Leaderboard

Popular Content

Showing content with the highest reputation on 11/25/21 in all areas

-

Thanksgiving is an American holiday and this is an international forum. Nevertheless, I would like to express my thankfulness to this Forum and all its members. Today, I became a patron to express my thanks in real terms. In addition I would like to specifically call out names of members who have been particularly helpful @Mark @JohnR725 @nickelsilver @HectorLooi @Nucejoe @jdm @watchweasol and many others!3 points

-

Well the watch is back on my wrist and the periodic amplitude variation is better but not gone completely. In the process of working on the issue I actually made the situation much worse with amplitude dropping to 180 degrees from 220 degrees. What I had done to cause that was to close the oval upper barrel arbor hole and make round with very little play. What I had done in effect was to move that barrel arbor hole back and away from the centre wheel and fixed the barrel arbor in a slightly tilted position. This caused the barrel teeth to run at the top of the centre wheel pinion and actually ride up the pinion and bind every 5 minutes. I fixed the issue by using cutting and smoothing broaches and staking set (6 or 7 small indents on the side of the arbor hole that was away from the centre wheel) to effectively move the barrel arbor hole back towards the centre wheel. Now getting 270 degrees at full wind and dropping to 255 degrees periodically (probably not solvable without replacing parts, centre wheel pinion and barrel teeth have some wear). All's well that ends well.2 points

-

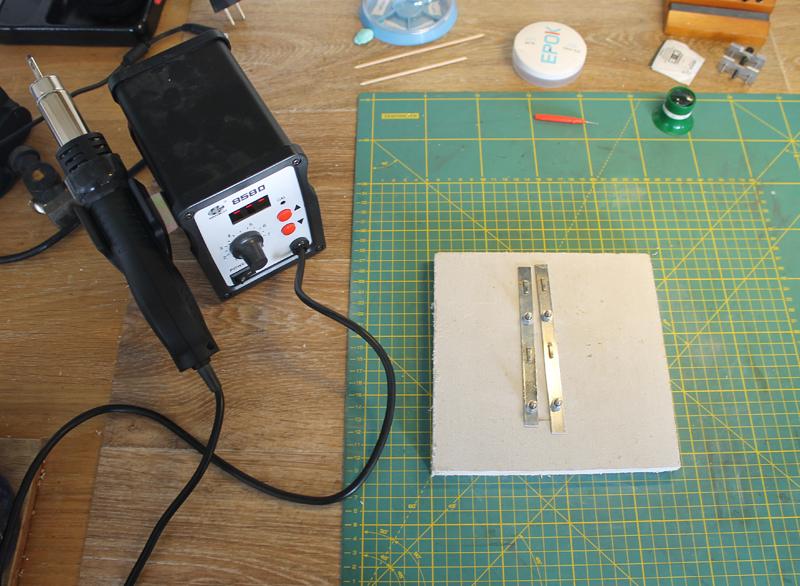

Thought it may be worth to share; I received a pretty beaten up, none-running 1890-1900 cylinder-escapement pocket-watch. It had all sorts of problems, a list too long to go into details. Among those problems was a bend/broken minute hand. It inevitably broke off when trying to straighten it. The center-hole diameter of the minute-hand was 0.5mm and the length was 15mm. The hour-hand had a hole diameter of 2.0mm and the length was 10mm. Searching the internet to find an identical set proofed futile. The watch is a heirloom so originality was a priority. The hands turned out the be made of bronze, a copper-tin alloy. Therefor it made sense to attempt soldering but the part that had to be soldered had a thickness of only 0.3mm. Both parts had to be fixed in place with a sort of clamp capable to fixing both parts, being heat resistant and "none-sticking". A soldering iron, even with the smallest tip, would be far too big for the job and to avoid touching the parts, I choose to use a hot-air gun used in electronics for soldering SMD-components to a circuit-board. A few test were made which tin to use and at which temperatures. 300 degrees C with tin used in electronics seemed to work fast and made the tin to flow nicely. I used a soldering flux-paste. The clamp consisted of two metal rails, slightly diverting from each other to give many clamping options, bolted on a plate of gypsum. Pulling over a #1000 grid sand paper, I made two 45 degrees chamfered edges on either end of both parts; The two parts were clamped in; Applied some soldering flux, heated it all up to 300 deg.C and applied a tiny bit of tin. Once cooled down, I removed some excess tin with a small diamond file. Here a picture of the back side of the minute-hand; And here the front; the tin didn't flow further away from the soldered joint or around the edges Most likely not the strongest repair in the world, but when not touched it should be strong enough to do the job. On the picture the hand color looks black, but that's due to the lighting. In reality the hand hasn't lost any of its shiny patina at the front ...... Anyway, I thought to share this repair as one of the many different possibilities1 point

-

Something I've encountered before in other watches reminded me to ask this. You wrote "The small second hand is so close to the dial that I definitely need to right gear to get it off." And earlier you wrote "The balance does rotate when moved and the watch ticks for about 10 seconds and then stops." I have encountered watches with sub-seconds hands that were rammed on so tightly that they inhibited the watch's ability to run somewhat. See how the watch behaves after you've raised the seconds hand to just above the dial. A tiny bit of clearance may make a difference. (You'll still need to clean it anyway, of course, but I wonder if it could run after getting some clearance with that hand.)1 point

-

So you are up and running, good feeling go the watchfix way and you will not regret the investment. buy the best tools you can afford at this point and as you get better they can be replaced . more than anything enjoy it.1 point

-

I have a plastic box with many small compartments used for storing pills, that I have labeled with the common parts of watch movements: balance cock, pallet fork, train wheel bridge, barrel bridge, click, keyless work, motion work etc. I put the screws from their respective parts into them to avoid mixing them up. in practice, most movements have the same screws for the bridges (balance cock, barrel bridge, train wheel bridge) so you don’t have to clean that many screws separately. Most of the time, the bridge screws, motion work plate maintaining screw, and keyless work screw are the ones that you have to separate from each other. The ratchet wheel screw, click screw, or crown wheel screw are usually distinctive enough not to be confused with the rest.1 point

-

Good for you! That's money well spent. I would rate the stereo microscope as the best upgrade for any watchmaker. I'm glad that you got the dual arm boom version because that allows you to tilt the microscope. That 15 - 20 degree tilt makes a world of difference. It puts less strain on your neck and back. And having the view off axis means you won't be blocked by your hand and instruments. I attended a webinar on the use of a clinical microscope in Dentistry a couple of months ago. The speaker said that "We can only do better when we can see better". Keep us updated on your journey into microscopic horology.1 point

-

Update Wow! Double Wow! Got my first watch fixed..ish. Well, second actually. Both Casio calculator watches from the 1980s. First one. Battery support snapped. New battery did not work. Ah well. Second one. Replaced with the new battery from the first. Worked a treat. Display shows. Woohoo! I'm a repairer. Not really, but it did feel good. Some of the press contacts do not work. So my next job is a strip and clean, not just a battery replace. Job for tomorrow. Really pleased. Tools and Glasses are good. VWatchie and all, thank you for the confidence boost. Leaning toward WatchFix. But I think it will be a New Years present for myself. Regards Ross1 point

-

Etachron is actually quite amusing t implies Swiss but the reality is it's Swiss and Japanese the toll the patent on one part of it. Which is why Seiko uses it in all of their watches along with the Swiss. It's a really a beautiful system as it allows you to make a lot of hairspring adjustments without bending the hairspring. Like you can rotate the stud to move the position of the hairspring you can open up the regulator pins and rotate the stud and make sure they hairspring is absolutely in the center between your pins you don't have to do conventional bending of the hairspring. Then you can close the pins down which as somebody noted above improves isochronism. But if you don't grasp how all of this works you can bend the hairspring or maybe do something else bad.1 point

-

Picked these up from Facebook marketplace in a lot advertised as "costume jewelry". Thought I spotted a familiar logo so took a chance and paid $31 NZD for the lot or £4 each. Also got a bunch of costume jewelry that's not pictured. I think I've used my buying luck for a while, all are working, all clean inside, just some cosmetic things to tidy up (hopefully nothing will show during servicing). Omega and Elgin will be flipped after they've been cleaned. Hafis will be kept as I collect them and Seiko will be kept till I get to the level of servicing chronographs.1 point