Leaderboard

Popular Content

Showing content with the highest reputation on 03/03/15 in all areas

-

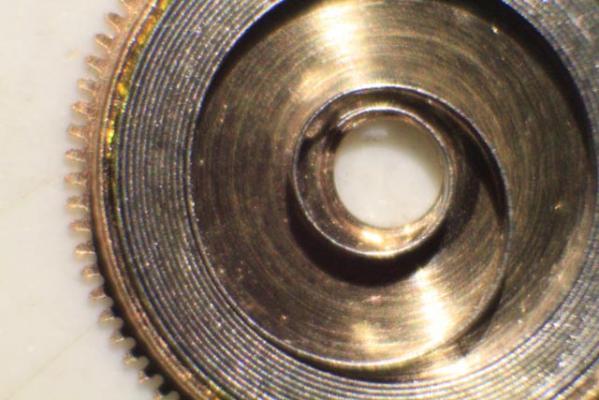

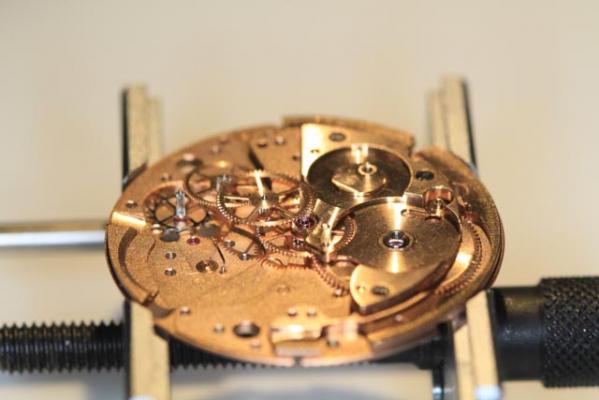

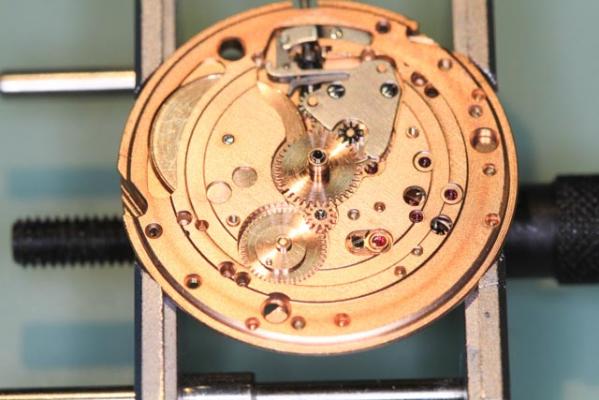

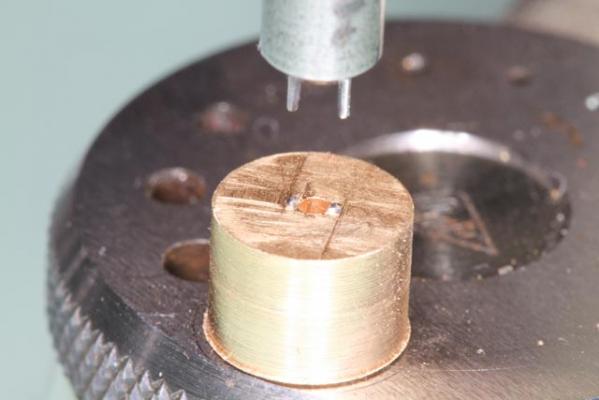

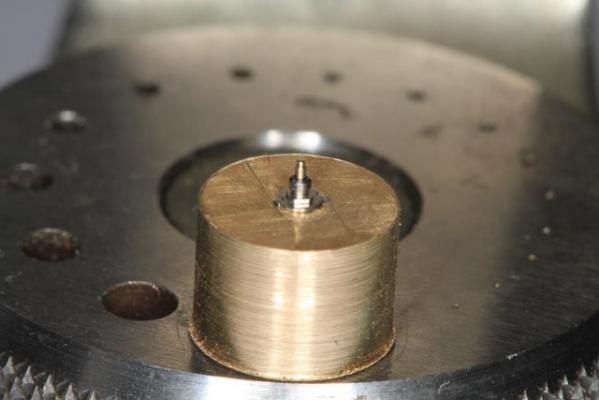

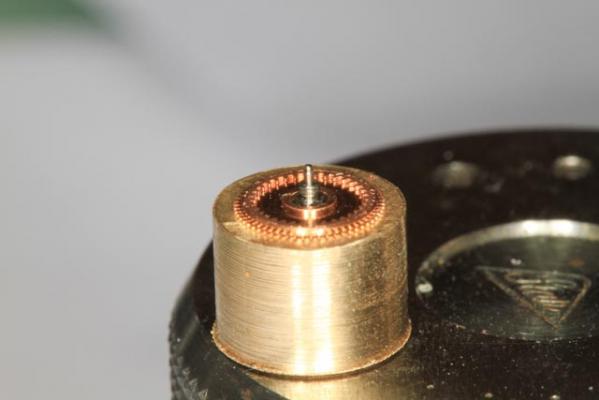

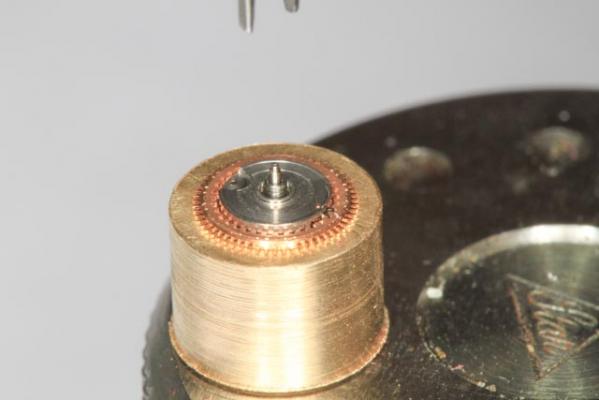

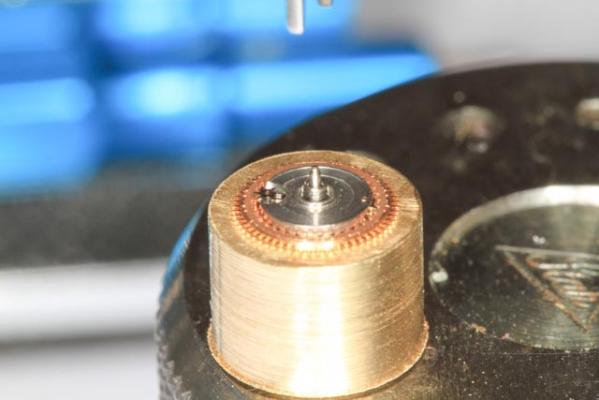

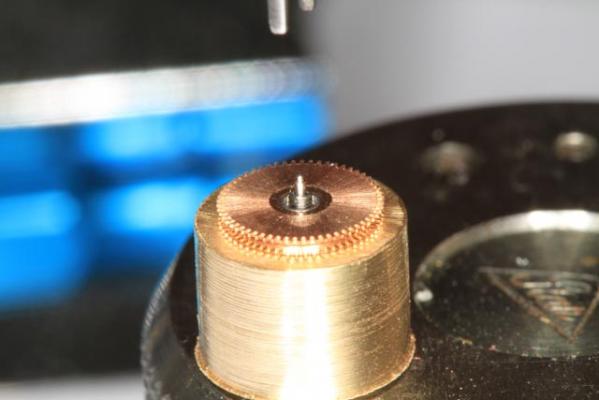

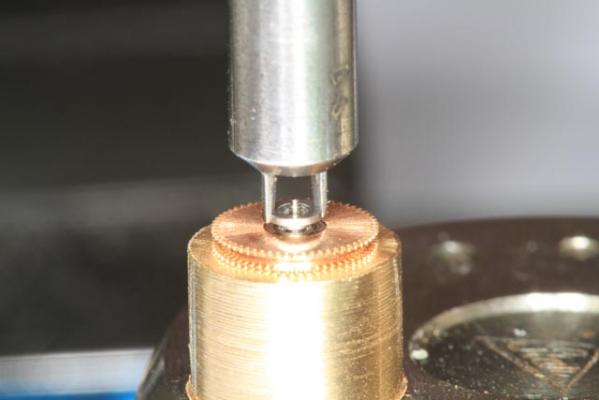

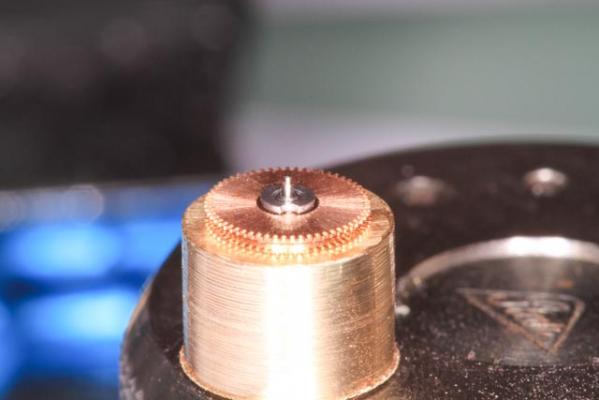

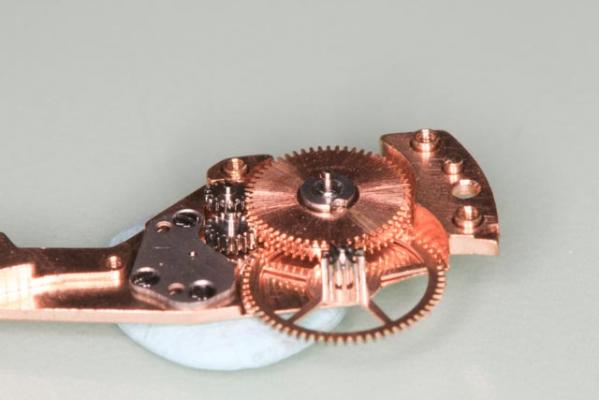

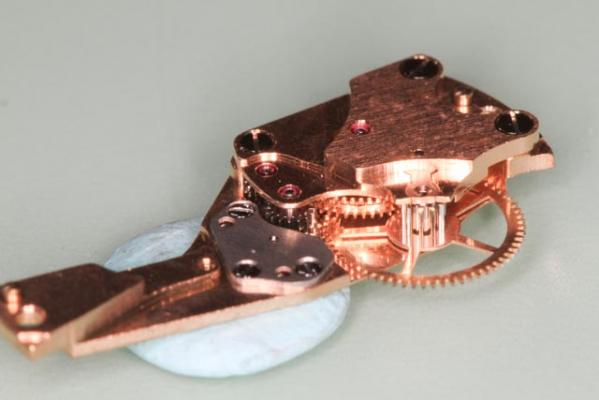

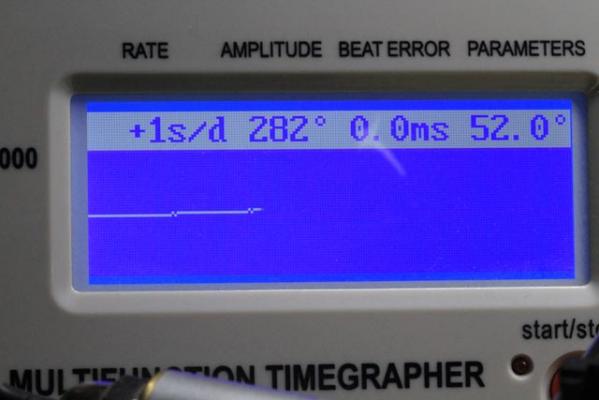

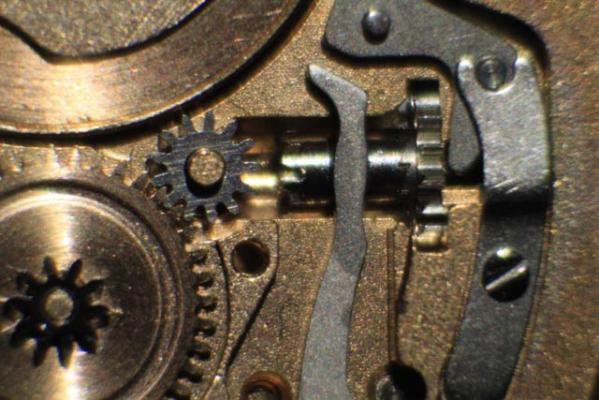

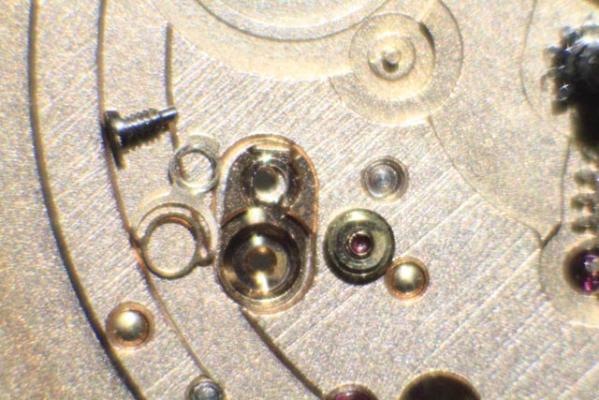

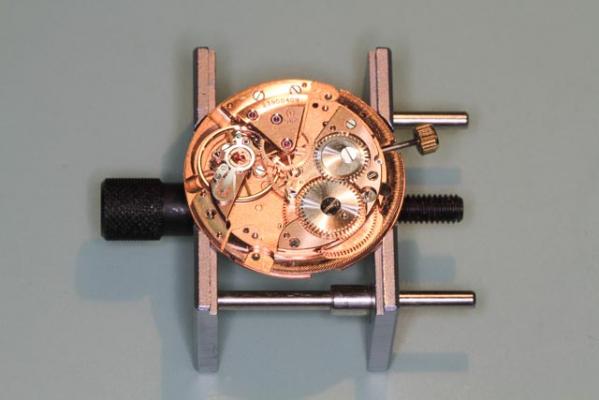

Here's a quick walkthrough of an Omega cal 562 I've just finished. Prior to the photos, I've stripped the movement down and cleaned it, experimentally, in Zippo fluid in an ultrasonic bath, which seems to be extremely effective and quick. I don't have a watch cleaning machine. Comments and criticism most welcome. First, I lubricate the barrel wall with braking grease 8213, and I add a dab of 8200 on the spring itself (not sure if I need to or not) Fit the barrel bridge and centre wheel. Lubricated with HP1300 Adding the train wheels - these are fiddly (i think because the jewels are all olives) Fit the train bridge. Lubricated with 9020 Fit the centre-seconds spring. I lubricated the seconds arbor with a tiny dab of 9020. I left the spring dry (vaguely remember reading that somewhere) Separate the ratchet from the manual winding wheel to lubricate it (HP1300) ...and reassemble Winding gear all back in place. Rodico will clean this up... Pallet fork in place. Strictly no lube! Tiny dots of 9415 on the pallet jewel faces, and worked the escapement round until there was reasonable coverage. Fitting the keyless work. 1300 on the wheel arbors, 9501 grease on the yoke and castle pinion Disassemble the lower incabloc setting. Lubricated with 9100. Train all together And running quite nicely Time to fit the motion work and the date-setting stuff. Completely forgot to take any photos! Now the fun begins. Assembling and disassembling the reversing gear isn't trivial. I made a tool that sits in my staking tool to screw it all back together. Here are the components of the reversing gear ready for reassembly I sit the winding pinion on my homemade tool: Then add the superior winding wheel (tiny dot of 9020 in the hole) Fit the superior satellite pinion to the winding wheel core. A dot of 9020 keeps it in place... ..when you sit it in the winding wheel Then add the inferior satellite pinion (their name for it, not mine) And place the inferior winding wheel over the top Then screw the inferior nut onto the winding pinion using another home-made tool: ...and we're done. Putting it all together on the automatic bridge Lubricated with 9020 And fit the whole lot to the watch. The instructions tell me to dip the rotor gib in a piece of elder pith moistened with oil (9020 again) Finally, fit in to the case. This takes several attempts since every time I attached the case clamps, a new hair or dust spec would magically appear behind the glass. Job done. Hope that was informative.2 points

-

On some split stem watches you do not pull the crowd out you just turn them case over and if the split part is in the right position the movement will fall out. On other split stems if the case and or case tube is to close to the split part there is no room for it to open and pull out so pulling really hard on one of these will usually break the crown off. Your photograph with the stem in the setting position it looks like the split part is too far into the case to slide out. So if you put it back into winding turn the movement over see if the movement will fall out. Then depending upon how tight the split part is holding the movement may not fall out it needs a little help.2 points

-

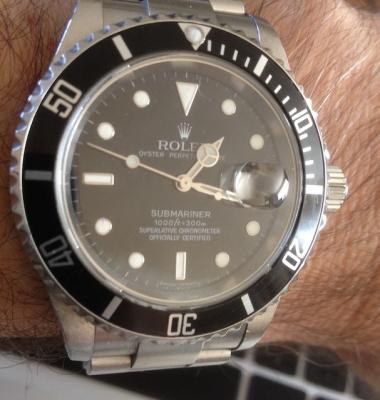

I finally finished servicing my Rolex submariner this weekend and I encountered few issues. I thought it might be useful to share the repair for anyone on the forum who tackles a Rolex 3135. Stripping the watch down & cleaning was textbook really with no issues by following Marks Vid. This is the cleanest watch i have ever cleaned The only obvious dirt was on the oscillator weight axle & the mainspring barrel. MAIN SPRING The first issue i encountered was the mainspring winder that I have been using for a while was not up to the task. The winders correct barrel shaft for the watch barrel was way to fat. I tried to use a smaller barrel with the correct shaft BUT because in effect I was fitting the spring into a barrel that was too small the catch that the spring hooks onto snapped & unbelievably the snapped part got wedged in between the shaft & spring. After fiddling for along time trying to release it, the spring flew hit the workshop door (see pic). I therefore had to fit a generic spring. KIF SHOCK SPRINGS The other issue was I removed & cleaned the balance jewels with no issues. However when I lifted the top KIF retaining clip of the escape wheel it flew and disappeared (found it this morning attached to the underside of the watch clamps adjusting thread!!!). i purchased two replacement clips but I just could not get them to fit & I eventually bent them. However on my next attempt I used a tip from noirrac (Joe) which was to cover the springs & bridge with cling film. This worked a real treat. However as this watch was in a very clean condition I thought I would be prudent & I lubricated the bottom jewel with a Bergeon Auto oiler. STRANGE ISSUE. before the service this watch was running consistently (never off my wrist for the 6 years) + 20secs. a day. So I purchased a microstella tool expecting to make regulation adjustments. However when I put the watch on the timegrapher after the service it showed either 0 or +3sec. depending on its position without any adjustment. The only explanation I can think of it is now fitted with a generic mainspring which is shorter in length. I also get a very brief bit of snow when changing position so I guess there might be a end shake issue with the balance but this is beyond my abilities at present Mark or somebody else might have a possible reason but I have no complaints it was a pleasant surprise. I would have liked to have changed the crown seals but could not find genuine Rolex seals or how to fit. I will do this when i source some. CONCLUSION. I would never have tackled this service if it was someone else's watch.But with Marks excellent vid & the help from this forum I thought it was worth attempting. The Rolex is a top quality movement and in my opinion servicing needs to be only be attempted with good guidance the correct tools. One dead Rolex mainspring Dial UP Dial DOWN Crown DOWN ON MY WRIST JOB DONE1 point

-

Found this site while looking for a setting lever for a FHF 025 that was broken. They seem to stock vintage parts & found what I was looking for at a reasonable price. Also sent with tracking info. http://watchpartsplus.com1 point

-

There you go CB, a real bargain!!! http://www.ebay.co.uk/itm/ROLEX-REF-NO-1080-MAINSPRING-WINDER-TOOL-SET-/221649162732?pt=LH_DefaultDomain_3&hash=item339b51d1ec1 point

-

1 point

-

Mine arrived from Cousins yesterday. It's just amazing. For fun I turned it off and went back to my original lighting. Impossible.1 point

-

@Profundus, you mean you don't have a proper set of Bergeon Prodding Tools in six sizes? Pfff, amateur... My normal cleaning process is 15 mins in Elma ChronoClean 1:20 at 40 degrees in an ultrasonic bath, followed by 2 rinses in Elma Suprol Pro. Apart from the Suprol stuff giving me a cracking headache, the whole process is such a palaver I wanted to see how a simple dunk in Naptha (with ultrasonic) would compare (the answer is 'favourably' - things are less shiny, but functionally clean).1 point

-

1 point

-

Superb! I'm using my mother-in-law for the same purpose (big magnet tied to a leg)...let the witch be useful for once! :D1 point