Leaderboard

Popular Content

Showing content with the highest reputation on 06/15/15 in all areas

-

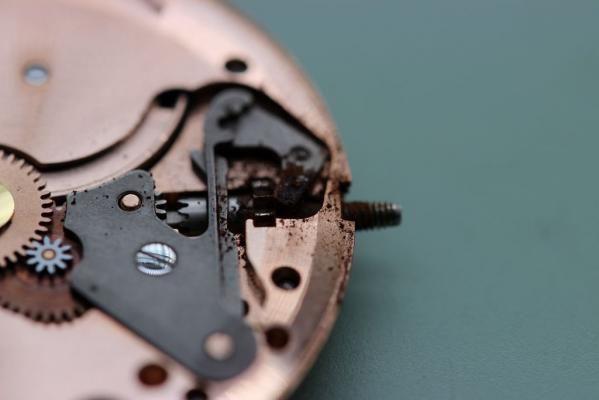

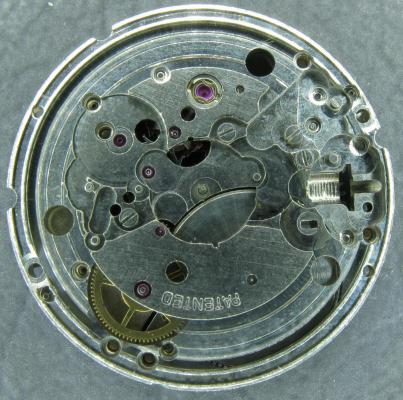

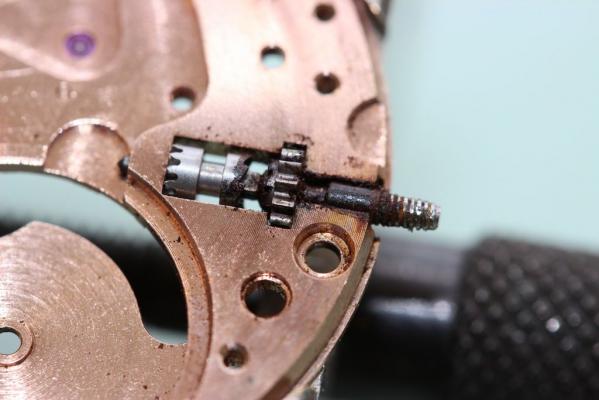

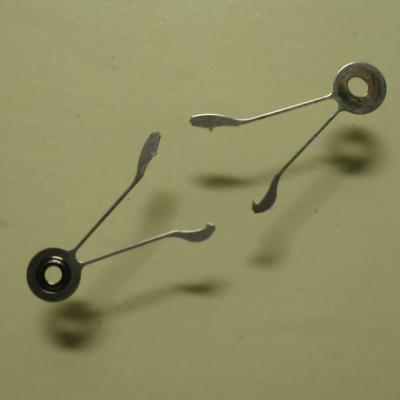

This nice Omega came in with a seized up keyless work. The crown could not be pulled out to hand set position and the watch could not be wound. I immediately suspected rust. Getting the movement out of the case was a challenge because the crown could not be pulled out. But luckily I could unscrew the crown from the stem as the stem was seized. With the movement out of the case, I can see evidence of rust. Time to get stripping (the watch). First challenge was unscrewing this dial screw which was rusted in place. A bit of oil and some gentle persuasion and it unscrewed. With the dial off I can see the extent of the damage which is quite bad - but not the worst I have seen. Off with the hour wheel: And the setting lever spring: And this is as far as I could get. That stem was not coming out, but I have an idea! ...3 points

-

3 points

-

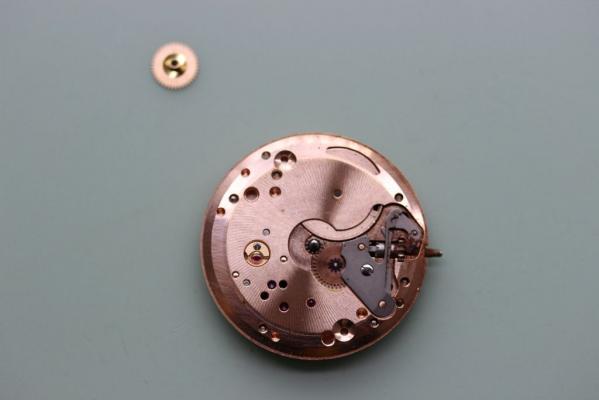

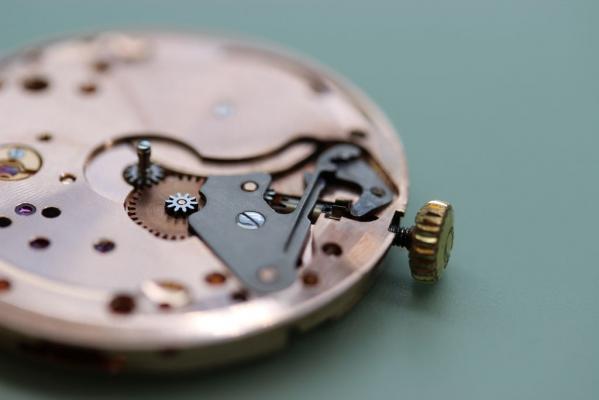

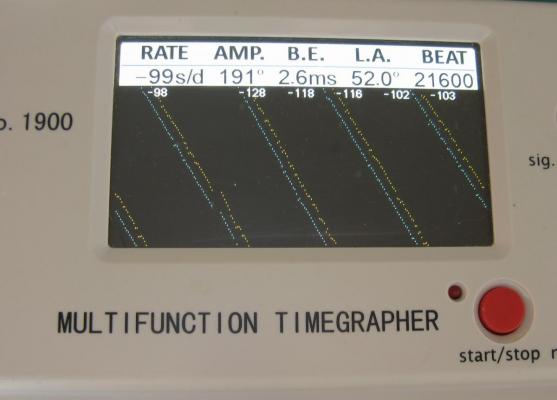

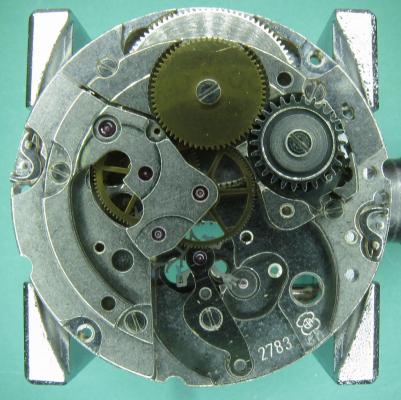

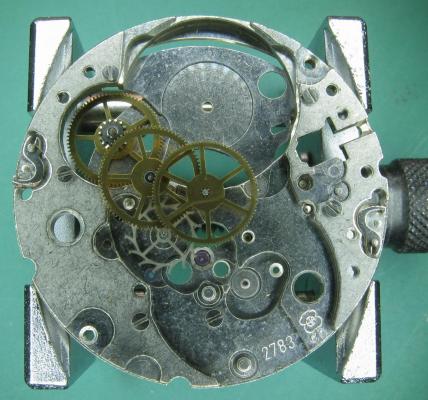

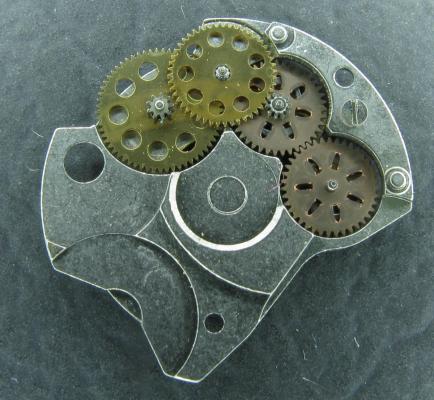

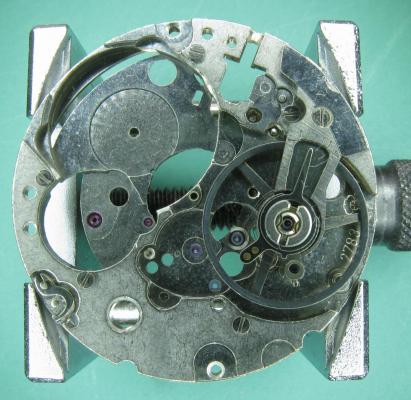

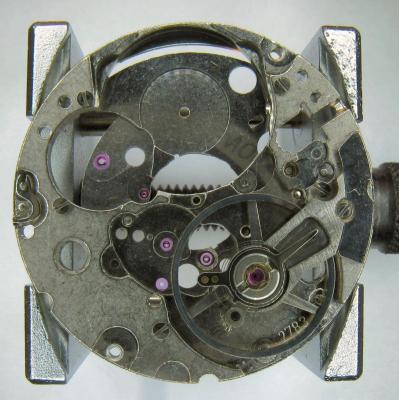

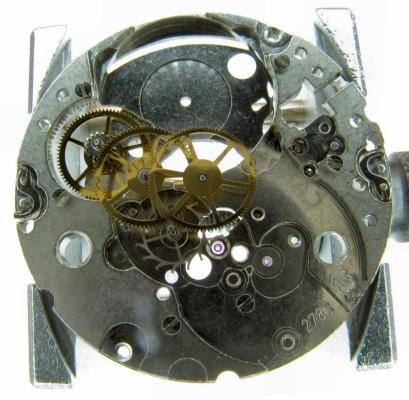

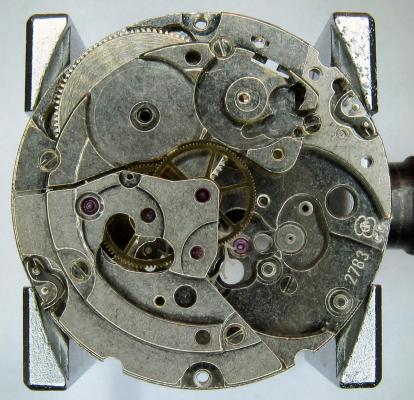

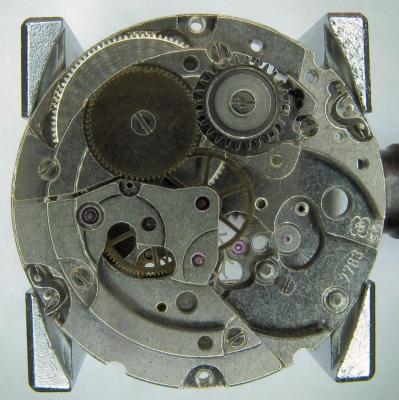

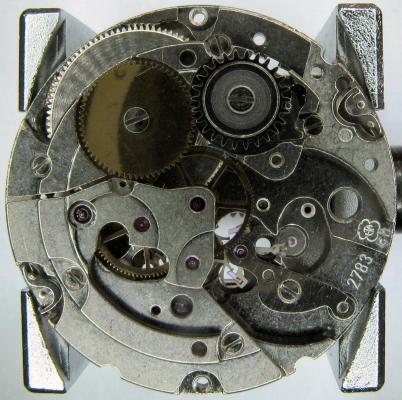

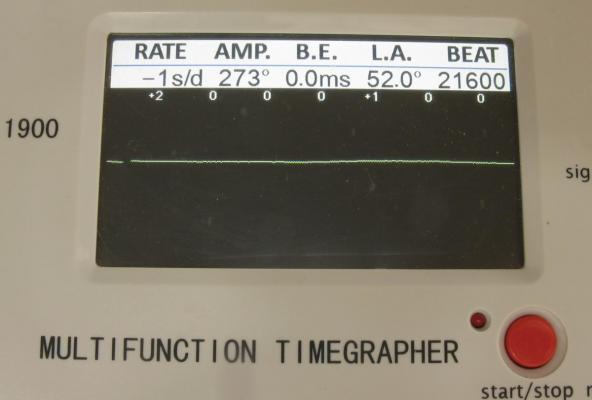

This is one that I picked up a while ago to restore and send on its way. A Cortebert 25 jewel auto probably from the 70's or early 80's. As you can see it was in need of a little TLC on the outside.... And by the look of it on the inside too. With the back off the movement looks pretty clean. It's an ETA 2783, a good solid workhorse, and apart from a couple of light scratches to the rotor and auto wind bridge, it doesn't appear to have been abused. With the auto bridge off the scratch can now be seen to extend to the ratchet wheel as well. Looks like someone slipped undoing the rotor screw and skated their screw driver almost to the edge of the movement. They must have been pushing quite hard. I guess they didn't get as far as trying to remove the dial. All pristine under here. Calendar works out of the way and layout of the key-less works exposed. Dial side stripped out. Just the balance pivot setting to come out. Flipped back over now and the balance and cock removed. With the remainder of the bridges, and the barrel out, the going train layout is revealed. This is the under side of the auto bridge with the reversing wheel cock removed to expose the two reverser wheels on the right, and two reduction gears on the left. The fully stripped auto bridge. I think that this might be the missing centre post that Tim was referring to in his post on the ETA 2873. And the balance and cock go back onto the main plate (minus the jewel settings) ready for the Elma. That's everything out of the cleaner and ready to go back together. The mainspring was in really good shape so after a very light application of grease, and a few dabs of 8213 in the barrel wall recesses it goes back into the barrel. The balance jewels are then installed with a bit of 9010 and the free movement of the balance wheel checked. Also the state of the hairspring and it's proximity to the balance cock is checked. All is well here so the balance and cock come back off and go to one side whilst the rest of the train goes together. Going train back in. I just love how bright and shiny it all comes out of the wash. Barrel and bridges back in place. HP1300 for the barrel pivots, 9020 for the second wheel, 9010 for the rest. With the ratchet wheel, crown wheel, and click in place I can now check the recoil on the escape wheel. All good. Pallets back in place and lock and draw checked, then a touch of 941 on the exit pallet, transferred to the escape wheel teeth by gently working the pallet fork manually. Then drop in the balance, and off she goes. It's then just a matter of reassembling the calendar works, key-less works, and the auto wind module, and the mechanics are done. And there's a nice drop of ETA goodness to confirm that all is well. A very gentle clean for the dial and hands, polishing of the case, and a new armoured crystal, and things look a whole lot better than they started. I hope that this proves useful to somebody. This has now had a 24 hour test drive and has managed to stay within a couple of seconds of spot on on the wrist. I really like the look of this one and it's a very comfy size, I almost decided to hang on to it but I just can't justify another at the moment, so it is now on eBay. If anyone is interested I will post up the item number although it should be easy enough to find. Marc.2 points

-

So next off is the main plate exposing the wheels. I was half expecting to find rust in the pinion leaves or pivots but all seems fine. Off with the wheels... A teeny bit of rust on the escape wheel pivot but luckily not attached - brushed off and left no stain. Now back to this bugger of a stem. The oil did not seem to help... But after heating it up with my spirit lamp, I grabbed it with my pliers and gave it a sharp pull. It came away just fine. The barrel arbor was quite rusty so I decided to burnish it - easiest way is to use the lathe... And it came out quite well... Just need to clean up the rest of the parts and clean the watch now. To be continued.2 points

-

Hi , I picked up this Bulova Accutron 2182 Deep Sea 666 ft. at the swap meet today . It was not running and I discovered it did not have a battery . That's the good news . Both stems and crowns were frozen in position . The 2 hr stem has a gear that rotates the inner bezel and there is some rust preventing rotation . The 4 hr position stem was stuck in the setting lever and freed up for removal on loosening the setting lever screw . I want to take the crystal out but am not sure how to approach this . I don't know if it is acrylic or glass , and if I should press or knock it out using my nylon press dies , or if I should use a crystal lift for this . Any help is appreciated . This watch is the same as the models that say "Snorkel" on the dial . Mine says "Deep Sea ". The picture I'm attaching is from the internet , but mine is similar . Thanks , Louis1 point

-

I think this is what you are after Ken. http://www.usersmanualguide.com/manuals/casio/qw305,307,309,314,315,358,364,388.pdf1 point

-

1 point

-

1 point

-

1 point

-

Really good write-up mate. Isn't it funny how when the word gets out you can fix watches, all the ones hidden in drawers for years suddenly surface :p I don't think my parents have a friend who's watch is not fully serviced now ha ha!! Its great practice and confidence buildings to do them though. Also I love the way a new crystal makes a dial face pop.1 point

-

R Rogart, yet another link to be added to the ever growing list. Have never worked on an electric watch but did once repair a case that had an electric clock movement inside. If I remember correctly it also had adjustments to get the timing spot on just as a mechanical watch/clock has.1 point

-

I really like the look of the watch Louis, but unfortunately I have never worked on one. :( Just as an aside, you would need one "hell" of a length of snorkel to work at 666 feet, and it looks like that one has been to 667. ;)1 point

-

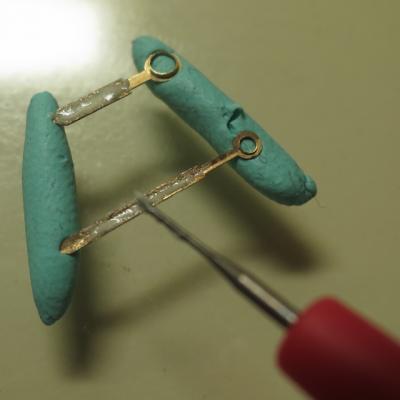

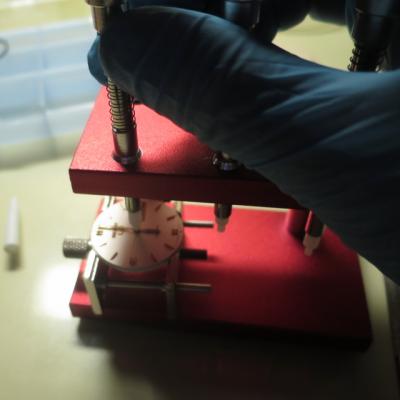

Don't worry, this is the last part. As I was wrapping up the movement service, I noticed that the automatic winding will not work. I found out that the pawl lever and the second reduction wheel are worn out. Compare the worn out parts in the left and the replacement parts in the right. After replacing the said parts, I went on to work on replacing the crystal, cleaning the case and bracelets and re-luming the hands. Yeah, I could have done better on the hands. The lume was too thick. I then installed the hands, placed the movement inside and demagnetized the watch. And here's the before and after shot. All done for a friend for free. :D I hope you enjoyed it. Please let me know any suggestion on how I can improve on my hobby.1 point

-

Maybe ofrei has the spring by movement and this will clarify what it is all about...for both of us?! Try and give them a call, they can be very helpful if you get them in a happy mood...I mean sometimes! :) Cheers, Bob1 point

-

There is some very useful information here:- http://great-british-watch.co.uk/watch-anti-shock-settings/1 point

-

Here's another I am working on at the moment (please excuse the not so good pics): Basically sound, no lifting varnish, but the usual age spots, blooms etc. Immersed into IPA & gently brushed with a sable brush for a couple of minutes, rinsed in distilled water for another couple of mins, then dipped in HG silver dip for a minute. Finally rinsed & dried: I would not suggest that this method is completely safe or will work every time, but the results have been good so far. Just don't try it on a friends Patek - particularly if he's a big barsteward!1 point