Leaderboard

Popular Content

Showing content with the highest reputation on 05/20/22 in Posts

-

2 points

-

If you're doing what you're supposed to be doing you should never see a magnetized watch. In other words you're always taught to demagnetized before even putting a watch on the timing machine. Which is why the pictures below were always interesting to me? I was doing a comparison of the Chinese machine with the witschi timing machine. The person who loaned me as Chinese timing machine gave me his collection watches because he was being puzzled by the results. I'm also attaching a PDF which tells you what magnetism looks like. So as you can see a watch that's magnetized can have a sine wave effect. When it's demagnetized that goes away unfortunately this watch was an extreme desperate need of servicing. There are other ways of show up with the hairspring is stuck together of run fast basically wanted demagnetized It any time you're putting it on the timing machine just to be safe Timing-Machine-Charts.PDF2 points

-

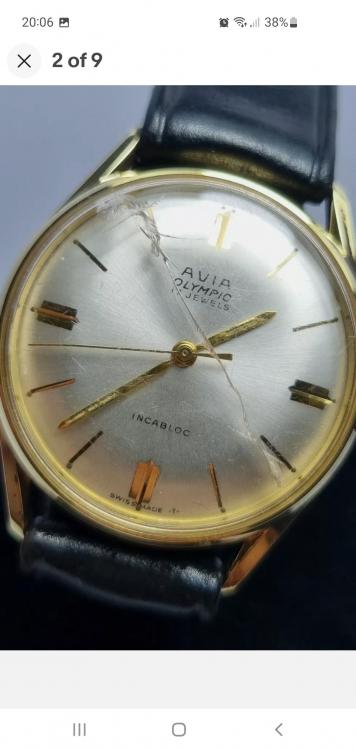

Hi, Thanks everyone for your opinions, although I was suspecting that the watch was a fake, I just wanted a more knowledgeable opinion here. I do agree with Neverenoughwatches that this piece doesn´t have any of the Seiko 5 attributes (https://www.seikology.net/blog/the-history-of-seiko-5), therefore, it is a fake beater, probably as Watchweasol said a Mumbai special (surprisingly, I´ve seen several around here). I do agree with most of the opinions that the cheap movement make it not worth the hassle to fix it, but I have a lot of fun doing it and learn some, so for me it was worth it. Second quartz movement in my hands, the first one an Omega 255.411... that took me a while since it has the wrong minute wheel. Hopefully, there was a wonderful tutorial with images in this forum, that allows me to note the wrong wheel. Thanks a lot.2 points

-

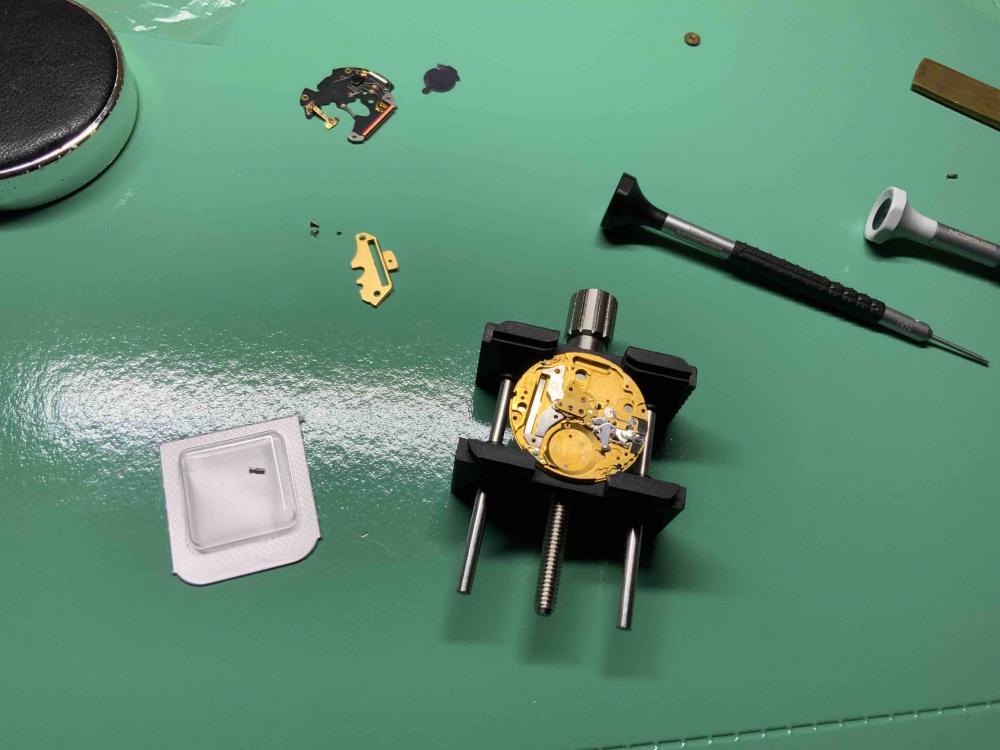

Sorry if this is repetitive, but I want to be sure I don't mess up this mainspring install since it's my first time. I posted a photo to be clear what I'm doing. I have the new mainspring in the container. Do I cut the seal from the bottom with the cardboard, or the top with the plastic? Which is easier? I take it the red object surrounding the spring is the washer holding the mainspring in place. How firmly in place is the mainspring? What's the tiny piece of cardboard inside the container? My understanding is that this is a clockwise wind. I read that it's best to use the end of tweezers to position the mainspring when inserting. How hard do I press? Do I pull up on the red washer with my finger or use a tool? Is there a video? The old mainspring is shown bottom right. I ruined it, but that's another story. Thanks.1 point

-

1 point

-

Don‘t know, but you can follow this logic: The pinion on the escape wheel should mesh with the so called „fourth wheel“ which again has a pinion that should mesh with the third wheel. The third wheel has a pinion that meshes with the center wheel on which the minute hand is positioned. The center wheel should have a pinion that meshes with the teeths of the main spring barrel. The wheels that have not been in place should be the fourth and third wheel.1 point

-

Welcome to WRT forum and good luck with your forey into horology.1 point

-

Best to clean without taking the jewels out ( clean in place) as you would a rubbed in setting. Tabs are not made of spring and if bent then setting would be permanantly loose.1 point

-

This was a sad phase of watchmaking with lots of corners cut to get the price down on many lower end movements. All of the ones I've seen like this require the tabs to be bent up to access the jewels; so you can imagine after a couple of servicings things don't work too great anymore. I don't recall if there are extra ports underside to allow an increase of cleaning solution contact- sometimes they did this with "permanently" mounted cap jewels, but either way, if machine cleaning with modern solutions usually they come out clean enough without disassembly.1 point

-

I do have to wonder why were grinding a component in existing watch?1 point

-

The retaining ring holding the mainspring you usually isn't plastic. Usually on the modern ones is anodized aluminum. Most of the time it's colored on one side to tell you that that's the side that supposed to go out. Then when you're inserting the spring you do want to be careful that it actually does go down in if you use your finger or something you can get the center part in but you might not get the edge in see what do want to be careful that the spring it does get into the barrel before you try to remove the ring.1 point

-

From the beginning of time roller jewel's did Come in a variety shapes including round. Usually all the weird shapes were in the earlier versions of watches. Typically on a lot of single roller watches the hole was drilled round and you're still stuck trying to get a half Round jewel into the hole kind of a pain it's much nicer if the whole is properly shaped.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

I put in the GR6773, and I have yet to put it all together. I am having a look at the balance and the spring, it seems to not be symmetrical when running.1 point

-

Hello and welcome. My results have been mixed too but I bet it's not uncommon for us beginners. For example, I struggled to get a balance on the right side of the fork and eventually dropped it on the floor. Tangled hairspring, got it on the correct side first time after that but obviously wouldn't run. Hehe.1 point

-

Pretty straight forward really. It came to me because the customer had had winding issues and the two piece stem had been pulled all the way out, so liberating the movement was just a matter of removing the crystal and it fell out. I don't know if they are all like this but the crown on this one had a very light line etched across it in the same orientation as the connector in the split stem so if the crown is still in situ all you have to do is align the line on the crown vertically and the movement will just fall out, no pulling with pincers to separate the stem. The movement is an ETA 2372 which is a straight forward manual winder. This one had issues though. It had an incorrect spring for the hack which was what was causing the winding issues, the hack pin which contacts the balance wheel to stop it was bent over flat, I found a paper shim under the train wheel bridge without which the centre wheel bound up tight as a result of zero end shake, and it had the wrong mainspring fitted. I couldn't get a replacement hack spring so I modified the closest replacement I could find so that it works. Straightening the pin was easy, as was adjusting the center wheel end shake with a jewel press so that I could do away with the shim. After that it was a straight forward service and fit the correct M/S. It's a really nice watch actually and I wouldn't mind owning one myself.1 point

-

1 point

-

@Randy55that's really helpful, thanks so much. The D-shaped jewel I have is indeed a perfect fit in the fork notch. I've got it shellacked in now, so we'll see if it will hold. So far so good. Thanks again!1 point

-

1 point

-

Hi John I found this from an old NAWCC forum response; Sometimes the manufacturers drilled a round hole even if the roller table was intended to hold a D shaped jewel. It was done because it is less costly to drill a round hole than to drill a hole then ream to a D shape, and it serves the same purpose. The D shaped roller supplies a more powerful impulse than the round jewel will, so I would advise using a D shaped jewel. you can use a D style roller jewel in place of the oval roller jewel, if the supply house have oval jewels that will be a new one on me. Been at the bench for 52 years and even though your watch had a oval and most likely factory there is no problem using the D style as long as the slot opening on the tail of the pallet fork has the correct size and you have properly shellacked it in place. Hope this helps Randy1 point

-

A typical newbie mistake is to assume that all individual components are individual and can be replaced individually. Typically on modern watches they hairspring is individually vibrated that meets its match to the balance wheel it's on. This means that even a modern watch they do very high tolerances you cannot swap they hairspring you will have timing consequences because the balance wheel and hairspring are not matched together there are exceptions to that if they hairspring is premade because it has an over coil then they can be replaced but? But this means the balance wheel now has to matched the hairspring at one time there what about an assortment of timing screws to allow you to match the balance wheel to the hairspring. Then there would be some fine tuning of trimming the undersides of the screws usually get everything the match in other words it's a lot of work. The easiest way to deal with the hairspring for the watch you have is something like this https://www.ebay.com/itm/115166778552 This is a balance complete this is typically the way if you need a balance wheel you would get a balance complete. Just make sure the balance wheel looks like the one you have there tend to be variations in American manufacturing especially with older watches where things well the book may say they're identical but the book is wrong there were variations.1 point

-

Tbh i didnt find it difficult to fit the pin and at the time i used an unadapted cheap pair of tweezers, as it was at the very start of my learning and was a case of a necessity and to just get the job done.The thought to trim one tip down came later. It might be that I'm lucky as i have a very steady hand even at 55 yrs. I have a very healthy life style, i dont drink smoke or take drugs and my diet is bob on. So I'm sure that all this helps. Any hairspring work i will make sure my blood sugar level is steady, a drop there can really affect your hands on fine manipulation. Fine tweezers a fair microscope and a steady hand. Superman does the impossible, we can do what is possible.1 point

-

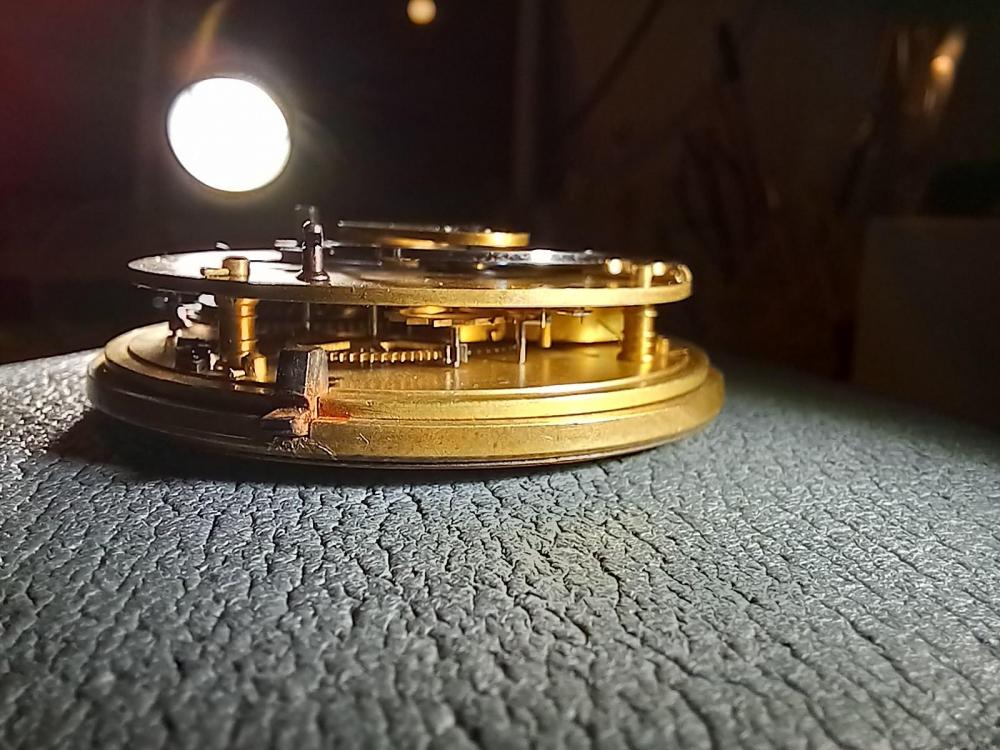

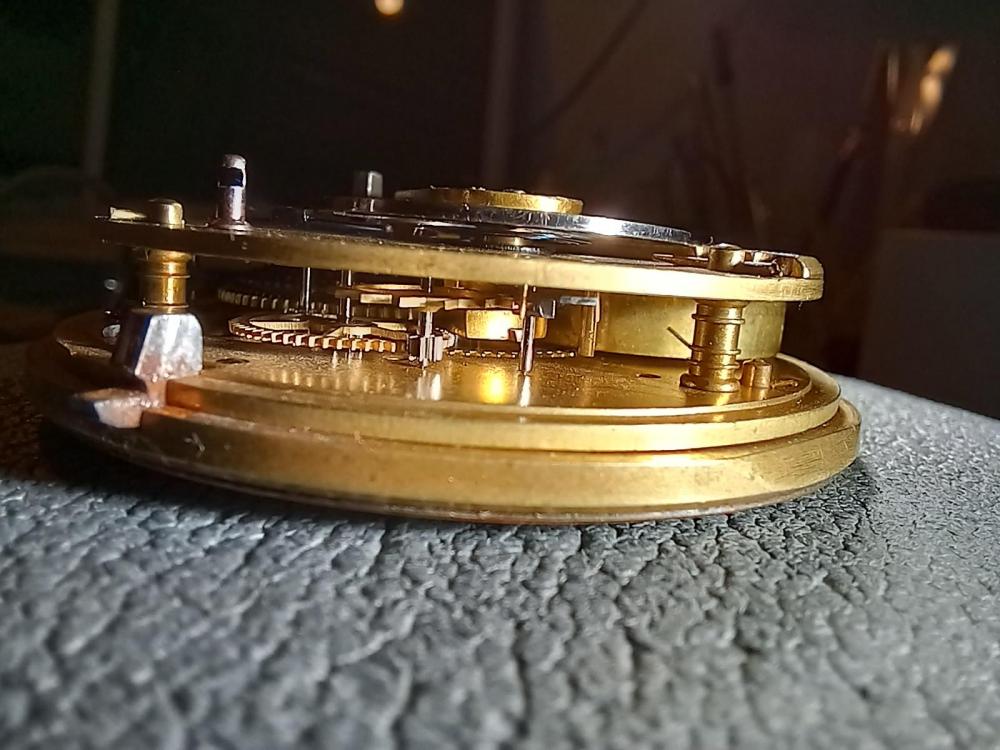

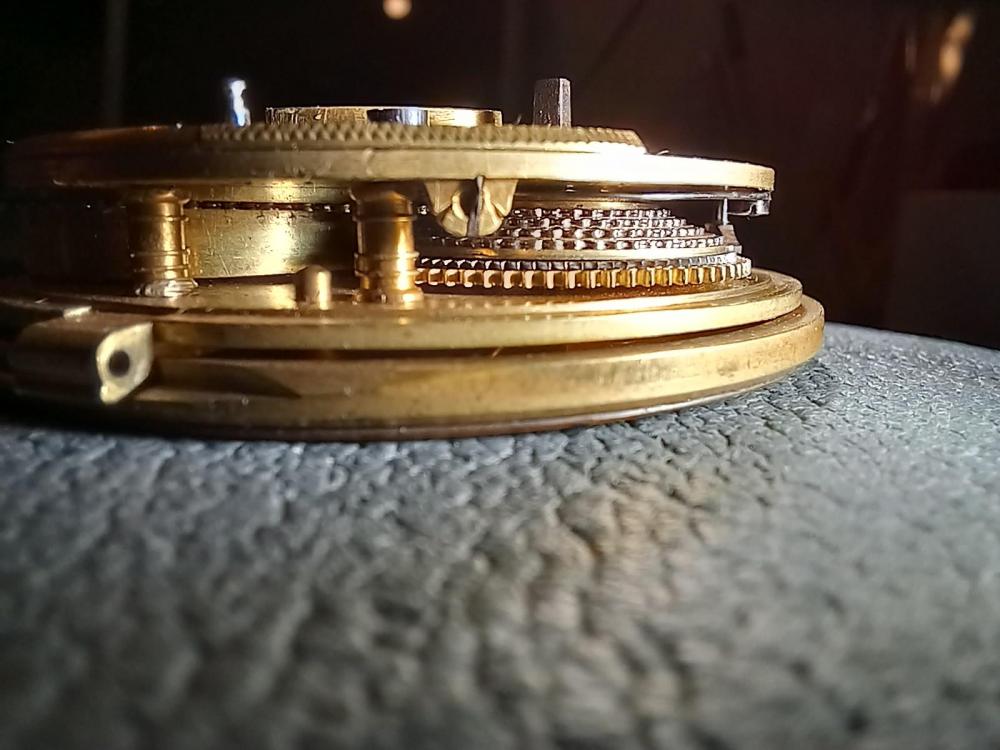

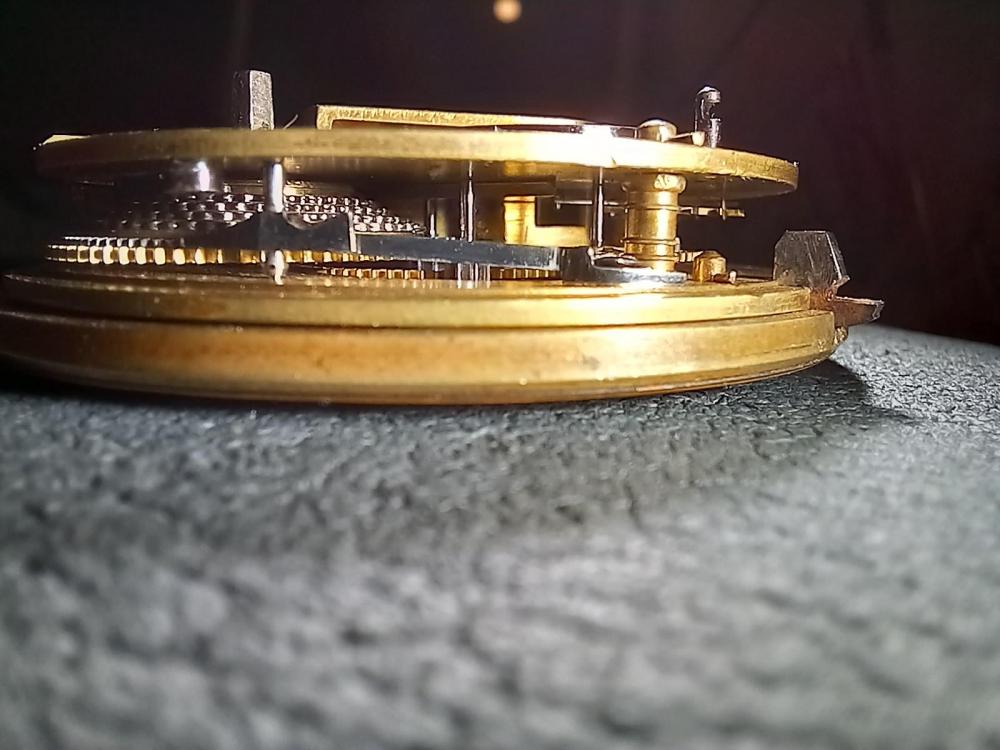

I thought I would add this as my first true achievement. I got the Audex running well but it's a movement only and we all know how hard cases are to source. I got a Smiths Empire pocket watch going but not keeping good time, I don't think it's worth the effort to go further. I have got several other movements to run. But this is my first one that I am proud of. Full service and keeping good time, don't have a timegrapher yet, my next purchase. Hands could do with a re-lume.1 point

-

Welcome to the forum! While you probably already know that the best way to solve your missing part problem is with an identical movement that has the parts you need. You may not realize that the hairspring and balance were typically matched at assembly. While I was working on an old Elgin I also found out that I couldn't just swap out a complete balance from one movement to another of the same grade since one had a double roller balance staff and the pallet forks were different. The two grade 313 movements had been manufactured 26 years apart. The screws ought to be easier to solve than the hairspring. Good luck!1 point

-

Thanks ww. So I'm really looking for three different parties. The case maker, the movement makers and then the finisher. I know that ingersoll and smiths were connected for a short while and that Ingersoll were American. I'm going to go through some company dates. The dial I suppose could have been swapped out for a no name, it does look in quite good condition. I'm more interested in who made the movement really . It needs servicing, it's escape time slowed down to once every three seconds on my bedside cabinet and was quite loud, it was rather unnerving and spooky. I think I have some strange mediumist talent going on in my head haha. Hi John yes it's near the beginning of this thread . I'm not sure how to get the movement out of the case. Found it. A pair of specks really helps. Lol Oh my word . Ive just been watching it run under my scope. I think I've just fallen in love with pocket watches. Hi John. I've worked out was going on. I'm home now so stripped the movement out of the case. There was no duty stamp, it was the winding stem that has scored a mark in the case back. Behind the movement are the same marks . The passant lion , the town assay (london) and the year letter 1876 and then the makers stand W C. and the journeyman stamp x. Were duty stamps a later addition?1 point

-

The usua w l method was that the watch maker would order cases from a maker such as Dennison who would make the cases to the specific sizes of watch, Of course being silver they had to be passed by the assay office hence the marking and date coding and the grade of silver used. In some cases the watches and the dials and cases ended up with the finisher who assembled them all together and fitted a named dial. He was not always the maker, people like bensons , smiths, ingersoll and may others made the complete watch and assembled it.1 point

-

Hi just setting up my new location from office to my conservatory I have yet to make a tall table to work from. You will see around the photo's that I had converted it to a Art studio about three years ago for air brushing but I couldn't control the air brush very well I even had lessons but gave up. So apart from my microscope what else is needed to complete the work shop for now. I do have a ultrasonic cleaner and I am using a 3D resin washer as a IPA last rinse cleaner it works quite well but they are in the garage. Lighting is all daylight bulbs and led panels above (two) any advice on improvements are very welcome1 point

-

1 point

-

Hi gang, I have replaced the battery in my wife's ESQ quartz watch. It has a snap back which was very difficult (for me anyway) to open. I replaced the battery and replaced the gasket with one that was as close to my measurements as possible, using a set of calipers. The gasket seems to fit pretty well, but when I attempt to snap the case back on the gasket spooges out and now looks kind of stretched. When y'all size your gaskets do you choose the exact inside diameter to match the back or do you choose one slightly smaller so that it stretches over the back? Also, is there any magic trick to getting a really tight snap on back snapped back on? Thanks all1 point

-

My wife has just informed me that Vangelis has died aged 79. An incredible composer and 79 is too young. I mean, who doesn't know Bladerunner? I know that some people on here listen to music while working or play themselves, so I thought this might be of interest to some. RIP0 points