Leaderboard

Popular Content

Showing content with the highest reputation on 04/08/23 in Posts

-

I've been working on getting myself a workbench put together. The kitchen island was not going to cut it for the long term. Seeing as I wanted to save as much money for tools as I could, I wanted to do save some bucks on the watch bench. I took a 2nd hand desk that I got for cheap, refinished the desk top, installed a LED light bar, added a power strip, and created some storage in the otherwise useless keyboard tray pullout. The hutch is good to store some tools and accessories. I've got a couple of drawers to store parts, supplies, and project watches. I put a chair pad down over the carpet, to hopefully keep some flying parts out of the carpet. Hadn't used this much yet, but so far it seems like it will work. Eventually, I would like to add a binocular microscope to the mix.5 points

-

3 points

-

T V these days is just full of rubbish programs. I think its better that it doesn't work. I don't own a TV I haven't had one for about 15 years. This way I don't have to buy a licence to line the corrupt BBC.3 points

-

3 points

-

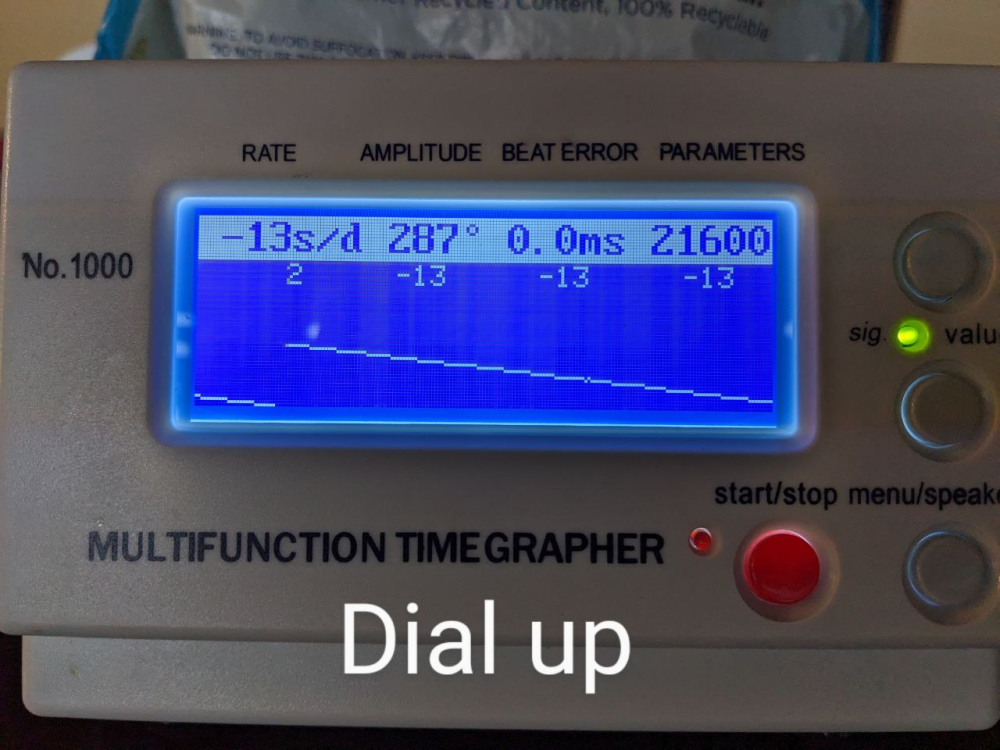

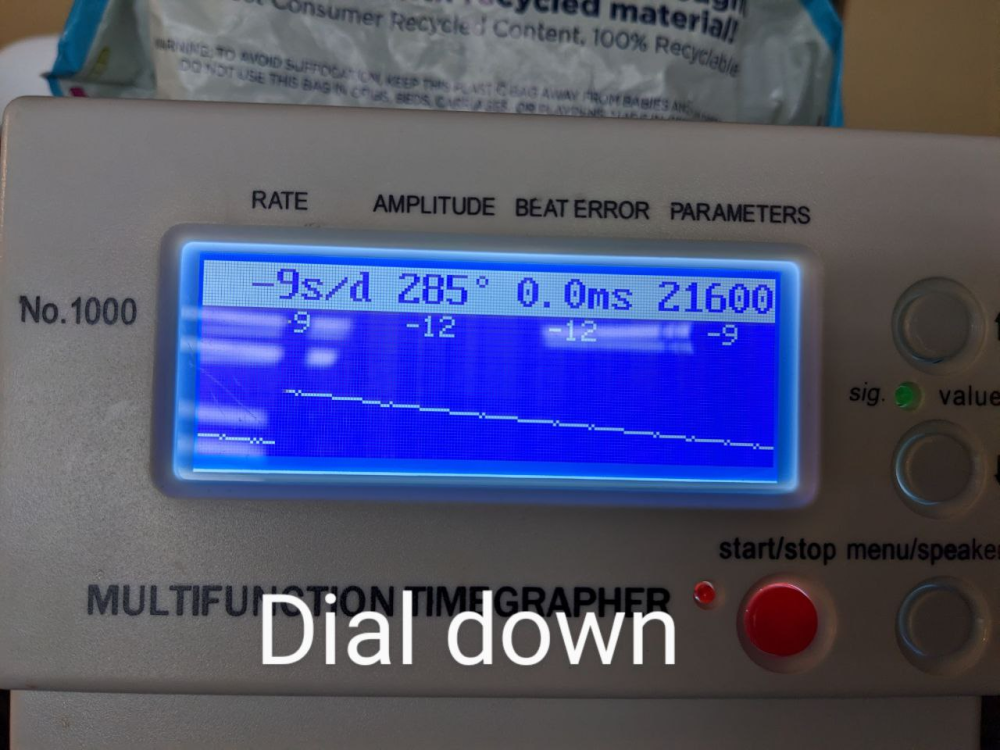

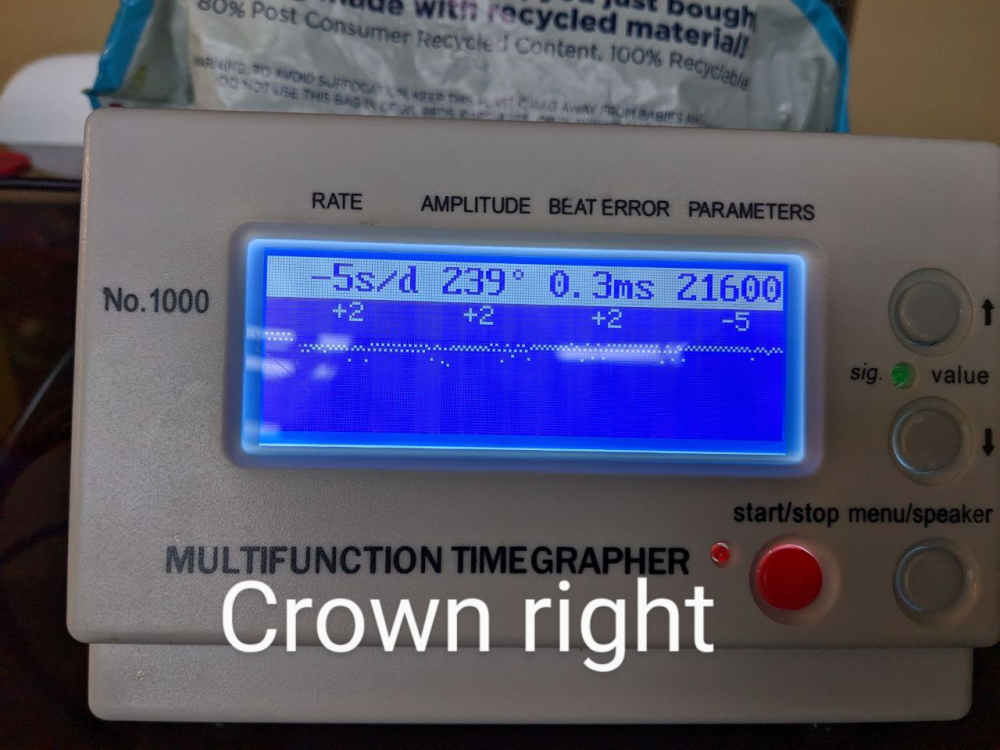

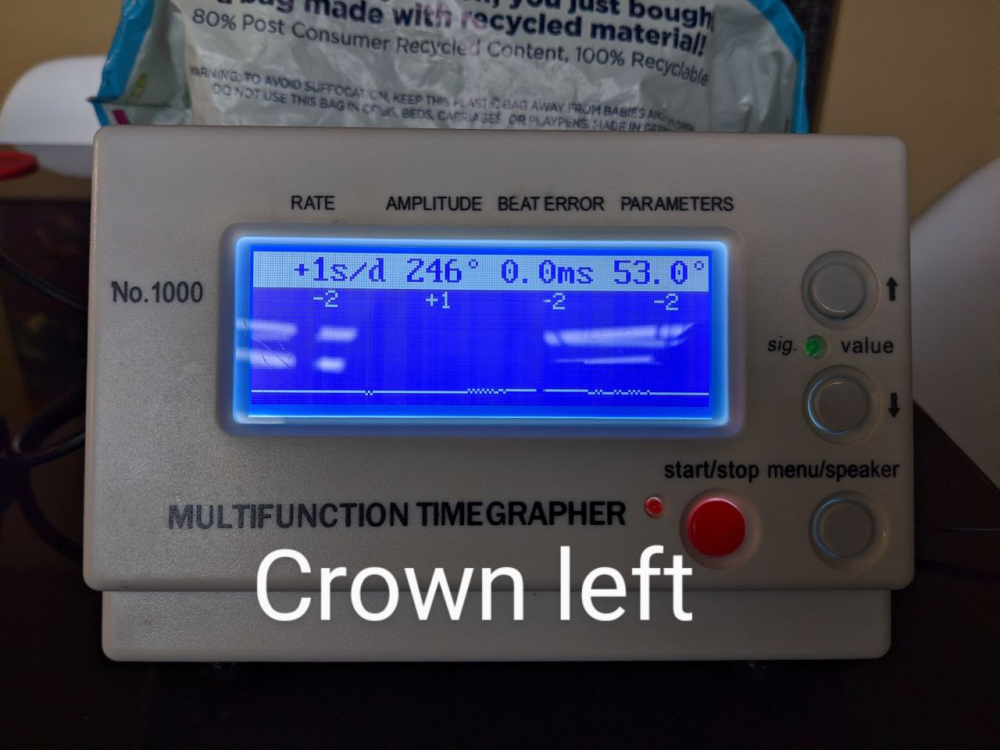

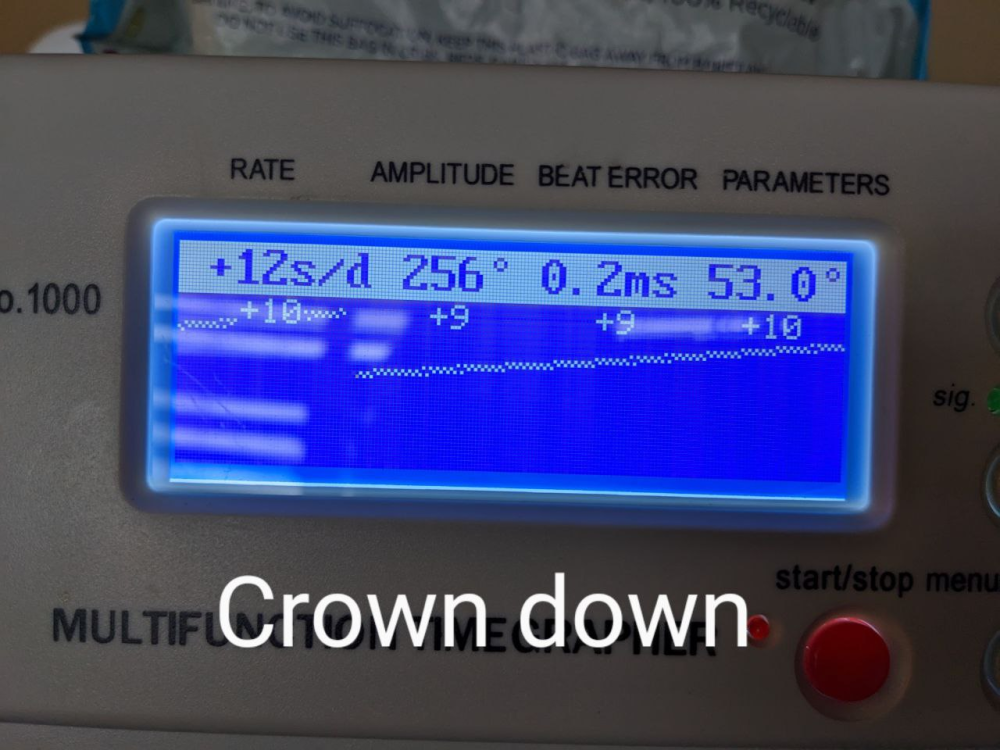

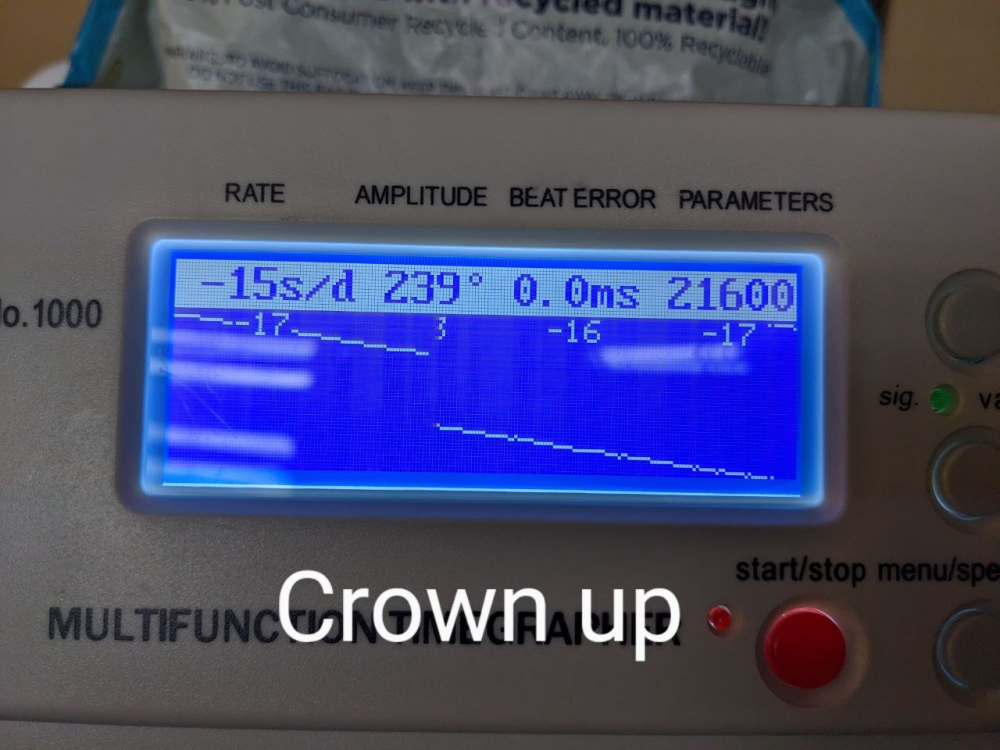

This is gonna be my last update. The final timing numbers after running it for a few days and things have improved across the board. God i could not be more happy with that amplitude. Delta could be better but i'm not even gonna try and mess with these old timey regulator pins. THe weirdness in crown right though...i dunno what that is. It seems to come and go though. Right now i'm doing my final on the wrist timing then i'll regulate the rate.3 points

-

2 points

-

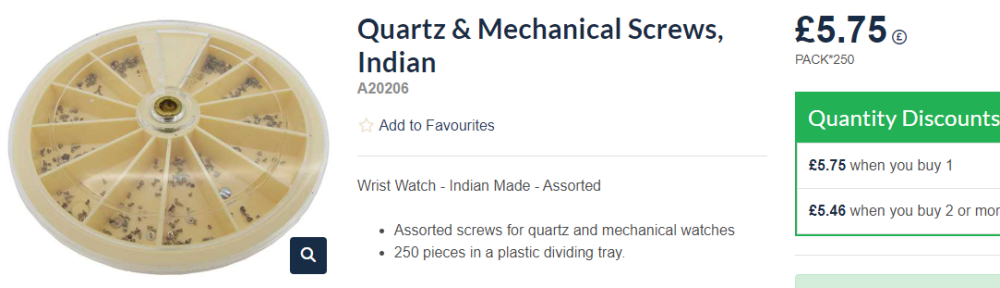

Cousins sells a range of different types of watch screws for specific purposes, Balance screws, Bridge screws etc : https://www.cousinsuk.com/category/screws-wristwatch-movement But I've also bought their cheap selection of screws. Some are new but some obviously removed from watches. I've found a suitable replacement screw many times.2 points

-

2 points

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Jonno65 Hello. Like you as a hobbyist I needed spare screws. Usually it was not the plate screws, but the specialist ones, reverse thread crown screw, long threaded barrel spring screw. These I had usually broken at the head as I have been too heavy in my locking. Like Tom I did initially purchase a set of spare screws rom an ebay seller. I have used only 1 since purchase, but it is god to have them in my spares box. Unfortunately the only way I have been able to source the required replacement damaged screws, has been to source the same movement from ebay. Can sometimes take months. As pensioner learning such a brilliant hobby it's problem being at the low end of the wealth ladder for hobbyist. I have £10 a week which I limit my self to use for the hobby. Therefore it can be a few weeks before I can even make an offer for an item. I do look for offers of multiple movements so that I have the opportunity to obtain a special part. Initially I would get 1 movement only to find that the actual part I needed was not actually there, or was damaged. Two things of note. One good, one not so.. Since I started at Christmas 2021 I have noticed that, apart from ladies watches, the price of mechanical watches and movements has nearly doubled. Makes life difficult. However, the price of tools has actually reduced marginally. Tools make the hobby so much easier. The right tools for the job. What has helped, is the Youtube videos of in depth watch restoration. I have learned so much. Know so little. Great fun Ross1 point

-

I have both the HP1300 and 9501 on hand (but not the 9504) but after having read through the now locked thread I'm still not clear if (in the absence of a tech sheet) one is preferred over the others throughout the entire motion and keyless works or if one is preferred in certain areas and the other(s) for the remainder. Any guidance would be welcomed.1 point

-

I just re-serviced the first movement where I used Moebius 9504 for the keyless works, etc. When inspecting the parts coming out of my cleaning machine I noticed that the parts that had been lubricated with 9504 had a "wax-like" surface. The only way I was able to remove this "wax" was to soak the parts in a degreaser (Horosolv) and brush them off with a fine paintbrush. Generally, I feel hand cleaning is too much work for me (unless necessary) so I will return to either Moebius 9501 or (more likely) Molykote DX as it's less expensive. I will possibly also treat the friction parts of the keyless works with epilame depending on the calibre. In my ELMA cleaning machine, I use ELMA RED 9:1 (max 10 min), demineralized water (approx. 1.5 min), IPA (approx. 2 min), and then I dry the parts in the heating chamber for about two minutes.1 point

-

I got an assortment really cheap from cousinsuk, any material house will stock them. It can be a faff trying to find one to fit but what is watch repair but an exercise in practicing patience? Tom1 point

-

So, electrolytic caps deteriorate over time. For linear power supplies, this is not a serious abrupt problem. However, for switch mode supplies which are 99% of the market, aging caps are a problem because ESR increases and the supply shuts down. I have repaired my Samsung 42" twice...both times--caps. I don't use it any more because I got a modern huge tv.1 point

-

1 point

-

1 point

-

Not a crt then. I think these are capacitors but not sure from the photos. Do not touch, they store charge, some can be deadly. They should be marked with micro farads. Google how to test them.1 point

-

Cock and bridge are reasonably interchangeable. Cock has one screw, bridge has two or more but basically the same thing. Sorry I can't resist but I feel sorry for a cock having only one screw. Hehe.1 point

-

Strictly speaking its the balance cock, rather than the balance bridge, hence the confusion. It contains no less than four screws! One clamps the hairspring stud, the other three look like a complete head scratching session. I *think* you are meant to loosen the one at the rear of the maguffin (macguffin, MacGuffin... you choose) on the cock, and slide things around using the other two. I'll keep you posted if I figure it out. Ranfft describes the 216 movement thus "12'''1 / 214, 216 / 215, 217: 3 train cocks", so there you have it.. The MacGuffin on the thing has 3 train cocks. A cock screw and a stud screw. More double-entendres than a 1970s carry on film.1 point

-

Hi All, I just wanted to post something about my first try at temperature compensation adjustment. Basically I have been working on my first pocket watch from 1935 that turned out to have a cal 19.71 movement. I had got this running very well with amplitude DU/DD of 310 degrees at full wind and 285 degrees after 24 hours. I did have to change the balance staff as that was terribly worn. I did notice that there was a variation in rate due to temperature. Normal +3 SPD Hot -2 SPD Cold +9 SPD It appeared that the split balance was under compensating. I read the books that I had on the subject (De Carle and Fried) that suggested that If I could move weight to the free end of the balance arms then that would give more correction at temperature. The books even gave a guide on which screws to move to achieve different levels of compensation. I proceeded with caution and moved the screws indicated. I was then thoroughly amazed at what this 90 year old watch was achieving: Normal +3 SPD Hot +1 SPD Cold +1 SPD I have noticed that the poise is just a little out now (as it was before) but I should be able to adjust that with considered adjustment of the 4 meantime screws as that is where the heavy spots appear to be. That's a job for another day as I am still in shock. Steve.1 point

-

This is common. I think the plasticizers in the orings soften the plastic box and sinks into it. If you pry the orings out of the plastic, you'll see the depressions.1 point

-

That's it, and it explains the extra holes and jewels too. It's a Poljot 2415A (Rodina) which is missing the entire auto-wind module. Not to be confused with the Poljot 2415 (Orbita) which has a fully integrated autowind rather than a bolt on module. I should have twigged looking at the case back which is designed to accommodate the autowind.1 point

-

Is it a new Squale 1545 with the Selita SW-200 or the previous version with the ETA 2824-2? The 2824 can have issues with the yoke disengaging from the winding stem. Mark made a video about it:1 point

-

Unfortunately there not available anymore. Unless anyone can tell you differently, you need to troll ebay and hopefully get lucky.0 points