Leaderboard

Popular Content

Showing content with the highest reputation on 05/02/15 in all areas

-

Welcome Tintin, Bob is spot on with the tools. Never buy cheap tools mate, you'll just end up having to re-buy the same tools again for better quality ones, and waste money. The topic of tools has been brought up in a number of threads on this forum, and I'll let you know now, you'll need to invest some coin if you truly want to enjoy this hobby. One of the first things that stops you finding this a rewarding and enjoyable hobby, is what I call "Failure Frustration". As Bob pointed out, and a LOT of us have discovered, not having the right tools, or more to the point: using poor quality tools that lack feel and precision, is often more the cause of failure than your ability, and your confidence will suffer because of it. You'll think you don't have the ability to work on movements, and give up; when all along it was the crappy tools that was at fault. And you'll miss out on a wonderful rewarding hobby, and one that you can pursue well pass retirement age. Remember Tintin, most of these tools will last your entire life, so buy the best you can afford. Tools to start with are: Green Bench Mat - Bergeon 6808 (This makes the small parts easy to see, and is a must. Screwdrivers - By far one of the most important, and expensive investments. There are only two brands to look at in my opinion: Horotec and Bergeon. How much you spend will determine the quality and feel of your drivers. I recommend buying them in a set with a swiveling stand - trust me, you'll thank me for this recommendation. Tweezers - Only brand to buy is Dumont - #2 and #4 in Anti-magnetic Steel, and #2 in Brass. Pegwood - Cheap off ebay Watch Hand Removers - Horotec 05.008 are a good set to start with. Watch Hand Fitting - You'll need two: Horotec 05.010 and 05.011 Movement Holder - Bergeon 4039 and 4040 Metal NOT Plastic Rodico - This is the blue coloured putty like substance for removing dirt and dust - a must have. Eye Loupe - I recommend a 3x and 10x to start with. Oils - Moebius 9501, 9010, 9415, D5 are the basic oils to start with. Greasing Pad for O-Rings - buy off ebay - Seiko S-916 OIlers - Bergeon - Buy them in a set of 4 Oil Pots - Expensive branded ones are not that important ... just make sure they seal well from moisture and dust. Caseback Knife and Jaxa Tool - for opening up the back of watches Air Puffer - Find one of ebay ... doesn't need to be an expensive Bergeon branded one. LED Desk Lamp - I purchased two flexible arm ones off ebay for around $25 Plastic Parts Holder - Watchmaking specific, with clear dome covers. From there, just like with tools for cars, the sky is the limit ... slowly build on your tool set from this basic list as your needs require. I hope this helps, and wish you a bright future in watch repair.2 points

-

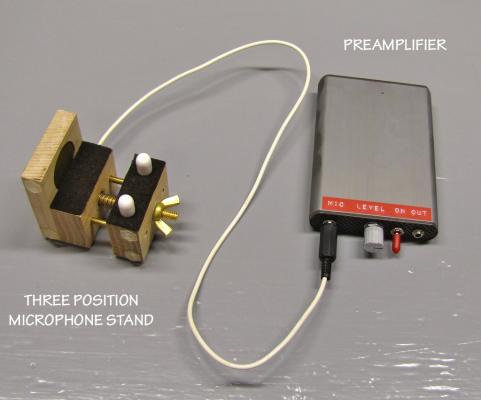

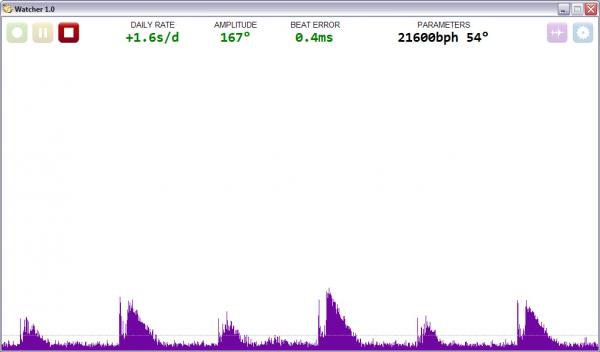

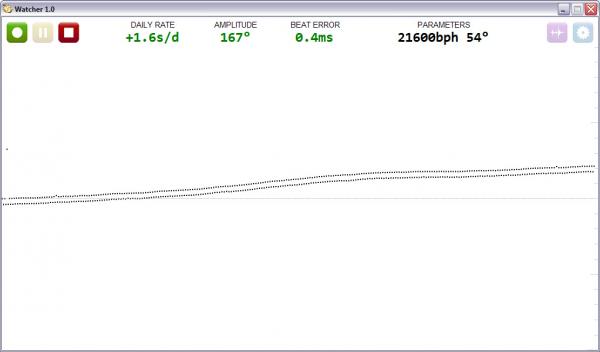

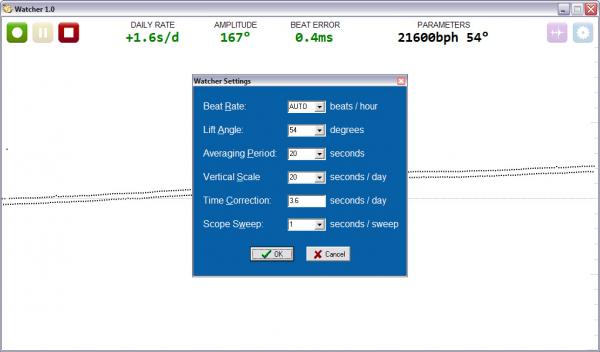

I'm a watch DIYer, having serviced two watches myself, partially using tools of my own making. One thing I've been working on over the last few months is my own PC based timing machine. I've finally got something working reliably, and thought I'd preview it here. My plan is to eventually write up a detailed article on my web site describing how to build the hardware, and providing a download for the software. I may also produce a "pro" version of the software with more features, to be sold for a reasonable fee. Here's the hardware, all home made of course: The next picture shows the timing trace from my "Black Lagoon", a modified Invicta 8926OB with a Seiko NH35A movement (yes, the amplitude is quite low and tends to fluctuate, topping out around 220 degrees - apparently this is par for the course for Seiko movements): In this picture, the software is in scope mode, showing directly the ticks and tocks. Notice how with this movement, they alternate in loudness. Since the scope mode was run after the timing mode, the scope also shows the threshold that was used by the timing mode to detect the start of each tick. And this is the settings window: Here's a brief list of features so far (I have to resist creeping featuritis): Numerical display of daily rate error, balance amplitude, and beat error. Horizontal "paper tape" mode with sub-pixel vertical resolution that can show fluctuations that are too small to see on a typical stand-alone timing machine. User selectable averaging period. Rate determination using linear least squares, which gives a more meaningful reading than just naively averaging the rate. Automatic signal and noise level determination. There's nothing to adjust. Aggressive noise filtering in the software to keep the hardware simple. Automatic rate detection for common rates. Simple, uncluttered, fixed-size display (1024x600). Scope mode to aid in diagnosis of various watch faults.1 point

-

1 point

-

Totally agree with Lawson about tools. I've only just started out and have made the mistake of buying cheap tools off ebay. It'd not worth it. Replaced a cheap set of screwdrivers now with Bergeon and A F Swiss one's, hell of a difference in quality. As been said decent tools cost a bit more, but should last a life time if looked after. Just not worth buying cheap.1 point

-

I had a watch maker sneaking through my bench and he said, "Man, I'm so sorry!" I said, "I know my tools are used and limited!" He said, "No, those condoms are really small!" I don't think he uses them at all, but I didn't ask because he caught me off guard. Lol Sent from my iPad using Tapatalk1 point

-

Hi Ken, I might be able to help out. I have a few Illinois I can pull the plates and take a picture and I have Swigart's books with all American watch movement parts lists. I need a little bit more info though. Size of movement, model number, serial number, OF or Hunter, Stem or lever set. I can see it's a 17 jewel bridge movement. Edit to add: Use a good, clean lighter fluid like Rosonol to clean, then a thorough dry. Don't use detergent and water. Stay away from flames :)1 point

-

I would also add a press to the above list. Some watches can not be closed without a press and it will also give you the ability to change crystals! Also one plastic tweezers for handling batteries! (inexpensive).1 point

-

Maybe it is time to service it...check for magnetism, jewels with caked oil, and hairspring for shorts (either magnetic, oil or simply kinks)! :)1 point

-

This may be useful http://beco-technic.com/index.php?cat=c10_Watch-Movements---Original-Spare-Parts.html1 point

-

Tore, I'm also new to watch repair and I can't tell you anything about servicing watches but I spend a lot of time on web auction sites looking for equipment. There is quite a lot of used equipment out there, much of it is good quality too. You will discover a lot of information by reading through all the threads on here, just as I have done. I was fortunate to find an old watch-cleaning machine - a Brenray - for which I paid £50. This is a professional piece of equipment but very useful for us amateurs too. Watch Mark's video on using a watch cleaner. I'm sure that you can find one too. As for plastic bins or trays, I buy the trays for making ice cubes from the shop that sells everything for £1. They can be made of rigid plastic or flexible silicone.1 point

-

Pop down to you local well known diy store and stick them on the area at the cashout which says keep cedit cards etc away !!! Any store that has magnetic security tags will do similar!!! This will demag tools but do not use for watches as quite powerful. I have also used a solder gun (the larger ones with a trigger) for tools not watches as a bit too powerful. Hold near, switch on and move away slowly as far as you can (should only take 5 secs or so). I also have one similar to the link above and it works fine provided you hold for a couple of secs and then slowly draw away.1 point

-

Unless original Citizen part is requirement then Miyota 5R21 is same as Citizen 5421 and is also offered as a replacement for 5421A http://citizen.co.jp/miyota_mvt/download/pdf/spec_5R21_5R32.pdf Cousins and watchpartuk have movements in stock (about £10), and Cousins has Citizen coil 246.137 about £11 !!!!1 point

-

1 point

-

Welcome Tore, You have a nice selection of watches if you stat to repair and service watches it becomes very quickly obsessive. Lots of knowledge & experience here on this forum enjoy your visits.1 point

-

Super! Thank you, Bob. I'll look more through the pages here on this forum (I had, to be honest, only been lookin a couple of minutes in the forum - then registered an asked this question). :-) Yes, I know all about the tools also becoming a hobby. My father has been repairing cars all his life and both buying and creating and modifying tools to do different jobs, and his car has been given the nickname "A toolbox on 4 wheels". He is sometimes helping others that has car problems by the side of the road - to get the car running again. ("Look, there is a car with problems. Let's help.") Ok, then I'll skip Amazon-tools and rather look for proper tools. I guess screwdrivers, tweezers and optics is the most important starter items (and a couple of small plastic-bins to keep all the small parts in).. TTYL - Tore1 point

-

A warm welcome to the forum Tore, and thank you for the comprehensive introduction. That is an excellent selection of watches you have managed to acquire, Will on the forum will be most impressed. I look forward to hearing more from you in the future. :)1 point

-

You should describe it as 'A platform escape wheel for a small Gübelin carriage clock'. 'platform' is important since other clocks have quite different escape wheels. It is particular in that there is a long shaft above the wheel. This is uncommon but it does make it very suitable for repair. Those with very short shafts have to be cemented onto the lathe chuck but yours could be firmly held in a standard 0.4mm or 0.5mm chuck. This would be a great advantage for the repairer. When inquiring about a repair add a photo. It will be easier to find a repair service than a replacement part. The cost will depend very much on the temperament of the watch/clock maker!1 point

-

How about this. http://www.ebay.co.uk/itm/191510796972?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT Just demagnetised a Watch, works very well.1 point

-

Hi Doug. I'm definitely with the other guys on this. If it's stainless, I would use 1200 grit wet or dry paper first and back it up with a stick and use it like a file and follow the contour carefully. Then use the stick with a touch of metal polish on it and polish using a fair bit of pressure, I personally use Solvol Autosol polish. Finish off with a specialist cloth for polishing silver, this is inpregnated with a very fine abrasive and will give your watch a lovely lustre. Please heed Anil's advice regarding opening and closing the back!1 point