-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

By nevenbekriev · Posted

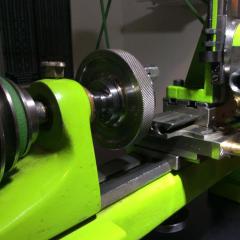

The movement is FHF, something like this. But it will not help much to find stem. Sometimes making one is easier -

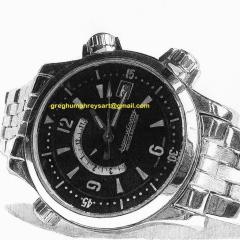

I think they all have their pros and cons, the one I suggested is a threadlock loctite product (Loctite is now owned by Henkel), In general I use the current one that is recommended on their Loctite page (link here) I use blue (243) for the actual crown the (stick is actually 248 which is the stick version of 243), like I said it is very convenient for using on stems. Blue holds the crown for everyday use, but can be removed if you need to with a little heat. I use the red 277 for things like stem extensions where I have no intention of ever removing it. The purple I don't use (but I have seen some youtubers use it) as I think the blue is removable so why take the risk on a weaker product. This is interesting, and a useful bit of information to know 🙂

-

Cheers JerseyMo, I hadn't realized anything< I thought this was the bezel...

-

Recommended Posts