Leaderboard

Popular Content

Showing content with the highest reputation on 03/31/22 in Posts

-

The hairspring must be flat. Imagining a watch where there aren't any twists or bends at the stud, the hairspring is good, if you look at the spring it will be flat; not just not tilted, but not cupped up or down. If the stud is too high the spring will be cupped up, in a concave shape; if too low, the hairspring will be cupped down, in a convex shape. The correction is to adjust the height of the stud*. Perhaps you didn't notice that it was cupped up, and have now corrected it- but check that it isn't cupped down now! Too far and the spring can touch the balance arms, but regardless for good timing it should be nice and level and flat. *Some watches have no height adjustment at the stud. That's a whole other can of worms.2 points

-

1 point

-

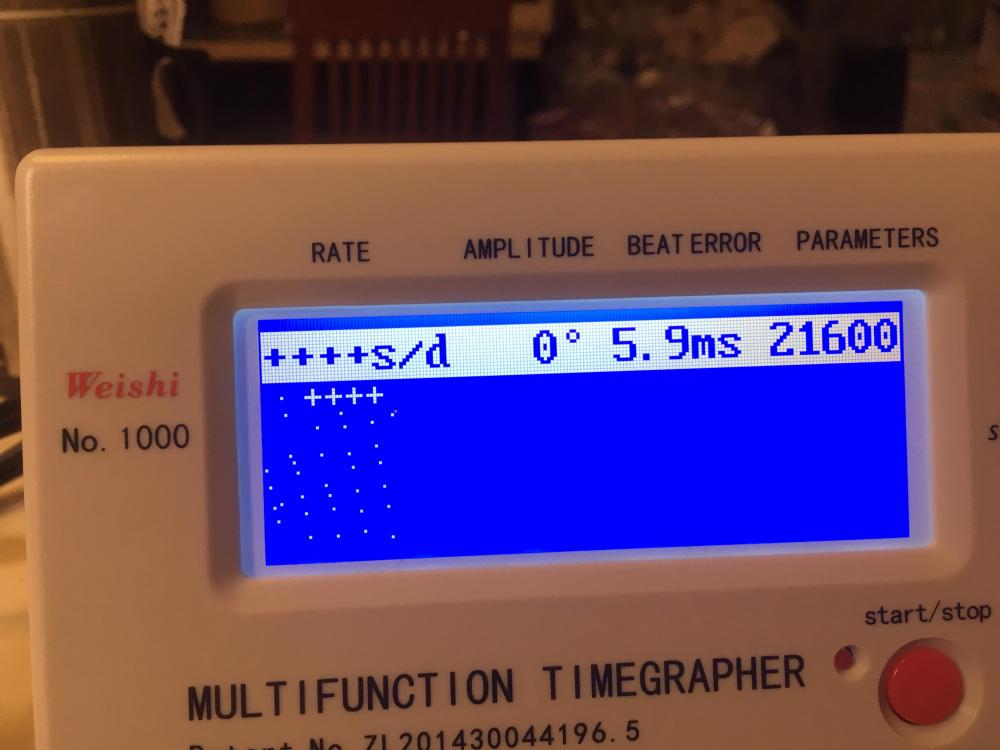

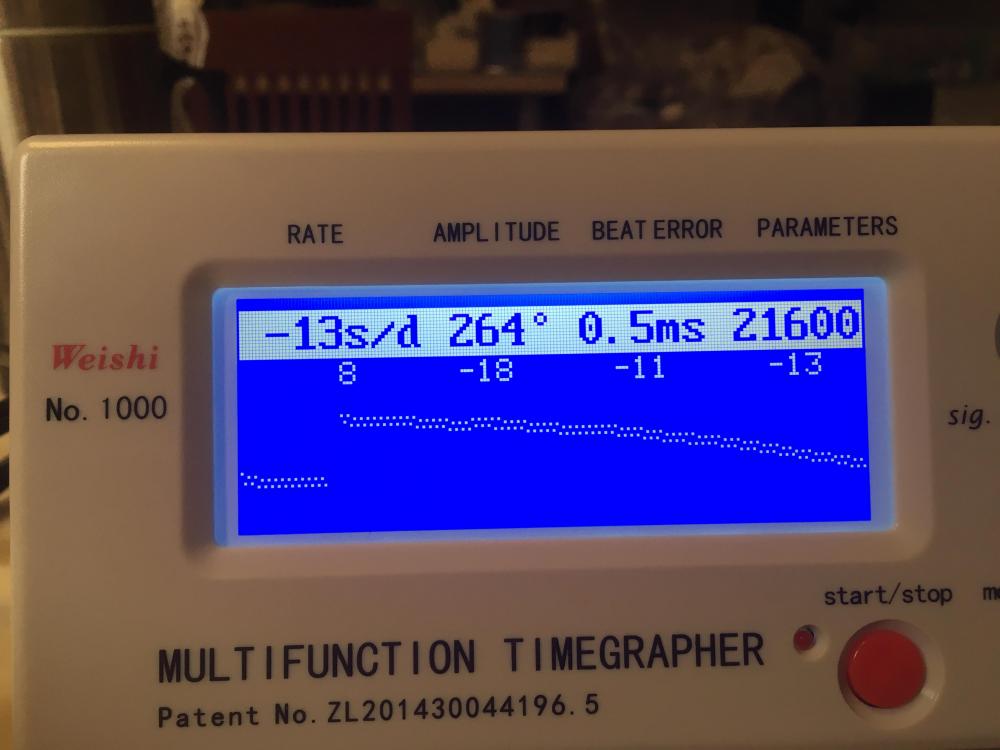

After reassembling the Tissot 2700 hairspring into the balance cock, I faced perplexing timegrapher readings. The amplitude looked good visually, but the timegrapher could not get a reading, and showed “snow” in the short instances where it got a reading. After repeated reassembly, cleaning and oiling, during which I wondered if I had damaged the escapement, or hairspring, I found out that the hairspring was rubbing onto the Center wheel. I got a clue when I heard some squeaking faintly. After pushing the hairspring stud lower, the timegrapher could get a reading! initial timegrapher read out initial hairspring stud position. Final timegrapher reading final hairspring stud position Reason I am posting this is because I couldn’t find any mention of this in the forums, although it is implied in some other posts.1 point

-

Are you using a plastic sheet as a dial protector? That can make it difficult for the hand levers to reach under the hands.1 point

-

From the document: The movements of the stopwatch minute hand and stopwatch second hand are interlocked. To set the stopwatch minute hand to the "0" position, continue to move the stopwatch second hand until the stopwatch minute hand reaches the "0" position. Since when doing the above, or just the normal reset, the seconds hand makes a full turn in like 1 second or less, the time taken is not too much to reset from a maximum of 30 minutes. If there were an hour counter that approach would be undoable. Note i corrected some wrong stuff I wrote above.1 point

-

as a student of geometry...I would say "coplanar spiral." In my other life, I read patents and provide technical analysis in a legal setting to same...so I get all wrapped around the axle on terms...it is an affliction.1 point

-

The height of the stud is important not just in troubleshooting but in regulation and adjustment also. Some teach to loosen the screw and let the stud find its own natural position. I suppose that more on the matter is in watchmaking books, of which I must admit I'm not a big reader myself.1 point

-

Again, I'm sorry but you are confused about what the shop did . We have contined discussions about quartz watch tools costing from 10 to 10,000 pounds and pretty much know what is available and what's not. Look at the devices that you have found online, and let us know if in their description it says anywhere that they can reset chrono hands. Please post a picture with the caseback removed to identify the movement. A fashion brand and model don't mean anything. There is no such thing as 'inadvertently' in watch repair. I am also afraid that you don't know how much branded quartz tester do cost, so have a look www.cousinsuk.com/product/witschi-quartzmaster?code=T61137 And they don't reset hands, why? Because they can't.1 point

-

Please post a picture. On the quartz chronographs I have worked on, there is a calibration procedure. Something like pull out stem to second or third position, then adjust the hands with the pushers, then return the stem to run position. no external tool is needed.1 point

-

I expect it all down to cost and manufacturing. You might ask why are the plates in American clocks so thin and skeleton type and not solid, all down to cost.1 point

-

Can't the pin be punched out? I guess you don't have a staking set, a nail might work. if you get it to move a bit penterants would pentrate in.1 point

-

Hello and welcome to the forum. attached a useful reference document for you. TZIllustratedGlossary.pdf1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Welcome to WRT. For a start, a simple magnifying loupe with a headband will do. 2Pcs 5X 10X Headband Monocular Eye Magnifier Magnifying Glass Loupe Lens Set Watch Jewelry Repair Tool Accessory For Watchmaker https://a.aliexpress.com/_m0Kef9U I think all of us will go through a dozen or more magnification devices and still hunger for something better. I went through simple loupes, headband magnifiers, clip on loupes, surgical loupes, etc. I'm currently using a stereo zoom microscope and it serves me very well. But I'm looking at a digital zoom microscope for very high magnification work. Enjoy.1 point

-

1 point

-

Hmm, ok. It has the right shape, still looks like it's been "modified" in the past. If the old one was riding up that's a sign that the divot was put too high; it's not making good connection with the slope. If the new one is too tight to fit all the way it could be that the diameter of the center wheel shaft is too large near the actual pivot portion (which from the photo could be true). Or it could be the divot in the cannon pinion is simply too much. My gut feeling is the former. If I had it here I would carefully check the diameter of the shaft, at the shoulder and further up, to be sure it's cylindrical, then gage the hole in the cannon pinion with a plug gage, then do whatever modification necessary. Do you have a micrometer?1 point

-

Another "makes it look so easy" video by one of our members @Repivot, this time about hairspring manipulation. https://youtu.be/IoBd-oxpEZ41 point

-

Hi Daniel. Oil thickness, or flowability, is indicated by viscosity (typically at 20 deg C). M8000 = 95, M9010 = 150, M9020 = 270 and M9000 (Quartz) = 100. So nearest to M8000 is in fact M9000 but M9101 is the standard for watch balances etc. The 8xxx series are mineral oils (ie natural hydrocarbon oils) and the 9xxx series are based on PAO synthesised oil. The latter has much better operating range, greater stability, oxidation resistance, and has an added anti-wear component, so will last longer and perform better. There is a 'viscosity change' test (but will not go into details) and for comparison 8xxx have +18% compared with 9xxx +2% (ie less thickening over time). Thinner oils will offer less viscous drag and the faster a part rotates the lower the viscosity requirement, hence a thin oil for the balance end and thicker oils towards the mainspring end. I would always go for the synthetic types despite their initial costs.(My earlier posts 'Lubrication Basics' gives more info and there are plenty of other posts to help you). Trust this helps a little.1 point