Leaderboard

Popular Content

Showing content with the highest reputation on 03/05/15 in all areas

-

4 points

-

Mark beat me to post it. :) The rest of the picture I posted you can find here. http://www.witschi.com/assets/files/sheets/Witschi%20Training%20Course.pdf Morten2 points

-

2 points

-

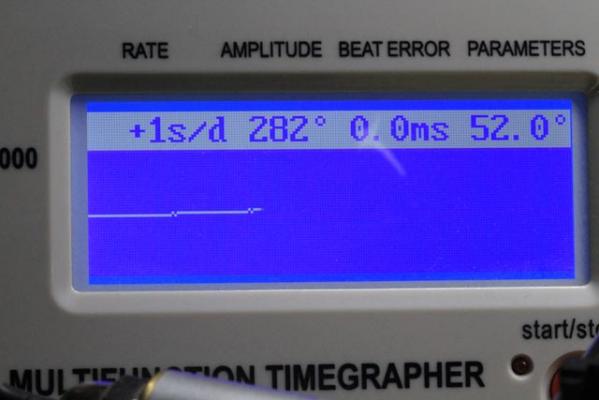

The problem you're seeing is a problem with digital displays for timing machines. So a confusing description you see one line because it's in beat. The digital numeric display indicates that your watche is running one second fast that means the line is going to have to slope upward by a very tiny amount. So the degree of the angle is so tiny the graphical display can't show it so instead it shows it being absolutely flat then a transition where you see the one in zero pixels weird staircase effect sometimes that it shifts up by one pixel to tell you it's going fast. This is one of the irritating characteristics of a digital machine versus the paper tape machine is the difference between one and zero always give that weird pattern of some fashion. The solution for a watch like this is to switch to a timing machine that has a resolution of +-99 Versus your current machine which has a resolution of +-999 seconds. Then much more expensive timing machine such as witschi you can change the magnification on the screen and expand the lines but you still stuck with the pixels you'll never get it absolutely perfect linear display unless you have super tiny pixels.2 points

-

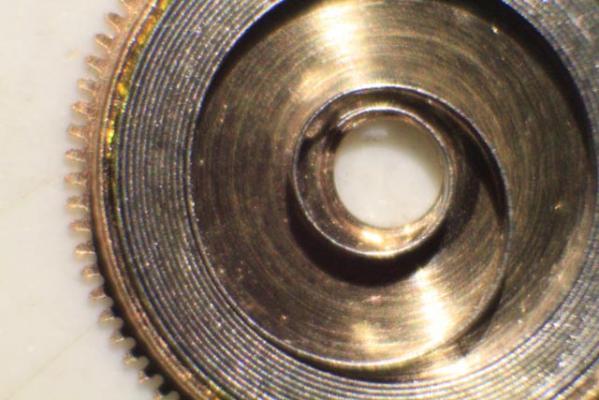

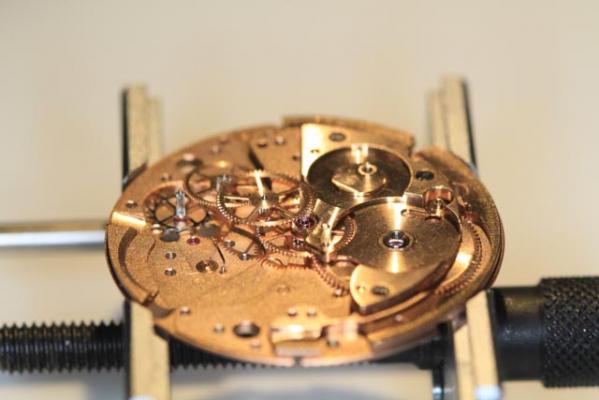

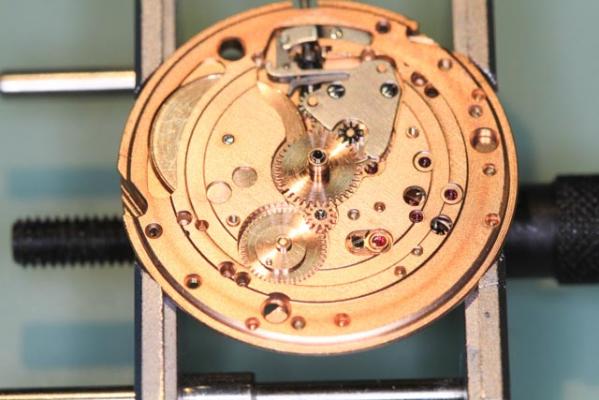

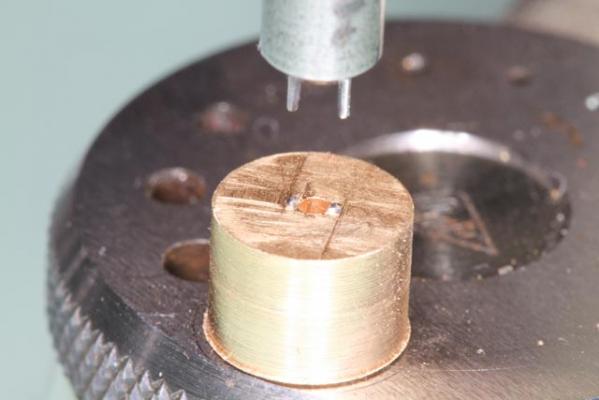

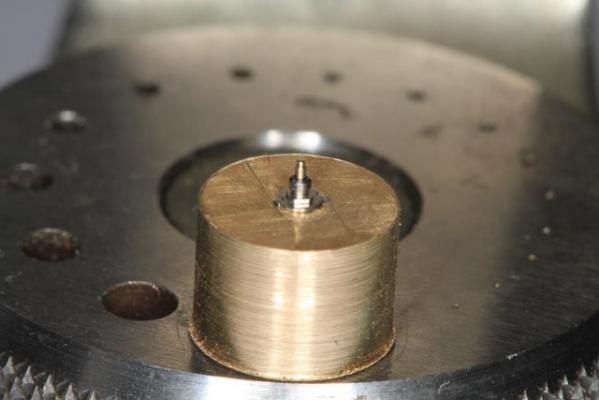

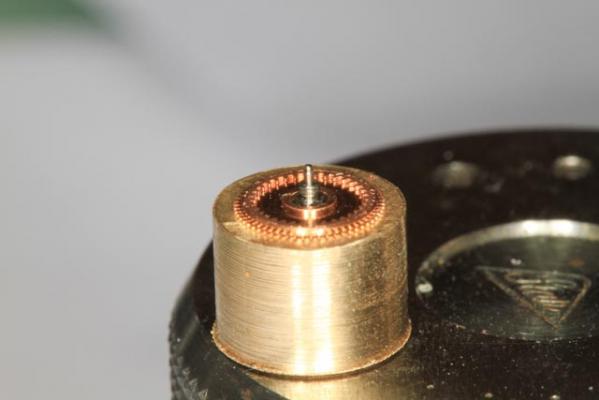

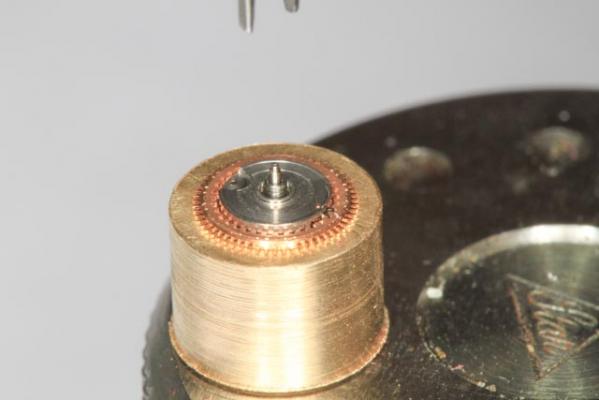

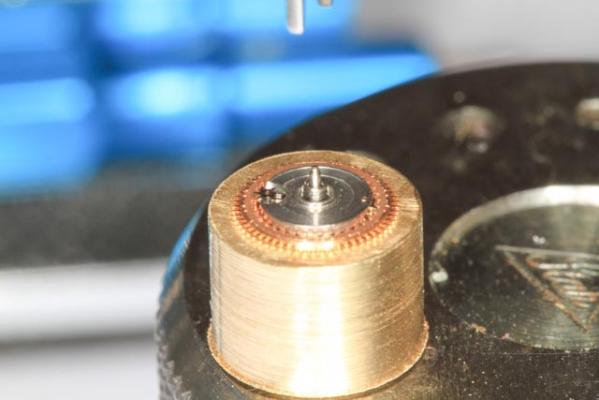

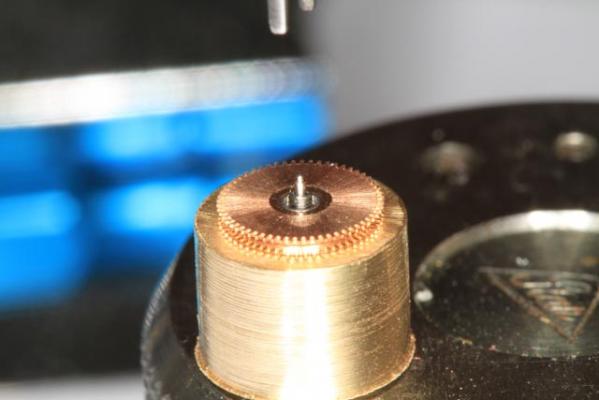

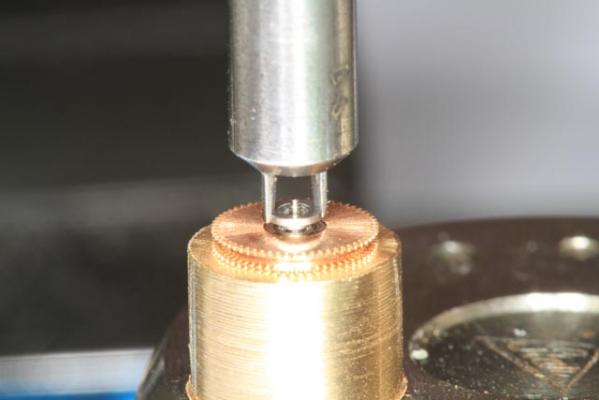

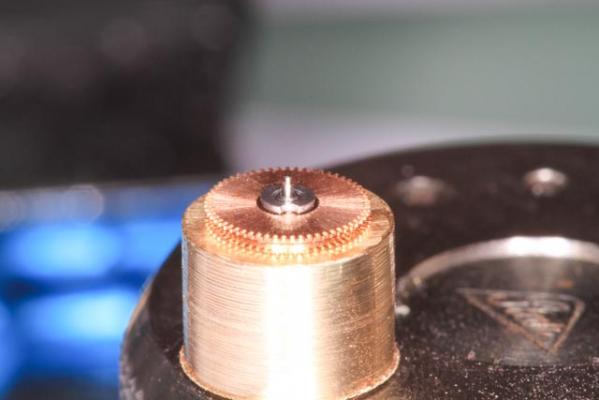

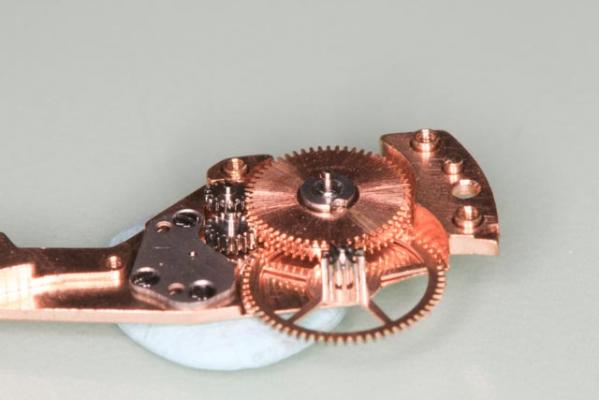

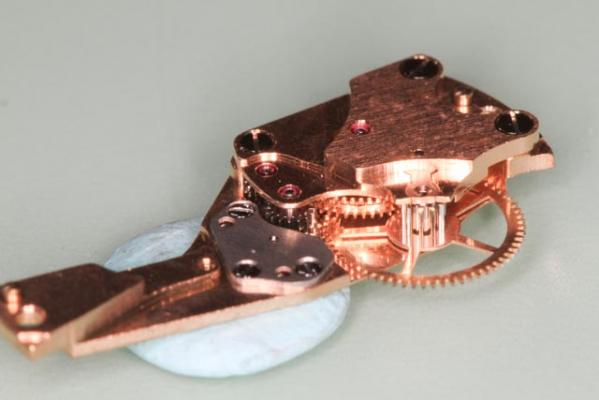

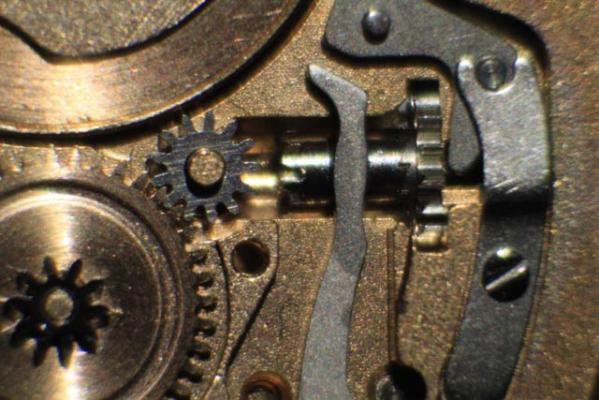

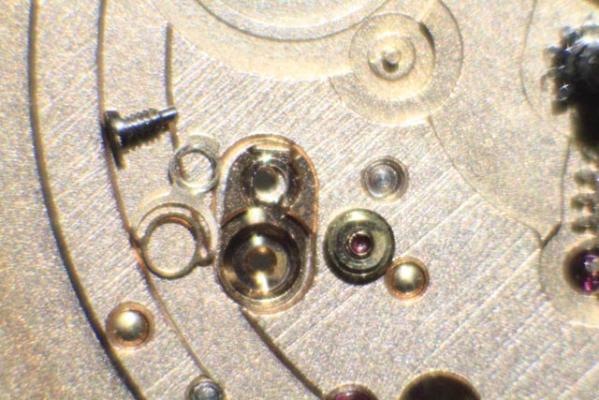

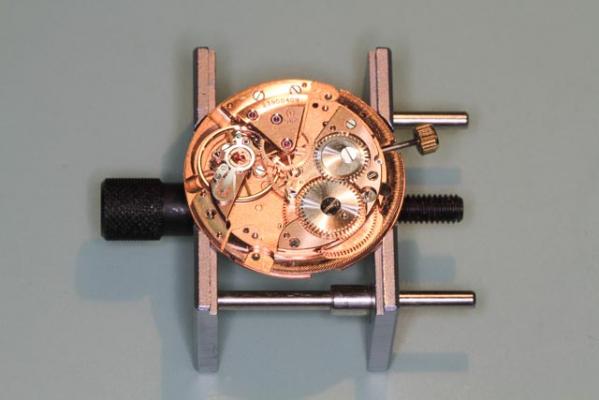

Here's a quick walkthrough of an Omega cal 562 I've just finished. Prior to the photos, I've stripped the movement down and cleaned it, experimentally, in Zippo fluid in an ultrasonic bath, which seems to be extremely effective and quick. I don't have a watch cleaning machine. Comments and criticism most welcome. First, I lubricate the barrel wall with braking grease 8213, and I add a dab of 8200 on the spring itself (not sure if I need to or not) Fit the barrel bridge and centre wheel. Lubricated with HP1300 Adding the train wheels - these are fiddly (i think because the jewels are all olives) Fit the train bridge. Lubricated with 9020 Fit the centre-seconds spring. I lubricated the seconds arbor with a tiny dab of 9020. I left the spring dry (vaguely remember reading that somewhere) Separate the ratchet from the manual winding wheel to lubricate it (HP1300) ...and reassemble Winding gear all back in place. Rodico will clean this up... Pallet fork in place. Strictly no lube! Tiny dots of 9415 on the pallet jewel faces, and worked the escapement round until there was reasonable coverage. Fitting the keyless work. 1300 on the wheel arbors, 9501 grease on the yoke and castle pinion Disassemble the lower incabloc setting. Lubricated with 9100. Train all together And running quite nicely Time to fit the motion work and the date-setting stuff. Completely forgot to take any photos! Now the fun begins. Assembling and disassembling the reversing gear isn't trivial. I made a tool that sits in my staking tool to screw it all back together. Here are the components of the reversing gear ready for reassembly I sit the winding pinion on my homemade tool: Then add the superior winding wheel (tiny dot of 9020 in the hole) Fit the superior satellite pinion to the winding wheel core. A dot of 9020 keeps it in place... ..when you sit it in the winding wheel Then add the inferior satellite pinion (their name for it, not mine) And place the inferior winding wheel over the top Then screw the inferior nut onto the winding pinion using another home-made tool: ...and we're done. Putting it all together on the automatic bridge Lubricated with 9020 And fit the whole lot to the watch. The instructions tell me to dip the rotor gib in a piece of elder pith moistened with oil (9020 again) Finally, fit in to the case. This takes several attempts since every time I attached the case clamps, a new hair or dust spec would magically appear behind the glass. Job done. Hope that was informative.1 point

-

1 point

-

1 point

-

1 point

-

For those of you who have never worked on one of these watches before the Swiss have something helpful. The first link below takes you to a step-by-step guide to how to disassemble and reassemble and adjustments. http://www.eta.ch/swisslab/7750/7750.html On this link all four watches that they have a step-by-step guide is listed. http://www.eta.ch/index.php?id=161&L=2 Then the absolute must have is the service manual. You can find it at this link click on the technical documents. Then rather than do a search if you look at option number one on the right-hand side it says caliber with a downward arrow click that and it will give you the complete list. https://secure.eta.ch/csp/DefaultDesktop.aspx1 point

-

Arrived yesterday and doubt that it will be coming off the wrist any time in the near future...1 point

-

Hi guys, My newly restored skx something or other (7S26-0030) mid size diver from Seiko, "vintage": By the way, if any one know the equivalence between the SKX (or whatever model number) and the 7SXX-XXXX correspondence/equivalence, please post a table. It would be very much appreciated (and useful). Thank you in advance, Cheers, Bob PS. I retrofitted this watch with the new NH36 (or maybe the NH35 from cousinsUK with day disc added, will have to open again to look. Same thing basically) movement so it now hacks and hand winds (The original movement is complete, working and serviced in a little box in case I want to make it the real thing). The aftermarket dial window is not exactly where it should be cut - a little too low, fixed by repositioning dial feet which I preferred not to do/not worth it -- but at US$6 including shipping I'm not complaining! :) New Movement:1 point