Leaderboard

Popular Content

Showing content with the highest reputation on 11/17/15 in all areas

-

Hi - allow me to introduce myself. I live in Germany (but am a US expat) and, living on the border with Switzerland (and actually working in Basel) I have spent a lot of time over the last 25 years looking in shop windows while my wife looks for shoes. When I moved here, I was wearing a Timex Ironman. Eventually I saw an IWC Portofino and fell in love with it. Unfortunately it was way out of my price class. However, I started paying more attention to watches. Shortly afterwards, Nomos came out with the first Tangente, and I fell in love with that. Still out of my range. I muddled through the years with various watches, including a fairly nice Cito (minor German brand) with an ETA 2892 that I stupidly left in a restroom in Switzerland and never saw again. Four years ago I finally bought my Tangente and thought I was set. But I also started acquiring other watches, especially Gruens (I grew up near Cincinnati). I have a handful of watches from the 50s/60s. And this year I was fortunate enough to buy an IWC Portuguese Chrono, which is pretty much the only chrono I would consider wearing and for my taste is about as close to a perfect watch as there is. It is most likely the only watch in this class I will ever own. But I still have a fondness for these 'other' watches, including a 50s Lacorda I bought a few months ago. Lacorda is a French manufacturer. This one is in nearly perfect condition, I was the only person interested in it, and there was something about the dial I liked. Unfortunately it runs very fast. Which brought me to Mark's video on regulating a watch (easy enough, as it turns out, and I have some basic watchmaking tools), which in turn brought me to this forum, which looks very interesting. So there you go, and there I am, thank you for your kindness, and here's a picture of the little Lacorda. I'll know tomorrow how it's running, but I assume it will take a week or two to really get it right. Steven2 points

-

2 points

-

Welcome to the club Steven!,,,err, I mean to the forum. :) Us gatherers of watches have a well defined personality....we gather! In any case, I hope you enjoy our forum and the good people we share it with. Also, that we can contribute to get that beautiful Lacorda -- as well as others -- on time and to your liking. It IS a very nice watch! I'm particularly partial for sub seconds and simple, easy to read dials. My recommendation, if you are set on learning about watchmaking, is to not only acquire good quality tools, but also to chose a "sacrifice" watch -- not from your collection if at all possible -- in good working condition and tinker with it (preferably Swiss and also a Japanese one as they are very common). Wait, that's TWO sacrifice watches! The goal is to provide a full service and finish in a same or better than when you started. The catch: your work should not be detected...as if nobody had touched the watch, i.e. no scratches, dents, kinks, etc. not even when opening or closing the case. Special attention to fingerprints, use gloves, etc. Once you reach that level, you are almost ready for your own collection! We have plenty of advise and shared experience around so you can draw it in to your advantage and we are always "on your computer". Cheers, Bob1 point

-

I purchased the Chinese crap, but the quality was quite frankly, crap, and not worthy of using on any watch, no matter what value of the watch being worked on. These Horotec models are perfectly suitable, I have all of these, its nice to have a choice which you can choose depending on the watch you are working with..1 point

-

I can't understand you tightwads. Why spend £7.00 when you could get a perfectly good Bergeon one for only £695.00 :wacko:1 point

-

Thanks again guys , using the holding the reset button technique and the jewelling tool as a hand fitting tool it is now sorted , I don't suppose this is text book horology but it's worked lol I will get one of the tools Clockboy recommends but the UK supplied ones are around £20 to the Asian ones £8 and i wanted to get this done as it is for a friend and the ones from Asia seem to take around 3 weeks to turn up , but now it's done there is no hurry and i'll order one from Asia thanks again Andy1 point

-

1 point

-

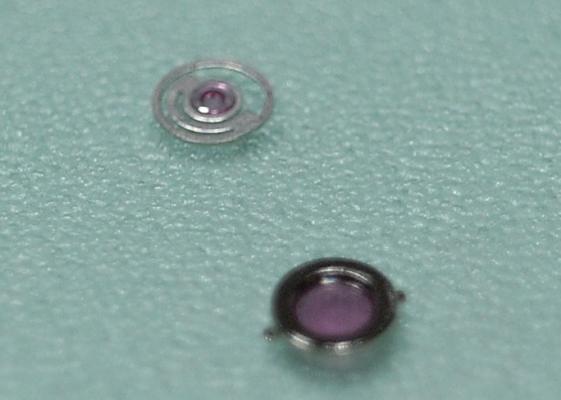

I use the same method as Geo also, but instead of using the Chinese tool Clockboy uses, I use the Horotec model. When fitting hands with Chronograph ETA movements, I use either of these.. Untitled by Micky Aldridge, on Flickr Untitled by Micky Aldridge, on Flickr Untitled by Micky Aldridge, on Flickr Only recently received the last movement holder, and its in poor shape, so will refurbish it.1 point

-

BTW, I just serviced a Skagen 755XLSLB automatic watch that has Miyota 8215 movement, so once again I found the walkthrough very useful (and this time for the proper reasons ;) )1 point

-

If it is a mechanical movement, run the chronograph, press stop, then press and hold the reset. While still holding the reset button, align and fit the centre second hand. It has to be pressed on very firmly to prevent it rotating on the shaft by the violent action when used. Holding down the reset button ensures that the hammers are held tightly against the hearts while fitting the hand. This is why there are special movement holders with buttons and lower jewel supports, to allow this to be done accurately and safely. Too much pressure when fitting the hand can move the lower jewel, and too little and the hand will move out of register when the button is pressed to reset the chronograph.1 point

-

My thoughts exactly! I would inspect every gear for teeth wear also while servicing. Another thing that comes to mind is the hands may be touching at certain places...for any reason (remember Geo's suggestion about bent pivots). Cheers, Bob1 point

-

Its been on the back burner for a while but now finished: ..oops, that was the before pic I forgot about (Nurse get my pills). Here's how we're looking now: I managed to fashion a bow from 3mm sterling silver wire supplied by Cooksongold.com, very good suppliers of findings, bullion, gemstones etc. Big thanks to: Clockboy - for the hand, although I used a fettled chrono one in the end. Please PM your address & I will return it. Edmund - for the lead on the crystal- perfect. Geo - for the bleach tip. Its worked really well. The hole was filled with Bergeon 1590 white wax. .............couldn't have done it without your help. Cheers!1 point

-

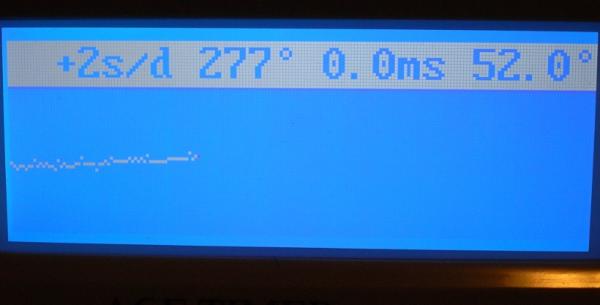

Assembly The rust that was on the Centre Wheel and Pinion cleaned up real nice, So the first step was putting all the Gear Train, Mainspring, Winding Gears, and the Automatic Work onto the Main Plate, and then locate all those pivots once the Bridge was placed on top ... this movement is a good test of your patience and skill :) As it's not possible to wind up the Mainspring for testing the Pallet Fork, I decided to install the Keyless Work so I could wind it up While I was on this side I also removed the shock system and oiled it. It's a very interesting system, and extremely easy to clean and re-oil ... perhaps the easiest I've come across. Flipped the movement and installed the Pallet Fork and Balance ... then cleaned and oiled the shock system on the Balance Cock. Started ticking straight away with very nice amplitude. Next was the rest of the Motion Work and Calendar Work Date Ring and Cover Plate back in place Lastly the Dial and Hands replaced. Again this movement used H3 tubes on the Dial and Hands, so very little clearance when fitting the hands. Back on the Timegrapher ... and she's purring like a kitten :) I thank the Lord Jesus Christ for the wonderful gift he has given me, I really enjoy this work, and every movement is an adventure. I hope you've enjoyed it as well, and it helps those who come across this movement to service or repair.1 point