-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

By Neverenoughwatches · Posted

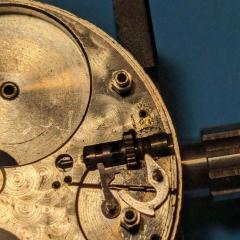

Den / Dennison is a unit measurement of size this is actually a mainspring gauge . I haven't heard of a pivot been measured in Dennison before. Though the small thickness gauge is usually supplied with a Jacot tool and is more accurately known as a pivot destroyer. -

Could it be an abbreviation for Denier? "Denier (/ˈdɛniər/) or den (abbreviated D), a unit of measure for the linear mass density of fibers, is the mass in grams per 9,000 metres of the fiber. The denier is based on a natural reference: a single strand of silk is approximately one denier; a 9,000-metre strand of silk weighs about one gram." The pivot gauge looks interesting, however I wouldn't trust myself to drive a pivot into a wedge incase it jams and gets damaged/snaps trying to get it free. More a comment on my ability and incompetence than the quality or design of the tool 🤣

-

As I've seen multiple posts here about multiple types of cleaning solvents, I've done little more than confuse myself more thoroughly that I was before. To see if I understand things correctly... 1. Is One dip is a solvent which is a cleaner and also a protective rinse for hairsprings jewels and pallet stones only? Or can it be used on all the parts (like the case and wheels and all the things) It seems like that would be much easier as it's just "one dip" but it is very expensive. 2. Isopropyl alcohol is a great cleaner for manual cleaning or ultrasonic cleaning (only enclosed jar) just not on pallet fork as it may loosen the shellac holding the stones. Does it have to be 99%? 3. When buying a small manual cleaning brushes, does anybody suggest a certain material of the brush itself?

-

I am new to the new to the watch restoration hobby I have the basic tools. I'm here to learn new things. And utilize my resources (you guys) to expand my knowledge and hopefully save some derelict timepieces from the trash.

Recommended Posts

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.