Leaderboard

Popular Content

Showing content with the highest reputation on 12/26/24 in all areas

-

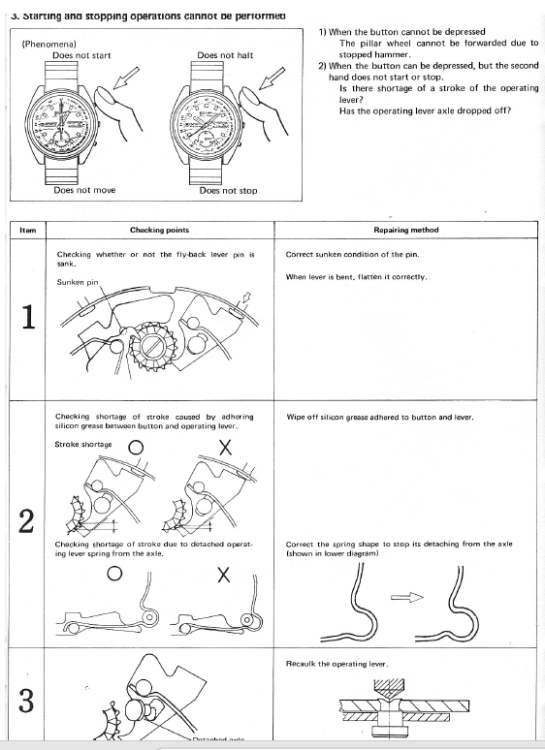

I've made a mistake that makes me feel very foolish. I'm sharing it here so other beginners might learn from my mistake. A couple of months ago I started working on a Seiko 6105 from 1975, the movement from a classic "Captain Willard" watch belonging to a colleague. The watch had its challenges and there were lots of things I was getting help with from more experienced people in these forums. I was at the point of reassembling the movement for the first time. The movement was running when I turned it dial up in the movement holder to fit the calendar works. All ok, check that the date advances as expected, then turn it over again to find the watch had stopped. Not only that, but the balance would now not swing at all. Not usually a pessimist, I nevertheless assumed the worst: I've caught the balance with the movement holder and broken the balance staff. I felt sick: this is no practice movement, it's a colleague's watch, and a classic, too. Mentally beating myself up, I immediately checked on eBay for NOS replacement balance complete, found one, and bought it. Later, I think it was the next day, or possibly a couple of days later I psyched myself up to go back to the watch, took the balance out and was surprised to find it apparently intact. Did I damage a bearing? Inspection follows: all looks ok. Reinstall the balance, it now swings freely! Much work followed addressing a few different issues with the watch but nothing that would explain why the balance went from swinging freely to not swinging at all. It remained a puzzle. Until a week or so ago when I was finally happy with the watch and reassembled it for the last time. I gave it a wind, dial and hands on, into the lightly restored case, set the time and date to the second, using what Seiko calls the seconds setting lever but is commonly called the hack, and strapped it to my wrist to give it a test run for a couple of days. Even then I didn't twig straight away. Yes, the Seiko 6105 is a hacking movement, the first one I've worked on. When you pull the crown out to position 3, a "seconds setting lever" in the movement moves in response to rest against the fourth wheel, acting as a brake and stopping the movement until the crown is pushed in. When I had set the calendar works I had, naturally, pulled the crown to position 3 to check that the date wheel advanced as it should ... then wondered why the movement had stopped. In the end it worked out for the best. I think I had been about to accept the watch as it was, not realising that the balance was actually touching the pallet bridge for part of its movement, and I also needed to polish out a divot in a jewel and adjust the side and end shake on the barrel arbor, none of which would have got the attention they needed if I hadn't been trying to track down what ended up being not a bug, but a feature. Now, can I interest anyone in a NOS balance for a Seiko 6105? (Just kidding: we don't do the buying and selling thing here.)3 points

-

3 points

-

2 points

-

2 points

-

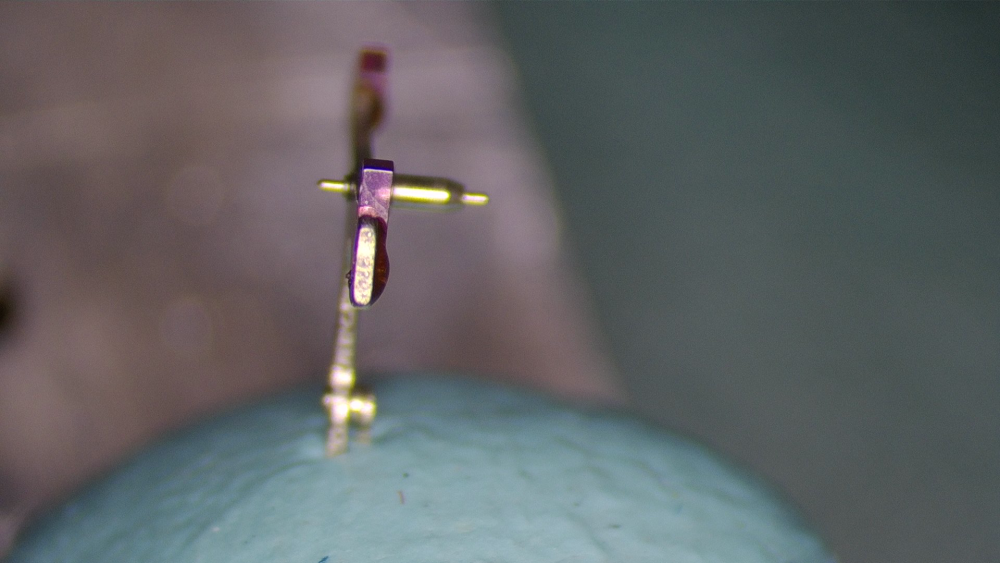

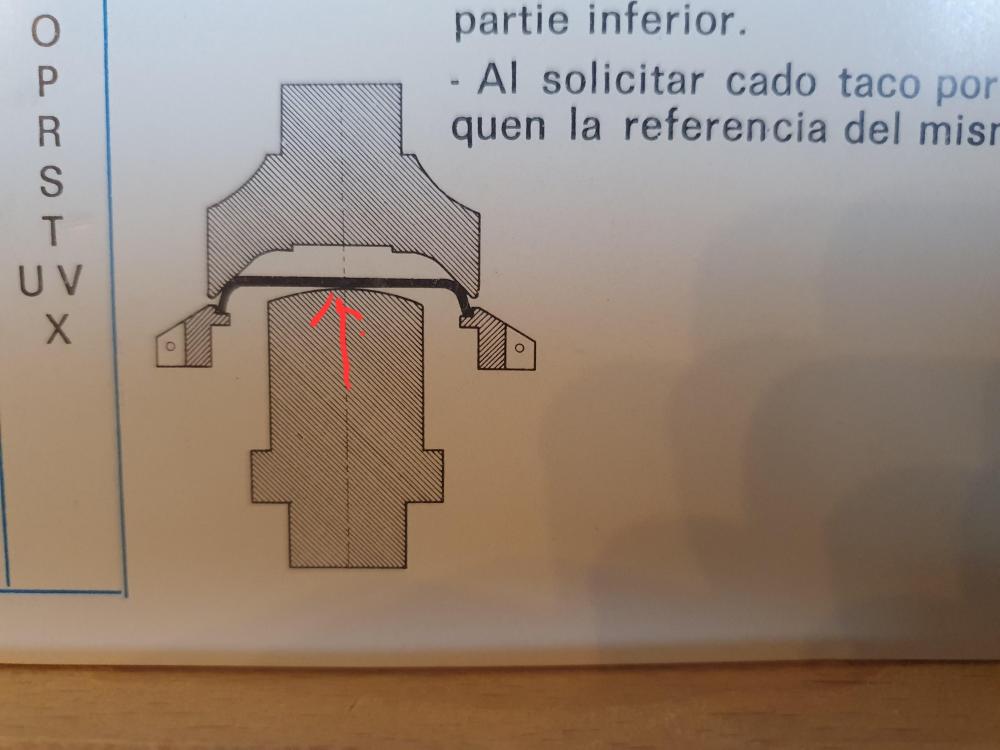

What an utter mess. Wrong size platform that has been in- correctly fitted. This has been taken from another movement you can tell by the mess of the screw fixing holes. Sounds as if it could be a depth problem. I need to see the whole works to see If I can spot something. I wish you could prove that it had been sabotage by those whose name is on the ticket. I can assure you he is no master clock maker but incompetent. That part is a part of a regulator but not from this platform.2 points

-

Some Euro coins are made of 89% copper and 5% aluminum, sounds like a good (and cheap) heat conductor. I've been watching those old pallet warmers on ebay.2 points

-

2 points

-

Some brands have widely varying lift angles, Omega has through its calibres a range from mid 30°s all the way up 70°. Japanese brands also have some very low LA, I found quite a few Citizen in the low 30°s A simple definition of lift angle...degrees of balance wheel rotation during one lifting phase of the pallet stones/escape teeth. At the opposite end of the lever...the start to finish engagement of the impulse pin/fork. The event of escapement takes up a portion of the balance swing, which equates to an amount of degrees known as lift angle. There is another definition....the amount of the impulse pin's movement of rotation from start to end of one escape event...but that basically adds up to the same previous definition. Looking at the shape and width of the fork slot and impulse pin shape and size may give an indication to a lift angle ? A simpler answer as to ' what is lift angle ? '...Its just a number that we tap into a timegrapher, a criteria ( some information regarding the escapement design that it doesn't know ) that it requires from us so it can calculate and tell us how far a balance swings one way from its rest point. Something that we can already do more accurately just by watching the balance wheel. It's handy to have a timegrapher show us constant change if any but that isn't dependent on knowing the exact lift angle. So in reality knowing lift angle isn't really that important...is it ?....not to me anyway.... because I ain't designing or making a watch.2 points

-

1 point

-

Each separate piece of gold will have its own hallmark. A guess of 10g of 9ct gold at around £20 per gram will give you 200ish quid.1 point

-

I think so, or rather that's where the hallmark I've seen is - there might be another inside the caseback.1 point

-

The watch really needs to have something about it to be worth much more. Looking at the movement to identify the caliber will provide an approximate date of manufacture.1 point

-

375...37.5% gold or 9ct Value will be little more than its gold scrap value. Is the bracelet gold as well ?1 point

-

Need more info on the movement and hallmarks but could be earlier than 1950 due to lack of the wings.1 point

-

Brass is the most often obvious choice for pallet warmers.1 point

-

Success. The watch is back together and running. More on that later... I did as NEW suggested and applied some pressure to the cover plate where NEW indicated. I was careful not to press too hard. That and snugging down the screws fixed it. Also, stem insertion is as I learned before, time-setting position. THANKS.1 point

-

Maybe I should have said, Richard, but I'm in deepest Essex. So you don't need the ", England" after the word Leeds!1 point

-

The broken piece is part of regulator. If it was from the original platform You will never know. For sure this platform is not original to the movement.1 point

-

Lift angle of USSR 2602 movements is 42. What seen on videos/ amplitude readings is correct. The conclusion is that for some reason the timegrapher doesn't calculate amplitude correctly. Who cares? If You know how to see amplitude, then don't mind what timegrapher shows.1 point

-

Could be some capillary action taking place in the space behind the stone, the mass of the shellac is then held in that vicinity .1 point

-

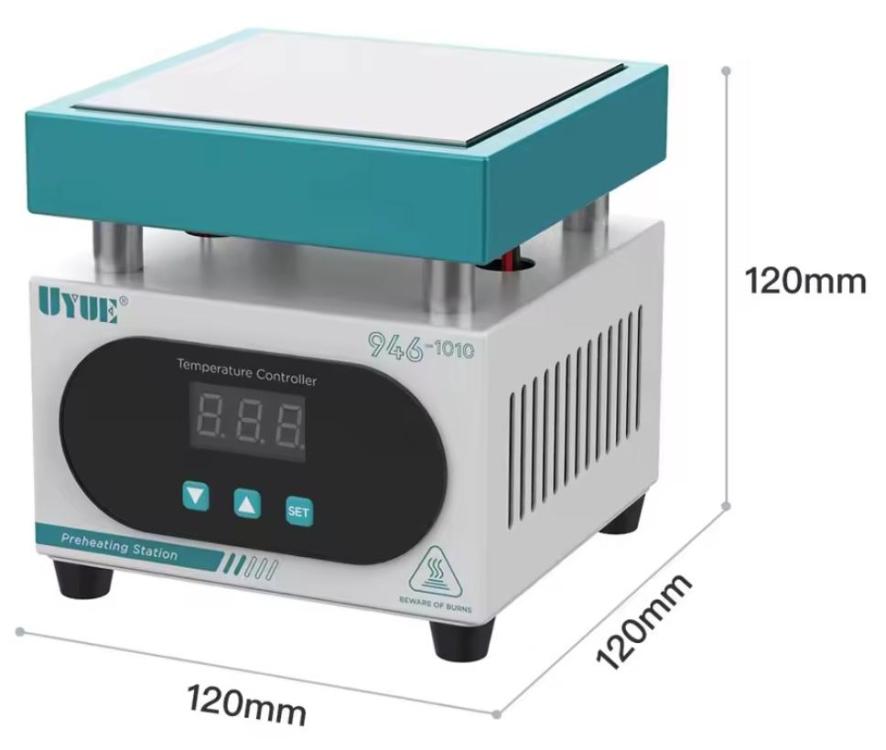

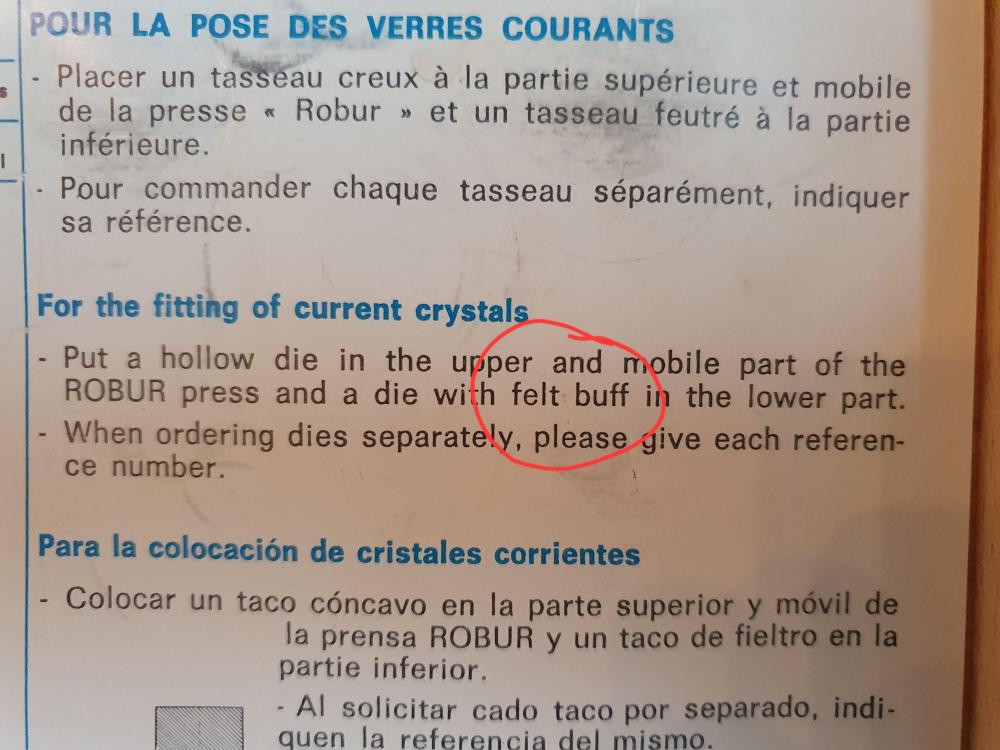

I read the instructions earlier on your box Case also screenshot them for future reference to help answering beginners questions. That inner curve of the cup dies obviously may need periodic maintenance, though with care you wouldn't expect them to damage at all.1 point

-

Definitely try a different medium. I saw the video and thought "Six minutes!!!" All your energy is going into heating up that big steel staking block. A little sheet of brass with a hole drilled to accept the pallet arbor will make this much faster. The only thing with using a hot plate like this though is that you might need to come up with a solution where one side of the pallet is insulated from the heat. You won't always want to be melting the shellac on both stones at the same time. Old school pallet warmer tools often only conducted heat to one side, and you could turn the fork around to heat the other, or only one half of a split piece of brass would be held over a flame so the other stayed cool - the fork suspended across the 2 halves. This is heavily on my mind because I am staying at my in-laws' house this week. All of their cookware is thick cast iron and it takes 15 minutes to bring a saucepan of water to boil.1 point

-

1 point

-

This is an interesting point. For me, personally, I don’t want to get too academic when it comes to amplitude or beat error or lift angles. I really just want to be able to restore vintage watches into healthy functioning timepieces. All this lift angle thinking yesterday got me wondering if I might just take a more manual approach to obscure and less precise movements like the ones I’m working on by just capturing the balance wheel on slo mo and further slow it down on the computer and eye ball the amplitude to know it’s working within a healthy enough range + or - even 10% inaccuracy. Especially considering that even with amplitude there seems to be some debate over what is “acceptable” or not. If and when I restore high end precision pieces I think I will be more particular. But for these practice pieces maybe I’ll eyeball and then test by wearing and if all is good I’ll call it a day I am learning so much at present, everything is so new and exciting! And I really appreciate all the help you all provide here!1 point

-

https://a.aliexpress.com/_EyKdzCy I was originally planning to get one for drying parts but people pointed out that it can be used to melt shellac. That was my second try on the video. First time I put the flakes more like in the middle of the jewel hoping they would melt straight down but they ended up as little shellac balls too stubborn to melt any more despite turning up the heat. Putting the flakes further in the back seemed to help. The fork is on a small steel staking block. I should try some better heat conducting material like copper or aluminum.1 point

-

1 point

-

I'm sorry to say you have learned the hard way my friend. When it comes to working on the dial side always remove the movement from its holder/vice. Another tip when you have removed the balance complete keep it out of the way and cover it.1 point

-

Yes try the test on a movement with a known lift angle. A picture of the pallet fork might give us a clue if the LA is correct and a definition as to what LA is.1 point

-

This is why the 180° amplitude marks on the balance wheel and plate work so much better. This is easy to do when there are 2 or 4 spokes in the wheel. To be the most accurate, have the balance in beat, mark the wheel edge at one spoke and the plate/bridge at the opposite spoke. Wind the movement until both marks align, then set tg lift angle to have the amplitude read 180°. For marking up I use ink and a fine oiler or for fun luminous paint.1 point

-

Ok guys I got myself a heating table and started experimenting with shellac and pallet jewels. I'm really a pallet noob. Here's an unedited video of the shellac melting. First the flakes melted into funny blobs when I had the table set to 100 degrees. I had to up the temp to 150 to get the shellac spreading more. How do you like it? Any comments appreciated. I also post some pics of the side profile.1 point

-

It's a touchy system. I use 9020 on the little satellites, and on the arbor that carries them where the other wheel sits. Hp-1000 closer to the rotor and for the rotor. Sometimes they still seem "sticky"- especially when hand winding. Then I reclean thoroughly and go with 9020 everywhere. I've suspected the plastic internal gear in the barrel bridge but never pinned one down as faulty. But some work just as smooth as silk, so they are capable of that. Not my favorite auto system.1 point

-

I don't wear or own a watch. I have 12 clocks in my home but I only wind one per week, each week it is a different one. I'm funny that way.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)