Leaderboard

Popular Content

Showing content with the highest reputation on 04/14/23 in all areas

-

one of the first shops I worked at the owner recommended or his suggestion was tight against one of the regulator pins which makes logical sense unless something happens. Like too much amplitude. this is the rule for flat hairsprings. They need a little bit of breathing room. If it's in over coil spring then the pins have to be as tight as possible but still allow the hairspring the slide. then I have an image for you the effect of the regulator pins a necessary evil if you would like to regulate the watch conveniently but beyond after a pain in the ass and be nice if we could just break them off and not have them at. Because as because plainly obvious timekeeping is affected by amplitude with the regulator pins.so if your hairspring is between the regulator pins which is where it's supposed to be ill have even timekeeping at least above a specific amplitude. The farther the pins are a part the worse this effect becomes. Then for whatever reason flat hairsprings need their breathing room so closing a really tight will have some unknown consequence. Yes everything has a consequence. In the case of an over coil hairspring those pins are just a little bit apart you can dramatically see the effect of going from a dial position to a pendant position the watch will slow down. And that's where is mostly all my pins are too far apart and that I tighten them and in the problem goes away hopefully. Then what if you're touching one of the pins as you can see it has a very different type of timing curve. This example if you are regulated for zero seconds resting on a pin everything would be fine until amplitude picks up enough that it lifts it off the pin.then the exact nature the curve will depend upon the pins spacing. Initially as you lift off you'll be slow very slow because the regulation point is now at the stud. Providing the other pin was within distance of the hairspring finally able to touch that then you end up with some point in time with the flat average at the higher amplitudes. theoretically I suppose anything is possible but I'm going to say no. But you can get some interesting beat error changes by going to crown/pendant positions. This is because as the hairspring sags because the effect of gravity it rotates the balance wheel and that causes a beat error. Also things like hairspring is not centered can cause beat errors. oh and if you're into this kind of thing is a video where it talks about a really interesting book. Plus if you find the book interesting the second link is where it can be purchased. https://youtu.be/op68gwVvsCo https://www.booksimonin.ch/home.php4 points

-

I love this forum. I love @JohnR725 because he puts an edge on every blade. I have three vehicles not counting the John Deere Tractor. Two of them are beyond 100K miles. I do the oil changes myself. Sometimes I make a mistake and get the wrong oil, like 5W-30 vs 5W-20. I dont throw the mistake away, No. I took chemistry. Remember very little, but I do know how to do mixtures. I just mix up some 5W-23 and get the job done. Sometimes it is 5W-24. I really don't care. My truck doesn't care either. I have even skipped changing the filter when I forget to order one on Amazon! At the end of the day, the guys selling this stuff are trying to make a profit, so you have to take that into account when looking at the recommended intervals. Go look at the expiration date on that acetaminophen. Yeah, you need to toss it in the can. Nope. That sh!it will last forever. I saw a government study about efficacy of meds over time and the reality is that those expiration dates mean almost nothing. But...none of what I just said is horological. So, lets get back on track. Cleaning solutions are a mystery to me, so I just buy L&R because I worked my @ss off for so many years designing circuits, I have lots of money so I can send Ofrei a few bucks to get the bona fide stuff. I have thought about mixing my own brew but I have also thought about DIY cardiac ablation to calm down my PVCs, but there are some things you should just not try. I will end with a reference to one of my other posts. I don't buy into the five or six different oils from Moebius. I use one oil, maybe two. That is it. Good enough for my Dad, good enough for me. For anyone who reads this 30 years from now...I AM AN AMATEUR WATCHMAKER. ANY ADVICE FROM ME IS TAKEN AT YOUR OWN RISK. I leave you with this4 points

-

3 points

-

I should imagine so! In this scenario, I believe you should see significant rate differences between low and high amplitude as well, which I guess is one way to detect this particular fault. Let's imagine the outer regulator pin having broken off or being bent way out of shape. If the spring rests on the inner pin at low amplitudes, it will spend a lot of time in "free air" when the amplitude increases, effectively increasing its length, slowing down the rate. This problem would perhaps even be exacerbated in some vertical positions, because gravity will help pull the spring out from the inner regulator pin. This is why the literature is so adamant that the balance spring should rest perfectly between the regulator pins and have very little "slop" to move about between the pins (the gap should be around 2x the thickness of the spring if I remember correctly). It's also important that the spring follows the arc of the regulator pins as perfectly as possible.2 points

-

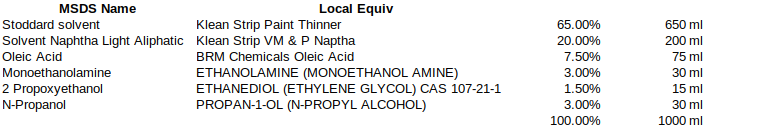

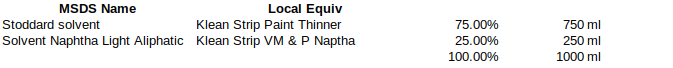

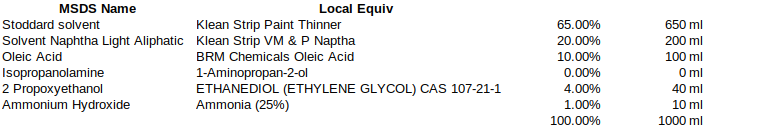

OK so I'm going to call it, here are my winning solutions: Non-ammoniated cleaning solution (AKA 566): Ammoniated cleaning solution (AKA 111): Rinse solution (AKA 3 rinse): Notes: All the recipes above are for 1 Lt (1000ml) but you should have enough information to scale up or down to suit your needs The non-ammoniated cleaning solution does settle to form a 2 phase liquid, but this does not seem to affect the cleaning ability (I have now done 2 watches with this solution and they came out sparkling!) additionally the agitation of the cleaning machine should mix them well enough during the cleaning cycle. The ammoniated solution is very sensitive to the ammonia concentration (I used a syringe and found if I was only 0.5ml over the solution would gel up and 0.5ml under and it would remain cloudy) - I always added the ammonia last and if too much ammonia was added it would instantly form a gel, however I have found that adding additional Oleic acid can reverse this. Rinse solution is difficult to dry (as is the L&R rinse 3) so you will need to follow the same procedure you use for using L&R rinse 3 to remove it - I plan to either use a 30 second IPA wash or a 30 second 100% naptha wash. But IPA is a highly contentious issue in watch cleaning, so you are all adults and can decide for yourself what you are comfortable with! I managed to find the stoddard and naptha on Amazon as they are both Klean Strip products (confirmed by reviewing the MSDS sheets) - I could have obtained the Oleic acid from Amazon also, but decided to use a local lab chemical supplier for this as the price was better. I also used the lab chemical supplier for the other chemicals shown above. Most of the chemicals seem fairly benign to handle, but I would still recommend you use caution and the correct PPE. However, the ammonia (25%) is very strong so I would recommend you decant your large bottle into smaller bottles for easier handling and use a fume cupboard if you are fortunate to have one or alternatively handle it in a very well ventilated area and keep your distance as much as possible as the fumes sting your eyes and take your breath away the instant you open the bottle! Good luck, and let me know your findings if you try the above!2 points

-

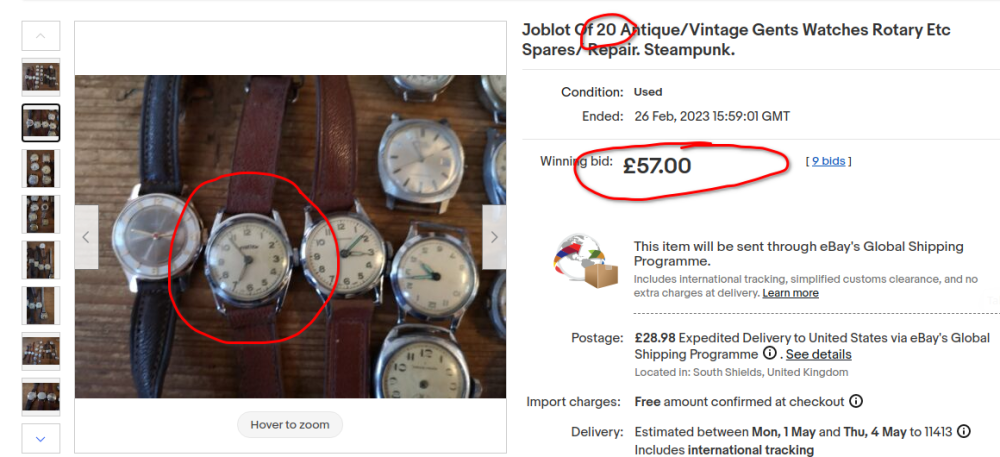

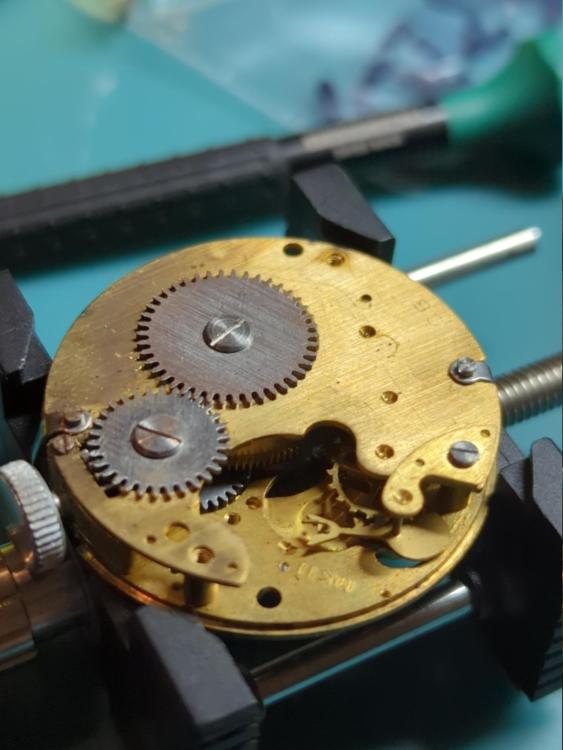

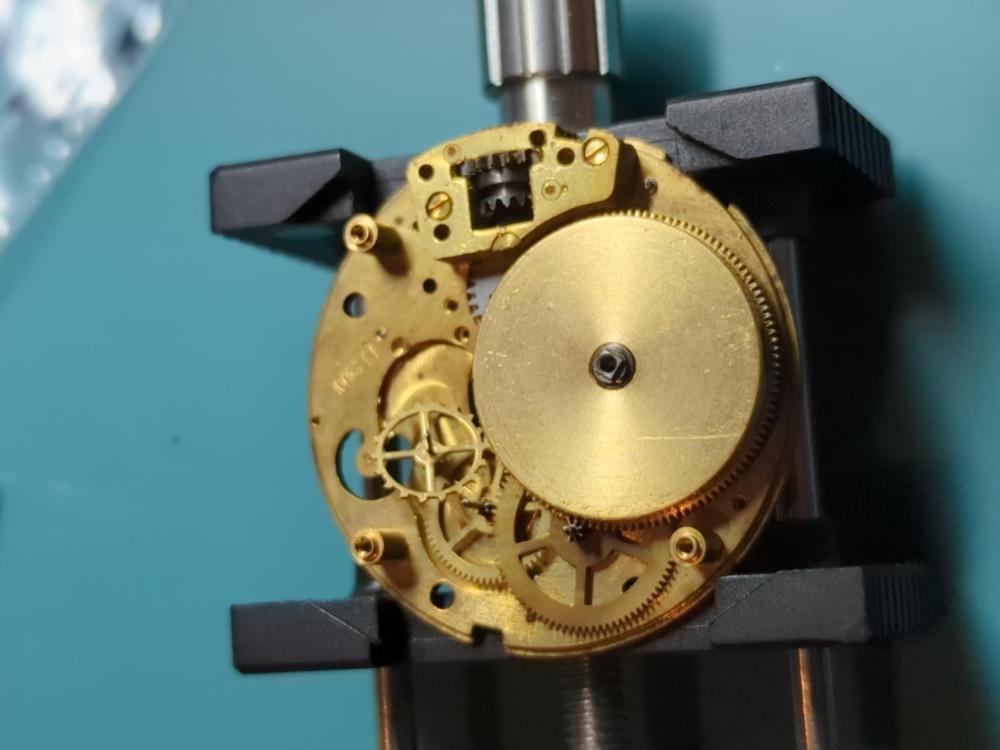

Got a lot of 20 watches for £57.00 which equates to £2.85 each. I decided to do the Aviation first (never seen this brand before, anyone have any information?) as I liked the look of it and it was made in England, you rarely see that these days so I wanted to restore some national pride! Also, I wanted to break my curse of the cushion type watches! Here is the front view when it arrived: And here is the back view: Here is the movement dial side: And the other side : And finally the finished watch: My timegrapher freaked out when trying to adjust the time, I think this has something to do with it being a pin pallet (?) so adjusted manually by trial and error and have it down to just a few seconds a day so happy with that . It is also missing a seconds hand, but decided to leave it out as the watch looks OK on the wrist without it, but I can add one later if I feel the need.2 points

-

that's kind of a yes and no answer that's not exactly the way the book is divided up sort of. So I snipped out a sample page you'll notice it tells you manufacture gives the model numbers the size the movement and what's the next column its movement interchangeability. This is because typically manufacturers purchase OEM movements not everybody manufactures their own watch. If you had 20 people purchasing the same movement and you're going to stock parts you wouldn't want to stock parts for 20 manufactures. Like for instance Bulova Caballo movement from somebody else so the purpose the bestfit book is to take all his various manufacturers they come up with a different numbering system so that you would only have to stock parts for all of them it allows you to cross reference to get your parts. But it goes way beyond that there's an entire section on the fingerprint system for the older watches the setting parts would allow you to identify or try to identify the movement you have maybe whoever made the watch doesn't give you a clue of which model number it is you look in the fingerprint system of figure out what it is and then hopefully find parts to really explain the bestfit book would take a very long time which is why you need to see them. For instance is a link below is a very peculiar link. You scroll down you have names of manufacturers or some other weird name like bestfit and if you click on that or you click on the models of the various watches in the various sections you come back to basically where you started from except now at the very top of the page I can example of this book it appears to be as two separate PDFs you can download it and then you can see what were talking about. https://watchguy.co.uk/cgi-bin/files first for those it didn't memorize every single model number we need to figure out what it is? Difference enough it might appear at the link below. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk and yes it does appear at the link above and it will take us to hear http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Hamilton_770 it was a pocket watch would go in a different direction but it's a wristwatch. then we end up with some peculiar problems like there is a Hamilton section in the bestfit book but there is no cross reference section or no generic parts because it's a Hamilton apparently the bestfit really is for cross-referencing Swiss imported watches not always entirely but so are the online reference no reference one of the other sites there's no reference. so for instance Hamilton has a parts book but everyone's parts books are different some of them lists them by the particular watch which I prefer and others list them in another fashion . Like this book lists all the individual parts in the individual part category but your movement is listed so you will villa find all your individual part numbers. http://library.ihc185.com/catalogs/ham1961/ham1961.pdf1 point

-

It’s probably a lot like anything in this hobby, setup a search with email notifications and hope that the specialist item pops up sometime in the next few years. The good bit maybe that apart from the headstock only taking 6mm collets the 8mm accessory should work as well. Happy to be corrected by our members who know better than me. Tom1 point

-

Great movement, I have one on my wrist at the moment make sure to check out this walkthrough if you haven't already: By the way, mine was also a non-runner when I got it. Turned out to be too little end-shake on the balance. The lower (mainplate) endstone assembly for the balance was quite easy to shim. Not sure if this is a common "fault" with these movements, but I'd suggest you check the endshake on the balance first. Try loosening the balance cock screw a little and see if it kicks into life.1 point

-

I have a similar set-up. My microscope came with the high camera connector you see. Then I have a 0.5x Barlow and the camera = it's quite high ! Even then, the view through the camera is higher mag than the eyepieces, I guess about 2x. I wanted the same view through each. I can't quite get all of a typical watch movement through the camera lens.1 point

-

I'm fairly sure that "Aviation" was a brand name of Newmark. If so, they were made by Louis Newmark Ltd., Perfect Works, Stafford Road, Croydon Surrey. There seems to have been some tie up between them and the Services Watch Co., Ltd. It certainly looks like one of their simple pin lever mechanisms. Some more info here -> https://www.gracesguide.co.uk/Louis_Newmark I'm not sure if Services/Newmark manufactured the mechanisms in house, or imported them incomplete from Switzerland, and built the watches from a mix of in house components (cases etc). Newmark also distributed Avia, which of course used Swiss movements.1 point

-

At the top of the forum you will see Resources click on that and follow to the country that you need. Here are a few that I dealt with many years ago. You can also do a search in google just type in watch material supplies in the uk. H S Walsh & Sons AG Thomas Meadows & Passmore1 point

-

By looking at the chart I would go for Tap 7. I use a cheap digital calliper. Works well for me. I always reset the calliper to zero before measurement. Hope this reply helps. https://blog.esslinger.com/stem-tap-mm-size-cross-reference-chart/1 point

-

Of course it's always best to reverse the part out, and you are 100% correct in saying that the hole is there to facilitate cleaning and removal of broken parts. So, that's where you should concentrate on. There are still a few unknowns which only you can see/know, like is there anything of the pivot visible in the cleaning hole, how much pivot is in the stump, with how much force was it pushed into it and what's the shape of it; conical or cylindrical. The shape and diameter of the part determines whether, as very last resort, you can push the part further in and out the cleaning hole, but that should only be attempted if everything else has failed and there is nothing more to loose. But your main focus should be to reversing out with any idea you may come up with. Perhaps a sharpened / pointed steel paperclip-tip, with the tip bend to an angle (say anywhere between 60 - 90 degrees) so you can access the pivot hole from the cleaning hole? A screwdriver as an aid to increase the down-force on the paper-clip? Needless to say, you have to get the stump out of the tool to work on it. Perhaps others do have other idea's which may help you? Suc61 point

-

This surprised me. I was amazed when a friend who worked in the US told me he bought tire guaranteed for 50k miles. Here in the UK, 20k miles is considered good (10-15k for front wheel drive). It's down to the hardness of the material used in the tires. Your tires are very hard, last a long time, but don't grip as well (that's why in US movies car tires squeal when they corner). We have smaller roads, roundabouts, and more corners where grip is more a priority. If we had lots of long straight highways, we too may have harder tires which might last 50k miles. I have always been amazed when I read that in the US you change car oil every 3-5k miles. Back in the 70-80s we used to. But since the 90s it's been 10k+, and since about the 2000s up to 15-20k (variable depending driving style). My last few cars (BMW) have been up to 20K. They have larger capacity (7L) and use fully synthetic oil. Being an engineer, I was very wary about claims that an engine could safely go 20k miles on the same oil without damage. But I've seen plenty of evidence that it's not a problem. e.g For the last 10-15 years millions of cars have been running in Europe using the long oil change schedule. If there was a problem, we would have millions of smoky cars with warn out engines. We have pretty strict emission regulations here, and if they burnt oil, they would fail the tests. Guess what - we don't have a problem. Your oil companies are doing a good job selling you all that oil ! Lubrication - always good for a discussion1 point

-

1 point

-

1 point