Leaderboard

Popular Content

Showing content with the highest reputation on 12/02/22 in all areas

-

I have said this somewhere else on this forum: working on radium is simply not a concern IMHO. I posted several government papers on the topic that support my view and I gave the anecdotal evidence that my father worked on radium watches from 1947 to about 1990 without taking any precautions that I am aware of. He died at 93 of issues unrelated to radium All that being said, don't eat it or ingest it through other body orifices. I have one of the inexpensive geiger counters...just for fun.4 points

-

Thought I would start a new thread rather than tag on to my last one about a broken motor. This is my second L&R restoration project. Harder than the first because of the bad wiring and broken brush housing. As noted in the earlier thread, I 3D printed the housing fix, and performed a complete rewiring of the motor. This thing was hacked by some previous owners--not unusual for this old stuff. The lamp was replaced with a neon one. The heater appeared to be taken from a coffee machine!!! Geez! What a mess it was. All of that is removed and I have ordered the correct lamp. This model L&R used a 220 ohm 50 watt resistor as the heating element. Impossible to find so far, so I may opt for a PTC heater (ordered one from China). No final decision on that. The cleaning basket interface is not shown in this picture, but I do have it. What I do not have is the three-tine spring that interfaces between the spinner and the basket. I stole it from this unit for the earlier one I restored. These are impossible to find--at least so far. I think this was originally black, but not sure. Should I paint it???? Anyway, it is at a stopping point until I get the needed parts...maybe finish next year.2 points

-

The crystal on this 404 club blue dialled Accurist got swapped this evening, so I figured it was time to show off the improvement. It is a complete smudge and dust magnet now, as you can see. No sooner had I popped it on my wrist than it was sporting a big thumbprint and some instant air bourne speckles. Despite all that, the blue dial is pretty impressive without all of those distracting scratches. Here it is under the inspection lamp, with the old crystal for comparison.2 points

-

It’s a generated sound rather than what the expensive Swiss ones do which is to amplify the sound so you can hear what the escapement is actually doing. I’m sure @JohnR725will correct me if I have it wrong. Tom2 points

-

I wouldn't really want it to be the last thing that was in contact with watch parts, but they can go into clean isopropyl or benzine to rinse.2 points

-

The stud is clearly tilted in the straight-down photo, and corresponds exactly to its behavior in the watch. A bend like that is pretty much always adjusted with the balance in the watch, making the adjustment right next to the stud. There isn't much space for tweezers there though on this caliber (swing the regulator away from the stud for a bit more access); in some cases you might have to get it close with the balance out, even overshooting a bit, then finalize in the watch. As it sits, the tweezers- which should be very excellent condition #4 or #5, will need to tilt toward the cock to make the adjustment. Best is tilt, with tweezers slightly open but in position on the spring, then squeeze. Grabbing then tilting will almost certainly make things worse. But if you haven't done such an adjustment, I would recommend practicing on some cheap movements first. This is a very nice watch, and if parts are out there they won't be cheap. And even if you find a balance complete, it will 99% of the time need some hairspring adjustment in the watch.2 points

-

Yes it definitely has to be worth the money because namebrand recognition and it comes in a pretty yellow box.. This is what we use it work.. Normally it's in the cabin and when you screw the lid on the candidate ask he has a metal like cork like thing that goes in first followed by the lead and we usually put a sheet of plastic between the lid and the cork like thing they help to seal it in place. Then it goes into a job are used to come in jars and when I purchased mine at the material house Debbie suggested purchasing the jar for general use and the camera for the spare solvent so I have my jar at work. Then the wording of environmentally friendly that's interesting isn't it? Are human beings considered part of the environment? Or are we only considered against the environment and we don't count? Notice the reference to use in a well ventilated place? That is kind of late well understated we had tape on one of our display cases so the store manager are owed my jar of rinse and that I'd not sure how she applied it maybe with a towel and well it was not good for her health basically this stuff is extremely volatile and has a really horrible smell so she was slightly lightheaded for a while or basically just didn't feel well like what would happen when you're breathing noxious chemicals so I tend to try to not to breathe it in even if it is environmentally friendly.. But still is a really good at removing stuff that doesn't like to be removed.. Just don't believe it2 points

-

Ah yes the old paralysis by analysis, but a wise friend sometimes says to me " if you are not sure what to do, then dont do anything ". Jumping on a decision can lead to making the wrong one. Becoming a bit philosophical here, its just a cleaner. For me if i was strapped for cash i would be trying the first two. Also for me if I wasn't strapped for cash but I'm a tightass anyway i would be trying the first two. And again for me Bergeon charge far too much for their products so i would be trying the first two. So i guess i would be trying the first two. It was a simple question MSB, I made a meal of it sorry .2 points

-

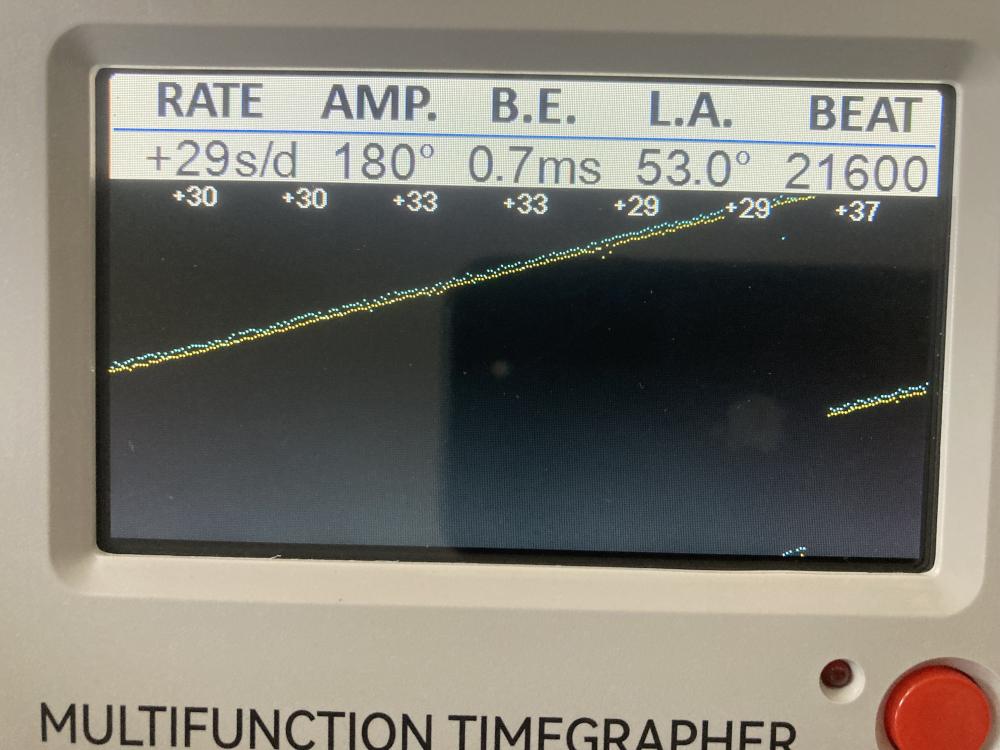

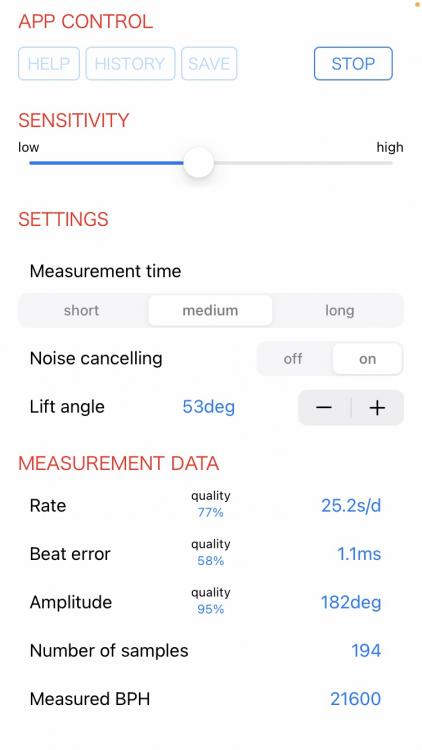

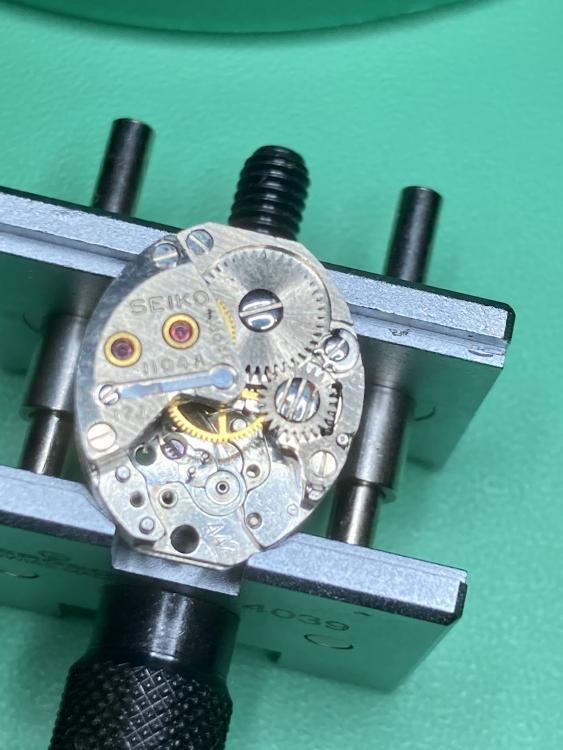

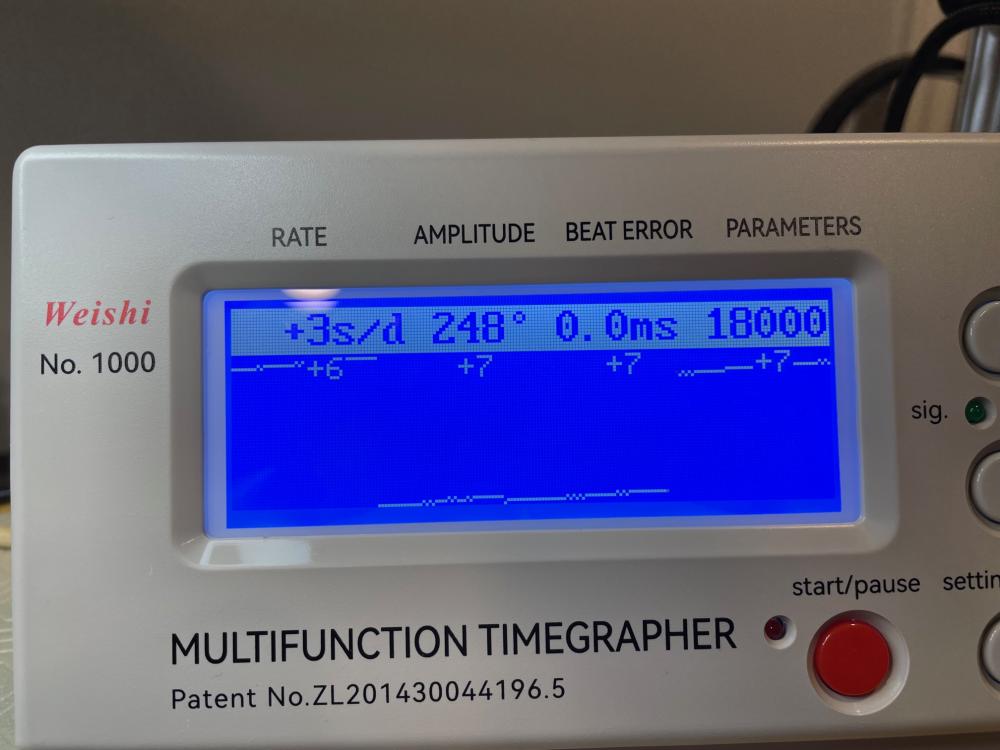

Good day everyone So, after practicing reassembly on a non working Seiko 7S26A with a dial foot lodged in the centre wheel, including rewinding (and breaking) a kinked mainspring, losing diafix cap jewels, and reinstalling a balance complete, I obtained two working movements from speedtimerkollektion., both 7S26A. The first was advertised as "the movement runs and stops." Turns out the hands were bent downwards and the second hand was blocked by a dial index. Once that was popped off, the balance wheel swung back into life. I put it on my newly acquired timegrapher: Found the readings varied somewhat depending on gain setting. Compared it with the app WatchTuner so decided to settle on this reading. Decided to attempt my first ever service. The parts were in worse shape than the previous non working 7S26 with crud and rusted areas. Cleaned the parts with rodico, pegwood, and pithwood before ultrasonic cleaning in jars with Petroleum Ether, Propanol, and 2nd rinse Propanol (3 min each). Cleaned the pallet fork and balance by soaking in a jar of Hexane. My little 1L 55W cleaner struggles to remove all the gunk and rust. Placed a few parts in white vinegar for a few hours to remove the worst of the rust. Definitely have to work on my cleaning technique given what I'm seeing under the microscope. Some screws are still discoloured. Reassembled and oiled using 9010, 9104, 9415 and 9504. Used S-4 on the first reduction wheel and pawl lever. Used notched pegwood to reinstall the diafix springs and a balance taper pin to oil the assembled diafix setting from the other side. My Chinese automatic oiler arrived with a bent needle that promptly broke so I am awaiting a new needle. I left the mainspring barrel well alone since it was winding and unwinding normally (unlike the previous practice movement). So this is the result without any regulation (which I have yet to delve into). I've got the second working 7S26A to practice on then a complete Seiko 5 7S26A watch I picked up on Yahoo Japan auctions. Will work on these before any of my own 7S26 or 6R15 watches. So after the Chinese ST36 (6497 clone) (a true victim) and two 7S26As, I wanted to try my hand at hairspring manipulation, balance staff replacement, jewel adjustment etc. Turns out Seiko Ladies tiny form movements are not popular with collectors. I obtained two working 1104A watches on Yahoo Japan Auction (for just 639 yen each) and nine non working 1104A movements from speedtimerkollektion (for about 1.50 to 2.50 USD each). Got some NOS spare parts so have some good practice material to work with. This is the first one I've started to disassemble. About the size of an American dime and older than I am.1 point

-

Actually You just beat me to the answer. Yes it's just a well it's a way of knowing that your watches running because it's making a ticking sentiment. But it's in no way resemblance of a real sound its synthetic. Which is why everyone in the right mind turns it off as it's really irritating. Then yes the witschi machines are nice most not all have audio. The reason I have to clarify is that work on my bench is an exotic quartz machine that does do mechanical watches that I typically never use unless I can't get access to the other machine behind me. The catch is it does not do audio. The other catch with this exotic quartz machine is it also does not do tuning fork watches which I spend a fair amount of time doing. But otherwise normally on the witschi machine like the watch expert two that I have is push the button and audio comes out. The same as the machine at work the nice machine just push a button on the screen and you have audio. There is no volume adjustment for how loud the audio is but it's loud enough to hear. It's really nice because if you're having issues like to hairspring bumps in the something it makes a pretty ringing sound and that you can hear you can hear a lot of stuff. So yes if the Chinese have fully grasped what they were doing we could add audio on the inexpensive machines but we Do not1 point

-

Sorry N-E-W, I was called away to dinner. What I was going on to say is that the radiation sensitivity to animals including humans (the LD50/30 - 50% die within 30 days) is species dependent (elephants are more sensitive than humans) but does not depend upon the genetic makeup of the animal. We can all safely wear radium watches whatever the condition of our hearts. btw did the dog die?1 point

-

Hi Watchbangers! Since I have started on developing my own DIY 3D printed watch cleaning maschine a while ago I thought I would share you my first prototype for watch cleaning baskets and their holder! If you want access to the ipt. and stl. files, you can find them down here for free : https://www.thingiverse.com/thing:5670073 I also put up a video explaining the whole development process and build here: https://www.youtube.com/watch?v=_jCzbtGDWRM Now since this is just the first prototype there is of course of a lot room for improvements. If you are interested in developing this idea you can gladly use my designs or write me your ideas! I hope this helps you all and that you like the progress!1 point

-

After MSB's adventure with this incredibly well designed spring that cant be resprung after its despring. I think i would be giving it a long soak and then some colonic irrigation where its sun dont shine.1 point

-

Sandoz, Camy, West end watch and Favre Leuba all of Swiss origin are still being made in India. To make it more confusing, Sandoz Singapore, Sandoz Hong kong and Sandoz spain all produced qualities inferior to Swiss. A joint production of good quality Cyma also Sandoz& files , Sandoz& Cie are all familiar brands. Rgds1 point

-

Unlikely but it might left the factory that way. Always worth doing a escapement check just to see if there is a problem. Then I've often seen people talk about moving the banking pins to increase or decrease lock but as shown from the image it also screws up the horn clearance. Which is why you should adjust for the horn clearance and then move the jewels not the banking pins. Then as were discussing moving banking pins the Swiss actually make a tool for this.1 point

-

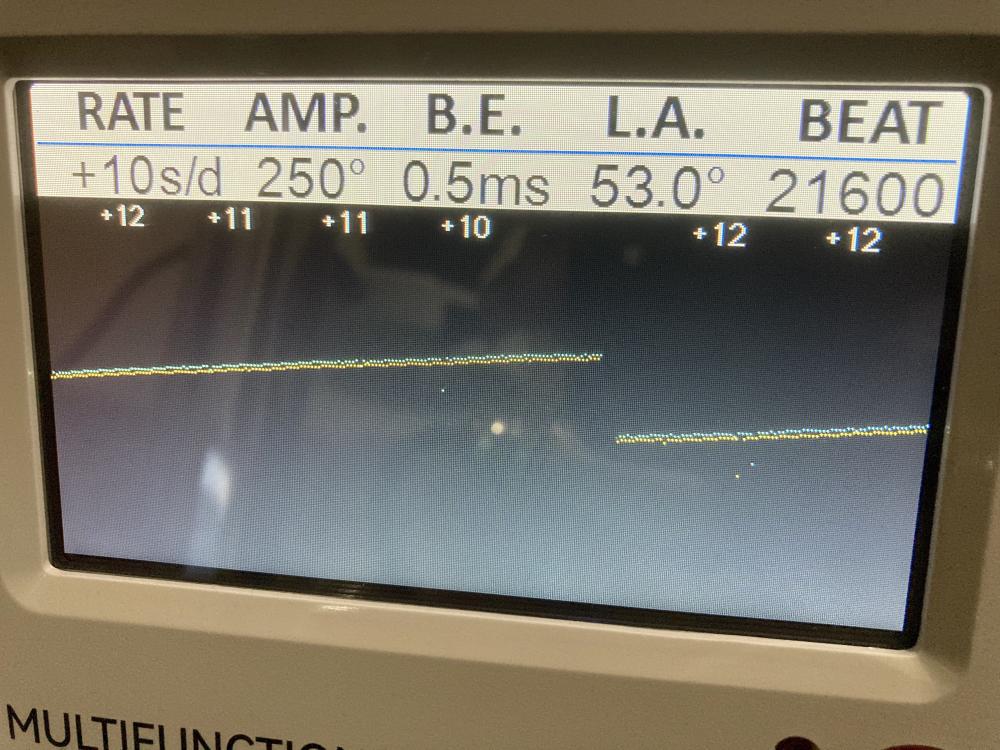

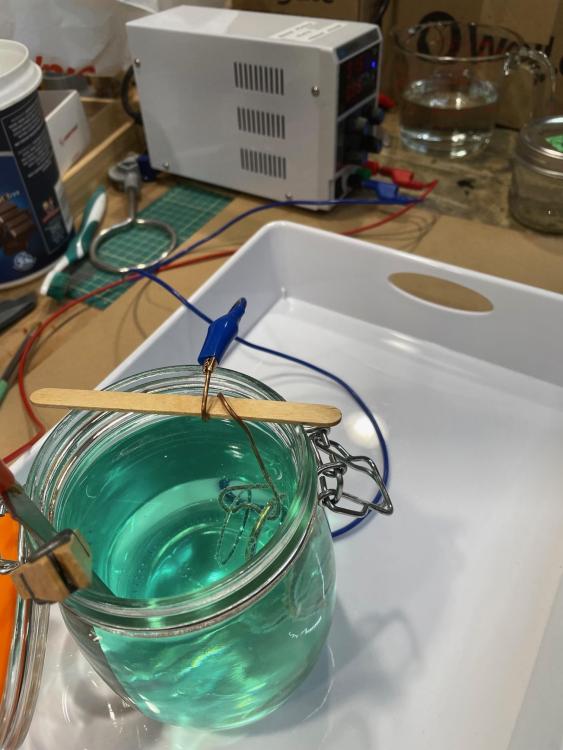

Hi all, Have been away from the forum for a while - it takes me a long time to finish a watch between work and family. My latest project is this vintage Wintex. This is the 3rd wrist watch I have worked on, excluding a built from internet parts watch. I was not able to find much on Wintex online but it seems possible that it was one of the brands started by Hans Wilsdorf before finally settling on Rolex and Tudor. If anyone has any other history/info I would be happy to hear it. The dial of this watch is pretty patina'd - I am not into dial restoration now and I don't know that I will ever go there. I do like the patina look. The case was in rough shape so I thought this would be a good watch to try out nickel electroplating on for the first time. I also didn't have a lot invested in this watch in case something went horribly wrong. So far I have only worked on manual wind watches with no complications. Time only. I am becoming comfortable with those. I have some more to tackle and then will move up to something with a date. The creation of the nickel electolyte was quite easy, worked like magic. I tried to be very careful when sanding the watch case of its old finish to not affect either lip for the crystal ring or the case back. Sanding went all right. Did not get all of the pits out on the back, but this is the back so I don't mind. I tried to polish the case with my dremel and the dremel red polish that comes in their sets. I have not often used a dremel to polish, I use it more for small cutting and grinding. The felt pads were a bit of a nighmare. Hard to twist them on straight, so when you turned on the machine they were off centre and the top exploded off. Also could not get the polish around the whole of the pad as a result of being off centre. Polishing went not bad as well, everything turned up nice and shiny. It is possible there was some small parts left of the original finish - it became difficult to tell the original finish apart once the brass was shined up as everything was so shiny. Next time I should probably try a polish that has some cutting to it, I don't think the red version does at all. Though I thought this may affect my plating, I pressed on anyway. Onto electroplating. Nothing exciting in terms of servicing the movement, everything went nicely there. I watched some videos online re: the plating but did not spend too long on the research. Worst case, I figured, I would have to sand down and start over. Having watched Marshall at wristwatch revival do nickel plating, I started with very low voltage. Less than 1v, to try to avoid bubbles and get a nice finish. Everywhere I looked online, it said the process should take maybe 20 minutes. More than an hour in, I was not seeing much happening. I finished up and, looking at my case, couldn't tell if anything had happened. There was nickel on the copper wire I used to hang the case. My case was warm coloured. I know Nickel has a warmth to it, but still couldn't tell, after staring at it so long, if anything had happened, or if I was still looking at polished brass. I should note the crystal ring definitely coated. Maybe due to it being such a small part the low voltage was fine. After a few days break or more, I decided I was going to try again. Googling about reactivating nickel for plating I found very confusing - lots of chemicals mentioned. I decided to try to dip my case again in my acid wash, but for longer this time. I was scared the 1st time and did 30 seconds. On my second attempt I left in for 2 minutes. When plating, despite the bubbles and hearing this would affect the finish, I cranked the voltage to around 2.5 volts. I was likely being inpatient. There were lots of bubbles, but I could definitely see something happening this time. I still ending up leaving the parts in for about an hour, rather than the 20 minutes others seem to need. I didn't want to raise the voltage further. Ultimately, I did not get a perfect finish on my case, as you can see. I am still OK with this as I think it matches the patina on the dial overall. It was a good learning process. Next time, I likely need to spend more time on case prep, and it may not have been a good idea to try to replate over my initial attempt. Also, I did not wrap my nickel anode in any kind of material to keep particle size down. There is nickel on the case. Some of it has flaked off, but what is left seems to be stuck good. Time will tell I guess. In addition to the case, I also lapped the case back with some sandpaper as it was quite scratched up. I discovered it was not perfectly flat, I was not getting contact in the middle. I used a rubber sanding pad to get into the middle. You can tell if you really look, but again, back of the watch, and it still looks nicer than before. I am considering this another success for myself and I will enjoy this watch. It also gave good results on my new timegrapher. Have a good day all.1 point

-

The abbreviations here would be for ordering an escape wheel or a lever. Based on their jewel set up. C/S would have a capped jewel on the train side, S/C would be a capped jewel on the dial side, C/C would be capped both sides and S/S would be capped neither side. Not entirely sure if the abbreviations are for capped and standard of the jewel or conical and straight of the pivot. Perhaps Nicklesilver can answer this for us .1 point

-

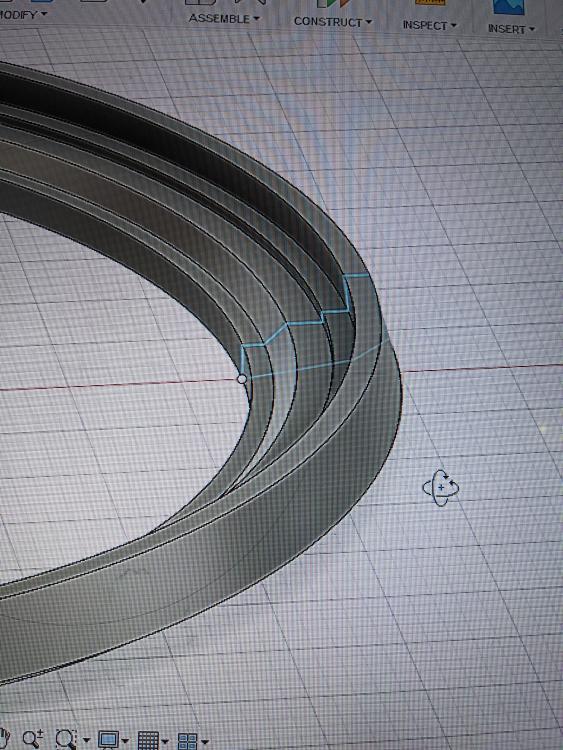

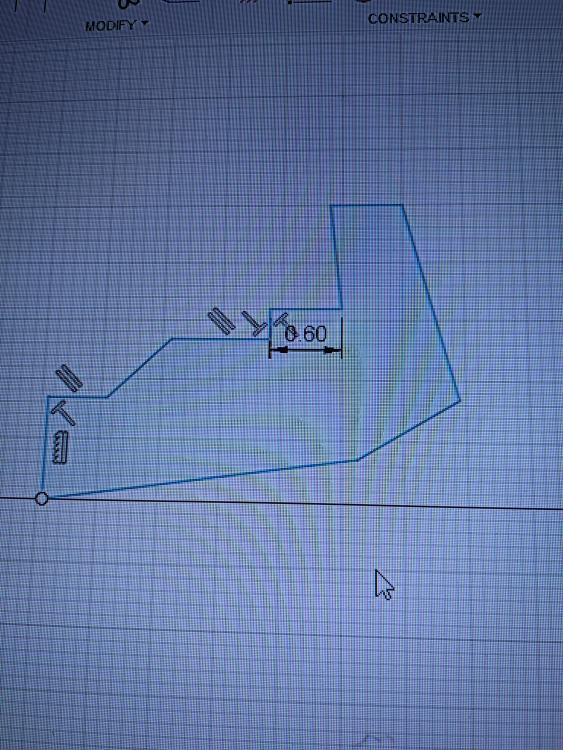

As part of my watchmaking journey I decided to replace some bezels on a watch that bezels are very hard to come by. I was able to pick up a donor watch with a bezel that I am taking measurements from. I am slowly learning fusion 360 and printing my prototypes. Once I have a working prototype I will manufacture them from either titanium or aluminum. This is where I am now on these orient dive watches.1 point

-

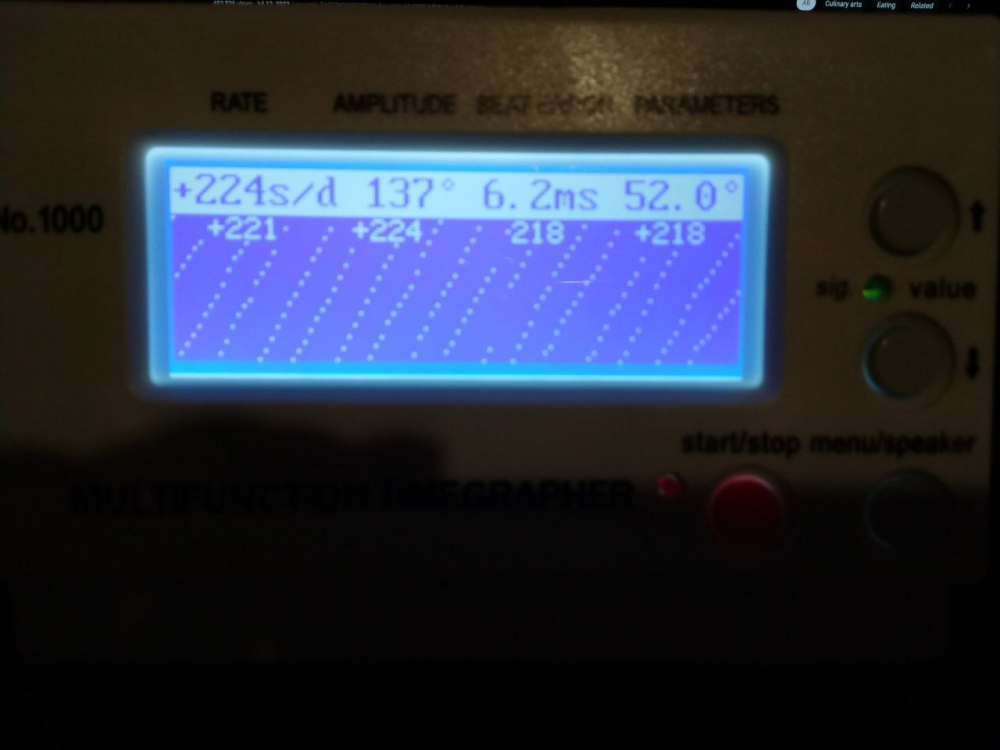

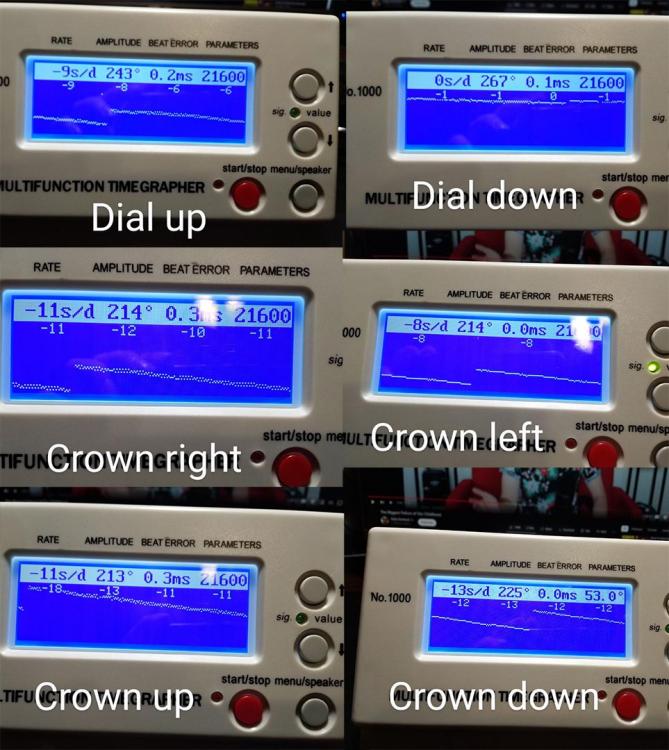

This is how the watch looked before i serviced and repaired it. Keep in mind this is with an at least ten year old unserviced mainspring/barrel. I do not have a mainspring winder and I'd rather mess with that when i get one. Initially i was pretty thrilled with how this came out, i did my initial regulation and adjusted it in the dial down position and was getting 272 amplitude after letting it run a few hours. Let it run 24 hours on a full wind after being told if amplitude stays over 190 then i'm good to go. In dial down it was 246 after 24 hours. I wound it up probably close to full and checked all positions here's what i got. Some pretty big deviations in amplitude and rate. I have a feeling that's more than i should be getting between dial up and dial down. On a well running seiko 7s26 I have i'm getting similar amplitude drops in the non dial up/down positions What exactly am i looking at here guys and what should i do better next time? I did some of my oiling before i got my microscope so i wouldn't be surprised if there's some jewels that aren't perfectly oiled, likely under oiled as i aired on the side of too little rather than too much. Also now that I have my delta what should i do with the rate? Looks like it could be sped up 5 seconds or so?1 point