Leaderboard

Popular Content

Showing content with the highest reputation on 03/17/16 in all areas

-

I don't work with stainless much in my watch world, as most of my work is on pocket watches. Nickle and sliver are much softer than SS. That being said, when I do the math, our wheel surface speeds are about the same. (The radius of my wheels are about 5 times yours, and your RPM is about 5.5 times faster). I wonder is torque, or lack thereof, is a factor for you? Other than the wheel hardness, the big difference here is the motors driving our systems. I'm have a 1 horse motor, which mean my wheel speed is pretty constant, even under load. I think a bigger wheel and motor would give you better results, as well as reduce the risk of point loading contact between the wheel and the piece. If you want the blemish to "flow", you need to heat the area around it as well. A larger, and subsequently wider, wheel will do that for you. I have a 6 x 1 inch fine deburring wheel I use when I working with knives, (another hobby) which does a good job of cleaning up scratches before I move to my soft wheels.2 points

-

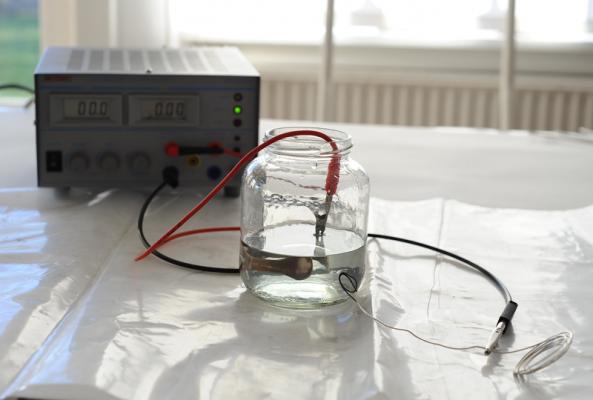

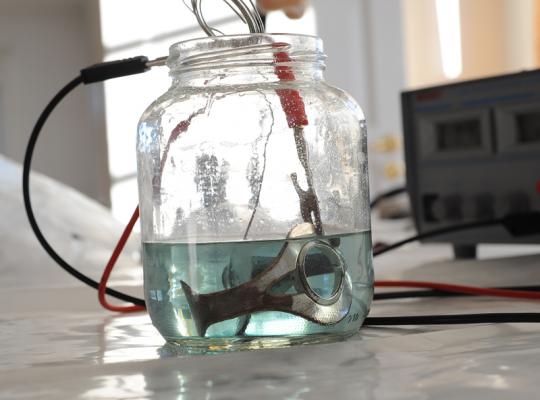

The watch came in yesterday ! :) It turns out to be a copper-alloy base-material, with a silver plating.......kind off, more to come...... The movement seems to be a very low beat. I can nearly count the balance swings, perhaps 2 beats per second? Amazingly, it keeps the time reasonable...... Took the movement and crystal out, to be dealt with later as this is first of all a plating project. At first glance some obvious problems were visible; First the crack left onder and secondly some strange wear on the inside of the bracelet Inside the bracelet the silver is worn off, but also the copper base-material seemed to be corroded & pitted. Initial thoughts were corrosion due to sweat, but later I learned the real (horror) story. Somewhere on the internet, even from an official company who's selling plating-equipment, I learned that one could reverse plate chrome / silver off an object. Later I found out (was told ;)), this is a VERY BIG NO NO, so don't follow this. One of those lessons learned of how not to do it. Anyhow, before I knew, ignorant bliss, I did this; I took a glass jar with heavy diluted sulfuric acid and connected some silver wire to the cathode (minus). The bracelet became the anode (plus) and so the metal-donor. It took only 1.4Volt and I limited the current to 2.2 Amps, to slow down the process and have ample of time to observe. As you can see, the silver came slowly off, revealing another (black colored) plating layer. A little further in the process, this 2nd layer suddenly started to come off in big flakes, revealing a rough copper base layer. This worried me, so I stopped and consulted my friend who is specialized in (hard-chrome) plating. First of all I was taught a lesson to never ever reverse a plating process. Reason being that one has no control over what gets taken out of the base material. This may ruin the whole object for any further plating! Secondly, because this is a cheap object, the base-metal is left pretty untouched, but gets covered with a thick soft cyanide based copper layer which is very easy to polish prior to the silver plating. This explains the second-layer I encountered, but also why the inside of the bracelet looks rough & pitted. The silver and the thick-soft-copper layer is worn off, exposing the rough base metal. The next picture shows the bracelet fully stripped of its plating (rest was done by hand), leaving a copper base-metal with all kinds of pitting and marks........some are mine after some sanding. A pretty rough bracelet of not the highest quality base-material :( Time to deal with the crack before doing any further polishing or spending time. First I opened the crack with a hobby knife, and widened it with a small Dremel diamond grinding wheel. I only had a 50cm, 1cm thick hard-solder rod, so I took a file and collected the shavings. Put this on top of some S-39 flux and soldered the crack, heating from underneath with a hobby burning torch. and after some sanding, the crack is repaired :) The next challenge is to make a smooth surface of something which isn't. My friend has this soft cyanide based "smoothing" copper, but is for sure not giving me any. He says, one mistake and I have to carry you away........not under his watch ! So, that's going to be quite some sanding and polishing to be done....... not sure if it's going to be mirror-finish..... To be continued..........2 points

-

So, here it is the one that is now my (almost) everyday watch choice: I like it very much and I think it's one of the best quality/price pieces for an automatic watch with a titanium case and a saphire crystal. The price is a little under 500 €. I 'm very pleased with it's performance, as I managed to adust it to get a < 1 s/day variance, ( despite the fact that when I received it, it was gaining a deceiving 15s/day!) Other interesting feature is an unusual complete fluorescent dial: which is very readable and very nice to look in the dark! Main technical features: Model Series: Spitzbergen F13 Movement Type: Automatic Movement Caliber: Citizen/Miyota 9132 Jewels: 26 Clock Face: Fluorescent Glass: Sapphire Crystal Chassis Material: Titanium Chassis Diameter (mm): 42 Chassis Height (mm): 14 Water Density (atm): 5 Chasis Color: Grey Lug Size (mm): 22 Wristband Color: Dark brown Wristband Item No.: 361080002222 Fluorescent: dial Vibrations (h): 28800 Max. Power Reserve (h): 40 Winding Direction: Bidirectional Complications: Power Reserve Display, Date, Sweep Second, Stop Second Add. Features: 24 h Display Special Features: Crystal Case Back Color: Beige Weight (g): 831 point

-

the videos have been re-released in high(er) def.... part 1 - https://www.youtube.com/watch?v=mTnxy_VKt5c part 2 - https://www.youtube.com/watch?v=pXz8RPEM21E1 point

-

Absolutely! I'm always trying on Ebay but need to keep the cost under 400, which has proven to be darn near impossible for an 18k/Stainless band:/ Gorgeous Longines! The current strap fits nicely, perfect color for gold:) Today's watch is another special one: Eberhard 8 Jours (8 day power reserve) Love this one, has the original alligator strap:D1 point

-

never opened one of theses, i assume its serviceable after a clean, be a nice project me thinks!1 point

-

virtually every epoxy should be mixed 1:1. with the syringe-style, you can usually press a little harder on one of the plungers if they're not dispensing equally. never thought about snipping the linkage. nice tip...1 point

-

Problem Solved. Sent from my iPhone using Tapatalk1 point

-

Check this lot from Ramon http://www.ebay.com/itm/4pc-Vintage-SEIKO-Automatic-6309-7009-6119C-Gents-Parts-Watch-AsIs-/201532545123 One of them has a nice dial and hands in good conditions. I think buying from him is almost a mandatory step for any Seiko tinkerer in the world.1 point

-

1 point

-

Today I'm wearing a 50s-vintage Shturmanskie. When I received it a few weeks ago, the minute had was spinning freely on its mounting, so apparently it had a hard time during shipping from Ukraine. So some TLC on the workbench got the hands sort out, and it's now running nicely. The movement, by Pobeda, is rather nice-looking. Cheers, Gryf1 point