problem was, the watch will run for several hours and keep good time but once it stops, with the second hand between the 35 to 40 second mark, it will stop intermittently after that. The second hand will stop at the same spot everytime - around the 35 to 40 second mark. Shaking the watch, moving the stem, adjusting the time will restart the watch. There was no problem with the way the hands were installed. At first, i thought it was due to a fiber (we have a yorkie running freely inside the house) on the escape wheel, but, even after striping and cleaning the movement, the watch will still stop the same way]. When it runs, the second hand moves smoothly. When the second hand stops, everything in the watch stops. Here's a picture of the movement *before* I found out (or rather, I fixed by trial-and-error) the problem. Note that the auto-wind mechanism was removed in this picture.1 point