Leaderboard

Popular Content

Showing content with the highest reputation on 09/01/15 in all areas

-

4 points

-

escape wheel and pallet can work independantly, ie you can buy a replacement escape wheel and it should work as planned. Bear in mind that if the watch has a faster beat-rate then the parts will not be the same. What is important is to view the interaction between the pallet stones and escape wheel, one should lock as the other unlocks. Since uffit runs for a while and only stops when you knock it this points to a something loose. Inspect the jewels really carefully with a powerful loupe. In my first reply I mentioned barrel pivots, to elaborate, this must have very minimal endshake...there should be no marks which show that the barrel has been rubbing on the main plate or barrel bridge. It must be able to get 'cocked' at an angle. Also look at the centre hole and centre-wheel pivots , if not jewelled. Check all pinions, cleaning sometimes fails to clear the gunge inside the pinion leaves. Another thing to check,..is the hairspring level? Install the balance without the escapement (all other stuff) so that you can check that the hairspring sits level and the endshake is correct. Finally, when mixing and matching used parts you need to bear in mind the fact that someone else was in there before you and he could have modified something. For example, replacing a balance staff is a fairly common task, but if the watchmaker did not have the correct one handy he could have modified another staff to fit.. part of the modification could include reducing the effective distance between the balance cock and mainplate to accomodate a shorter staff.. this can be done by removing metal off the base of the balance cock or by pushing the jewel in the mainplate deeper in. Vice versa to increase the distance by inserting shims. You need to work thru the whole watch... from barrel up to balance.. looking at each individual component, its pivots, its clearance and its interaction with the next wheel/part. Tedious but part of the job..! Anilv3 points

-

2 points

-

hello, after a long time i 'm here with my project, the case is last version case polished, i have also a micro billiard, unfortunatly the dial is not last version .. i hope to have it on september. Please what do you think ? i hope in the more comment ! thanks http://s15.imagestime.com/out.php/i1034875_WP20150804001.jpg http://s15.imagestime.com/out.php/i1034876_WP20150804004.jpg http://s15.imagestime.com/out.php/i1034877_WP20150804005.jpg http://s15.imagestime.com/out.php/i1034878_WP20150804006.jpg2 points

-

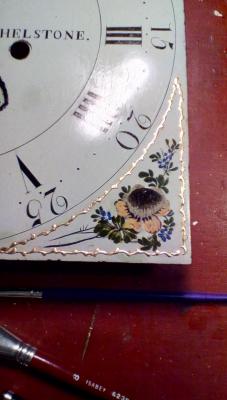

Finally got round to putting gold leaf on my long case clock dial which I restored a while ago,the pictures had been over painted by Mrs Mop and looked terrible,I managed to remove it and there was enough of the original left for me to redo it,all the numerals and minute rings etc were gone but usering UV light was able to see them all very clear as old inks were charcoal based and they Flores, the case is good and now just waiting on the movement which my brother is going to do,but as you can guess family comes after paying customers.The clock is about 1785/90 and is a nice example of a Cornish long case.1 point

-

The chicago PDF course is very dated but will give you a nice little entry point. I can also recommend the DeCarle book "Practical Watch Repairing", again, very dated but the principles taught are sound. I don't recommend doing anything with a quartz timex, they are not supposed to be repaired, the plastic plates will melt with any kind of watch cleaner or lighter fluid for example. I would recommend getting a chinese replica UT6197 off ebay or from Cousins (about £30) to practice on as it is a nice big movement and very easy to dismantle and put together.1 point

-

The help, advice & welcome I've been given on this forum (community) has been priceless. If I can give back in my own little way it would be my pleasure. I just hope they are what George is looking for. Sent from my GT-I9505 using Tapatalk1 point

-

Hi George, I have an old set of baskets which came with my elma & I replaced with the blue set from cousins. They are just taking up room in a drawer. I'm currently in Turkey on holiday, but on my return I'll post some pics & your welcome to them for the cost of postage if they are any good to you. Sent from my GT-I9505 using Tapatalk1 point

-

adding to my post above. You have one watch with a damaged pallet fork right? When a pallet fork goes bang....either thru a broken pivot or pallet-jewel, what can happen is the mainspring power is released suddenly...this can really mess up the teeth on the escape wheel. Anil1 point

-

1 point

-

1 point

-

It does sound like you have some 2870 wheels in there as its running at 28800. I don't know this calibre but, are all three hands running fast? I suspect it's just the second hand. You can calculate thus calibres correct rate by counting the teeth on each wheel as pointed out by Marc. Here's an example for an Omega 561 where the barrel drives the second wheel which is attached to the cannon pinion so: The second wheel large gear has 64 teeth and rotates once per hour (3600 seconds) by definition as the minute hand is connected to it via the cannon pinion. The 3rd wheel has a small gear of 8 teeth which meshes with the large gear of the 2nd wheel. So, for one rotation of the centre wheel, the 3rd wheel rotates 64/8 = 8 times. Therefore, it rotates once in 3600/8 = 450 seconds. It also has a large gear and that has 60 teeth. That large gear meshes with the small gear on the 4th wheel which has 8 teeth as well. So, for one rotation of the 3rd wheel, the 4th wheel rotates 60/8 = 7.5 times. Therefore, it rotates once in 450/7.5 = 60 seconds. It also has a large gear and that has 77 teeth. That large gear meshes with the small gear on the escape wheel which has 7 teeth. So, for one rotation of the 4th wheel, the escape wheel rotates 77/7 = 11 times. Therefore, it rotates once in 60/11 = 5.4545 seconds. It also has a large gear and that has 15 teeth. This is the one that meshes with the pallet fork and so, the teeth pass the fork every 5.45/15 = 0.3636 seconds. There has been a little rounding of numbers in this paragraph for simplicity. This tells us that this watch beats at 2.75 Hz ( 19800 A/hour = 2.75*60*60*2) as 2.75 times per second means one beat is in 0.3636 seconds. I just copied this from something else I wrote but, it will make sense to everyone here. If I wanted to change this movement to run at, say, 28800 A/h, I could do it just by changing the number of teeth on one or two wheels. I can't immediately see a way to do it with one as it would have a lot of small teeth. Usually the fourth wheel runs at one revolution per minute as then we can easily mount a sub second hand on it. So, maintaining that but changing its large gear to have 96 teeth (was 77) and the small gear on the escape wheel to have 6 (was 7), it becomes a 28800 movement. Nothing else needs to change and it now runs at 4/3 speed (a bit like my life since I passed 50...) All you need is the correct wheels from Cousins for a 2871. Hope this help, Chris Sent from my XT1039 using Tapatalk1 point

-

1 point

-

Hi ginger, I recently cleaned a movement that had similar signs of water ingress & I found this video Mark did very useful. Although it's of a 7750 movement, he does show & discuss a couple of methods he used to clean the particularly bad areas. I think it's round 14mins in https://youtu.be/BesSK67Mzms.1 point

-

1 point