Leaderboard

Popular Content

Showing content with the highest reputation on 11/14/23 in all areas

-

...after a ham-handed week of peril that left a wake of parts in trays here's a victory- Fontainemelon ATP with some lovely dial patina- the photos do not do it justice. New Spring and crystal is all- this one wasn't harassed much over it's life. T'was stuck up tight with dried lubricants but cleaned up beautifully excepting a bit of finish on the lower barrel. Some fiddling this morning has it back in beat and the hairspring a bit more on the level- runs flat as a pancake up/down and three- amazing. Was deserving of a new strap so I ordered one of the military reproductions, though if you like old leather with cheese I kept the old one, likely the first and only other for this watch... ....hopefully this doesn't start an ATP kick. I'll try to temper meself...4 points

-

3 points

-

That's how it looks to me too, but still a nice looking watch, hopefully the gasket is a recent thing (maybe took the case back off for sale pictures??) and there is no rust. The brush finish on the case looks fresh too, but the lines are still sharp, so whoever did it they did a good job, hopefully this bodes well for the condition of the inside if the watch too. Great find, more than a little jealous!2 points

-

Hi all, just thought it had been a while since I posted any projects. I've actually been quite busy preparing for a local market where I plan to sell some watches for the first time. Here is one of the watches I worked on, a Seiko 7S26, it actually needed quite a lot replaced on the automatic works, but I got there in the end. Before front and back And the finished watch: Here is another Seiko I worked on, this time a 7S36 from my friendly supplier in the Philippines, this one with a sport style case. And the after shot, I ditched the bracelet that came with it to use on a future project, it was a Seiko bracelet but wasn't original to the watch. Thoughts, comments and suggestions greatly appreciated.2 points

-

2 points

-

Yes, this is what I was saying, just differently. If he's seeing 270 degrees of rotation from stop to stop, that's 135 degrees of amplitude, which matches what he's seeing on the timegrapher. The video he posted bears that out as well. Edit for clarity: because the rest position should be halfway between the extremes.2 points

-

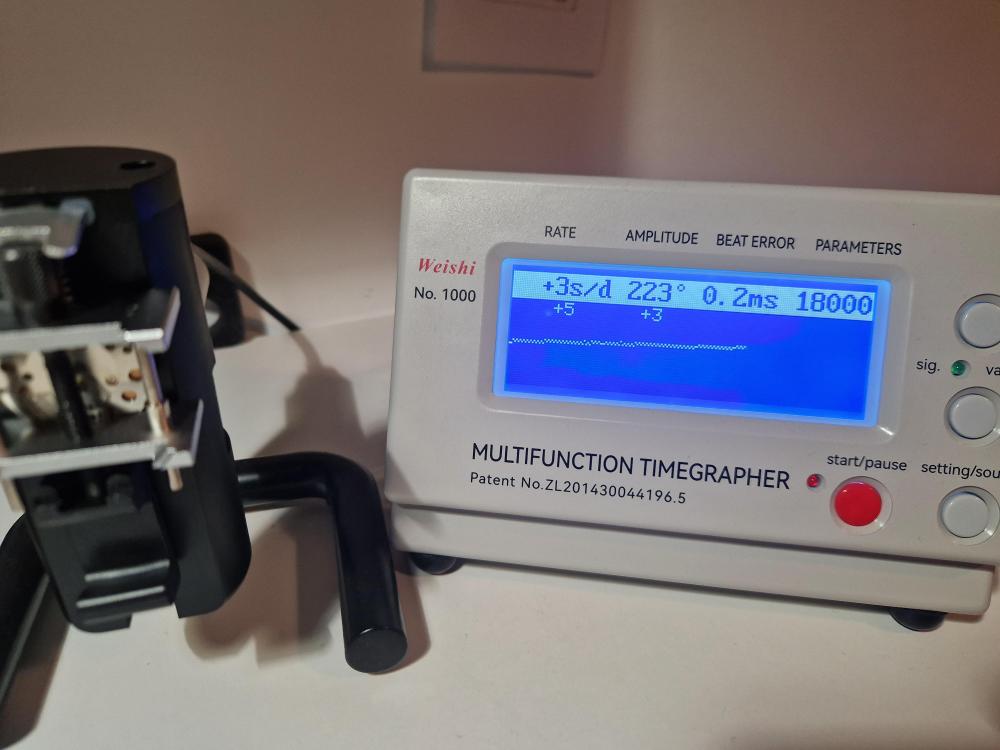

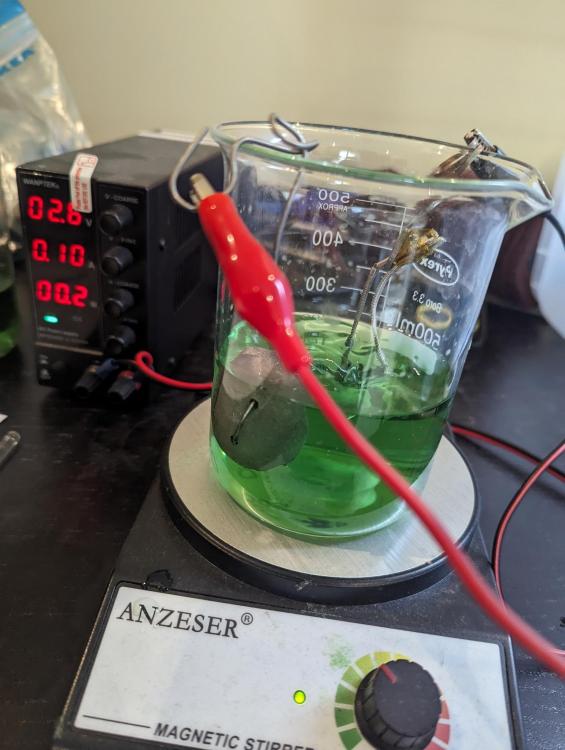

So.. good news!! New ratchet wheel arrived and everything works just fine. While it now definitively confirms where the problem was, we will probably never know how the ratchet wheel ended up with such a bizarre off-center hole. I'm also very happy that the hole-closing on the bridge and barrel arbor holes seemed to have worked well. Sure, I'll only know in a few years if the repair was long-lasting, but at least for now it doesn't seem to cause any increase in friction - quite the opposite: Amplitude is very high with nice, stable traces. Here a picture at full wind and dial up: And before you say anything, dear @JohnR725, here are pictures after 24h in dial up and vertical crown down positions: Dial up at 24h: Crown down at 24h:1 point

-

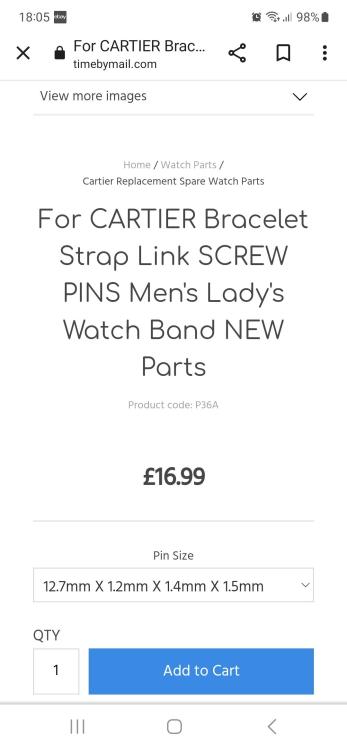

I know I may be stating the obvious, but you do know that both screws are a left-handed thread? Also, alum is a bit crap, unless you have lots of time on your hands. the best thing to use if you do need to dissolve screws in Bergeon Visson which takes less than ten minutes when whatever you need dissolving is put in a crucible and heated with a spirit lamp. make sure there is nothing like a minute wheel post in the crucible which is usually made of steel. Also Incbloc setting will dissolve, so be very wary what you are doing https://www.hswalsh.com/product/screw-loosening-extractor-fluid-vissin-bergeon-4503-0050-hv401 point

-

No, You can use alum only if the screw is in brass plate. All the steel parts have to be removed from the plate, othervise they will dissolve too. Arbour will be damaged for sure.1 point

-

1 point

-

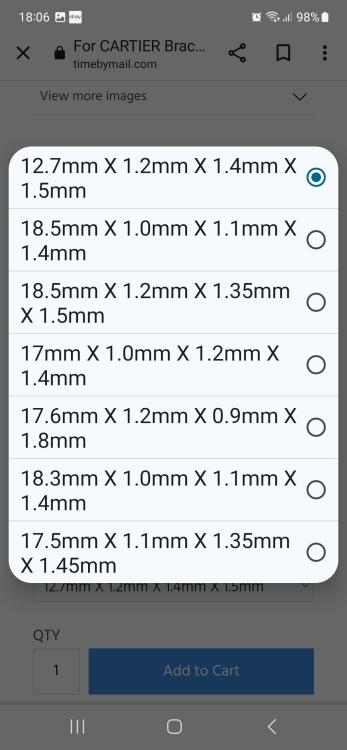

This is pretty close. It is a little longer than ideal, which will reduce the power reserve and it is a little narrower, which is within acceptable parameters 1.20 x .12 x 325 x 9.5 (Tissot 2481) Automatic Cousins Ref number 24817711 point

-

1 point

-

Thanks! Always a nice to buy new tools I might as well buy a new mainspring then, if they don't have the correct dimensions on cousinsuk, where else can I find one (except ebay) (1.25x9.5x0.12x270mm according to Ranfft Watches)1 point

-

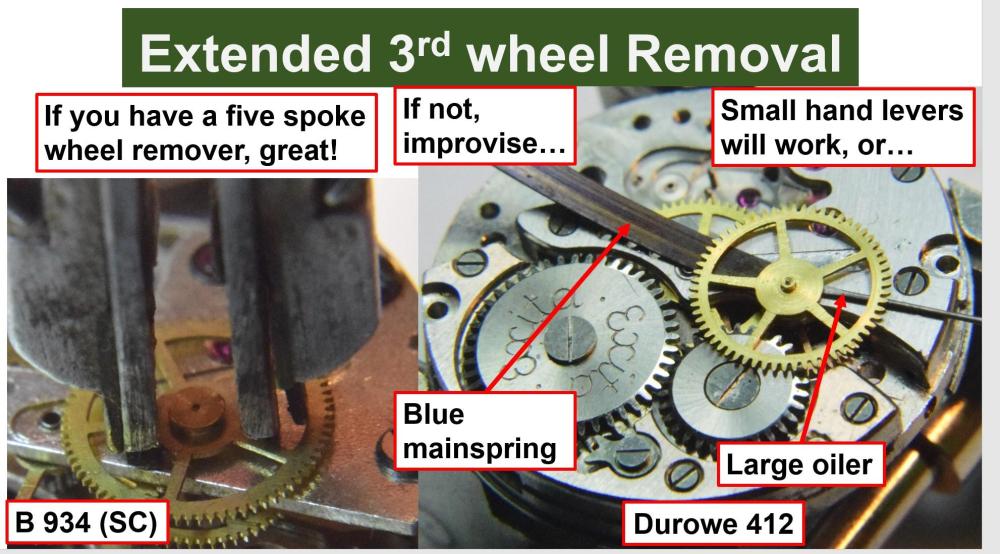

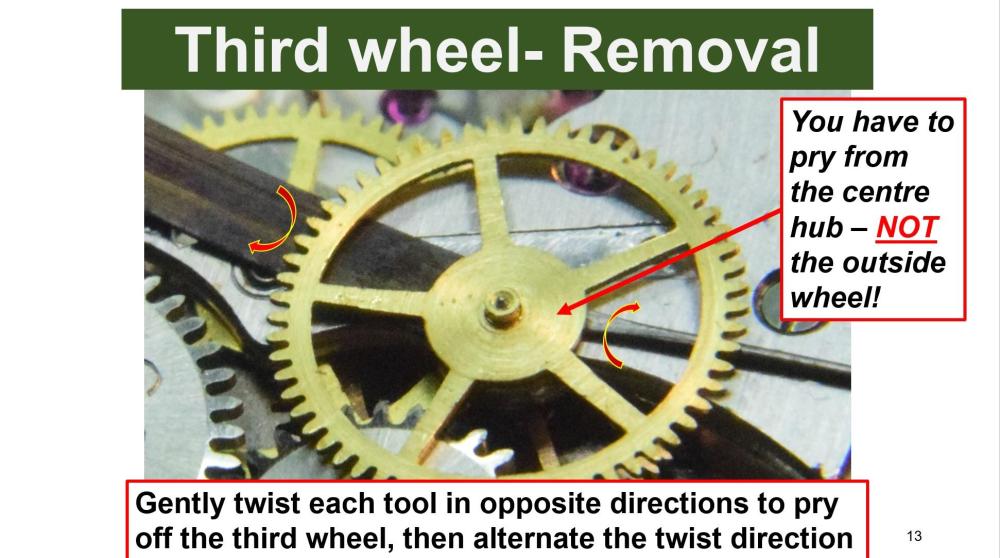

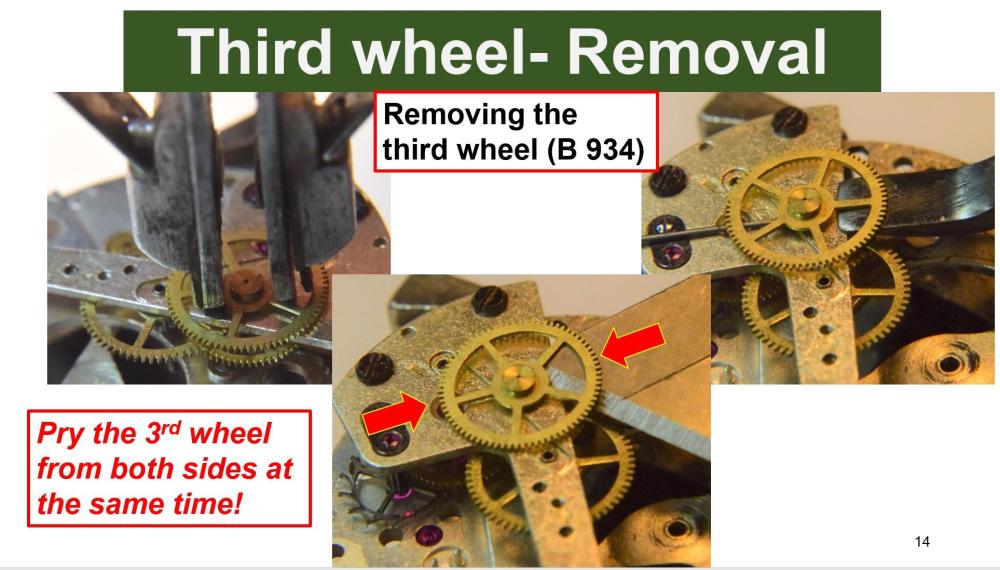

I keep saying to my students "Just because it is on YouTube doesn't make it the truth!" It's a dangerous place. You need a five-spoke wheel removal tool https://www.cousinsuk.com/product/5-spoke-wheel-remover-bergeon to do the job properly1 point

-

The wheel actually made me very confused when disassembling the watch. I tried to take it out but it wouldn't move, so I found a youtube video of someone taking the same movement apart and they didn't remove it either. I guess that the real mistake was to assume that video was "correct" instead of doing more research. I will start over and clean it properly! Thank you very much1 point

-

1 point

-

My test for a freely swinging balance is, remove the pallet, give the balance a strong blast with a puffer. It should still be swinging after 30 seconds.1 point

-

As it is your personal watch, I would say not to worry too much about what you see on the timing machine. As @nickelsilver hints, TMs aren't all that reliable. I've had situations where my Chinese Weishi 1900 indicated 240 degrees amplitude when in fact it was 300 degrees. For more details you can check this and this post of mine. I suggest that you put your timing machine on the shelf for the time being and instead investigate how the watch fares in the real world. I have been surprised several times by how well watches worked in real life, showing somewhat frightening results on the timing machine. Wear and use the watch consistently for a few weeks and read how much the precision deviates per day. If the watch consistently goes a certain number of seconds too fast or too slow per day (give or take a few seconds), you know it's working as it should and then it's probably just a matter of you needing to regulate the rate.1 point

-

Just forget about hairspring magnetization. In this movement there is much that can get magnetized, but not the hairspring. Hairsprings that can get magnetized, made of steel, were used long time ago, with bimetallic compensating balances for example. But not after WW2. Something else: You best timegrapher reading is actually the one with 286 degr. amplitude. That’s why I said I doubt that the balance/hairspring are couple, as there the timing error was more than 700 s/day. What You need to do is find how and where the hairspring now touches/rubs. This could be the balance arms or the cock, the hairspring may be not in plane that is parallel to the movement. May be in rest position it doesn’t touch anything, but when balance turned to 90 degr. for example. Please, do the free oscillations test – remove the lever and with the balance in place, turn the balance to 180 degr. and release it, then count the number of free oscillations to the full stop. Here, as with the amplitude, one oscillation is swing to the left +swing to the right, so You must count only swinging to the one direction, or just the expandings of the hairspring. The good result is about 100 – then we will know the balance, bearings/pivots, hairspring – all OK.1 point

-

1 point

-

Was more if a question than a conclusion, its hard to tell from a picture, if its original then its in great shape, if not the person who did it did a good job .1 point

-

1 point

-

Ok so far, I have been able to magnetise/demagnetised a couple of scrap movements and it detected both states fine. You need something magnetic to set it up and find the magnetometer on your device but it’s simple to setup and use. Tom https://download.cnet.com/lepsi-watch-magnetism/3000-31713_4-78588377.html1 point

-

I think this is a timing machine issue. There's a reason the Chinese ones cost 50x less than the Swiss ones; the Chinese ones are pretty good but not super good.1 point

-

It may be the light but that to me looks like it has been opened and the gasket has been trapped between the case and caseback. Tom1 point

-

You amplitude is about 135 degr. It is funny how today’s people rely on stupid machines as timegraphers to show them amplitude and beat error. Is it normal? I mean, how they lived before the WW2, for example? Especially when balance is with 2 arms/spokes, the first thing one will see when observing a watch working, is the amplitude and correctness of the zero position of the balance. No need to use timegraphers for this, like someone blind asking someone deаf... Now, there is a picture where timegrapher shows 286 with +737, was it real? If so, then You must look carefully on the hairspring and try to understand where it touches or rubs. I wonder too, if this ‘NOS’ balance is couple with the hairspring, and seeing how the roller is placed, I am in doubt.1 point

-

I have a Janta Pearl machine too. Changes I've made/making: Added a main switch and replaced the power cord with a grounded plug. Grounded to the case. Remove the spring. I may put it back but shorter. Just long enough so the head won't drop on the glass bottles. I really like the 3" plumbing plug idea for bottle caps. I grabbed those when I saw it. Replace the all the tape with soldered connections and heat shrink. Ordered the automatic relay switch today from Grainger. The version mentioned above by @jimzzilla isn't available currently, so I got 21EW91 which just has a finer resolution, only goes to 102.4 seconds rather than 1024 seconds and DPDT switch 4X850. Perhaps replace the two chocolate bar (aka euro style) blocks with screw terminal blocks. Really happy with all the suggestions to fix it up. Thanks to the group!1 point

-

Are you checking on a timing machine or an app? On a machine try changing the gain (you want the sensor in contact with the crown). Beat error can change with position. Amplitude as well. Amplitude will change with state of wind, but in horizontal with a new watch should generally be over 270. Do you know the lift angle?1 point

-

1 point

-

1 point

-

You need a CRYSTAL PRESS to fit in crystals with tension ring.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)