Leaderboard

Popular Content

Showing content with the highest reputation on 09/17/22 in Posts

-

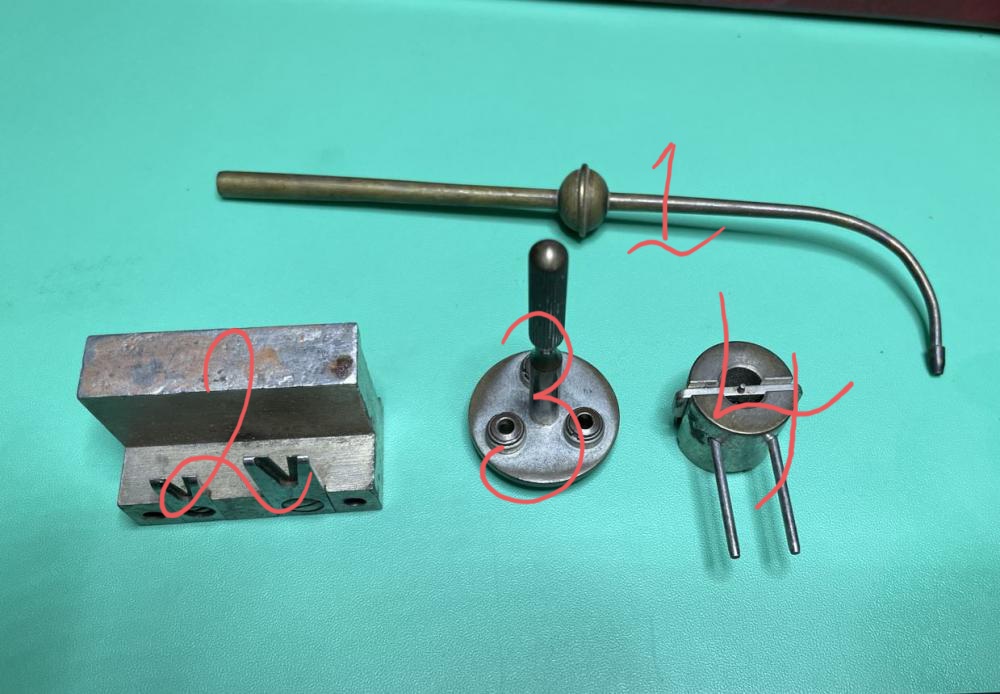

I'm a longtime member of another forum (non-watch related), and personally know several of the members. I have posted up some of my recent watch projects as a several of the people there have told me that they enjoy seeing that kind of work being done. One of the members (whom I haven't met previously) sent me a private message telling me that he had his grandfather's old watchmaking tools and asked me if I'd be interested in purchasing them. We started to talk and he sent me a few photos, which got me excited! He then proceeded to tell me that his grandfather was the official clock and watch repairer for Queen Juliana of Holland. He sent me a photo of a newspaper article his family has kept from the Tulsa World newspaper back from the 1970's, stating that his grandfather was one of the best watchmakers in Holland. After he repaired a special clock for Queen Juliana that was given to her as a gift from Prime Minister David Ben-Gurion of Israel, she was so pleased with his work that the queen became one of his clients! The story goes on to give a history on his grandfather, and was very interesting to read. I tried to upload a high quality photo of the newspaper article, so you can zoom in and read it if you'd like to. He told me that his family has kept his grandfathers tools since he passed away many years ago. They never had any intent of selling them, but after he read that I was getting started learning watchmaking and knew that I was local. They decided to offer them to me for sale with the strict provision that I do not sell any of them, but rather use his grandfathers tools as I continue to learn watchmaking. I was happy to agree to his terms. I finally got home this evening after meeting him on the other side of the state and began going through all of the items. There is a complete staking set with every single piece still in the box, all of which are in fantastic condition, a Jacot tool, a lathe, several sets of broaches and files, bags upon bags of parts, a poising tool, and some other tools that I honestly don't even know what they do at this point. I explained to him that some of the tools were beyond my current skill level. We both smiled when I said that because the whole idea was for me to use them to learn as I continue to move forward. Here are some photos: This last photo is of a few tools that I haven't yet figured out what they for. The bottom/middle tool I thought perhaps was what you use to hold hands if you need to use a broach to open up the eyelets, but it does not separate to allow you to install the hands, and the holes are quite large. I'm unsure what any of them do quite honestly. I think I got a really good deal. I purchased all of these items for a total of $600. I know the staking set is probably worth nearly that by itself. I'll need to find a motor to use for the lathe, but I'd imagine it'll be some time before I get to a point where I can use it. I have an immediate need for the staking set and Jacot tool, so I'm going to find some fishing line and restring the bow so I can spin the tool. If anyone can provide any insight on what the 4 tools are in the last photograph, I'd be very appreciative. I'm pretty excited to use these tools, and am extremely grateful that his family thought me worthy to continue on using his grandfather's tools. Hopefully I made a good investment!5 points

-

1 is a blowpipe, used in conjunction with an alcohol lamp or bowtorch. It allow a part of the flame to be precisely directed. Hard to explain but you can see it in use at 1:30 in this vid.3 points

-

I haven't seen any so far. But the smallest size die works just fine to compress the centre of the crystal. I think it would be quite easy to make your own dome dies. Just embed a correct size nut into a piece of wood or plastic and turn it down in a lathe.2 points

-

2 points

-

I have the Bergon 8250 screw type press with lower bakelite concave dies and they work fine for acrylc crystals.2 points

-

What a lovely gesture from his family thor, you must be very pleased. You are obviously a well thought of member on your other forum. You have a lot of equipment here to help you with raising your game and learning some of the more skilled aspects of watch repair. I think i can help identify you mystery objects. 1. Is a bit of a guess, i think to do with the lathe to oil the bearings. 2. Looks like a homemade collet / roller remover. 3. Is a mainspring winder. 4. Looks like a movement holder, but would need to see the other side of it.2 points

-

Evening all, here's my latest 404 club success. An Accurist LED watch. Came to me as part of a job lot. A little grubby and missing battery cover, though still had the original bracelet. After some gentle cleaning popped some batteries in shorting the top of one of the batteries to the case and was amazed it burst into life. Easy fix. After a couple of months I managed to find a replacement battery cover from a donor and it's been working ever since. If there's any LED watch experts out there I'd love to know who made the module. I guess it wasn't a cheap watch back then either, probably hundreds in 1970s money. I just love the red led's, I don't think they make them like this anymore.2 points

-

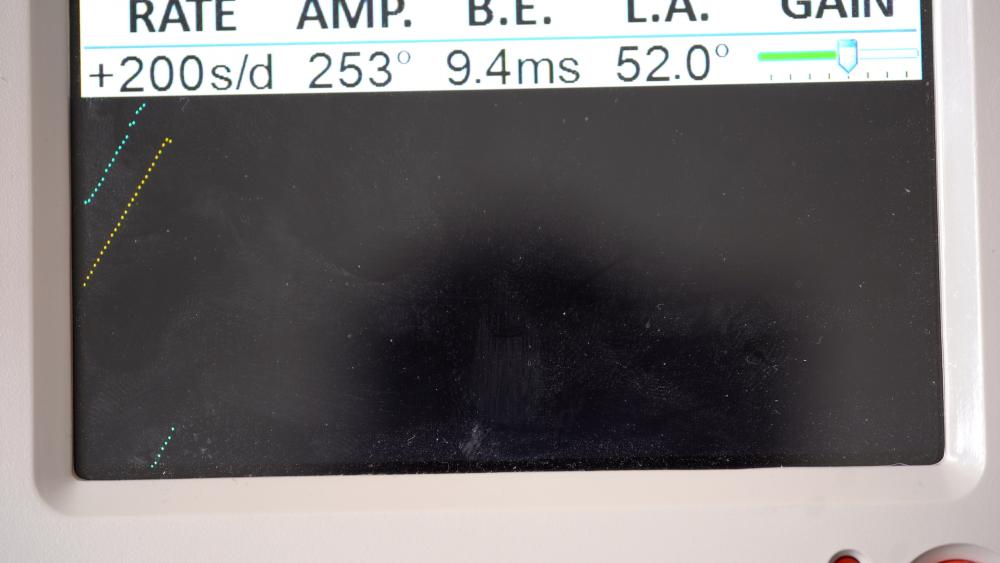

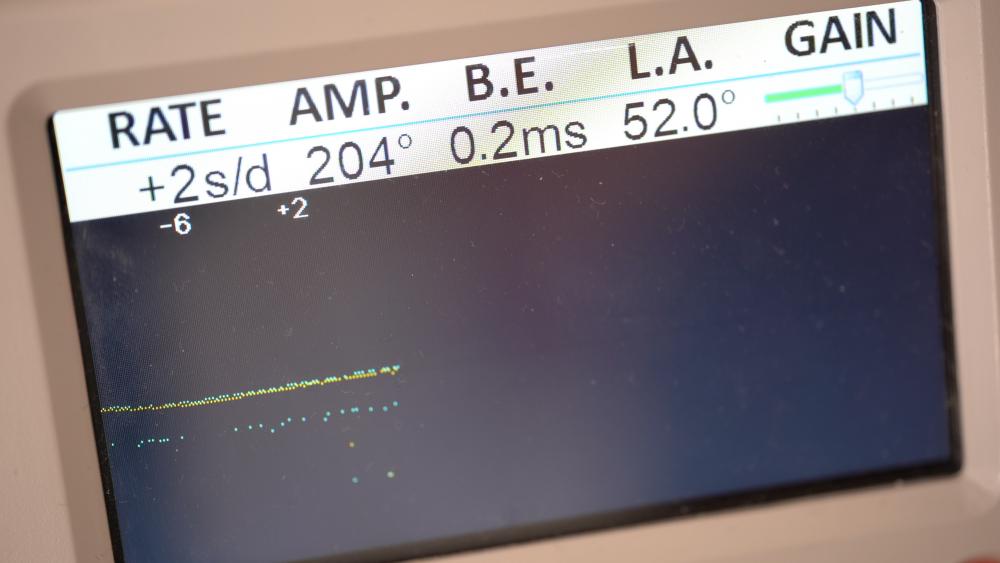

Hello watch bangers! Its been a while because I have decided to change my project schedule a bit but nevertheless, I bring you my most recent watch! This Report will be focusing on my work on an old Citizen watch with a Miyota 8200 movement! Next to the usual service features such as crystal replacement, lubrication and cleaning, I will also be talking a little about dial feet repairs since this watch needed one! Nevertheless, for you lazy people out there, here is the 4k fully commented video on Youtube: Overwise enjoy the read! Arrival status: Here is the watch when it first arrived on my work table Here is a list of what is wrong with this poor old watch: - Missing front crystal and dirty case back crystal - Detached hands - Misaligned dial - Non-Running movement So as you can see this is quite alot of work, but we will be covering all of this and the result definitely are worth it! Disassembly: 1.Removed the detached hands to protect them and screwed open the case back. 2.Removed the case, the dial spacer and the dial ( which had no dial feet attached anymore) and strapped the movement into the holder. 3.Took off the golden day wheel clip and the day wheel. 4.Unscrewed and removed the date cover to reveal all the setting subsystems. 5.Removed the date wheel by releasing tension on its little spring. 6.Took off the date spring and the two quick date and day levers. 7.Off with the canon pinion and the minute and whole wheel. 8.Removed the stem setting system ( Yoke and setting lever) as well as the translation to the canon pinion ( the two translation wheel and their cover). 9.Finally removed the clutch to complete the front side disassembly, well except for the balance jewel! 10.Flip the movement and remove the Rotor. I was really lucky and had a green gilden rotor on this miyota 8200! Loved the look of it! 11.Removed the complete balance. Loved the cool contrast of the round balance shape to the square jewel cap! 12. Undid the pallet fork bridge and lifted both of them away. Pallet fork jewels looked good under x20 magnification. 13. Unscrewed the brutalistically designed main bridge and took it off to be able to dig into the inner gear works. Took off all the gear leading from the escapement to the mainspring and moved on the to the ratchet system. 14.Removed the ratchet system and moved on to the Mainspring barrel and winding wheel which where both removed. 15.Here,I came to the final sub bridge where I removed the sweeping second pinion . 16. Lastly, I removed the final bridge and the underlying wheel which went through the mainplate. With this 99% of the disassembly was done! You can see all the parts (Around 75 I think) assorted in my sorting box! Mainspring As always, I did not have a spare mainspring at hand not did I plan on getting a new one so we once again go to servicing the mainspring! Unwound it out of the barrel and it came out pretty decent, maybe a few small nicks and unevenness but nothing major! After a manual rub down in lighter fluid and alcohol and the following lubrication of its whole length and the barrel insides, carefully wound it back inside to get this result: Cleaning Since I have decided to just keep going with the manual cleaning method, It is the usual process! A good soak in lighter fluid followed by a rinse in isopropanol alcohol. I of course did not include the balance or the pallet fork into this methodology since the alcohol could dissolve the shellac used in the jewel adhesion. I just gave them a good lighter fluid bath! Lubrication All the lubrication I used: Moebius 9010 - Basically All jewel bearing Moebius 8200 - Mainspring lubrication and barrel bottom and under the barrel lid. Moebius 8217 - Mainspring barrel grease Moebius 9415 - A miniscule amount on the palletfork jewel tips Moebius HP 1300 - Slower moving contact points such as: Metal barrel bearing, canon pinion and hour pinion sides Molycote DX - Heavy contact points mainly in the gearless setting system. Reassembly: Just follow the disassembly steps and you should be good! Dont forget to clean and lubricate the balance shock jewels. I haven't really taken any pictures of that process but they will be coming in the following reports! Here is one right after I did the whole process: Dial feet Repair: Now dial feet repair was quite a big issue for me since I always buy used watches and their parts online. And very often I would be super enthusiastic about a lovely looking dial that I snagged just to get it and realize that the dial feet are snapped off. And since I dont like glueing dial and not even mentioning the fact that glueing dials on watches withd ay/date complication being basically impossible anyways, I had to find another way. After some research, I decided to go into the field of resoldering the dial feet onto the dials. Now this has alot of variables which decide if it works out without ruining the dial ( dial material, print, cover, thickness etc..). I went onto my balcony and used a little tools holder, solder, copper wire, safety goggles, soldering paste to solder the copper wire used as a replacement to the dials again. Here are a few pictures of the balcony: And here of the “fixed” dial, even though the back does look absolutely demolished. You dont see that side though hehe. I wont write down the whole process here but I probably will do a more in depth one on a separate post in the proper forum. Timegrapher Test: After everything came back together, it was time to test my work on the good old timegrapher! Here is the result right after reassembly without any regulation: And here it the watch post-regulation: The low Amplitude is probably a mixture of the mainspring not being replaced and not being wound fully! Im also not very satisfied with the slight background noise with is visible on the graph ( just because I like my lines neat and straight haha). Oh and I regulate the watches to their best performance in two position. So once dial up and once dial down. Everything else really is outside of my skill, ressource and patience level xD Final Results So here are the final results of the restored watch! I did end up buying a fitting original citizen stainless steel bracelet but I did not have the chance to use my works camera to capture pictures. Anyhow, the pictures of the watch still look great to enjoy the view! Conclusion So in conclusion, working on this watch was a nice experience! It was cool to show you guys the movement since this was the last movement of a 6 watch lot which I finished off! I loved the brutalistic but kind of aesthetic design on the parts so shout out to the people at Miyota. Im writing this up last minute since im going on holidays tomorrow and I havent done anything in terms of packing or cleaning so i'm sorry for the shallow and short finish! Hope you guys enjoyed the write up and hopefully the video! Criticism, comments, tipps and anything else really can be put into the comments below! Enjoy the next weeks and see you watchbangers for the next watch!1 point

-

Me too, and i bet it will be a lot more than anyone else can. I must admit i did wonder if something was amiss here in graham's explanation. It wasn't my understanding of isochronism. As far as i was aware the period between the ticks remains the same or as near as, regardless of the force applied to the balance wheel, or its amplitude .1 point

-

The more watches the better, of course! However, if you're on a budget you could momentarily convert your wristwatch into a pocket watch while taking a brisk walk I'll do that John and I look forward to seeing what you can get out of it!1 point

-

It's the same as with the Robur press, it compresses the crystal on the lower domed die then you lift the case up and release the crystal. EDIT: I'm talking about the Bergeon press I mentioned above, I'm not sure about the Aliexpress ones.1 point

-

SUCCESS!! I managed to separate the ratchet screw from the barrel arbor. I ended up soaking the subassembly in CocaCola overnight and with a couple of taps on my staking set with a punch collinear with the screw axis, it loosened up the crude holding it together. LH thread. I'm going to mark that screw head with three lines to indicate to whoever takes it apart in the future that its a lefty. Thanks for the tips y'all !!1 point

-

What a remarkable story and you have purchased not only some wonderful tools but tools with history.. An initiative for sure to learn the skills the previous owner for sure had. The middle tool might be a watch mainspring winder.1 point

-

The staking set is 'Siso'. It's labeled on the box and on the opposite side of the base unit, it's just not visible in the photo. It seems very sturdy, has a lot of weight, etc. I played with the adjustments and centering stake and it is smooth as can be. I'm really pleased with this staking set and expect it to perform well. The mainspring winder is a bit on the smaller side, but I'm sure I'll be able to use it on some future projects with appropriately sized mainsprings/barrels.1 point

-

These winders are limited by the fact of their sizes and often do not fit. Be careful that the spring does not fill up all of the space inside the winder, this can make it difficult to free the winder pin from the spring cut out. This winder does have a specific name which escapes me at the moment but i do have one still in its original box. I will have a look when i am home, it was also mentioned on the forum a while back. No.4 still does look like a movement holder, look at the jaws they are recessed back to hold the mainplate in position. but possibly adapted for an extra proceedure. Not sure what the central addition is for. I can't comment on the quality of a Pultra lathe, but i would think with its owners standing it should be good. I have noticed you may need some more collets though, a good selection when you have become proficient with a lathe would be more like 30 +. Not all collets are the same, different diameters and thread cut. Try find a name on your staking set, plenty of accessories here. Haha i am excited for you , i love new tools1 point

-

My thoughts exactly. I will be using the staking set and Jacot tool this weekend, but it's going to take me some time before I'm ready to use that lathe. It's nice to have it though. It'll just be in the box for quite some time still, and I'll need to sort out the motor and pick up a turning tool set and cutoff tool. All in good time though. In the meantime I seriously have to figure out a storage solution for all of these tools. My current watchmaking bench does not have the capacity to neatly organize all of these tools. I'm either going to build some shelving and reorganize the workspace or perhaps buy a roller toolbox that will fit underneath an adjacent taller workbench I use for gunsmithing/reloading stuff. It's a small room, but I'll make it work. I've been told that I'm not allowed to extend out beyond the smallest room in our house!1 point

-

https://www.ebay.com/itm/163064066227?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=hEpW_XVlQOS&sssrc=2349624&ssuid=v36TsHWBSw-&widget_ver=artemis&media=COPY I think you are in luck!1 point

-

All of these types a motion or basically random there is no pattern. if you wind up a watch that you're looking at and it's not running how you start the watch? Do you give the watch a little bit of a shaken the balance wheel starts to move what if there's no power on the watch you give that little shake does the balance wheel move in other words if you can supply extra low energy in the proper direction you can influence the balance wheel. If you have a repetitive motion like walking where your arms swinging back and forth and your watches facing the right direction isn't that kinda similar to the action of starting the watch wouldn't that be an external influence causing the balance wheel to rotate? Try moving the watch on your wrist to an odd position. By odd position right now on your wrist swinging back and forth it's getting a really nice pendulum motion to turn the watch 90° so it's on the side of your wrist ill no longer get that motion see what happens. this comes back to my reference to the stabilization time in the timing machine I've seen it I've seen what I put watches on the machine I can see them changing rate because of the extra role influence of motion causing the balance wheel to behave inappropriately. Then today we see the lighter weight balance wheels running at a higher frequency they should be less likely to be influenced by this kind of thing. See if you have two watches the heavy old-fashioned 18,000 beats with screws. Then try something modern 21,000 or 28,000 try that the next day you probably find very little influence so the lesson here is buy yourself a nice quartz watch when you go for a walk or get a different watch. Have a pocket watch there's less body motion were a pocket watch normally would be1 point

-

My understanding is that the mechanical oscillator in a watch will be disturbed by motion. Inertia, gravity, and changing the bearing surface of the balance staff due to the changes in position will all affect the rate, with varying results. That's why John was talking about stabilization time on a timegrapher, if you wave a watch around while monitoring the rate you can see the effects of the motion. Typically, higher rate watches are more stable, but there are a lot of other factors, too. Size of balance, etc. etc. It is not surprising to me that a sustained uniform motion would cause a sustained change in rate. Since the discussion had wandered into the topic of mainsprings, I can say that even if a mainspring with an automatic bridel is wound tight because its jammed and not slipping, "knocking" suggest that the spring is not the correct size. The slipping is to provide relief to other components, especially the auto wind components, so that they are not working against a fixed load. This will cause extra wear on and possible breakage of the components. If the bridle is slipping too early, the result will be less run time than there should be. The watch will never be "fully wound", and for instance, may not run through the night. Cheers! Marine chronometers were typically mounted in boxes with gimbals. This was to shield them from the effects of the ships motion at sea. This doesn't compensate for the up/down motions, but the effects are minimized because the balance staff stays riding on the small pivot end, and since the chronometer stays "dial up" , it is less affected by poise errors. Studying the solutions that were employed to create an accurate timepiece for navigation purposes will often illustrate the problems that the designers were trying to overcome. Cheers!1 point

-

Hello @VWatchie, If I understand your situation (and I am not sure I do), I believe what you are experiencing is a timepiece that is not providing the expected isochronous timekeeping that you seem (I think) to feel that a fine watch "should" provide: https://www.google.com/search?q=isochronous+meaning (please forgive me if you are already well-accomplished in this aspect of horology) One of the reasons why time pieces are tested in (typically) six positions (DU, DD, PU, PD, PL, PR) is the very real fact that their consistency of their timekeeping (isochronism) is heavily constrained by certain expected physical characteristics and demand requirements, one of which is that the time piece must at least satisfy minimum Display requirements. In other words, the watch needs to enable the observer to be able to "tell the time" - which, interestingly, is one of the criteria that you mention in your above message as being almost trivial...considering your access to both digital and atomic time keeping. A design expectation for watches is that the Display must offer a minimum visibility to the wearer when they need it and are looking at it. In the modern era (and especially with respect to wrist watches) the movement is not in the position we typically need it to assume when we want to "tell the time". For most people, the device is mounted on the wrist in such a way that you need to raise your arm to look at its Dial, at which point the device (hopefully) tells you the accurate time. Your beef is that this is not happening. You are not getting "the accurate time". This is a claim (I think) that the isochronism of your mechanical wristwatch becomes unreliable when you are vigorously moving about. Most wrist watches are not designed to handle situations you are putting your wristwatch in, where it is being subjected to the kind of physical forces that you might generate in while working out. Interestingly, I have read recently about how sub-par isochronism might be somewhat self-cancelling through the random motions we generate as we move through the day. Obviously that is not happening for you. Part of this is the rhythmic and regular motions that a workout might produce. This will certainly wind an automatic watch. It may also be affecting the supplementary arc of your movement in ways you do not desire, amplifying the beat in one direction suppressing it in another. According to my understanding, Breguet came up with the Overcoil in an attempt to enhance isochronism, and I would also classify his Torbillon as another attempt to make the isochrononism of split balance time pieces more reliable, and of time pieces in general through another degree of mechanical isolation. In my studies, I have not (yet) seen a mechanical escapement designed in such a way as to be isochronous in an environment characterized by high-G. Temperature - yes. Humidity - Yes. High-G? Not yet. My suspicion is, if that research was ever performed, it would have been performed with escapements that are not purely mechanical in nature due to the inherent limits placed upon us by the Swiss Lever (and others) escapements. My instincts tell me that electro-mechanical escapements have a natural advantage in both high-G and No-G environments. This may help to explain the presence of the Accutron "Tuning Fork" movement in various facets of the Space Program (SR-71 control panel, Apollo control panel, Satellites & Astronaut watches). If you wanted a High-G/No-G resistant isochronous movement, my suspicion would be that it would need to be mounted somehow on a gyroscope - and I do not know personally how well a gyroscope handles instantaneous changes in direction. My guess is the gyroscope would fail. I also believe that there are serious limitations to the use of the Archimidean Spiral in High-G/No-G environments. I welcome any observations and insights from other members regarding the above. But you have a happy alternative: Buy yourself a Timex Ironman Triathlon, which seems to have been purpose-built for your design question. I myself used them for over a decade while engaging in armored combat, which is a very high-force and very fun pastime. My examples kept time just fine. I just had to change them yearly because the case eventually broke due to being rained with blows...even through the armor. But they still kept the time. As you can probably guess, I find this aspect of Horology fascinating, and I could go on further - but I've not got the time (right now) as I am working on a project that uses extremely high-precision clocks to instantaneously determine the origin of specific sound signatures in an urban environment in a Public Safety context. g. ---1 point

-

No, I'm not trying to solve a personal problem. I'm trying to gain more knowledge about timekeeping in mechanical watches as I find them extremely interesting and intriguing. It's my no 1 interest in life! (I have plenty of quartz watches and even atomic time via the Internet). I honestly don't mean to sound rude, but I must confess that I'm having a really hard time trying to understand your writing. I believe you use some sort of software that translates talk to text, right? You probably have a very good reason for that, but it doesn't seem to work all that well for me. Anyway, I'm doing my best but just saying in case my responses seem to be off. Yes, I wasn't making that up The problem... No, let's call it the phenomenon (that I'm trying to understand rather than solve), occurs either way. However, this phenomenon seems to be aggravated by a poorly lubricated mainspring, but that's a different matter. I guess what I'm looking for is some sort of confirmation to my theory or assumption that the timekeeping of low-beat movements (without any issues) is generally more affected by wide continuous pendulous motions over an extended period of time than hi-beat movements (without any issues). Maybe it's already a fact!?1 point

-

Great walkthrough! I think you would have got a much better amplitude if you replaced the mainspring and a better power reserve. I know some Seiko purists like to keep original mainsprings, which is fair enough. I'd love to see some more walkthrough's in the future, as you clearly have a knack for presenting it in a clear way. Nice!1 point