Leaderboard

Popular Content

Showing content with the highest reputation on 02/09/19 in all areas

-

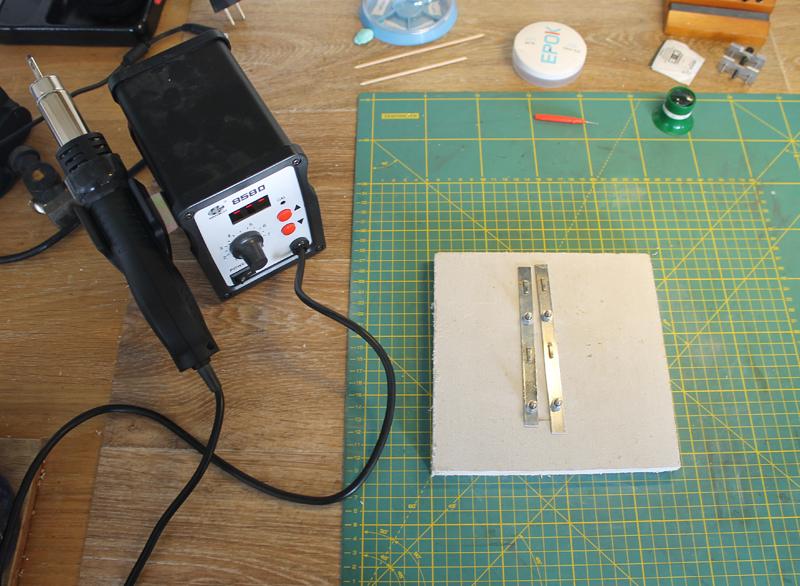

Thought it may be worth to share; I received a pretty beaten up, none-running 1890-1900 cylinder-escapement pocket-watch. It had all sorts of problems, a list too long to go into details. Among those problems was a bend/broken minute hand. It inevitably broke off when trying to straighten it. The center-hole diameter of the minute-hand was 0.5mm and the length was 15mm. The hour-hand had a hole diameter of 2.0mm and the length was 10mm. Searching the internet to find an identical set proofed futile. The watch is a heirloom so originality was a priority. The hands turned out the be made of bronze, a copper-tin alloy. Therefor it made sense to attempt soldering but the part that had to be soldered had a thickness of only 0.3mm. Both parts had to be fixed in place with a sort of clamp capable to fixing both parts, being heat resistant and "none-sticking". A soldering iron, even with the smallest tip, would be far too big for the job and to avoid touching the parts, I choose to use a hot-air gun used in electronics for soldering SMD-components to a circuit-board. A few test were made which tin to use and at which temperatures. 300 degrees C with tin used in electronics seemed to work fast and made the tin to flow nicely. I used a soldering flux-paste. The clamp consisted of two metal rails, slightly diverting from each other to give many clamping options, bolted on a plate of gypsum. Pulling over a #1000 grid sand paper, I made two 45 degrees chamfered edges on either end of both parts; The two parts were clamped in; Applied some soldering flux, heated it all up to 300 deg.C and applied a tiny bit of tin. Once cooled down, I removed some excess tin with a small diamond file. Here a picture of the back side of the minute-hand; And here the front; the tin didn't flow further away from the soldered joint or around the edges Most likely not the strongest repair in the world, but when not touched it should be strong enough to do the job. On the picture the hand color looks black, but that's due to the lighting. In reality the hand hasn't lost any of its shiny patina at the front ...... Anyway, I thought to share this repair as one of the many different possibilities2 points

-

That is truly cool... a tool from Playtner’s school. Playtner closed his school in 1913 but moved to Elgin, Illinois in 1921 and openned the Elgin Watchmakers’ College. He retired in 1923, recommending William Samelius replace him as director. He returned to his home in Kitchener, Ontario. A relative noted that he became a bit odd as he aged. A student watchmaker visited his home before he passed and was surprised to see the main floor set up as a complete classroom, all equipped. Playtner owned all the equipment at the CHI and I guess that after he passed away, his family sold it all. Mind you, his will didn’t mention more than one lathe. Check “Canada’s Master Watchmaker, Henry Playtner and the Canadian Horological Institute” available from [email protected]2 points

-

1 point

-

1 point

-

1 point

-

After my original post, I enlarged your photo and identified your movement as an Epson VX3j. The repair manual doesn't note a reset as being required after a battery replacement. Occasionally when a watch has lain dormant for a bit, the oil sets and the works won't turn. Try gently warming the movement for a few moments with a hair dryer set on low. Watchmakers have a tool that will pulse the stepping motor freeing it up. You might take it to a local watchmaker and ask if they can perform that service for you. If the movement has perished, all is not lost. The movements are both plentiful and inexpensive. With some modest tools and some patience, you can change the movement yourself. Plenty of videos are posted on YouTube showing how to do it. Try bringing this one back to life first though.1 point

-

Very funny. I’ll prepare a video on how to replace the hooks on mainspring winders....if enough people want this. Sent from my iPhone using Tapatalk Pro1 point

-

On the back of your watch, Casio usually marks the movement caliber inside a box. Go to Casio's website and enter those characters into their search engine and retrieve your user manual. Instructions will be included about how to reset after a battery change if required. If not, you have other issues.1 point

-

Here's an 8mm Rivett Watchmakers lathe I picked up awhile ago. Rivett was a really high end lathe maker. Started by a Canuck who headed to US to find his fortune, the Faneuil Watch Tool Co was founded in 1984 (name changed to Rivett in 1905). I bought the watchmakers lathe kit a few years ago from an estate. It was owned by a watchmaker in Stouffville Ont and the accessory kit is really complete including dividing plates, a Hardinge polisher, bezel chuck and a wheel cutting attachment (shop made). As well there is a large selection of wheel cutters, one set visible on wood dowels and the other in a small wood box. The box lid has a note saying they're from the late Mr Playtner, 1890, principal of a watchmaking school in Toronto. The dates don't entirely make sense, as Playtner founded the Canadian Horological Institute in Toronto in 1890 (he was 25), Canada's first watchmaking school and he lived to 1943. I'm guessing the Stouffville watchmaker acquired the items mid 20th century after Playtners' passing. Apparently the school drew from afar and had at least one tie in to Rivett; its students won the top three awards from the Faneuil Watch Tool Company's 1897 competition. He was also the author of "The Analysis of the Lever Escapement" which I gather is still relevant and cited today. I've also got a 1897 Rivett 608 which which is arguably the preeminent instrument lathe of the time, or for that matter perhaps for all time: for example it would hold .0001" over 6 inches when new. They were unpainted with polished castings and cost more than man's annual wage and were often found at Universities - mine came out the Cornell University Materials Engineering Lab. My 608, made before the 1905 name change, has the Faneuil name plate. As well they made a tool makers lathe, the 1020 which is comparable to the Monarch 10ee or Hardinge HLV. Anyway, enough about Rivett, I thought you guys would like to see the watchmakers lathe. Any other Rivett owners out there? feel free to post you pics here1 point

-

I feel all your pain, I've had trouble with these and I found out the hard way about checking for the hook on second hand winders. I'm expecting to see a tutorial pop up from @jdrichard on how to knock one together soon (and although I'm joking I wouldn't be too surprised, there doesn't seem to be a lot that man can't manufacture!)1 point

-

1 point

-

Hi There are probably others out there like me who have bought the largely unimpressive A*F Bezel remover - https://www.cousinsuk.com/product/watch-bezel-remover-af-swiss?code=R31399 I decided to try and improve mine a bit by making it more stable, therefore able to exert a more steady pull under pressure. I used an old timex crystal tool I had spare and trimmed the edges of the rubber, and ended up with this: It now works reasonably well (better than before anyway) at removing rotating bezels from clamped watches, and can be used one or two handed - it's certainly a lot easier to exert even pressure and lift. It's still not that brilliant really as it could do with a bigger and stronger lip to go under the bezel instead of mainly using side grip. As per usual I rather rushed the job as I wanted to see if it could work. The ring really needs securing at the top as well at the ends, but it was too late to change when I realised this. Also I should have trimmed the rubber more neatly, but it is fine where it touches the watch. Stephen1 point