Leaderboard

Popular Content

Showing content with the highest reputation on 05/03/16 in all areas

-

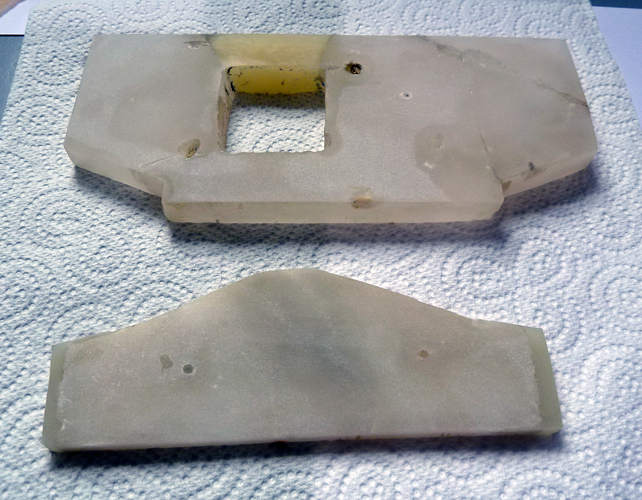

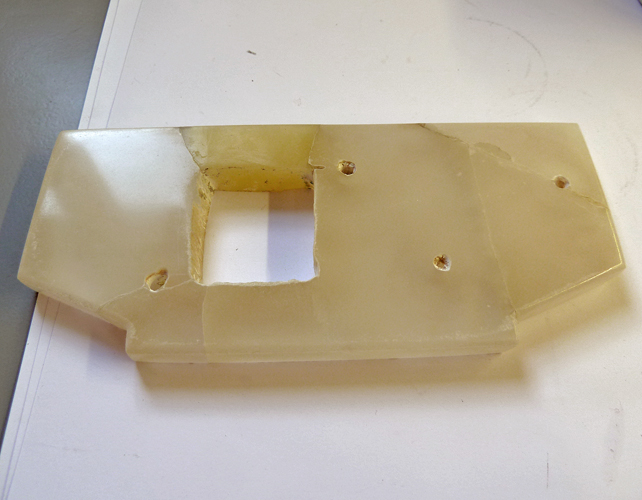

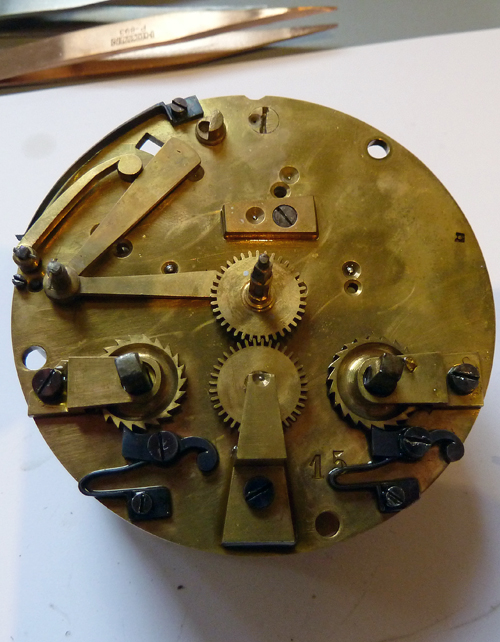

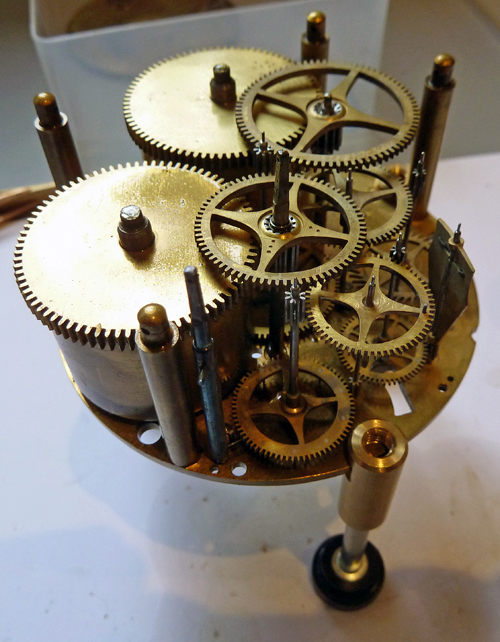

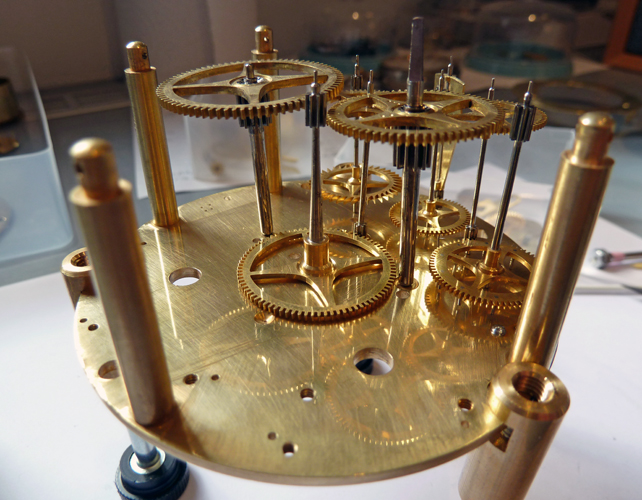

A friend threw this thing at me recently: Bought at a recent car boot sale for the princely sum of £10, it also has a glass dome (not shown) in good condition. The bad points: 1. Lots of thick gold paint. 2. The figure is missing something in her hand (a mirror?). 3. The alabaster base is cracked in several places, with a section missing at the back. 4. The alabaster on the front is cracked, too short on the sides & has had a non original brass plate fixed to the front. 5. Hands are rusting. 6. It looks like it's taken a few heavy knocks in the past. 7. The sub base is very poor, worn gilding, moth eaten velvet & cracked. 8. Very, very dirty. The good points. 1. It runs. 2. err.. 3. that's it. Right, lets see what we can do (a polite request to the conservationists among you- look away now, you may not like what you see!) Movement out and seen from underneath the previous attempts at repair: The studs holding the figure & the clock case to the base have been replaced with various odds & ends. The base has had some interesting repairs with epoxy: Copious amounts of gold paint: The base with the ill fitting stone & brass inserts: After stripping with Nitromors, acetone & an old tooth brush, were back to the original gold plate (what's left of it). The holes in the treasure chest will be filled with epoxy: A new mirror is fashioned out of a piece of scrap alloy & epoxied in place (note the casting detail showing now the paint has gone): The cracked alabaster base is soaked in acetone for about a week to remove the old epoxy then resembled using clear epoxy: The missing section is remoulded by laying the item face down on baking parchment, fashioning a couple of dams out of old Rodico & filling with epoxy (Araldite in this case): Mould removed, more clear epoxy applied to fill the cracks. Also the front stone is extended using the same method: Filled & sanded using wet & dry papers. The colour match on the front piece was adjusted for a better match by adding a little more of the clear Araldite. It looks like it originally had a couple of rosettes fitted: Given a further polishing with diamond impregnated polishing pads it begins to shine, unfortunately alabaster is almost impossible to repair invisibly so we will have to live with the cracks. It is however somewhat more stable: Onto the movement. Stamped S (Samuel) Marti, Medaille de Bronze - this being awarded during 1860 in Paris. The company later received the Medaille d'Argent in 1889, so it would have been produced between these two dates. Nothing major to report, just a bit tarnished, oily & grubby: Duly cleaned in Horolene, checked & showing (amazingly) no discernible wear: The case was originally (very thinly) gold plated, showing the copper base coat & spelter in places. As electroplating is too expensive, gilding using gold leaf was attempted first but the colour was far too bright yellow, so the case was repainted using a couple of thin coats (to preserve the detail) of Rustoleum brilliant gold (Valspars equivalent was also tried but looked to brassy). New screw studs for the clock case & figure closely matched to the original ones still in the figure were sourced from www.ba-bolts.co.uk . The alabaster stone base inserts still looked a little dull, so were given a thick coat of clear acrylic high gloss varnish. The non original brass plate covering the front alabaster insert was replaced with 2 brass rosettes from Cousins & painted to match case. The gilt sub base was sprayed gold & the fabric recovered using purple dressmaking velvet with gold rope trim. The wood main base (not shown in the final pics) was cleaned & french polished. Movement regulated. Dial cleaned. Hands re-blued etc: ..........and this is what it looks like now:2 points

-

2 points

-

My new solid 18k gold baume great watch and I love it great watch great brand Sent from my SAMSUNG-SM-G925A using Tapatalk1 point

-

1 point

-

Thanks for the kind comments all. Oldhippy - Thanks for the extra info. All work undertaken by me. The pendulum did match (sorry no photo & the clock has been returned). The steel parts were cleaned in lighter fluid but were in good nick so left alone. The rest got a dip in Priory Polishes No1 Clock cleaning fluid (sorry - mistakenly said Horolene in the original article), rinsed in water,then IPA, dried, followed by a good rub with Priory Polishes impregnated brass cloth, then IPA again, dried & finally rubbed over with a clean Selvyt cloth. The dial appeared faultless, amazing really considering the state of the case.1 point

-

1 point

-

Yeah, that lever looks...how can I put it, not original? I think it should be more....maybe "finished" is the right word? Either way that would be quite an achievement I, at my level, would not dare to tackle. Hope it all resolves successfully. Cheers, Bob PS. It is possible to modify a movement adding jewels...it is simply an expensive proposition or as you say a detour from the original design.1 point

-

Hi Tin Tin, since you did not clean the balance jewels that would be a good place to start.. did you dismantle the balance jewels in the mainplate? While you have the balance off..inspect the pivots closely.... it may have mushroomed or bent. Anilv1 point

-

The point is it isn't on your wrist, so why put wear on the autowind parts? In the OPs case (and mine for most of my watches, particularly the valuable ones) the watch is worn very little but the wear on these parts will be the same as if it is worn all the time. Even the best autowind parts have a limited life span because of the constant movement and associated wear. As you say your watches will certainly outlast you (I have cheap Timex autos going strong that are as old as me, and I'm not young) but the autowind parts won't, even less so if used constantly. I suppose it wouldn't matter if you always pay for an official service as these parts will probably be replaced automatically and are already covered in the cost. However I intend to service my own watches and would rather not have the expense, and even more so these days the trouble/difficulty, of having to replace parts unnecessarily. These are the reasons why I have gone from using an eight watch winder and rotating all my automatic watches on in the past to not doing so now. Obviously others may choose to do things differently. Stephen1 point

-

Glad you got it figured out. I really like those chronographs. Been working on them a lot lately since they are a little less expensive than some others and I am enjoying working on them. Back in the early 70's my Dad got a 6139-6005 with the dark blue dial and I thought it was the best watch I had ever seen at the time. I now have that watch and I can't begin to say how much it means to me. I am thinking about giving it to my daughter as she can just barely remember her granddad. Charles1 point

-

Did you undertake all the work yourself because it's looking good. I'm going to concentrate on the clock movement. Do you have the original pendulum it would be stamped 1515, the numbers 5 2 is the French measurement for the length of the pendulum. It is an 8 day French movement with count wheel strike on the back plate. The proper way to clean these movements is to polish all brass with brasso using a cloth, all screws should be cleaned up and polished normally in a lathe and polished with very fine emery sticks then blued, all brass should after being cleaned and rinsed and dried should be chalked brushed using French chalk which you buy in a block this prevents tarnish. After all the bashing about the clock has had the dial is in one piece, I can't even see fine hairline cracks even the key holes haven't been touched.1 point

-

Great job Ry, I haven't worked on this movement yet but definitely a great job! Cheers, Bob1 point

-

Good job JD, I'd love to see the video when it's ready! and yes, the jewel you are talking about, it may make a difference once you clean and oil it. Cheers, Bob1 point

-

Just finished a 6139 Seiko Chrono and it is a bit of work to assemble . Good work. Sent from my iPhone using Tapatalk1 point

-

My Sekonda today, with Poljot 2612.1 alarm movement. This was the first watch I ever serviced. When I received it, was running 28 minutes per day slow, amplitude was 86°, and beat error was 10ms. The acrylic crystal was also really badly scratched up. Now it's running +/-5s/d, amplitude is around 280°, and beat error around 0.5ms, and I've polished the crystal. I also recently overhauled the very stretched folded-link jubilee bracelet. I did a write-up of the service here, http://www.stefanv.com/watches/restoring-a-russian-alarm-watch.html, and the crystal polishing here, http://www.stefanv.com/watches/polishing-an-acrylic-watch-crystal.html.1 point