Leaderboard

Popular Content

Showing content with the highest reputation on 08/24/22 in Posts

-

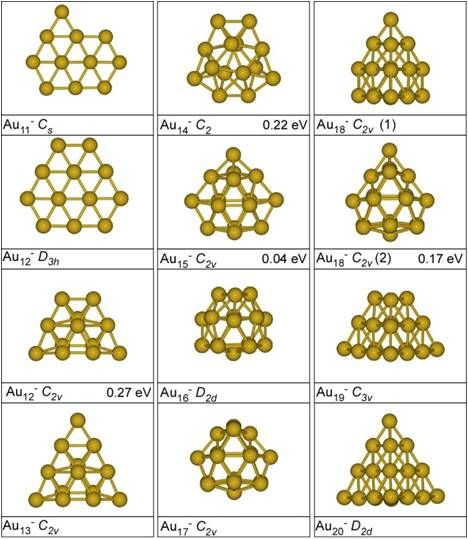

Hello @thor447, When you get it, post better quality photos at the highest possible resolution. Normally speaking, pure Gold (AU) does not normally "rust" (oxidize) as its molecular composition does not have spaces in its electron shell to be able to interact with Oxygen, which is the usual suspect when we talk about "rusting". There's simply nowhere for Oxygen to bind to the typical complexes of Gold atoms: So, by definition, gold is a tough metal to oxidize - or even get to interact with anything else, which is why it's called a "noble" metal. But it can be mixed with some other metals and it can be dissolved into a solution, but not by things we normally come into contact with in everyday life as they are quite corrosive (aqua regia) or toxic (cyanide), or high energy (smelting). There's some reasonably good information in Wikipedia about gold that can help give you some background if you don't already know a bunch about it. Personally, I find gold fascinating for its many uses: https://en.wikipedia.org/wiki/Gold When things are "gold plated" that means that an alloy of gold has usually been used, which is typically an amalgam of gold plus some other metal at various proportions of 1/24th. So, the other metal(s) used to create that alloy may be what's oxidizing that ring - or it might be dirt, or something that dripped on the ring, or a product of some form of galvanic action because the ring got wet and touched something it shouldn't have. It's hard to tell. https://en.wikipedia.org/wiki/Galvanic_corrosion As for polishing the stain(s) away...beware! Plating is measured in microns, so it's super thin. You might be able to get away with a delicate silver tableware style hand polish buffing cloth but even then some people on this forum might get tense. Anything more abrasive than that (Silvo, cream silver polish) is almost certainly a no-no. Mechanical polishing with buffing wheels and cutting or polishing compounds (rouge) is likely out of the question. But all is not lost. While you cannot put plating back on unless you want to go to the trouble of stripping and re-plating, which is a hassle and very time consuming, I did recently see Peter Grande use an applicator to selectively re-plate the gold plating on shoulders lugs that had been worn away. I've seen people use this before - but I don't know how well that plating adheres over the long term in such a high-wear area as wristwatch lugs. Considering the reasonably weak bond between plating and the base metal in general, I doubt it will last as long as a total re-plate because fully plated pieces offer no purchase point (seam) for mechanical detachment to begin. g. ---- Disclosure: I worked in a gold mine for two years to make enough money to pay for University. Over the past 20 years, I have consulted extensively to the the Jewelry industry in Hong Kong in terms of both Design and Fabrication. One of the subject areas I teach in at HKPU touches on the topics of Precious Stones and Precious Metals in our Jewelry Design stream, which is incorporated in our Fashion Design Undergraduate Program. Hong Kong is a jewelry and watchmaking center, and we have many hundreds of graduates working in the Jewelry industry in Asia.5 points

-

3 points

-

Heh, ask anyone who has bought the whole kit and most of them would tell you they've never touched half of it. In my case, I've only done two pocket watches and I just bought mainsprings for those (at less than $10 a pop). Outside of that, I use #6 and #7 all the time. I then had a lot of Seiko 4205 movements I worked through and bought the #3 set for that. Total investment was 300GBP and I've done many, many movements with it. I've recently added #4 and #5 to the set as part of my monthly Cousins orders (which I'm yet to even need), although I suspect I'll never get anywhere close to the 1kGBP amount that a full set goes for, but even if I do end up needing all of it, the pain will be spread over a loooong time. I get to use what I need now, without giving up right out the gate because I can't afford the whole set. Of course, my needs are different to yours but I was just throwing out some real world (for me) numbers out there. Ay bud, I can't tell you how many barrels I've opened up where all the plating has rubbed off the insides because the main spring is even slightly out of true. The fact that these barrels are suspiciously clean is a dead giveaway that they've been manually fitted. As Mark said earlier, you won't know you doing it wrong till you unwind it again to check. Or you get to see the movement 3 years later after the interior looks like a worn set of brake disks.3 points

-

Eyup G. I have two slightly more modern versions of this tool. Neither of them rarely fit. You are relying on only five options of sizes. Often the size differences are either too big or too small. I also have a fully adjustable winder that has a limited minimum size. Its a bit of a faff to use and really only fits pocket watches. The coned example you have ringed is an extreme and tbf i do think that hand winding is getting a bit of a bad rap here. There are good and bad ways to approach the technique. Obviously a bad technique will give a poor result adversely a good technique will yield a good result. This is my opinion Obviously from my experiences but until it has been thoroughly tried and trialled by any individual it honestly should not be discounted. As always do what works for you but dont be affraid to try something different Watchie swears by this tool, in fact he sleeps with it under his pillow lol. ( nothing wierd i suspect but then again knowing watchie who knows ). Bloody hard to find one anyway , I've tried many times over.3 points

-

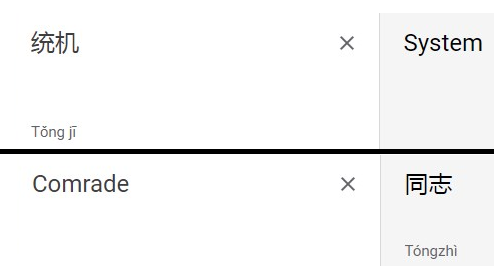

Hello @AndyHull, Thank you very much for the link and resource. Very interesting history! I had no idea...but it makes sense what they did - in the period of military emergency that has existed since the end of WWII in China - to mandate that timepieces nationwide share a homologous movement, thus eliminating the need for watch repair technicians to waste time mastering more than one. Very pragmatic and very CCP. Before the Communist Party came to power, China wasn't really timepiece oriented. I dimly remember visiting the clock pavilion in the Forbidden City about 20 years ago. It was filled with ornate clocks that foreign nations had given to the (then) ruling class in the hopes of currying favorable trade terms with them. This would be gifts presented to the Empress Dowager, Cixi (1835 - 1908) and her string of chosen successors, which included the Last Emperor of China, Puyi (1906 - 1967). One of their most sacred duties was to perform planting and harvest oriented ceremonial rites in the Temple of Heaven, which was constructed in 1406 for that purpose. When I visited it, you could just walk around the place. There were no crowd and no security to speak of. Back to the Hall of Clocks in the Forbidden City. The Hall was empty, dusty and not very well lit. Some of the larger desk and mantle clocks were under simple Plexiglas barriers, others just scattered around on tables and there were also a few floor-standing models (I think). If I remember right, there were little yellowed cards that said things like "Gift from Ambassador of France, 1892" with no further details. There was nobody around. Nothing was running. There were no tour guides or tape recorded tours back then. Consequently, it was definitely a "meh" experience, but I wonder how things look (and how I'd react now that I've evolved into a "watch geek") after China has exploded economically - which usually creates the kind of prosperity that results in people having enough resources and free time to become clock and watch geeks. I bet things have changed dramatically, both in terms of setup and interest level. Looking at recent photos, it seems they've spruced up the place, but the clocks all look the same: BTW - I believe that name for this "unified" movement is also likely to have been a very clever Chinese homonym, which is one of the hallmarks of a language of only 800 sounds and tons of consequent puns, play-on-words and humor...as well as several examples of well-intentioned portmanteau-style words like the Standard Chinese sounds for "Coca-Cola" and "America", for example. The word for Comrade in Standard Chinese is, phonetically speaking, "Tong Je Men", or "Comrade Perrson", which can sometimes be reduced in common speech to the short form "Tong Je". When I was living in Beijing, it was very common for people to hail each other in this way, especially if they did not know each other that well. I remember that the older generation used the term habitually, especially if they were Communist Party members or had been participants in military action. The verbalization for the name of this watch movement is "Tong Gee" which is phonetically extremely close to "Tong Je" and it would only take a tiny change in the vocalization of these two terms to slip verbally from one to the other. I wonder if that's not an accident when you consider how important timekeeping is for a country and government that places such an emphasis on the military aspect of things, of which time management is a critical element. For instance, did you know that China has only one time zone? Everything in China runs according to Beijing time. NOTE: For those of you who may wonder about how or why the above came to be and how a Canadian boy who grew up in Quebec and who is now living in Hong Kong could write about such things...I read Chinese and Japanese history as an Undergraduate student under a Harvard-trained Sinologist who himself had been trained by a giant in the field of Far Eastern Studies, Edwin O. Reischauer. I claim no credit - I had a great teacher, and he had a great teacher.3 points

-

3 points

-

I do the same. I have a few winders that often dont fit and sometimes trap the spring so i use a pin vise with a dog leg bent needle in it. This helps me feed the spring in once i have it started, it actually wovks pretty well considering its a bodgy makeshift device. The bent end fits down into the bottom of the barrel center hole. Once you have the spring started place the device onto the spring and spin the pinvice while feeding the spring into the barrel. The barrel has to be mounted in a movement holder, i use an adapted jewellers vice with pegwood inserts for grips, these bite into the teeth of the barrel to stop it moving. It can be easier to spin the the movement holder instead of the device. Its much easier than it sounds lol. I'll see if i can upload a demonstration, here is what i use in the meantime. This is a very closely gaurded secret of mine, and the items i use are heavily patented. Please do not tell anyone or i may have to come looking for you . A very thin smear of oil on the mainspring is advisable, if anything to protect it from oxidation especially on an old carbon spring. You could lift the barrel lid and place a drop of oil across the wound spring. Not best practice and some may not agree with that ? The oil would eventually work its way around. Ideally the spring should come out and be properly cleaned, as dirt could remain trapped between the coils. You will need to tackle it at some point so now is as good as any opportunity . Try my method of reinsertion that I've left you after old hippy's post3 points

-

2 points

-

2 points

-

Can you tap three or four hols in a piece of stock. In a triangle or square pattern that would just circumscribe your finger tip. Depending on the pattern, make three or four screws at a time, thread them all in an polish on a piece of glass. I've seen the tool that is supposed to be used for this and it looks very expensive and hard to find.2 points

-

That's comforting to know. I would assume that once you're to the point of charging for your efforts, an expense of this type is justifiable. At this point I have other places for my money than a tool that will not pay for itself and will need to defer this for some time. I can't understand (if you can maintain) the same geometry experienced by the mainspring while removing it (both in angle and bend radius) how that it can damage the spring while reinstalling it. I try very hard not to negatively affect the spring in any way and feel that I succeed on average. It's nice to see that I'm at least not alone. Thanks Mark. Shane2 points

-

Timex has a fascinating history. The descendant of Waterbury Clock, Waterbury Watch, & Ingersoll, the modern company was formed when Norwegian refugees from the Nazi advance bought Waterbury Clock in 1941. They promptly built a state of the art manufacturing plant, and proceeded to build mechanical time fuses and gyros. This plant was something, it could be flooded and completely covered with water. Enemy planes flying above would only see a quiet pond This was on Ingersoll Hill, named in honor of the Ingersoll Brothers. Cheers! History from "Timex, A Company and its Community 1854-1998"2 points

-

Hi guys, I have started a project in Github to generate all the possible types of mainspring winder sizes from a single base design using a Python script. https://github.com/vishnu350/rs-mainspring-winder The STL files can be downloaded from the release section: https://github.com/vishnu350/rs-mainspring-winder/releases This project is a 3D printable "Rising Sun" watch mainspring winder for hobbyists. Mainspring winding for hobbyists has always been a problem, as most of us cannot afford the $1000 Bergeon set. Or sometimes, the appropriate size just isn't available. This forces most casual hobbyists to resort to handwinding or other similar stunts, which is not ideal. This mainspring winder is designed using FreeCAD to be easily 3D printed with no post-processing/finishing required. It will approximately cost $5/set by most 3D print service providers (use eBay to find someone near you). The design is parameterized, allowing you to dynamically change the size/dimensions of the winder and the entire design will be recalculated accordingly. The RS mainspring winder is a pleasure to use when constructed correctly, and can wind in both clockwise and counter-clockwise directions. I have uploaded a video describing the 3D printed RS winder parts and how to use it. Will appreciate any help or feedback as to further improve the design, as I actually do not own a 3D printer (I pay for each print). I also do not know the complete range of sizes that is required to be uploaded into the release section. Also, the optimal design parameters may still not be perfect, but it seems to work pretty well for me at the moment. Thanks.1 point

-

Most amateur watchmakers use existing tables or work tops for doing their repairs. The big problem is the height is usually far to low to be comfortable when working for long periods. The cost of a proper watchmakers workbench is in most cases prohibitive, bearing in mind I am talking about hobbiests and not professionals. My solution to the problem was to make a small table to sit on top of my computer desk that gives extra working height. It also slips underneath the computer monitor and allows normal desk height when I require to use my wee lathe. The Bergeon sheet has been trimmed down to A4. I decided on A4 as it allows me to use a clean sheet of A4 paper every time I assemble a movement. All edges are raised to prevent components rolling off, the front edge being slightly lower than the others. The overall height is 150mm, but this could be made to suit the individual. Ideally I would have made it slightly taller, but it would not slide underneath my computer monitor. Here's a couple of photos.1 point

-

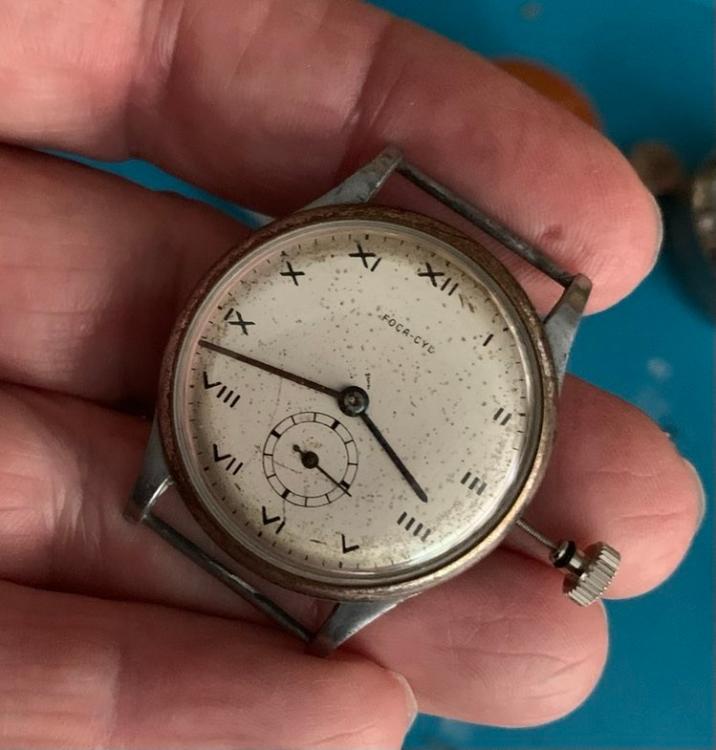

Picked up a job-lot few weeks back that had this interesting fixed lug case watch. Inside I found an AS 960 with missing winding stem. Found one from a seller in Portugal. Part arrived today and now I'm testing the time keeping. Besides the stem, I have replaced the crystal that was very yellow. Next up I think I will attempt a nickel plating.1 point

-

I feel Timex watches routinely get a bad rap. They held a significant market share for a considerable amount of time for a reason. They helped the average American get through their day with acceptable accuracy at a reasonable price. While deciding between a Timex or arguably a better watch, I'm sure many a customer agonized over what may now seems to be a minor difference in price, regardless of what that difference may have gotten them. We will never know how much the economy end of Swiss production would have cost without the millions of Timex watches to compete against but I can't imagine it would have been any less. To my knowledge, my Grandfather exclusively wore Timex watches and he never broke one. For me, that's a good enough reason to want some but they're not all I own. Thanks for reading. Shane1 point

-

Hello My name is Tadas and I’ve just started watch repair I’ll mainly be focusing on vintage watches and just watch restoration in general I’ve got all the essentials and some extras (tools) for the repair this includes a ultrasonic cleaner oil and some fun tools anyway I’m glad to be here I’ll sure have a lot of questions and I can’t wait to begin.1 point

-

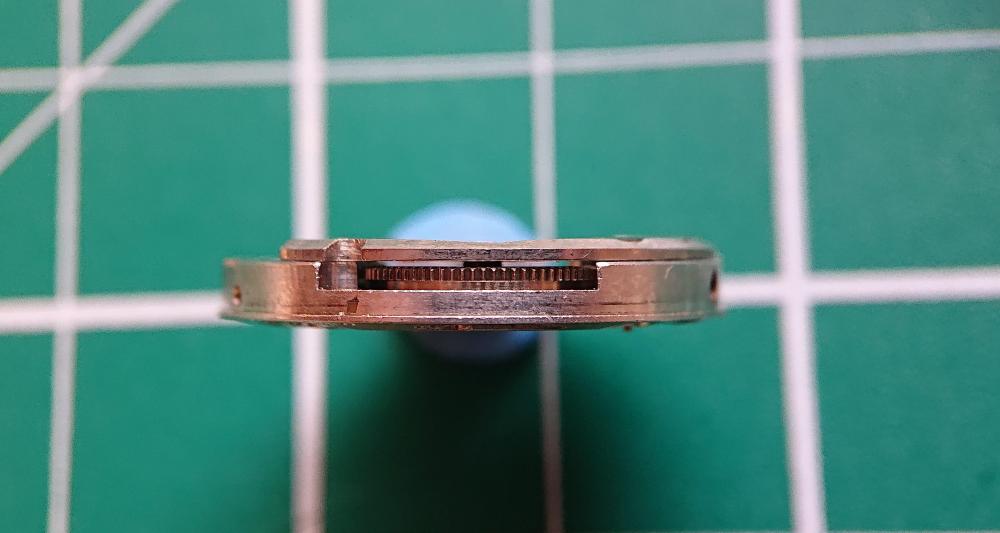

I've taken possession of an Eterna wristwatch belonging to a family member, in need of a service. It's in a sorry state externally. It barely runs and has terrible variation in between positions. It has been serviced in the past. There are four servicing marks in the case back and scratches on all of the bridges. It definitely requires deep cleaning. On examination, I found two significant challenges requiring attention, which are damage to the barrel bridge and the setting lever spring. Spares are no readily available for this movement and donors rarely come on the market. Plus it's time for me to move on from fault finding and parts replacement on to greater challenges. 1: The mainspring barrel bridge pivot hole is ovalised. The barrel arbor is no longer orthogonal to the plate and bridge. There is obvious wear to the upper side of the bridge from the ratchet wheel. I've resolved this issue by fitting a bushing to the bridge. I practiced the technique, refining each time on a couple of old citizen movements before working on the eterna: Having mounted the movement on a wax chuck I centred it on the lower barrel pivot using a wiggle stick, ensuring the movement was fully flat on the chuck: I then fitted the barrel bridge, and bored it out to about 2.7mm to regain the centring. I then bored the hole to 2.99mm using a seitz reamer. Following Perplexr's instructions on youtube, adapted to the tools I have available I turned a brass bushing 3.00mm in diameter and 0.44mm in thickness, pressed it in to place and broached it to size ready for a test fitting. If the fit is good I'l deburr it and re-plate the bridge. Happily the barrel now sits square, rotates freely without side play and with correct end play I then finished the bore with a burnishing broach, deburred and replated the bridge. Regrettably I scratched the surface of the bridge when boring the hole. You can see the scratch running up from the chamfered circle where the bushing meets the original material of the bridge. Oh well, it's only one more of many. It niggles me as I managed not to to do this on the practice pieces. Part 2 of the challenge (the setting lever spring) is rather daunting and I'm struggling to find the materials. I'll post it as a question in the other forum.1 point

-

Sounds like a seller I've used before on ebay, he always states the condition of balance. Little pieces of history. Ive had a few bits and pieces from him. Fine to deal with even on his more expensive watches. There are a few good sellers at the moment with a lot of stock. Id love to know where they get them.1 point

-

@TadasJ@Neverenoughwatches If not ask for an "Material Data Safety Sheet" on it. They have to tell you. And yes I know that their not called MSDS any more but I've been calling them that for going on forty years and I don't remember their new name. Shane1 point

-

Well done matey, dont beat yourself up about the scratch, you've made a cracking job of it.1 point

-

Hi Larry, Nice to meet you and welcome to the forum! I like your break fix routine! I just lose parts. =D happy to have you here with us. -Drew1 point

-

Lol. How do you know, have you tried something different ? I've tried many methods of that approach, launching various parts of a watch at walls. It doesn't work for me but maybe you have a gift for it1 point

-

Well hello Larry. You jammy bugger. Take it as a win matey. I would love to see you do it a second time though . If you do i have half a dozen watches that need new balance staffs, post me your address matey and i will send them your way to drop them in the same manner. Cheers1 point

-

Hi, My name is Kacper. I've been collecting watches for a few years, mostly vintage Japanese and USA watches. My collection is coming close to 30 in terms of size. Lately one of my watches broke so I started to get tools to fix it by myself. Let the journey begin1 point

-

This has worked for me so far. I might look into getting the tool @mikepilksuggests Oh my...I saw this image and then went to the video. Hmm...looks like a screw back before he pops it off. Is it really a snap back? Interesting.1 point

-

Sometimes you have to give the tool a smack with a hammer (small hammer). Case in one hand, holding knife/tool in place, hammer in other. I've only needed to resort to that a few times, and never damaged anything even though it's rather violent. But a friend of mine did it on an Omega Ranchero and the shock knocked the paint out of the original hands... Mike's tool is probably the best bet.1 point

-

Really making good progress on this now. Barrel bridge and setting lever spring are sorted. I replaced the mainspring with the one recommended by cousins (and also on Watchboy's database) and sadly the watch knocked somewhat at full wind. I replaced the spring with one 0.005mm thinner and it now runs well, with about 295 degrees in the horizontal positions and 265 in the vertical. Timekeeping is good, so it's time to reassemble it. The only fly in the ointment is a broken movement fixing screw. I've had a few attempts at making one to match, from pivot steel. I used a razor blade knocked on a #4 file to cut the slot, and a cheap Indian die. First attempt is a good fit but it doesn't look too smart. I made the cap too thin and the finish is rough: Second attempt, still rough: So I've been experimenting with duplicating a variety of screws and finishing them more finely, however I'm struggling to get the crisp finish the original screws have. I I just burnish them with a ruby stone and then an arkansas stone the finish is crisp but not fully polished. If I mirror polish them I lose the crisp edges. I'm using improvised tools (green rouge on a cocktail stick in a rotary tool: Any suggestions for a better way to do this with basic tools would be gratefully received.1 point

-

If you want to get someone's attention, put an "@" in front of the name like @JerseyMo...just FYI Good job with the Timex find.1 point

-

I received this in a box of yard sale rejects. The box cost $14.00 US and had twelve watches in it. That's $1.67 if I kept all twelve but since I have only kept three, I'll accept that it actually cost me $4.67 US. That's only 3.95 pounds stirring as of this morning. Considering that it needed a mainspring that I salvaged from another partial Timex movement, that I already had, I hope it still qualifies. I plan on giving it to a coworker since he has coveted my Timex Camper for some time. Don't let him know it's a surprise. Shane JerseyMo, I read the post on yours. Nice job.1 point

-

If at the time, there was a watchmaker on every street corner and they all used the best practices and procedures, where has all of their tooling gone? There still seems to be a significant number of watches to go around and they all still needed servicing but we have a mismatch in certain aspects of support. I can't see how the quartz revelation suddenly stopped everyone from wearing and valuing the mechanical watches they already owned. I can understand why Timex lost that fight. It was their market base that moved towards quartz watches and servicing their movements never made any financial sense. But better, higher end watches must have always meant and been the status symbol they were and now are. An aspect of that time that I was to young and disconnected from to pay any attention to. Thoughts? Shane1 point

-

I understand how you feel and when I say that every thing has value, there are limits. After hearing how Mark was tasked with a cheep alarm clock to practice his manipulations, I first took apart dozens of cheep quartz watchs with the understanding they were never going to work again. These watches often have parts so small that ladies mechanical movements will feel massive afterwards. I still have several little containers of screws, hands and one of jewels that I removed from them. Everything else was scrapped. I would think that this type of movement would be readily available in Hong Kong. The best of luck. Shane1 point

-

thank you for having me disable retired old nut trying to change crystal on wrist watch every video wants you to remove the watch face by removing the case back unfortunately the face is larger / and or being blocked by addition metal seal stuck here are the specs Watch Information Brand Name Saa'i Timepieces Part Number AAW-02-TG-SL-B1 Item Shape Round Dial Window Material Type Mineral Glass Display Type Analog Case Diameter 40.00 Band Material Leather Band Color Black Special Features Chronograph Movement Japanese Quartz (Miyota Watch Movement) below is the watch in question please offer any and all advice1 point

-

You guys do know you don't have to buy the WHOLE Bergeon mainspring kit right? Just buy the winders and arbours as you need them. Sure, you have to wait on shipping for the first time you need it, but then you've got it for next time. Most popular for men's wristwatches are the #6 and #7 ones. So get those to start (right and left set) and you're in for maybe 200GBP. Then you add as you need in future, bringing the barrier to entry muuuuuch lower, without resorting to having to molest mainsprings by winding them in by hand. If you're working on something you're not likely to work on ever again (like a pocket watch), then just buy the mainsprings themselves.1 point

-

I would sand them down and try to get the grain as straight as possible on the last few passes. Most flat surfaces have some 'surfacing' to help stop the spread of oil so a polish may not be the best thing. A straight line rough finish using sandpaper may not be as good as the original geneva stripes or perlage but may be better than a fully polished surface. rgds Anilv1 point

-

As you look at the wheel that has the warning pin that is next to the fly wheel imagine you are looking at a clock face the pin needs to around the 10 to or there about. The rack if its a rack striking should drop onto the Snail this will then strike the number one tooth at a time will be gathered by the gathering pallet.1 point

-

Difficult to say from the photos if the discolouration is on the surface or underneath. Hopefully it is surface , depending how thick the plating is how much polishing it will take. Start off gently with a dry microfiber cloth, if this is not enough then a light metal polish like brasso is not especially abrasive. Solvol is more so, i often use this on plated cases with good results though. A good plating will withstand a light machine buff with a high grit compound. I haven’t managed to wear though a plating with a buffing pad as yet and the results are usually very good. Watch some of the nekkid watchmaker's videos. Joe is bloody good at case restoration, it will give you an idea of how much a plating can take. Generally a 10 micron plating is pretty tough and will take some machine buffing. Just to add to this Thor. The bezel on its own will be relatively flimsy so any over enthusiastic polishing may distort it. To be on the safe side mount it on the empty case first. Always best to ask the seller for an honest appraisal of the item they are selling.1 point

-

Goodness, thank your for taking the time to type out all of that information. I, along with others I'm sure, certainly appreciate it. When the part arrives I will take some high resolution photographs and post them to the forum. In the meantime, I will try to research alternative methods, including what you described in your reply. Thanks again.1 point

-

Fungible. Now that's a two dollar word. Someone used the word gleaned earlier dut I didn't have time to respond. I just started a thread about Timex watches in "Chat About Watches & The Industry". I didn't think it was appropriate here. Shane1 point

-

I have not received it yet...it is in the mail, so I cannot say much about it until I do. I am optimistic. Yes, the jewel plate is as you read it. I just turned a staff that needed a pivot size of 0.12. I used both the jewel plate and a micrometer to cross check. While chucked in the lathe, you have to be careful with the jewel plate (or anything for that matter) because it is easy to cock it slightly and bust the pivot. My jewel plate was part of my inheritance, but I have looked at them on ebay out of curiosity...yup, pricey. On dimensions...the JKA tick marks are 0.01 mm (10 thousandths of a mm). This is, 10 um. I prefer to think in terms if microns because that was my life in semiconductors for 40 years. The jewel plate is marked in hundredths of a mm. Confusing.1 point

-

I have recently moved from someone who has a watch to someone interested in watches. Then to focused interest and collection (4 Omegas). And now to horology. I like to buy non-functioning watches at flea markets (average cost $2 each), fix them up (usually cleaning and a new battery), and give them to people disadvantaged and in need of a timepiece. The most complicated things I have done involved replacing a quartz movement, which gave me some practice in dealing with hands. I have dreams of learning enough to tackle simple repairs of more complicated watches. But if it doesn't, that's fine. I am a retired academic with a few serious interests, this becoming one of them. I have found some of the forum threads here very interesting, and hope I can find a way to contribute. Del Kimbler (DelK)1 point

-

Best option in my opinion. Hand winding springs in always leaves doubt about what damage could have been done. Have you ever taken a spring out and seen that its coiled upwards? Usually that's because its been wound in by hand - and so the spring can potentially be rubbing on the barrel lid. Not judging - I've done it myself in the past, even automatic (slipping) springs, but you never know if damage has occurred unless, of course, if you remove it again to inspect - a new spring is pre-lubricated and ready to fit into your cleaned barrel, and they're relatively cheap to purchase. Using Mainspring winders, like many aspects of watch repair, takes practice and patience to use them without damage - but I personally feel that the potential for damage is greater with hand winding in.1 point

-

I couldn't get on with watch mainspring winders. If you know how to take the spring out then do so and clean the parts then use finger cots and put the spring back in then oil the spring, some will oil the shoulders of the barrel first before putting the spring in.1 point

-

Not easy to film - but I managed to film it in one of my Rolex YT videos - you just have to search. Also, this doc included with the Rolex microstella tool might help you... Microstella Tool.pdf1 point

-

This is iteration number six or seven...it is hard to keep count. Methodology for this turn was aided by a number of phone calls with a forum member...coaching me... I made a carbide file to do the finish work on the roller side. It polishes extremely well. Full disclosure...I started with a large pocket watch staff because I have had some issues with my other starting material. However, I made every cut except for the hub. I am posting this now while I am happy before disaster strikes. Today, I will install the balance, check the fitting in the watch...then install the rest. No matter what happens, I can say for sure that my skills (minimal as they are) are improving. I think the pivot on the left is a little short, but hoping it will work fine.1 point

-

the problem will be usually tag modifies the components which is why the number after the decimal point isn't showing up on the typical lists. Like for instance at the website below has a whole bunch of 555's just don't have 232. although second link has the parts list. So we really need is a 555 manual and the parts list you should bill of figure out what in the obtaining that that will be the challenge conveniently it and not go spend a lot of times and 70 found you some links I'm not seeing any 555 manuals out there? But you can use a similar manual and figure out what parts you need is are all really basically the same can't quite remember but I think sometimes you can change the first number and it becomes a higher a lower grade movement so you may believe is a 255 manual for instance just to get an idea what the part numbering is and then look on the parts list. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA-ESA_555_111. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_555.232 turns out cousins has a 555 something manual is a said you're not good I probably find the exact manual but he should bill still figured out from the parts list the manual etc. but you're still stuck with the watch companies like to make subtle little changes because they can because they were buying the movement and I'm surprised we were not a parts list of be surprised if you get some of those parts but maybe you can 3259_ETA 555.115,125,415,425.pdf1 point

-

There was a discussion yesterday regarding the morals of owning a Russian watch. Mark pointed out after it got too political, that there are plenty of forums to discuss power crazed genocidal manics, not in those words of course as he is too polite and sensible, my own embellishment of those same feelings. Never the less he was present, or with my conspirative thinking mind someone that has access to his account.1 point

-

One of the main issues I faced, is if the plunger doesn't snugly fit inside the housing barrel, it wont be able to plunge correctly. The mainspring tail would get caught between the gap while plunging. What I did was, I would always print multiple plungers and hope one of them would fit snugly. But this is not a good solution for everyone. Lubricating the mainspring and barrel helps a lot, but is still not a solid solution. So I had a good think about it, and added three 'teeth' to the plunger. Low and behold all of my prints work regardless of how snug the plunger fits! Please print the latest version with this change (release v0.5 and above).1 point

-

Yes this can be tricky. If winding in by hand I find it useful to place the T out of the hole and whilst you are winding in it will slip round (it does this naturally) and when you have several coils in then you can push the T further round until it engages the hole, then continue winding the spring in. Not easy but works well after some practice. If winding in by hand then don't pull the coils to tight. And I am aware that some repairer purists may scowl at me for ever suggesting winding in a spring by hand, and they would probably be right :) The old mainspring winders (similar to the ones clockies use) are the correct tool to use I believe - I have to say though that I have never used those, I confess that I put these ones in by hand being careful not to kink or stress the spring. You can tell when a spring has been badly coiled in by hand - when you remove it it goes into a cone shape.1 point

-

I have always cleaned the balance mounted to the plate, with the jewels in place. That's how I was taught when I was an apprentice and I have been doing it ever since. Never once damaged a hair spring, never once broke a pivot this way. I have broken pivots in other ways but that's another story :)1 point