Leaderboard

Popular Content

Showing content with the highest reputation on 11/16/20 in Posts

-

2 points

-

If you are able to cut a new wheel then do so. I always believe parts are there for a reason. Its also good practice to have the clock working in its original condition.2 points

-

Hi Yasser right, Have a look via the search function . top right on the home screen. use the phrase ""BFG 866 walk through"" then scroll down the results and look for Jon "Baumgartner BFG 866 Walk through" Jon did quite a comprehensive walk through the diss assembly and re assembly of the BFG 866. A study of his posts will give you the information In graphic detail. It is very Good2 points

-

Hi As Joe says use a stem holder ( pin vice) and pull vertically, As I recall bergeon canon pinion tools come in different sizes and are expensive for limited use.1 point

-

Try your stem holder tool, tighten it real tight over the canon pull streight up.1 point

-

1 point

-

Your third picture shows stud sitting at the begining of the TERMINAL CURVE( right after the bend), whereas it should be at the end, "end of hairspring" Just like ashF shows. Mount the stud in stud hole of the adjustment arm. Unpin the hairspring. Thread the hairspring through stud hole all the way to the end of hairspring. Re-pin. You have a good terminal curve already, minor manipulation like this is routine.1 point

-

In case of balance cock clockwise, balance receives the impulse while turning in clockwise direction and vice versa for anticlock. so it depends on weather the cock is mounted on left or right of the movement.1 point

-

1 point

-

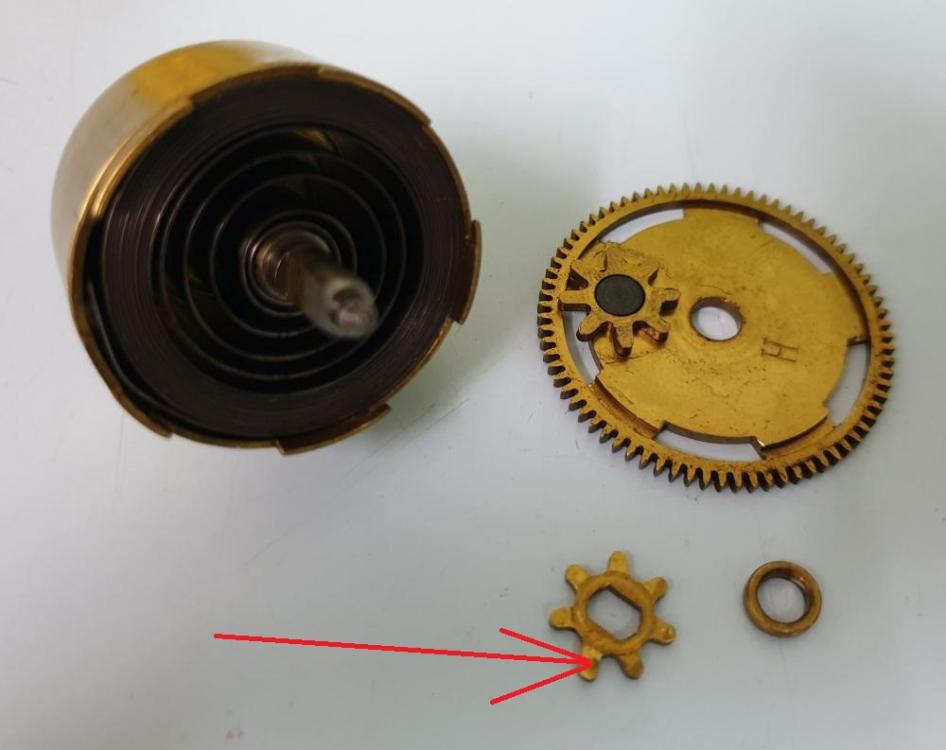

Ugh. These reps are always a mess to work on. I believe the click is provided by the octagonal spring. The funnily bent end probably goes in the hole and the other end bears on the “teeth” in the bezel ring.1 point

-

Hi Tech sheet for the 866 allached. hope its some help for you. 2529_BFG 866,866.31.7 (5).pdf1 point

-

I found it. A piece of dust filament fouling the impulse jewel. I need some type of air filter in my workspace (office). Thanks for all the help!1 point

-

1 point

-

One other caveat...beware of the JESUS spring..small little springs in the works that fly off to only God knows where..when working on or around them I like to put the watch inside a gallon sized plastic bag..I work on top of a sheet of copier paper.. the springs get contained and you can spot them easily against the white paper.1 point

-

The 2409 is pretty simple and robust, although I confess a preference for the 2209..proceed slowly..take pictures as you go..be very careful with the balance staff . If this is your first attempt you may very well mess it up..luckily used 2409 can be bought all day long on ebay or etsy for very little money. To do this right you are going to need some decent screw drivers and tweezers.. and a movement holder. Economy grade is ok for starters..1 point