Leaderboard

Popular Content

Showing content with the highest reputation on 02/05/15 in all areas

-

Here's mine, it's a set of wire cutters that I have drilled and tapped to accept a screw to limit the amount of squeeze that you give the pinion. If you go this route it is easy to make very small adjustments at a time until you get the correct fit. It can be done without using a drill or a mandrel in the pinion if you are very careful, but it is a lot safer to use one. Remember, this is a trial and error fitting exercise to get the best fit.3 points

-

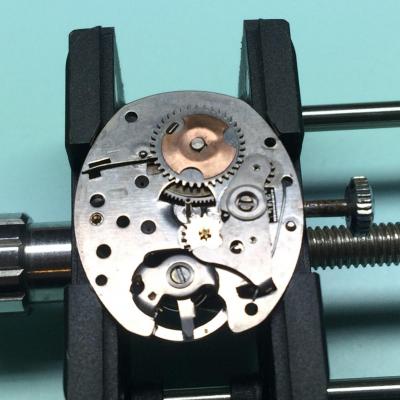

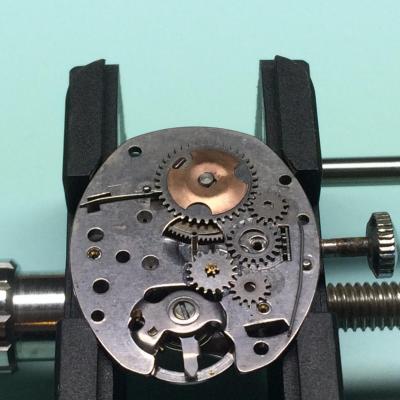

I still have my very first watch, a Scooby Doo watch about 30 years old and it hasn't worked for the last 25 or so it's just been living in various drawers for a long time. I finally plucked up the courage to try and get it going again after my recent successes, after all I couldn't make it any worse anyway! Obviously it's a very basic movement in there, no jewels and the dial has bend tabs on it so I'm pretty sure it was never intended to be serviced. There are no bridges, just one plate holding everything in place, it was pretty tricky to line everything back up. The ratchet wheel was held on by a copper coloured clip and there's a very odd keyless works in there, everything was a bit alien to me! A good clean and he runs again! Finished, very happy. As soon as it started ticking it brought back memories. I remember looking at it in bed with the torch light on a Christmas morning waiting until 5.00am because that's the earliest my brother and I could get up to open our presents!2 points

-

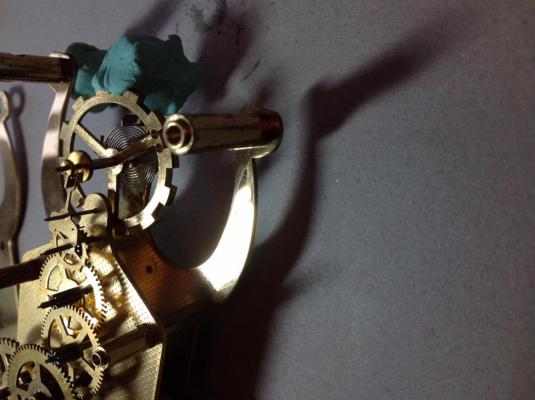

Hello, Well I took off the backplate, Looking at the Anchor it became obvious that both bins were both bent back I bent them in the opposite direction and they are straight now Put it back together with judicious use of rodico to keep them near the right place IMG_1024.MOV Its been running for three hours now but I will leave it overnight - looks hopeful All being well I will put it together at the weekend and post a final pic or two to finish off. Thanks to all for the help. Cheers (Bacardi, Lime and soda with lots of ice) :thumbsu: Vic2 points

-

Hi folks. A member of another watch forum is selling 2 large books of ESA worksheets dating roughly from 1980 to 1990 - some quartz, some electric/electronic and some auto - which I've agreed to buy. He lives in Brighton so I'm going to meet up with him next week and do the deal. I'm proposing to make them available on this forum for download. My first project, when I've received them and checked them, will be to list them and post the list here, prior to any conversion to PDF. Should any member need a particular sheet, I'll be happy to create a PDF of it and upload it here. Eventually it would be good to get each worksheet uploaded, but I can't say when that might be until I've got a better idea of quantity, etc. I hope this will be a useful resource for the forum. Cheers, Will2 points

-

My latest recording - tenor guitar, acoustic guitar and bass... http://youtu.be/GVq9pwUpC9o1 point

-

1 point

-

Noted and filed...in a separate folder so my watches stay sober! :)1 point

-

1 point

-

Provided you don't make the pinion too tight, it should just snap in place with the rest of the movement assembled.1 point

-

That was plucking excellent Will. :)1 point

-

Hi Rogart, I have become abit of an expert on the AS movements after purchasing a Mido with a similar problem, 3 movements later I got it working!. It is the small gear on the end of the Large driving gear that needs to be tightened. Its part number 201/1. The Canon pinion is driven from that along with the date change mechanism. Cousins have the parts list if you search for AS1882.1 point

-

1 point

-

The last time I was there I had a great evening in the Kingston Mines. Blues and booze, what more could you ask for?...................Don't answer that! :)1 point

-

1 point

-

I think he is in Chicago. A long way to go for a beer, but possibly totally worth it!1 point

-

The cannon pinion is needing tightened. There are various tools available for doing this, have a look on EBay you should be able to pick one up cheap.1 point

-

What are you like Dan, any excuse to justify a beer! :). Great that it's fixed though.1 point

-

I really had to do something to my workshop. There just wasn't enough space to store all my tools/parts. This became so frustrating (things were laying on the floor in the end) that I finally pushed myself to tackle the issue. After a visit to Ikea and some time to put everything together, it's ready. You can see the result below :-) Sorry, no 'before' picture available. I'm really happy with the result!1 point

-

http://www.watchrepairtalk.com/index.php?/topic/1211-Seiko-Lift-Angles#entry11754 [emoji12] [emoji9] [emoji16]1 point

-

Remove the main spring from the barrel, give it a good clean and lube.1 point