Leaderboard

Popular Content

Showing content with the highest reputation on 05/21/15 in all areas

-

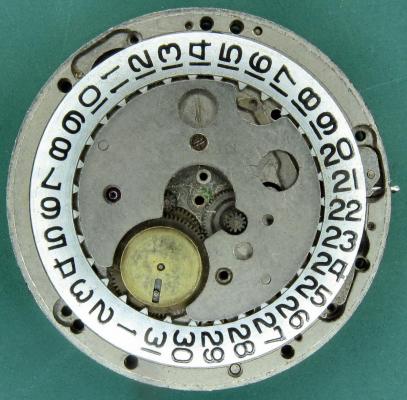

Hi everyone, Thought I would share a recent ebay purchase with you all. I've been after a Cyma for the collection for a while mainly because all I have read on various forums say they are typically under valued good quality watches. So whilst busy at work on a night shift I had a quick look on Ebay to see what was on offer and was drawn to a listing for a 9ct gold cased Cyma Watersport. The listing description was as follows, A very rare original 1950s cyma swiss watersport, has subsidiary dial sold as spares or repairs works but winder has seized as has been unused for some time,9 karat gold,classic Gentlemans timepiece,will make a very nice watch ,strap in good condition. SOLD AS SPARES REPAIRS Looking at the pictures the dial looked to be pristine and in far better condition than most watches of this period, the case looked very clean and tidy too. The watch was on at £100.00 buy it now, so far so good I thought the only worry in the description was the seized winder, waying it up I thought okay buy it if it turns out to be a dud I will recoup most of the money on the gold content of the case. So I went ahead and took a chance. So this is what arrived yesterday in the post The watch on first inspection is in excellent condition, out of the package it was ticking away nicely, first thing to check the winder, which to my surprise functioned as it should it wound freely and clicked outwards and set the hands as it should, I am though pretty certain the crown is not the original, but it does look good on the watch, how the seller had come to the conclusion it was seized I don't know. The case itself is of very high quality with a srcrew in caseback free from marks or scratches the watch has the appearance of having a separate bezel but is in fact a two piece case. I then decided to have a look at the movement, at this stage I suspected from the overall condition of the case and dial it would be in a good state of repair,but on removing the case back another surprise was waiting to be discovered, The listing had stated the watch case as being 9ct gold and on one of the lugs of the watch there is a hallmark which is too small to see clearly with a loupe, so the seller must have just assumed it to be 9ct. So the swiss 14ct hallmarks where a pleasant surprise the hallmarks also indicate that the watch case was manufactured by C.R.Spillman a quite notable case maker who manufacture the early oyster cases for Rolex, this explained the overall quality of the case.T The watch head without strap weighs 29 grams so I would guess that half that weight will be gold content. The movement was protected by a gilt metal dust cover and just as I thought is in a excellent state of repair, I think its a cal 414 KA but I could be wrong as the calibre numbers are obscured by the balance wheel. It is in very good condition with a scratch where someone as removed the dust cover a little carelessly in the past , I would also add I think this dates the watch to the mid 40's. Over the last 24hr it has lost about 15mins so a service is in order, so I will send it off to my usual watchmaker for a service, I don't know enough yet to have ago myself and its too nice a watch to get my clumsy hand on. So overall this item was not as described but all in a good way, I also received another surprise in the package the seller also sent me another watch as a freebie, he had sold it a few weeks ago and the buyer had failed to pay for it and he didn't want to list it again. Its a Ebel with a eta 2824 auto movement, it is something I don't want so I will offer it as a project ( It has a Broken stem ) on the parts page for the cost of postage later today. Wayne3 points

-

2 points

-

Balance staff replacement. Take 2. :) Wile I am waiting on my order that includes the balance staff for the Elgin I decided to move on to a Hamilton 16s that is waiting on a balance staff replacement. Cut the old staff out and riveted in the new one. Process went just as smooth as it did on the Elgin. Stripped the movement down and gave it a good cleaning. Reassemble and lube and then it was time for the moment of truth. Installed the balance assembly and was very pleased that it swung with no clearance problem. Gave the watch a couple of winds and there she went ticking away! So I guess I will have to call this one my first balance staff replacement. At least fully successful. Bought this one pretty cheap. These watches with broken staffs are very available at great prices. I am so glad staff replacement is now a repair I can do. Thanks everyone for all the knowledge and advice I have picked up from you guys. Here is the watch. Hamilton Watch Co 16s. 17 Jewels Grade 974. Stem wind, lever set. Made in 1927 Runs sooooooo strong and held within 15 seconds the first 12 hours it's been going!2 points

-

2 points

-

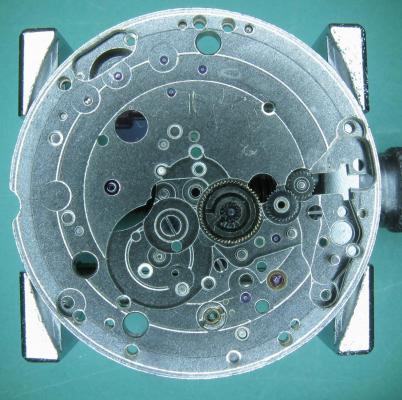

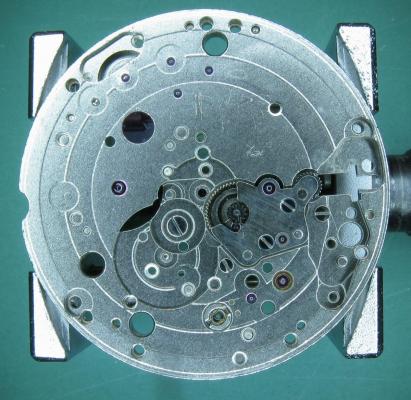

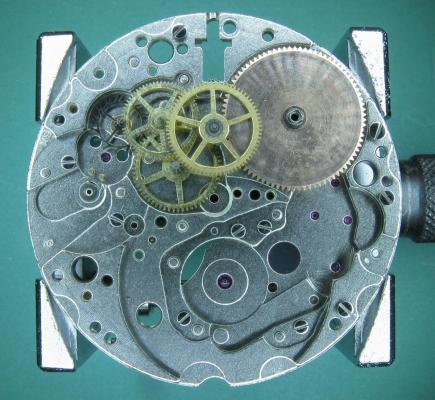

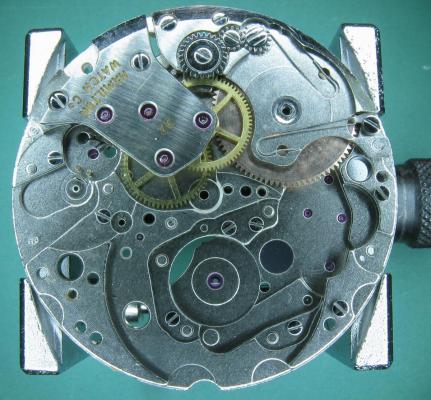

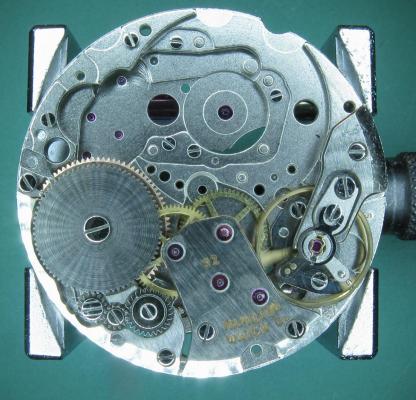

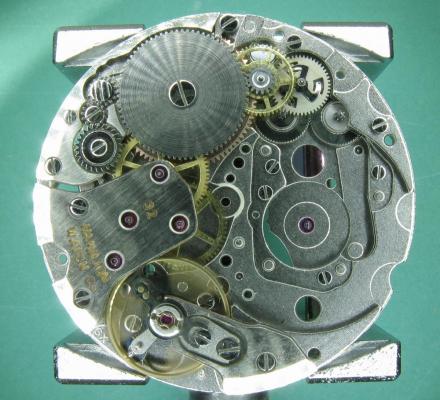

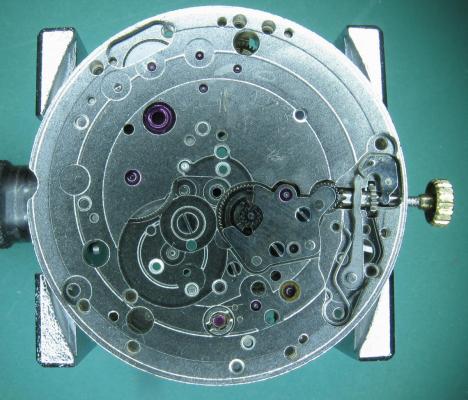

This is what I got up to over the Easter break. It was a project that I bought as a box of bits for a few quid about 4 years ago because although I had no idea what it was (the listing didn't say), it looked interesting and I fancied the challenge. It turned out to be a Hamilton Intra-Matic Westminster which the previous owner had tried to "fix", got as far as dismantling, and given up on. Cosmetically it was in good order but mechanically was not good. The rotor pinion had lost its bottom pivot, as had the second wheel (centre wheel in a more conventional wheel train). And because it had spent some time rattling around loose in the box of bits the hair spring was in a poor state, and what had me really stumped when it came to working out how it all went back together was a large and rather complicated looking wheel and pinion assembly for which I simply couldn't find a home. Any way, it was put to one side until I could track down a donor for the parts and to hopefully show me where the "spare wheel" went. The movement is a 30 jewel Hamilton 92 micro-rotor, which is a re-badged Buren 1281. Unfortunately (for me) this has been used in a number of higher end autos and also as the base movement in some big name modular chronographs because of its thinness, which means that they tend to hold 3 figure values even as spare parts donors so it took a while for me to track down a suitable candidate at the right price. However, I did manage in the end to nab one for just over £30 and it arrived at the beginning of April, so the fun could begin. No strip down on this one as the Hammy came to me fully dismantled, here is the donor as I got it. It's a Buren 1281, a bit grubby with some missing screws, and the minute hand pinion has seized onto the centre post. I later discover that the canon pinion (which is actually on the second wheel pinion) is loose and I reckon that someone had diagnosed the loose canon pinion, had tried to correct it by tightening what they thought was the canon pinion, which was in fact the minute hand pinion, onto the centre post, over did it, and caused the whole thing to seize, hence spare parts movement on eBay!!! I stripped out the second wheel (complete with canon pinion which I tightened), rotor pinion, balance and hair spring, and the main spring (which was in better shape than the Hammy one), and then put the parts through the cleaner; the Hamilton 92 parts had already been cleaned. And here we go with the good bit. The Hamilton 92 main plate; cleaned and ready for reassembly. I usually start with the wheel train when I build a movement back up but that's not possible here because the motion works bridge also carries the lower pivot jewel for the second wheel, so the motion works have to go in first. With the bridge in place you can see the pivot jewel in between the minute wheel and the intermediate wheel. The movement is flipped and the wheel train and barrel (cleaned and greased main spring, and braking grease on the barrel walls) are positioned. Train bridge and barrel bridge installed complete with crown wheel and intermediate winding wheels. At this point the end shake on all of the wheels was checked and the general free running of the whole train tested, then the pivots oiled. The ratchet wheel in place, the pallet fork installed and the escape wheel teeth / pallet jewels lubricated. The balance dropped in and off it goes. Then the auto winding reversers and reduction wheels go in. The three armed spring on the first reduction wheel is a ratchet which prevents the rotor from helicoptering during manual winding. Unfortunately it also gives the crown a very gritty feeling when you hand wind which takes a bit of getting used too but it is normal. Bi-directional flip-flop (for want of a better term) gear and auto wind ratchet in place. Cover plate on and the micro-rotor assembly installed. Turning things over again the keyless works go in. Then the calendar works, date wheel, and cover plate. Before the dial and hands go back on. Confirmation on the Timegrapher that all is well. The obligatory wrist shot. And something more formal for the album :-) This is now an absolute favourite of mine and has a permanent home in my collection. It took a lot of waiting to get the donor but it was well worth it. The watch has been running continuously since 11 April kept wound from wearing it when I get home from work in the evenings and at the weekend, and has remained within a few seconds of reference time. And the "spare wheel"..... was precisely that, it didn't belong with the box of parts that this project started out as. I do hope the seller didn't miss it :-)1 point

-

This is a Tissot i recently serviced . The dial has some rust dots and the hands where really messed up . I had to glue the dial with thee small dabs of epoxy .Because the dial feets where broken . And dial dots didn't work . Going to change or polish the crystal a little more though . The rotary is a nice looking watch . That isn't anything i have seen in Sweden . Going to take a look and see if i find myself a Rotary with date and stainless steel case .1 point

-

Possibly the old varnish. If the print is under the varnish and sound this method should work but great care needs to be taken. I have found many watches to have the print on top of the varnish and tends to come off far to easily. Got this old Smiths Astral in the other week: Although the pic doesn't show it too well the dial was in a right state with varnish lifting, discolouration, water damage to edge etc. Took the plunge & dipped it in HG silver fast shine (Goddards silver dip is the same I believe). Most of the minute markers had lifted with the flaking varnish so the rest were removed. When dry sprayed with acrylic varnish. The result:1 point

-

I have a similar gadget but on a smaller scale that had me puzzled for a while. It came in a job lot of bits and bobs from an old watchmakers estate and I couldn't figure out what it was for. However, in the same job lot I found a copy of the "wide awake catalogue", a supply house catalogue from the mid 1920's (I think). Browsing through it one evening there it was, my mystery tool, and it turned out to be for tightening hair spring collets. It's nice to see your larger scale version in use CB. Incidentally, the "Wide Awake Catalogue" has since come in incredibly handy for identifying old tooling. If anyone has any mystery items that need a little light shed on them just post a picture, I'll see if I can find it.1 point

-

What a good read, I have enjoyed these tales. I do hope the Health and Safety people don't get to read about vaguras incident. They will have us all wearing eye protection. Although I must add, I once had to attend Accident and Emergency with an eye injury caused by............ safety goggles :D1 point

-

1 point

-

Hi Guys, A little story about a gravity clock I repaired recently. A fellow clockmaker from Tiffanies had a gravity clock on his bench for month's. The problem was that it failed intermittently, no particular time or position on the gear bar. While it worked, it had lots of pendulum overswing, until it stopped, my friend bushed everything and asked if I would try to fix it before it found a home in the parking lot. I suspected the gear bar assembly since my friend did beautiful bushing work. In order to test the gear bar, I disabled the click so I could run the movement up and down the bar to see if it would bind up, it did but not always in the same place. I looked in the movement and there were two large round brass guides that slid on the back of the gear bar, they both had developed flat spots where they rubbed on the bar. I rotated the guides about 15 degree's to expose an unused curved area, readjusted clearance as well. Gear Bar and guides must be kept dry. Took a 1/2 hour to repair and now the customer is very happy with it. My friend owes me a beer Al Takatsch1 point