Leaderboard

Popular Content

Showing content with the highest reputation on 10/20/22 in Posts

-

3 points

-

Hi all - this is my first watch build from internet parts, following completing an online course. I went with the seagull st3621. It was difficult to find a version with this finish, and also the 6:00 seconds. I ended up finding this on eBay. On AliExpress there was only one version which I did not like. The 9:00 seconds movement seems more popular but the 6:00 subseconds is more pleasing to me. Movement from ebay as noted, and everything else from AliExpress. I disassembled and washed, lubricated the movement before use. The only issue I ran into was that it seemed the dial feet were ever so slightly too short and I couldn’t get them to bite on the dial screws. Eventually this was creatively solved by extending the feet with super glue, and also bending one very slightly. I wanted to get a nice strap and was not too pleased with the options on North American websites (and their associated prices) but was happy to find another Ali vendor that only makes straps. Cost wise it was still much more than other options on Ali but I am pleased with the quality and they may be my go-to for straps. I’m happy how this turned out and am pleased with the exercise. I have a few vintage watches lined up to work on next. Just waiting on a strap for a medana and then will post the results of that one. Take care. Also wanted to add that I was surprised at the lack of dials available. In my mind initially the choices were going to be significant. It turned out to be quite the opposite.2 points

-

Thanks for letting me know - ive fixed a file permissions issue, should be ok now.2 points

-

Try kroil if you got some? thought about center drill, pilot drill, drill and then easy-out it? how about adding more leverage/torque by adding a cheater pipe/tubing at the end of your hex wrench? When I got my Unimat DB200 I took all down by hand then bought a gallon of carburetor cleaner and soaked parts in it overnight. Even comes with its own basket to lower into the can to put the lid back on while you let em soak. Still have the can and use it often. for the big stuff I would dip my toothbrush and copper brush into it to do by hand.1 point

-

when requesting help its only good manners to introduce your self so members know who they are talking to and their skill levels. It avoids talking down to an experienced guy or too complex to an absolute beginner. By knowing the Poster we can pitch our answer accordingly.1 point

-

This is the same as I have and it is at a good price. https://www.ebay.co.uk/itm/255741069069?mkevt=1&mkcid=1&mkrid=710-53481-19255-0&campid=5338353466&toolid=20006%26customid%3Ds%3AGS%3Bgc%3ACj0KCQjw48OaBhDWARIsAMd966AUMYEFlILmYT4IhJjWEJ9layiGD0NHvO14xpHlKGs-c8JtVENGAUIaAkHsEALw_wcB%3Bpt%3A1%3Bchoc%3A2&customid=s%3AGS%3Bgc%3ACj0KCQjw48OaBhDWARIsAMd966AUMYEFlILmYT4IhJjWEJ9layiGD0NHvO14xpHlKGs-c8JtVENGAUIaAkHsEALw_wcB%3Bpt%3A1%3Bchoc%3A1&gclid=Cj0KCQjw48OaBhDWARIsAMd966AUMYEFlILmYT4IhJjWEJ9layiGD0NHvO14xpHlKGs-c8JtVENGAUIaAkHsEALw_wcB1 point

-

1 point

-

Haha, funny you should say that as I’ve refined it a little more today - even tested it on the dirtiest movement I could find. I’ll put a little something together and post it somewhere soon1 point

-

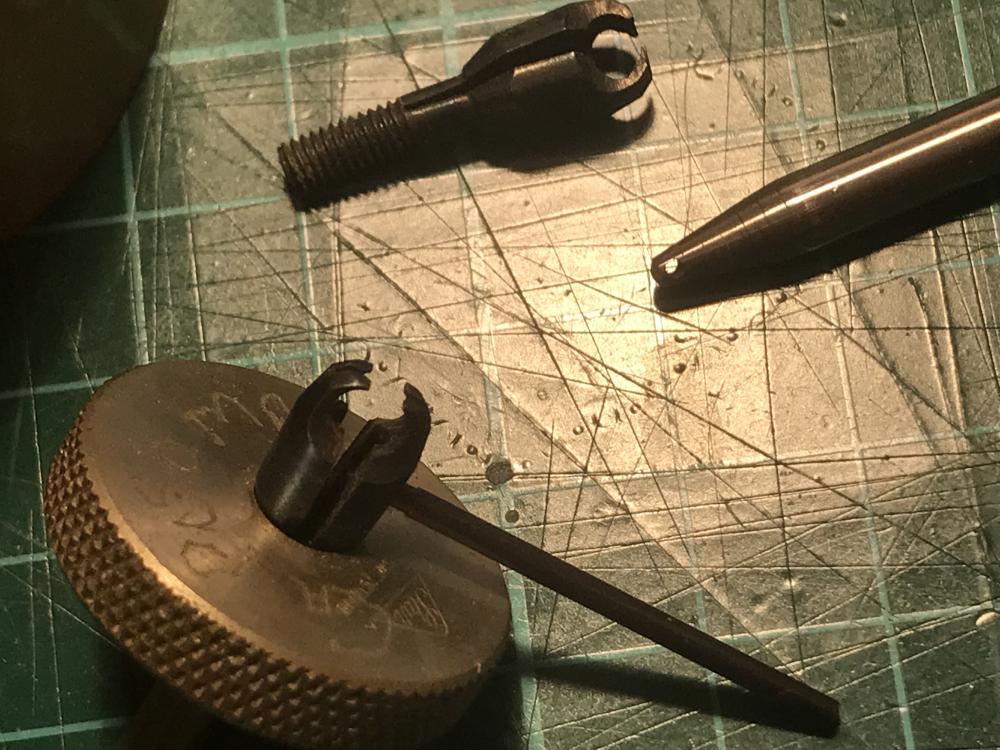

Does anyone recognise this? The punches have a very small hole on their tip (balance staff pivot sized?….). The punches also have a perpendicular hole through the entire punch, close to the tip. The black claws screw into the stump which tightens them. They look a bit like pullers…. Any suggestions appreciated!1 point

-

Those are excellent numbers - to get DD/DU so close shows you have got the balance pivots and jewels nice and clean ! 9010 is fine on 18000/h pallet jewels - best to be sparing with it, as it can spread around.1 point

-

Well that's strange. They were there when I made the post last night, but now they're all broken. I also can't go back and edit any of my posts for some reason. Hope I didn't break any rules. I'll try attaching them to this post again. I just tried uploading the images again and got an "unknown server error." I'll have to try again later. In the meantime, I've made an Imgur album here with the images. Last night, amplitude was 256 dial up, 233 dial down last night. This morning it's 264 and 268, respectively. Beat error of 0.1, and losing less than a second a day. Really shows what a difference letting it run for a while after servicing makes. I actually don't have 9415 yet, and have been using 9010 on the jewel faces. I've read that it's the best alternative. No, there was barely any side shake at all. I even remembered to check it this time1 point

-

Are you in South Africa perhaps? That sounds like the stuff BJ Oberholzer sells. Which, by the way, is exactly what I use. Chronomex for cleaning and their Hexane rinse afterwards. I've done many, many using an Ultrasonic and now recently a watch cleaning machine and I'm pretty happy with the results. EDIT: I see now you're in South Africa so it's the same stuff I use. I have to admit I'm jealous that you've found watch cleaning machines locally to restore. I've been looking for ages till eventually building my own1 point

-

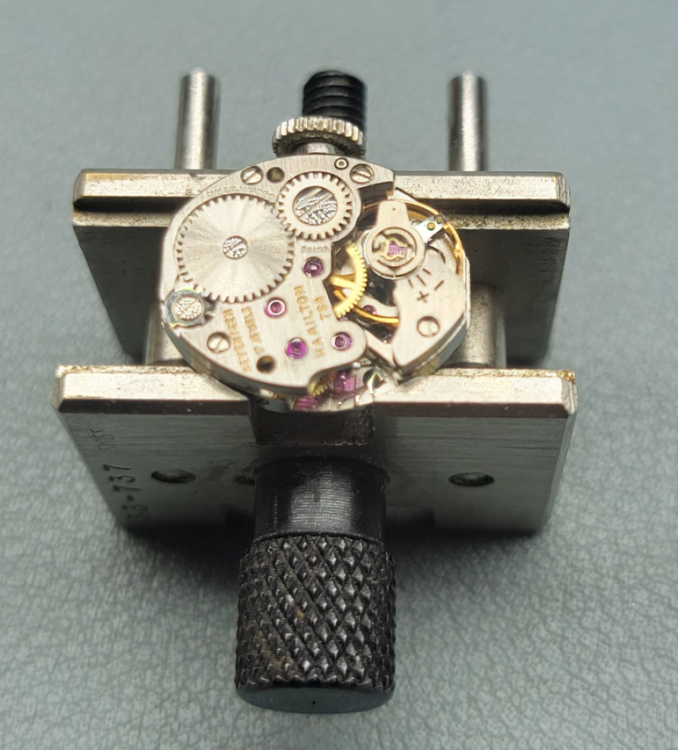

I hate working on ladies watches, but this belonged to my aunt and the family asked me to service it. She was a wonderful lady, so I made an exception. All of the train wheels are covered with one plate. I thought it was going to be a royal pain to assemble, but surprisingly it went together without a hitch. When I dropped in the balance assembly, it ran really goofy and stopped and when running it was at 28,800. What was going on. Geez...the hairspring was sitting on top of the center wheel. Well...everything is so small...so tight. Anyway, I made it right and it is running fine.1 point

-

The original arbor will fit into the chuck without any problems. But you'll need a set of containment rings to capture the spring and remove it from the barrel. The letdown tools are needed to power down the mainsprings safely before taking the plates apart. Don't be tempted to save on them. All of us who have, had black fingernails to show for our folly.1 point

-

I have never used that type. Didn't it come with instructions? I would have thought all the tools would be included. Just in case the paper work is missing you will find it here. https://mb.nawcc.org/threads/re-post-of-webster-mainspring-winder-instructions.76702/#lg=post-575421&slide=01 point

-

Yeah i know there'll be ins and outs to the plating, but electrolysis in itself isnt that involved...Yeah sliding decals looks the way to go either that or laser etching if you can get hold of the gear. But I reckon you're right there the result will rely heavily on getting a smooth surface finish. But paints (and they are paints when push comes to shove) like nail varnish are designed to smooth out to a even finish so I reckon if you thinned them down enough and airbrushed them you could get a good result... But i have some experience making sliding decals as you use them alot on guitar headstocks. its not that difficult if you have a good printer... I suppose you could even go as far as powder coating and gold leafing...1 point

-

I don't have any experience with Chinese machines with a gain settings so that I don't know. having looked at schematics for older timing machines they typically have automatic gaining controls built in. Even though there is a volume knob they still have an automatic gain control. Looking at the manual for the witschi machine that I have you tried on your set the knob at the middle position and I don't really remember ever having a problem with that. The manual does state that there's an automatic gain control so basically I don't remember having to adjust because it adjusts itself. Now the machine at work the very expensive witschi only has for you the level the numbers 1 to 4 and at least it has about oscilloscope so for having a timing issue will look at the oscilloscope and we can see why if there's a single problem. Usually with really quiet watches will just increase the number and I'm guessing because the automatic gain control it doesn't seem to make a spectacular difference of was the watches really quiet or the other problem. The biggest problem at all for timing machine seems to be picking up a good clean signal. So holding a watch in the timing machine pick up holders critical anything that interferes with that is going to disturb the signal while the signal is an audio frequency range it's not picking up audio it's picking up the vibration so anything that interferes with that will mess up with the timing machine sees., That workers with Seiko watches with their plastic movement holding ring case stop the watches will look horrible out of the case they look beautiful. But is not just Seiko watches things like a heavy Rolex watch or any heavy metal case it becomes sometimes problematic to pick up the watch. Sometimes if you put the crown to touching the pickup if you like you get a better signal otherwise the watch has to come out of the case then unfortunately that is a true statement. It's why you need to visually verify that the watch looks like it's doing whatever the timing machine says. The graphical display has to agree with what you're seeing and then the numbers have to agree with that also. So to see random dots on your machine you have a problem the numbers are worthless and you're going to have to troubleshoot the watch. If you go to a super low amplitudes more common on a Chinese machine or the machine at work even if it is more expensive if the amplitude is too low the machine will read the wrong part of the waveform a give you a nice happy amplitude which isn't there. That's where visually observing does it look like it has a nice amplitude versus what the machine tells you. so yes unfortunately you have to be careful on how you interpret what you're seeing and figuring out whether you're actually having a problem with you and your machine or whether it's the watch that's the problem.1 point

-

Eyup matey thats a nice timepiece that gets a nod from folk in the know. I would leave the dial alone its ok, it looks like a thin coat lacquer that might lift along with some lettering if you try any restoration on it. Good luck with the plating it will be a cracking watch if it restores and polishes up well.1 point

-

1 point

-

1 point

-

You can see that it was used beyond the transition from "waterproof" to "water resistant" and also through the radium-to-tritium transition and beyond. Even as shock protection became commonplace, lower-tier makers often used "Incabloc" on the dials as an attempt put something there to help drive a buyer to pick their watch out of the case. In fact, the early electronic watches still had a balance, and you can also see Incabloc printed on the dial of some of those (look for a Mirexal Electronic Incabloc) so it survived into the late 60s/early70s until the full-on quartz revolution occurred and most watches no longer had a staff that needed to be protected. (Or because many of the cheaper mechanicals that still survived used non-Swiss movements with another protection system such that they couldn’t lay claim to "Incabloc" any longer).1 point

-

I think partly my cleaning wasn’t as good as I thought it was, but the main issue was I think incorrect oiling if the pallet stones.1 point