Leaderboard

Popular Content

Showing content with the highest reputation on 12/31/24 in all areas

-

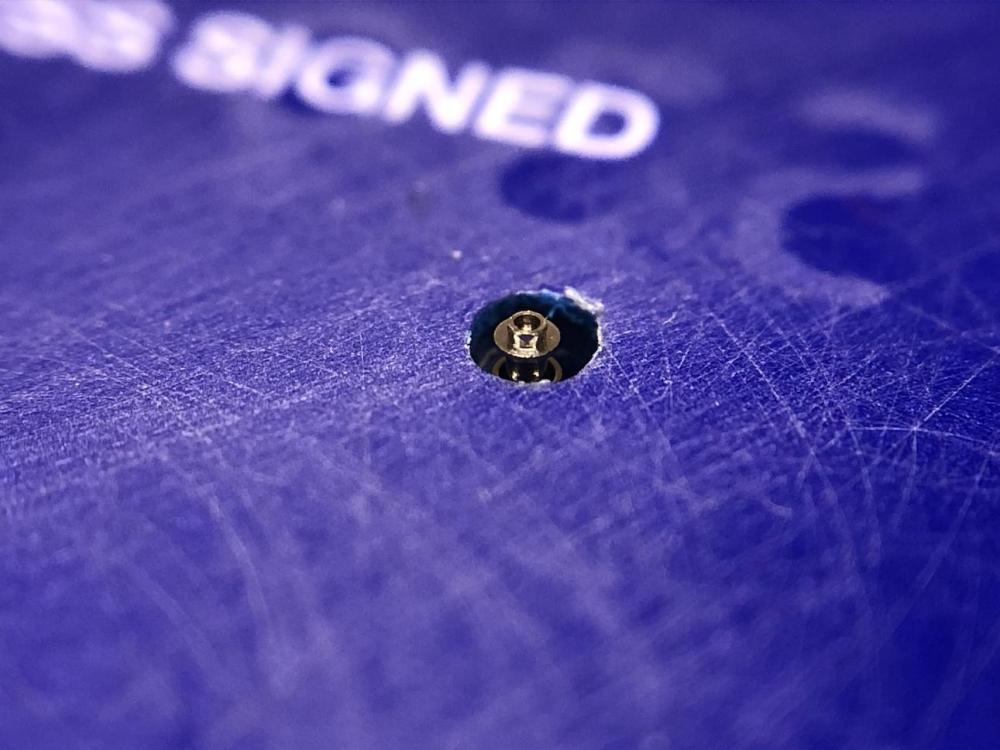

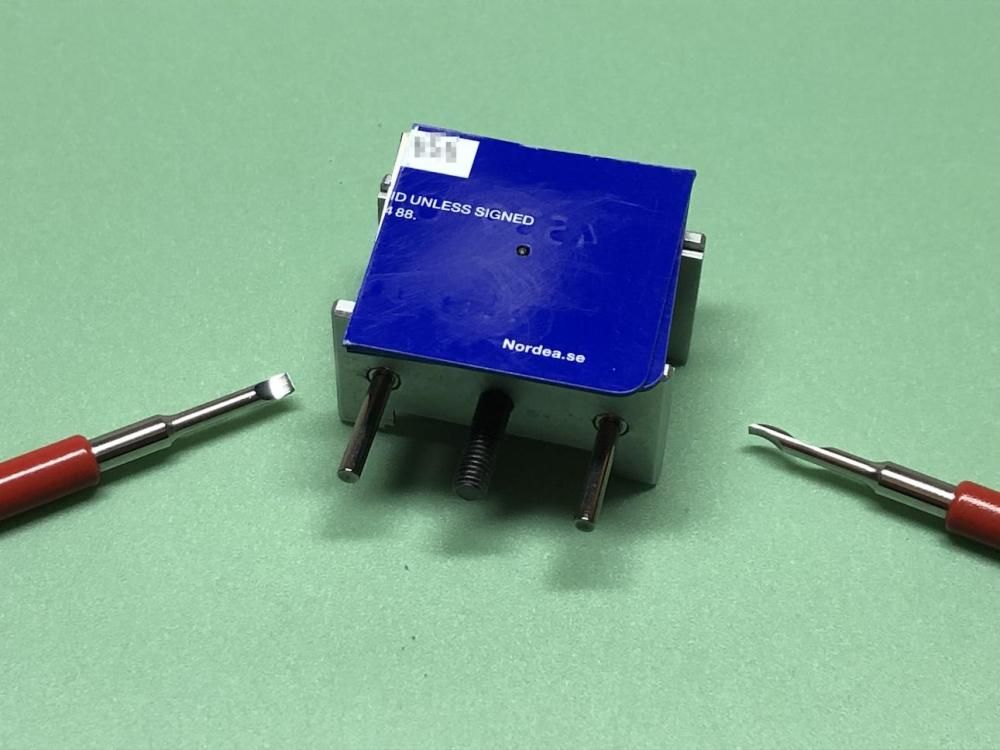

Mission accomplished! I really can't thank you all enough for your help. WRT is all about this, and what a fantastic way to finish the year! Before getting in there. Two layers of my wife's card were required. Ready for the operation. Hand levers are ready to go. Not too much force applied and it snapped off with a slight click. Oh, that thing is tiny. Zero damage to the pivot. Wishing you all a truly Happy End of the Year and New Year!4 points

-

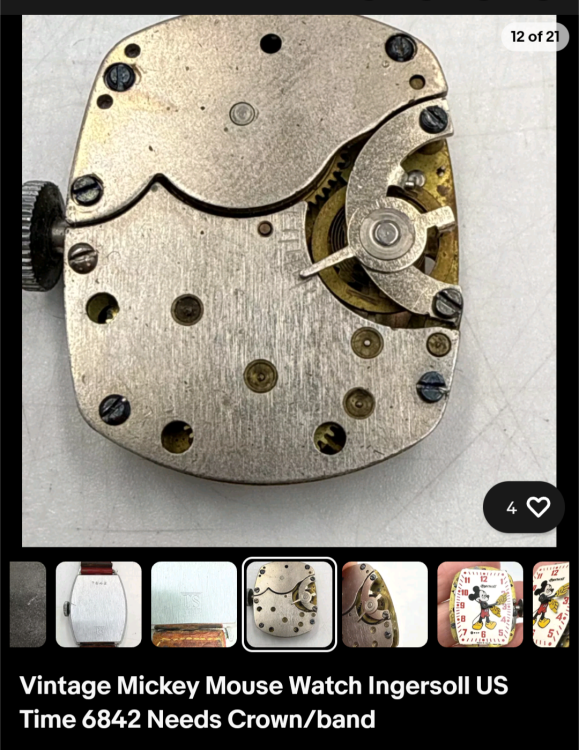

I think it's probably 1953 as it looks like by 1958 they'd changed the Ingersoll and dropped the W.D.P. https://www.watchophilia.com/photogallery/mickey-mouse/3 points

-

Thats a " Big Boy's " lathe Only thing to do is join the club and get that lathe that you want Michael3 points

-

Right - I have been chuckling about this. It's like Gandalf telling all us hobbits down here in the Shire how easy it is to defeat a Balrog.3 points

-

My first ESA 9162 movement. Bought as a non-runner. It hummed but there was no movement in the hands. Turns out there had been a battery leak (not clear from the description, grr...) which had spread to one of the modules and the index wheel. I cleaned plate with some bi-carb and water. The module had suffered heavy pitting on its contacts so I replaced it for a spare left over from another project. The index wheel was problematic. After cleaning and soaking in essence of renata the crystallised battery contents was still solidly attached. It was also covered in brown "gunk" which I could not identify. Assuming it was a lost cause I put it back on the module plate and ran it through the sonic cleaner for 15 secs. I checked it through the microscope and miraculously it seemed to work! Cleaned up the case and crystal (original) and put it on a home-made brown leather strap. Quite pleased!3 points

-

Nice work. I find that an acid works best for cleaning battery juice damage. The battery juice is potassium hydroxide and is very alkaline. Sodium bicarbonate is also alkaline, so there is no reaction. I used to use vinegar for neutralizing battery juice but I found that phosphoric acid works even better. The phosphoric acid comes in the form of a rust remover bought from a hardware store. I dilute it 1:1 and brush it on with a size 00 artists brush. The acid works immediately and bubbles can be seen. It also brightens up brass and removes rust, the green corrosion crystals and stains from the plates, without any hard scrubbing. Do not leave the acid on for too long, as the brass will start turning reddish from "dezincfication". It usually takes less than a minute. I then wash the parts immediately in distilled water. I have managed to revive many shorted circuit boards this way.3 points

-

Ah. But now you have the perfect excuse to get one Seriously, if you're working on older movements, a lathe will often be needed/handy.3 points

-

I want to provide a follow-up to this most interesting issue. I found a seller in Mannheim, Germany who had the calendar wheel (that I strongly suspected was bad or wrong) and I purchased it from them. It came in today, and it is the exact opposite orientation of the one I had. I installed it and the day and the date now change over in exact unison with each other. It's a thing of beauty! I have no clue about the bad calendar wheel. I don't see how it could have been re-arranged in any way, as it appears to be a riveted part. I can only suspect that the part I had was not correct for the movement? But yet, my customer says it worked just fine when it was brought to me? So, the only take-away I can share here is that if you buy watches or take in watches for repair, always do a thorough functional triage of the watch prior to opening it. It's important to see how it works before trying to fix anything, and may help with your sanity when you run into a problem like this. In conclusion, it was indeed a bad part, the watch is working like new, and you can cue the "Twilight Zone" music. Thanks to everyone for your assistance.3 points

-

Happy new year everyone!! Some may already be in 2025, others will follow soon. It has really been a great pleasure to get to know you in 2024. I thank you all for your help. I think this forum is really one of the best and kindest places on the Internet. Love and peace to you all!2 points

-

2 points

-

2 points

-

Yey well done " our kid " Happy New Year "H" x I remember years ago before contactless and card machines when we had to sign a receipt for our goods and then the cashier would check our signed receipt signature against the one on our card that was used to produce the receipt so that they matched. I never used to sign my cards and once a cashier asked me to sign my card in front of her so she could check it against the receipt I had signed 5 seconds earlier. " yes they both match thank you sir " Just googled the machine that did that, chunka chunk manual machines that the cashier swiped the credit card details over onto carbon copy paper that we signed. Wow ! Blast from the past....late 80s2 points

-

Excellent! And beautifully documented. Happy new year!2 points

-

2 points

-

I had someone get in touch with my from somewhere in Asia saying they had broken the pivot off of the anchor arbor so I did a video on how I do it although I hadn’t done an anchor arbor before but had done a few escape wheel arbors, anyway I thought I would put the video on here as it may be helpful to others. Dell2 points

-

Well if you're going to p.iss someone off, it may as well be your mother in-law2 points

-

Fast rates are common to the shortening of the active point of the hairspring. This is the position on the hairspring from which its oscillation begins, in a correct functioning balance that point is between the regulator pins. The further in towards the hairspring the active point is the faster the hairspring will beat. Once beyond the active curve where the regulator pins reside, If the hairspring's natural coil shapes are interrupted then that is where the active point will begin. So coils touching something or touching each other due to magnetism or contamination will move the active point from its regulated position. I tend to imagine magnetism as an invisible, interfering contamination...that can be bad or good...but bad in this case.2 points

-

40 years of working in the construction industry you learn to improvise, make-do, use whatever you have and think on your feet. Construction involves the use of so many different materials, often its a case of which material suits the job best. I'm waiting for the day I can use concrete in a watch ...a dail maybe . Usually a quick look around your environment will provide your needs, 2 days ago I used one of my mother in- laws table placement mats as a white board to sketch an idea for a watch part graining technique for MB to look at. Much to her annoyance and to my joy .2 points

-

OK, I tried again with some rolling and now I'm satisfied with the results. Thanks.2 points

-

Thank you for the tip, R It came at just the right time since I was just wondering what kind of plastic piece I could use. Just to be safe, I think I'll go with my wife's credit card. Unfortunately, I've always been bad at improvising, and perhaps that shows all too clearly to those who are perceptive. What else made you suggest so many different types of cards!? Regardless, I’m very grateful for the suggestion! It is indeed New Year's Eve tomorrow (or actually already), but hopefully, I'll have time to make an attempt before the champagne bottle is opened. Good thinking! Credit card and hand levers it is!2 points

-

I know I may be a bit OTT but I don’t like the idea of not being able to burnish the anchor pivots of the torsion clocks I restore, I know nothing moves very quickly and the anchor only rocks back and forth but if I burnish the pivots ( I don’t polish just burnish) it removes another variable because torsion clocks need to be as friction free as possible, anyway after a bit of thought I have found a way to mount them in the lathe. Dell1 point

-

Here's that dial and tonneau case from a 1948 Life magazine ad. Too bad they don't picture the movement. https://clockhistory.com/0/ingersoll/document-1470-1.html?page=2 The Ingersoll wristwatch movements from the 1930s were not terribly different than the later Timex movements in the 50s except decentral seconds. And all of them were basically scaled down versions of the Ingersoll dollar pocket watch movements from the 1920s Here's the movement from the late 1940s model, resembling the dollar watch construction.1 point

-

that is a Model 22 movement that was introduced in the second half of the 1950's. the 201 is a factory number and not caliber.1 point

-

1 point

-

1 point

-

Mickey dials with the hands don't appear in Timex catalogs until 1968, but those numerals are different than your dial and I am sure the 1968 model had an M24. They were still listed as Ingersoll character watches throughout the 1960s but the dials in the 1960-67 catalogs don't ever seem to show the characters. It does seem possible the old Ingersoll movements were still being sold later into the 1960s if the catalogs still mention Ingersoll and US Time in connection with the character watches. JerseyMo would just know know the year from his own head. If this blog is to be believed, your watch was in production as far back as the 1940's. https://vintageradar.com/en-us/blogs/vintage-magazine-vintage-watches-jewelry-and-fashion-blog/ingersoll-mickey-mouse-watches-since-19331 point

-

Yes it is the same as the M22, probably the most challenging Timex movements to reassemble and with the fragile copper spring strips holding tension on the stem retainer bar. But I'm not familiar with that format of dial codes. I think 1963 would be right around the last year you'd find this movement before the M24 replaced it.1 point

-

1 point

-

A man who makes no mistakes, makes nothing at all. I like the saying, if you try to do things sooner or later you will f&&k up. The only way to make no mistakes, is to do nothing.1 point

-

1 point

-

Glad it worked out, happy new year to you too. What makes me laugh is the "Invalid until signed " almost impossible to write on.1 point

-

Hey guys, I've made some changes to the code, to adding a spinning drying cycle, without adding more buttons. I have coded a long press to the main button. Video is attached https://youtu.be/WEQgm2lDEdo?si=le2T1PB69OdClNLu1 point

-

They are very handy for re pivoting and straightening bent pivots as well. I have got three, one with a dual chuck which is very handy.1 point

-

I agree, they're usually the best bet in Europe and surrounding countries But CousinsUK are not big suppliers of vintage parts. So this Tissot part is unlikely to be in their stock. Ebay or Urdelar.se then..1 point

-

Along with the other advice here, if you have a smartphone with super slow motion video, take a slomo video of the balance in action. I always do this as a sanity check.1 point

-

On that note, @shmengel, where are you located? It's always helpful to indicate this on your profile or in your introductory post. Sourcing parts is a big part of watchmaking and advice on that is highly continent-specific.1 point

-

Then it’s back to @JohnR725 ‘s suggested look at the hairspring and see if it is catching/rubbing someplace. Tom1 point

-

if everything is adjusted correctly moving the regulator should cause a problem like you're seeing. One of the things that really kills amplitude is hairsprings that are not flat. So for instance if you hairspring is touching the balance arms that would be very bad for amplitude. It be really nice to get a picture of the balance wheel in the watch not moving so we can see what it looks like. thinking about the jewels did you notice that one side is flat on the other side has a curve? The flat side goes in the curbside goes out otherwise you have an end shake issue and conceivably loss of power. then I'm curious about the Phone app the name of it. Then when you look at the oscilloscope you can see what the problem is it's not actually triggering where it's supposed to be. I'm curious about how you're holding the movement in the timing machine a picture that would be nice. Then some close-up pictures of the balance wheel and hairspring in the watch so we can see what that looks like. Then just in case you don't have the technical guide I've attached that. NH35_TG.pdf1 point

-

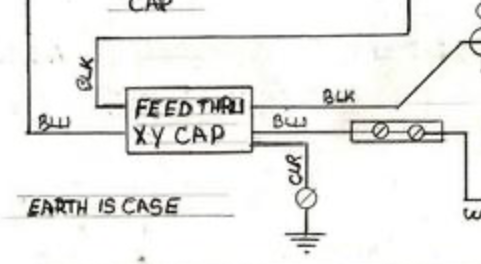

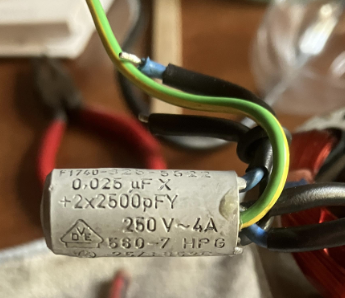

There should be 5 as your diagram and it should be connected to earth. One way to see if it's still working OK is to have a radio plugged into the same socket and see if you get interference when you start and stop the motor. Edit Just looked back at your photos and it's their just sleeved Green/Yellow as the earth.1 point

-

I have heard the same thing from a local watchmaker about the Seiko chronos in that there is more stress when it is not running than when it is. Which might be why there is no sweep or sub seconds on these; the design call for the chrono seconds hand to be used like a sweep seconds hand.1 point

-

1 point

-

Just to return to this old thread and say not too long after this I took up the practice of giving all train and balance pivots a 5sec twist in the finest EVEflex light green by hand. That has made an enormous difference; I can skip it because I don't want to risk removing a balance complete to reach the upper pivot and invariably I am unhappy with the result so I go back to take it apart and actually clean the balance pivots with EVEflex and every time it results in a huge amplitude gain. (huge because I'm usually working on filthy old watches) I still am not too hurt if I don't reach 270, but seeing a movement rise from a very weak 210 at full wind up to 250 after cleaner balance pivots is pretty satisfactory. But most importantly, it eliminates loads of problems with uneven dial up or down performance. Worth the few dollars.1 point

-

I've managed to straighten an extended third wheel pivot a couple of times. They're buggers for bending when the indirect center seconds drive wheel is removed. Think I rolled the pivots between two flat steel bars If you don't get those straight, the wheel intermittently disengages with the seconds pinion. I remember doing something with the 5 spoke wheel's hub as well. Anyways rolling is a good way to straighten out stufft that is round and malleable.1 point

-

Haha you do actually have to visit once in a while. That would seem like a crazy idea, but this is watchmaking I guess. Stops folk servicing their own watches. Haha the perfect alibi. " Honey , I'm just off to -The Gym- for a couple of hours with the lads" " oo come back all fit and pumped for me darling " " er.. hmm...yeah..I'll try "1 point

-

The collet holder is identical to what is currently still made by Horia, the little faceplace is not available anywhere other than second hand. I've never used it, it just doesn't have the precision to be useful (I do faceplate work in the lathe). Horia also has the reamers available individually. They offer both roughing and finishing ones, the roughing are 5 sided like the Favorite, the finish are "D" type like Seitz and Chatons SA. I would get the D type. Only hitch- the Favorite reamers have 2.2mm bodies, while Horia is 2mm. You don't have a 2mm collet in the set there, so you'll need one, also available from Horia.1 point

-

Modern friction fit jewels can be used as rubbed in, but some preparation of the jewel is needed. At least one of the edges needs to be rounded as to allow the collar to lay and fix the jewel. For this purpose, the jewel must be glued on the face of thin rod (thin as the jewel OD). Then the edge is to be ground on diamond disk or plate while the rod is rotated by hand. The hole for the jewel seems still usable1 point

-

1 point

-

I use the black smallest oiler for everything apart from grease on the keyless works where I use the biggest. Tom1 point

-

Here's a picture of my 6139. I had the same problem as yours with the pushers. I wasn't able to find original pushers before but the aftermarket pushers I placed have so far held up. I also got it from ebay. That was 3 years ago. I also make sure that the chronograph is always running. From what I read from other watch sites, thie movement will last longer if the chronograph is running.1 point

-

Worth having a look here too https://www.ebay.com/str/vintagetimeau?_trksid=p4429486.m3561.l161211 no affiliation but they are a very well known Seiko specialist based in Adelaide south Australia. They have seiko parts and gasket sets made for their own use and sell the surplus. Tom1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)