Leaderboard

Popular Content

Showing content with the highest reputation on 11/22/21 in Posts

-

I recently received a bag of broken watch bits in the post with a note attached. The note read, “see what you can do with this lot”. I wasn’t very hopeful but it turned out there was at least one complete watch in there. After spending time piecing everything together I realised a new quartz movement would be required. An ETA 64111 seemed to fit all the measurements and one was ordered. After a lot of dial cleaning, hand straightening, and case/ bracelet polishing I ended up with a complete working watch.1 point

-

Hi Ross I would consider what jdm said Get a handfull of moderate tools and have a go an old cheap pocket watch first as the bits are larger and easier to handle then if you get it right get a cheap watch and have another go, By this time you will know whether you have the aptitude, patience and careful hands and vision to carry on. Not forgetting the enthusiasm. If the fever still burns there is a trail of knowledge to follow. When I started a long time ago there were no videos, no courses, just the occasional books you could lay your hands on. Today people like Mark are willing to share knowledge that was once a closed shop to the amateur/hobbyist, If you are serious in doing this the oppertunities are there. Even after all these years I still enjoy it and get a kick out of fixing it, a house full of clocks drawer full of tools and I still indulge in making more tools. The first thing they do with the dead is empty their pockets and then its too late. You will create a few cockups but that's what the forum is for , to get you over the hurdles and help. all best.1 point

-

1 point

-

jdm, Plato. Agree with you both. I'll get my feet wet, then if feel capable, take the plunge. Regards Ross1 point

-

1 point

-

Yes, the stem just locks together. BUT, before trying it, wait for another member with more experience than me to confirm. I don't want you to damage your watch with bad advice.1 point

-

That was exactly the topic what I was referring to. My comment was tongue-in-cheek. If I looked at my trade, the equivalent would be that we are not allowed rags to clean up any possible over lubrication or greasy handprints. Bit silly, really.1 point

-

Welcome to the forum Miles. I am looking at the distance learning course via the BHI in the UK. I am also reconsidering the course that Mark Lovick (CEO of this forum) runs. There is no longer any school teaching either watchmaking or clockmaking in Australia.1 point

-

Is this one of those times where you are so blinded by messing something up, that you can't see the obvious solution?! Bl**dy hell Marc, you might be right! Ill have a look and reply...1 point

-

Hi Pheonix watch eh Rose from the ashes, Have a beer and dont sulk being 1/2 a mill out using hand tools is pretty good go to bed with a smile1 point

-

The last two are French as OH has already identified. I have found they are remarkably well made BUT don’t break a pivot. I don’t know what metal was used then but even if tempered drilling to replace a pivot is extremely difficult. Re- joining the two half’s of the last one Can be done using tile adhesive.1 point

-

Hi Willow If you treat the french clocks like the wife only better you will do fine do not be afraid1 point

-

Hi all nice clocks. The american ones are probably Ansonia They will keep you out of mischief for some time. Just be careful with the french ones as the pivots are glass hard and will not suffer abuse at all, but having said that they are beautiful clocks to work on. The American ones have a look on the net for David La Bounty he is quite an authority on the clocks and has some technical data on them regarding the levers. Have fun and enjoy it.1 point

-

1 point

-

Another new member that last visited the day after he joined, and that was it. Maybe when very bored he will come back.1 point

-

In his example he talks about the Hamilton 992 and he talks about dynamic poising. Even makes a reference to Even in the US, W.H. Samelius was aware of these procedures in 1944. But I'm confused? My confusion is I looked it up the Hamilton 992 came into existence in 1903 was upgraded modified or something in 1931 basically improved and continued on until 1940 when it was replaced by the Hamilton 992B. So not saying it's impossible to do dynamic poising but how exactly did Hamilton dynamically poise a watch in 1903 when there were no timing machines? Plus he even references somebody having knowledge in 1944 which is four years after this watch was discontinued wasn't that clever of Hamilton to know how to dynamic poise in 1940? Then in case you're curious I think the earliest reference I have to a timing machine is 1934. But it's time standard is another watch and basically electronically compare your watch to that watch. Then it displayed the discrepancy on an analog meter. What's interesting is his reference to Samelius and 1944. Because the Elgin research Department released a publication on electronic timing machines July 1944. This is because things like watch factories would be the first to embrace any form of technology that would allow them to either do things better or faster. Find this really interesting points out one person even though he references that there were others conceivably every single person who ever is written the book on replacing a balance staff. But still we find out the roots of the evil is Henry B. Fried Who I bet you Clark has never even met? Strangely enough I've met him on at least three occasions and I still have Memories from two of the meetings. Strange he really didn't seem evil and bad but maybe I just wasn't paying attention. In case you're curious here's a link that talks a little about him. https://hs-ny.org/scholarship Now back to mutilation here's a link you want to scroll down until you get the section on titled Unit 5 - Poising Balance Wheels And you can download the PDF https://mybulova.com/vintage-bulova-catalogs The Bulova manual was the training manual of the Bulova watch school. That matter influenced a heck of a lot of people and still is a very popular book today. I do a minor disagreement with Clark in that he points out that screw under cutters basically have no control over what you're doing and if you know how to use them you have a great deal of control. By Jocelyn see that the book talks about how to use the under cutters. But does bring up an interesting problem that Clark has pointed out and I'm going to references PDF now On page 31 he explains that removing weight from balance wheels is my interpretation the work of the devil. So he gives a good reason why you should never do it butIf nothing is ever changed why should you add timing washers any more than you would undercut so that's a problem. Then there's another problem I'm attaching an image dynamic poising Look what Greiner has in their manual. Whether your static poising or dynamic poising if it's heavy you're supposed to remove weight. We also get another problem which is Clark is working on a railroad grade watches preferably ones that have never been mutilated. What about all the other watches that are not railroad grade watches were they all dynamically poise I doubt it. I doubt they even dynamically poise anything except railroad watches and they couldn't really do it before timing machines and even then there is a confusion over what the heck dynamic poising is?I was looking at a book strangely enough you probably heard the name before it's the writings of Samelius I'll put a link to the book farther down below it really is a good book. But anything or any time he talks about dynamic poising he's more concerned about the hairspring not being centered not being flat and basically it's the hairspring there is almost no reference to anything related to the balance rim. The other problem I comes up is what you do with already mutilated balance wheels? I've seen on other discussion groups are supposed to replace all the screws with new ones but most people don't have that option. This means you're going to have to equalize things and undercutting is still a valid thing if it's done with control. Whether your statically or dynamically poising that's no excuse for mutilating the balance wheel. If your static or dynamic poising the balance pivots have to be perfect. If you have bad pivots you're going to have bad results. To give you an idea of how important the pivots are I know a shop that services a lot of Rolex watches. If they have anything resembling a timing issue a poise issue anything they just replace the balance staff. Which is why find it interesting when people are trying to dynamic poise watches with balance staffs at her hundred years old there obviously not going to be perfect enough. Here's an amusing blank is that one of those devil worshiping tools I see? Then what is he doing to his balance wheel although he's not mutilating the screws so maybe it's okay. What's interesting with this example is he could've just dynamically poised it because it should have been really close in the first place. https://www.great-british-watch.co.uk/how-to-poise-a-balance-wheel/ Then I was trying to find a link but are not finding it going to find anyone selling this book it comes up on eBay apparently finding hints that it's been there in the past " Watch and clock information please" by W.H. Samelius. Technically it's not actually a book written by him sort of? What it is he wrote answers in a magazine started in 1921 and somebody else took everything he wrote and put it in this book so you have almost 400 pages well with the indexing of 400 pages of answers to questions. Even have amusing things like he's referred to the Dean of American watchmakers and is a really nice preface probably written by a friend as I existed at the same time you might have remembered his name from up above Henry B. Fried. The book really is a nice reference but I move stay with poising the way in the back is a will section on poising just a reference a static poising the poising tool basically says what poise should be then he makes a reference to dynamic poising this is where things get really interesting. He does reference you need a timing machine. But before he talks about distribution of weight and also talks about they hairspring several times I've seen references to the hairspring is really important spends most of one column discussing hairsprings stuff then he finally gets to unequal distribution of weight on the balance rim or the balance rim itself may be out of flat. Is concerned about balance not being flat this is back to you have to be absolutely perfect to dynamically poise just because my messages and longer enough even talks about workers that screw up the temperature compensation basically by adding or deducting away from the balance not realizing the position of the balance screws is an important factor when adjusting the watch for temperature changes . Then rather than quote something I'm just going to scan a page that I find interesting.1 point

-

I'm not sure in the cloned mainspring is whether they are different then the original mainspring. But we also have to look at whether it is actually a 6497 or 6497 – something in other words they run at a higher frequency and I think that's a different mainspring than the standard 6497. I think you need to work on your technique here? Usually for the handle when you wind the spring in you let the spring unwind the handle so than there is no tension and then to unhook it you just have to be really careful of what you're doing. So in other words when your winding it backwards to get it done clock you don't want to somehow wind the spring backwards. Because you just trying to get the hook unhook from the spring. The other thing that happens is if you choose a Winder that's too small the entire spring gets jammed inside the Winder and that's an issue. Fortunately if you choose carefully with the new spring you should build just shove it in and not have to play with the Winder except of course you don't get the lesson of learning how to use the Winder. Looking at the references the 6497 or 6497 – 1 depending upon the source is either 440 mm or 450 mm. I'm noticing what one of the problems this trying to find a reference for 6497-2 that's what the Chinese clones usually are 21,600bph trying to find a listing of the size of the spring or even finding anyone that acknowledges such a movement exists is proving to be interesting. Unhelpful because and not getting a size but if you have access to someone would best fit parts its number is 770/274.The other way I see the part number is 771/6497-2 Which is still unhelpful because I can't get a size so I have no idea how big or small it is. Based on run times the Chinese clone watch I suspect that that's probably what you have. On the other hand if you just Google that you want to mainspring for this listings will come up like this one and it does present a minor problem of pulling the spring is shorter than what your spring is. Which tells us the Chinese modified that and basically it may be an issue. https://www.startimesupply.com/merchant2/merchant.mvc?Screen=PROD&Store_Code=1&Product_Code=ETA6497-2-MS&Category_Code=1H-Parts-Movt-Mspring-ETA1 point

-

I can't comment on the movement until I see the workings of it. If the dial has wax filled markings which to me it looks like it has you can re-silver the dial. You can buy all that is needed in a kit from any good clock suppliers. Here's two videos on re silvering1 point

-

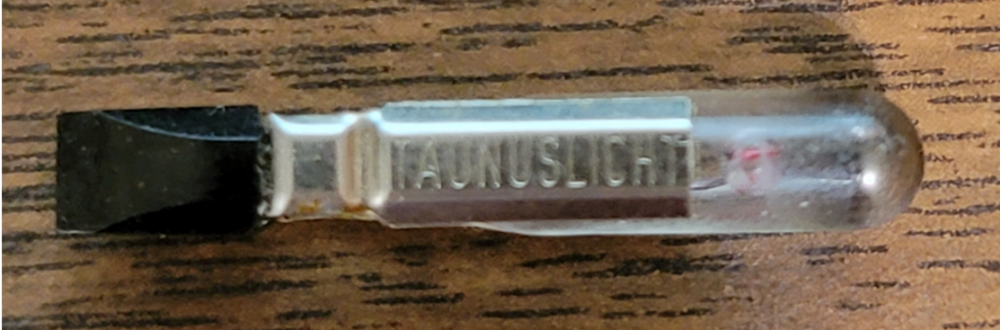

Continuing with my Vibrograf obsession (finally got off of lathes!), I noticed that the pilot lamp was dead. A quick search on the interweb did not yield a replacement, so I just modified the lamp by changing it from an incandescent bulb to an LED bulb while using the same bulb housing. Unsolder the old bulb and solder in the LED+resistor.1 point

-

Update: So I explained to the seller that I didn’t feel comfortable purchasing the watch without a qualified person looking at the movement and authenticating it. Luckily he understood my apprehensions, so the watch was taken to a very respectful watchmaker in the East Anglian region who confirmed that it was indeed genuine!! Thanks to everyone who shared their opinion and knowledge1 point

-

Since lubrication technics and material seems to be a frequent returning subject I thought one could collect some links and pdf files on the subject in ONE Place so it is easy to find them. Here comes my contribution in this link Collection. Moebius ------------------------------------------------------------------------------------------------------------------------------------------------------------------------ Home (list of lubricants) http://www.moebius-lubricants.ch/en/products/oils New (Just a lubrication chart) http://www.moebius-lubricants.ch/sites/default/themes/moebius/extras/pdf/tableEN.pdf Old (Moebius sales program, more detailed information) Moebius Sales program.pdf British Horological Intitute (BHI) ----------------------------------------------------------------------------------------------------------------------------------------------------------------------- http://www.nawcc-index.net/Articles/BTI-The_Practical_Lubrication_of_Clocks_and_Watches.pdf American Watchmakers - Clockmakers Institute (AWCI, Nice and detailed pictures.) --------------------------------------------------- Train Jewel Lubrication https://www.awci.com/watchmaking-excellen/applying-oil-to-train-jewels/ Cap Jewel https://www.awci.com/watchmaking-excellen/cap-jewel-preparation/ Pallet Fork https://www.awci.com/watchmaking-excellen/lubrication/1 point