Leaderboard

Popular Content

Showing content with the highest reputation on 12/05/24 in all areas

-

Exactly, how are you going to learn when problems are going to happen and how you are going to avoid them and fix them if the youtube guys edit them all out. An un-hidden problem in a classroom is going to have lots of discussion around it and the outcome of the student class all learning from it. And most likely the teacher also, as the students have ideas and can also teach.3 points

-

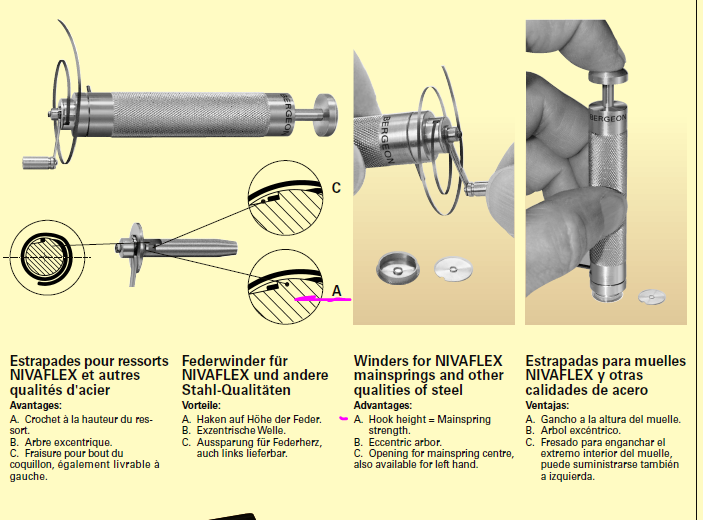

am attaching a PDF and here's a image from the PDF. When dealing with modern mainspring is exactly as quoted above the hook cannot stick out very far at all. The mainspring winders set at one time had other types of samples which I'll show in the picture below for vintage blued steel Springs and it sticks out whole lot. So if you have a vintage set you need to order replacement handles because otherwise it's not going to work at all. It's not like one set a handles works for everything. Then the modern handles usually don't work with the vintage blued steel Springs. here's a picture of what the modern handles should look like vintage handle notice that the flux sticks up quite a bit which is really needed for blued steel Springs. than a handful for a different type of mainspring winders which I typically use for pocketwatch Springs. Notice it's a pin and it sticks up quite a bit. If you get the spring wound in super tight with anything that sticks up like this you are not removing the handle. Which is why your mainspring does have to be properly sized for the winder Mainspring winders 7023 A B C.pdf one of the things I find interesting is teaching people in real life versus teaching people by video on YouTube? I wonder if it's possible that people on YouTube forget that they have a live audience and things don't always work as nice and smoothly as they show. If you're in a classroom situation you make a mistake it becomes apparent extremely fast that there is a problem. But And making videos perfect video is because her supposedly perfect you don't get the feedback of if you made a mistake typically. Instead you get all the people praising you for how wonderful things are3 points

-

2 points

-

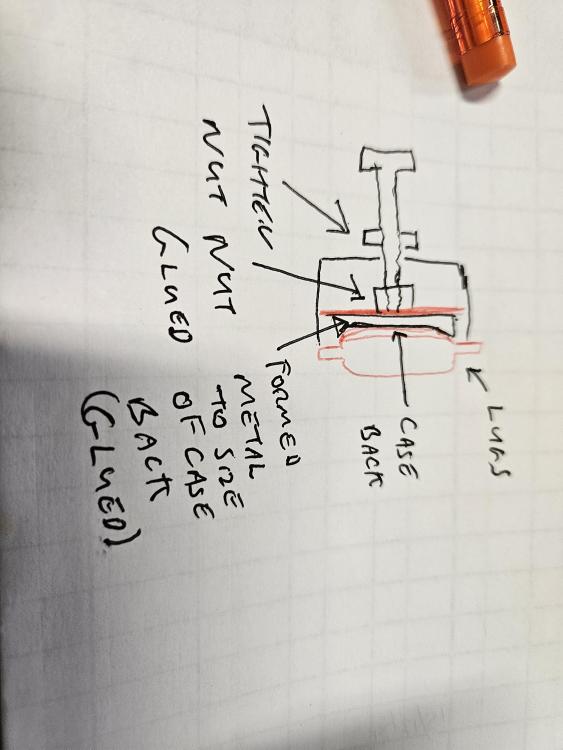

This is going for a sheer force pull over the whole back as opposed to popping one section of it, so requires...more effort, just that direct point loading on the lugs that bothers me, the outer case rim of the tool might want to be tight up to the lug joins and evenly distributed. Great idea though Can't say I've ever been stuck for removing a back, screwed on or pressed on. The only time i have is when it wasn't actually removable, the watch put up a valiant fight,yet died a true hero's death2 points

-

2 points

-

Red Loctite will be absolutely sufficient for the forces involved. We used red Loctite on lots of things when I was an apprentice. I don't think I have ever attended something that has failed that showed evidence of a bolt that had been assembled with the use of red Loctite bolt coming undone. Loctite 243, even though it is more for threaded fixings, would be ample for what you need. Probably the cheapest one as well.2 points

-

I found that using feeler gauges (the blade type used for adjusting valve clearances on engines) work fine for eyeballing distances under the microscope. The flat sides make alignment easier compared to round pin gauges. As to fitting the bush: definately don't loose the press fit. You don't need much to keep it in place. A tiny bit of solder around the shoulder is more than enough. If you're doing test pieces: my first suggestion was using some locktite, you still might try that as well.2 points

-

2 points

-

Absolutely it does,and not many are honest enough to leave in their mistakes. Might seem harsh , but those are the ones I have unsubscribed to. I think I'm down to 3 left that I will watch2 points

-

Hi folks, I'm a 50yo Australian bloke from Melbourne, always been interested in watches, especially digital ones. Wish I still had that LED one my grandad gave me when I was a kid... Had a couple of cool Casios in the 80s, I'm a sucker for a dot matrix. Friend gave me a DBX-100 about ten years ago, and I forgot it in a drawer until last year, when I decided to have a go at fixing it up. Released in '86, these suffer from screen bleed and the button pad turning into mush, but the screen was still pretty good on this one, only a tiny bit of bleed in a couple of the corners. It was a bit beat up too; while sniffing around for a replacement crystal, I found a NOS example crazy cheap; US$100. Bad screen bleed and mushy buttons... Swapping the screen was easy enough, and I was able to find a NOS button pad from a slightly later model which folks use to fix these up... Now it's worth like AU$1k! Thought I was pretty much done, but recently started hankering for a FS-00 (why aren't people more into slimness in a watch?), and their scarcity led me to look beyond eBay, where I found the JDM and proxy services... $2.5k later I own close to forty interesting Casios worth at least $4k, I'm hoping... My retirement savings could use a bit of a boost; hoping I've found a side hustle to do that.1 point

-

My workshop record for a watch ' awaiting parts' is five years. A lovely Alpina bumper 584 Auto. Not a common animal and all the setting lever springs 445 seem to have been used up so the usual world searching has proven fruitless. Just about to abandon ship when rescue arrived in the form of Ranfft Mkll. Whoever rescued and improved this site needs a medal. A post from 7 years ago by Mitka's Vintage Watch service showed the same broken spring on a similar 582 Auto being repaired using a factory part for the Manual Cal 586. This sent me searching the Ranfft pictures and it's clear that the spring looks common to 582, 584 Autos and 586 ,588 and 589 Manuals. Since I was unable to find any parts information out there this was useful knowledge since a fresh now more general search showed one in Sweden for a 586 at URDELAR.SE . It arrived this morning and it is correct. Buns for tea. Hope this helps - Neil.1 point

-

Nev, you are lucky to have the pliers type, no reason to be jealous! With the pliers you mount a glass within seconds, instead of fumbling endlessly with that wheel… I use nothing else for simple acrylic glasses, though there is a Robur, too, catching dust. Frank1 point

-

Case you went to a lot of effort there lol, and I appreciate that. I kind of figured that the shape of the dome dies are not that important. Its only a shape for the crystals to be bent over, for that reason is probably why my two sets are very different. The ones for the pliers have a rough radius, but then come to a shallow point at the tip. Its ok buddy you dont need to do anymore Case , you've given me the idea what i need to do now to match the cup dies. I do appreciate your time, it looks like you've been making paper chases for xmas Nice Robur sets by the way, I am rather jealous now1 point

-

1 point

-

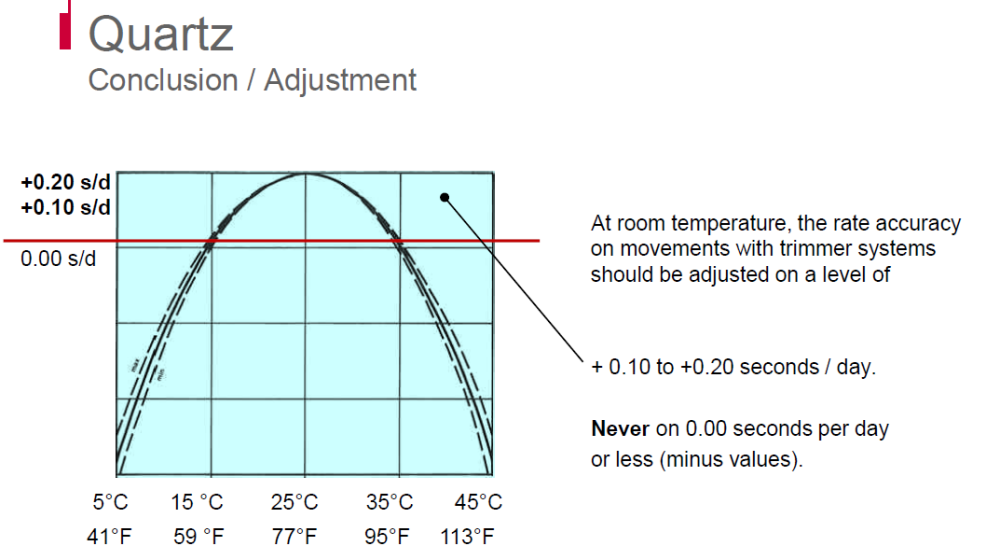

Interesting because? I'm attaching specifications of Omega quartz watches because we have nice specifications for quite a few watches and we can work out a approximation of what a quartz watch can and cannot do. So excluding the best timekeeping and one of the extreme worst the majority of quartz watches keep time within -9 / +15 Seconds per month. Then your timing machine has a problem as well let me give you something that witschi has the commenting on the effect of temperature and did notice when they give a suggestion of rate it's in seconds per day but it is a fraction of a second. You run into several problems first most quartz watches no longer have trimmer capacitors to adjust you cannot adjust the rate at all. Then whatever you're comparing You are quartz watch to has to keep time better than the quartz watch by quite a bit. Then were talking about seconds per month fractions of a second per day and measuring fractions of a second per day is not impossible but in the case of the quartz watch would be impossible. Typically a quartz watch would step once per second which means you cannot break its accuracy down to less than one second. Mechanical watches typically at 18,000 beats per hour there secondhand step five times per second and you can get a fractional seconds. So can you regulate your quartz watch yes if it as a trimmer and if you want to take months to do it. 8641_WI_18_QUARTZ MOVEMENTS - TECHNICAL CHARACTERISTICS E cousinsuk.pdf1 point

-

1 point

-

1 point

-

Count me in as your marketing rep....with a gob like mine I can sell anything....including horseshit to a stables owner1 point

-

Bugger off, Bergeon are going to pay me £1000, 000 for my idea, hehe. Joking apart, yes brilliant, if between us we can make a tool for stubborn back, then we all win.1 point

-

Better still This is why our group is so great...someone has a good idea and then we jump on board to build on it1 point

-

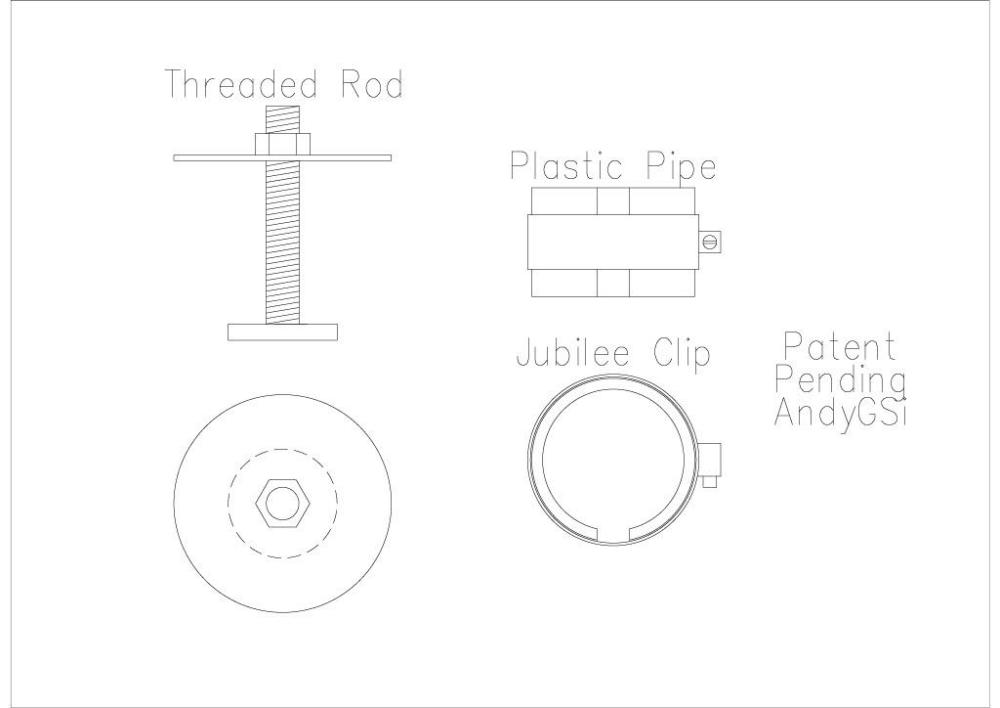

That reminds me of the adjustable mainspring winders that use 3 prongs to form an adjustable ring. You'd need to find a way of securing the top plate to the jubilee clip.1 point

-

Ok. I know I have a radius gauge somewhere.... I'll see if I can find it and get back to you with some dimensions.1 point

-

Push against the legs isn't ideal but I think if the force is across all four ut should be ok. Let me know how you get on.1 point

-

I would use only one small piece of solder, it will be enough. Then, I would hold the plate dial side up and put the solder and the flux on the plate and touching the edge of the bush, then heat underneath1 point

-

1 point

-

Well, I suggested soldering where soldering I meant with soldering iron and solder for electronic cirquit boards. Of course, not the rubish led free solder, but real one, led containing. Heating no more than 250 degr. I am not sure for the Loctite. It is designed for arbor in a bush or nut on a bolt. Here the detail has to bond with the plate by flat surface and the detail may simply fall off to the outside direction if some pressure applied on the barrel arbor from the other side. I have grown with soldering iron in my hand and have all my professional life spent repairing electronic devices, so this is hard for me to imagine that soldering will be a problem for someone. But yes, some training may help. As a principle - if the fit is true tight, then no solder will get in. But here it will be no problem if the solder will not get to the cylindrical part of the bush, it will be enough to flow on the plain part between the plate and the bush. So, if You decide to solder, put the bush in place, add some flux, then touch with the tip of the soldering iron with some solder applied and wait to heat, the solder will float where it is needed as it will be attracted by the gap. Another way is to cut small piece of solder and put it in place (with flux), then heat the plate on spirit lamp flame or with torch just until the solder floats in place. It is important afterwards to clean the flux - if it is acid one, then use some alkaline solution.1 point

-

My apologies, i didn't really doo a great job of stating my issue. I'm trying to figure out when it's time to keep pushing through an issue and when it's time to accept a loss and move on to another project. The watch has actually started running and gained 4 minutes over 8 hours so I suppose it's not fair to call it a total loss, but still has issues I suspect are outside my skill set, at least for now.1 point

-

Thanks Tom , the red sounds suitable, and the green might be overkill. The heat did bother me, and so bismuth solder paste I would chosen. Thats a possibility Andy, leaving a soldering gap to fill up. On another note, I seem to remember you picked up a green Flume book by mistake, are you still looking for the red ? Thanks Michael, i think I've made a decision,so loctite it is. Its a trial run besides , so it will be getting tested.1 point

-

Movement details are just next to the coil. When you say it needs a new Crystal do you mean a Lens? If it is a new lens then you remove the old one and measure it.1 point

-

Thank you! Ok, that is what I suspected, an ordinary quartz inside. This accuracy or better you can also get from a Weishi or any soundcard based TM. For real quartz accuracy tests you would need a reference about 10x better than a quartz. But of course you can make comparison tests and adjustments with that device or with any of the mentioned ones, if you already know the error of of the quartz watch (as you will do with mechanical ones): just change rate by the difference. Only precondition: quartz frequency of your tester must stay invariable during test time(s). This however is uncertain after switching on and the following 15-30 minutes. Frank1 point

-

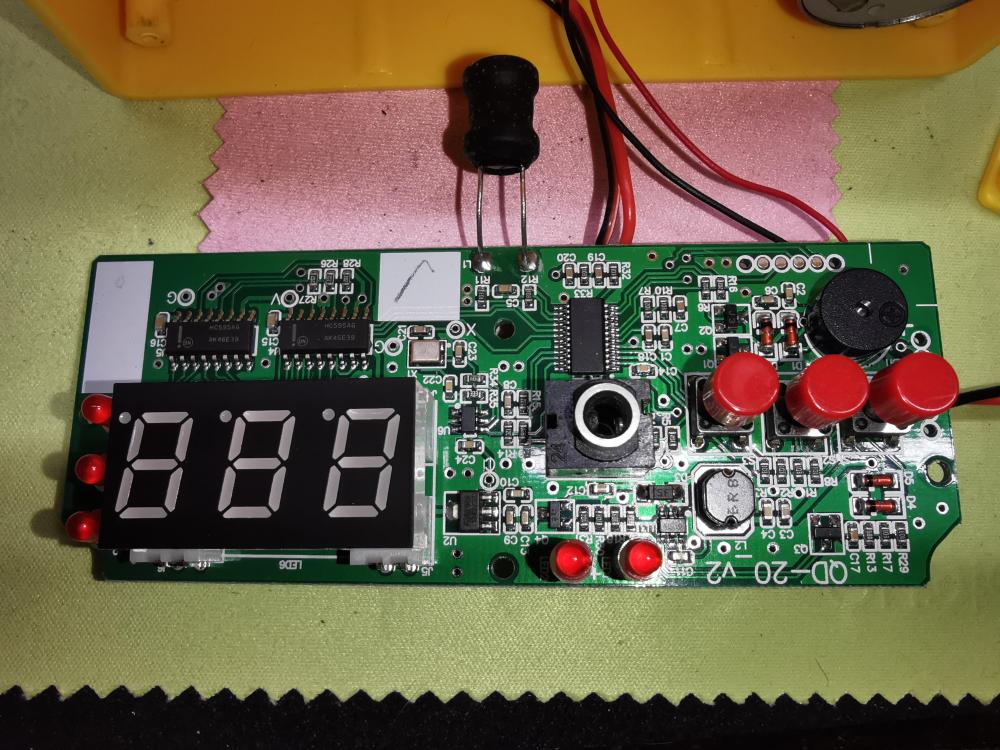

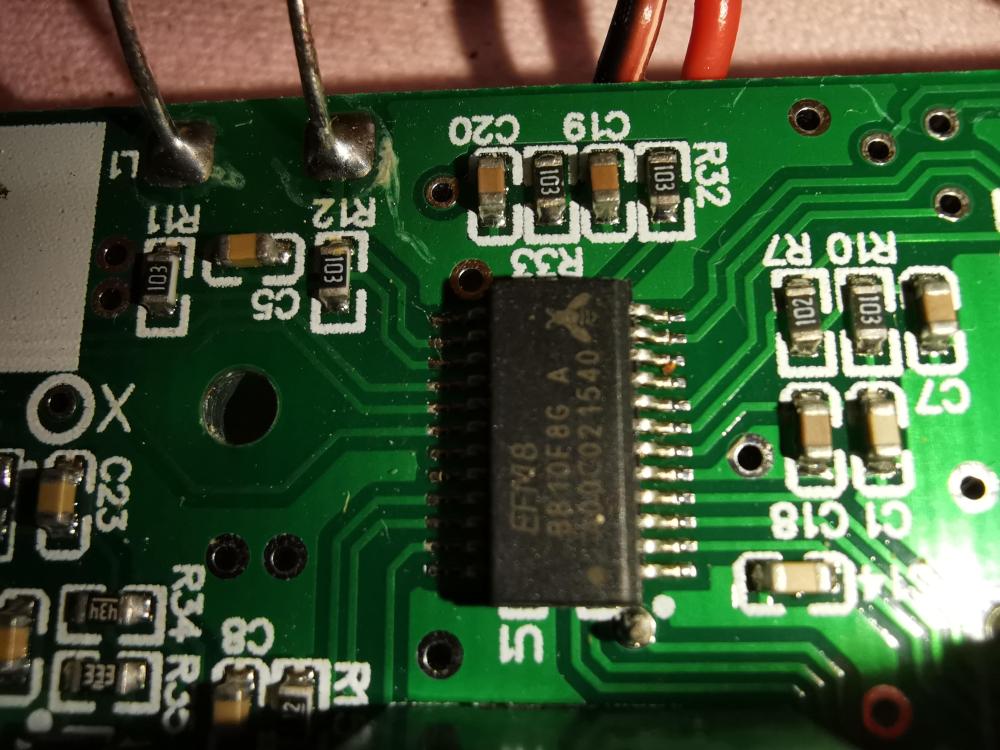

Andy, do really believe this item can test the rate error of a quartz watch? Sorry, but I don‘t. Where are the technical data of this toy? Frank1 point

-

Mike over at “my retro watches “ YouTube channel has a few videos showing some digital watch repair. i think the issue may be that we have only had digital watches for 50 years whereas mechanical watches have been around for a few hundred. Add to that the wonder humans have when seeing any complex mechanical device do its thing compared to seeing what is essentially an inanimate black box doing its thing, world of difference. When you also add in the idea that theoretically it would be possible to create or repair most of a mechanical watch or clock in a spare bedroom they are different beasts. Whilst we often cannibalise mechanical movements for parts it is not always the only option. Unfortunately in the digital watch world cannibalism is the only option so for most I expect that is not so interesting. Tom1 point

-

Could you incorporate another shoulder in the back flange to allow solder or some other adhesive to flow under.1 point

-

It’s looking good Rich, I think you could do this with any of the medium/high anaerobic setting threadlockers rather than silver solder. As you said there would need to be sufficient free space between the parts for the flux to sit so the solder will flow properly. My other concern would be potentially warping the plates applying heat to them. Tom1 point

-

Thanks case, I will try the locktite as well, that idea takes the heat off ....terrible pun day A quick google on loctite has given me the decisions of the red or maybe even the green one.1 point

-

...I'm super bummed that there's nothing like the mechanical watch repair scene for digital watches; trying to find any sort of resources online is a woeful exercise in mostly fail. You'd think it would be easier to build a knowledge base around repairing something so much simpler and less subtle (paradoxically enough - this is just from the point of view of repair), but I find myself here after fruitlessly searching for anything, anything at all, around replacing ye olde incandescent bulb in a 'Blue Thunder' Casio A201, and drawing a total blank, except to see this place has a dribble of activity around digital watches... I'm chasing the faintest whiff here.1 point

-

Since this hubbed bush was easy to make....twenty mins maybe a little more from start to finish including the bore. Most of that time was the final sizing up and measurement checks, which were tricky as I'm using pin gauges to check the length measurements ( I need some sort of end micrometer or dial gauge set up) . I've decided to make a trial run in a scrap plate. One thing I'm not sure on which is why I'm trialling it first, and that's the soldering into place. As it stands the body is exactly 1mm and the trial hole is 10 microns under at 0.99, so I have a friction fit. My plan was to have two pieces of solder under the hub section and then apply heat from under the plate to make them flow. @nevenbekriev @caseback This leaves me with the problem of pressing the bush home at the same time because of the friction fit should I loose the friction fit so I dont need to use a jewel press and press the bush home with a probe by hand ? Or do i press the bush home and then solder it in place....I'm not entirely sure how good the capillary action will be in such a tight joint. I could be making a few of these bushes1 point

-

Just a note- I've filed down hooks on many winders. The hook has to be nominally the same height as the spring thickness, but a little shorter works fine too. Once the first wrap of wind comes around it's going nowhere, and this strength increases as you wind.1 point

-

It helps to keep in mind also that the hobbyist youtube guys (with some exceptions) do not show you their mistakes. You don't see the 2 or 3 attempts to get the mainspring properly hooked onto the arbor before cranking on in and maybe the failed attempt to slot the bridle end in before unwinding and redoing it. I assure you these things happen from time to time but don't make the final edit.1 point

-

Hi transporter, I picked up 3 weights with chains and a pendulum on eBay and now have the movement working on my test stand, it seems to be running well, so fingers crossed. I bought a cheap music box on eBay, and swapped the prongs over, it works, but it isn't great so I bought a second one which should arrive later this week, this one looks closer to the original so hoping it will be a bit more tuneful. I bought the paper to repair the bellows, which looks simple enough so that's my next job when it arrives. I also found a back with the gong attached which I had to modify slightly but that now fits. It has been an interesting project so far. The wooden case needs some TLC, its covered in paint splashes which I have tried to remove but I think I am going to have to repaint at least some of it, it looks like a chocolate brown matt emulsion so I thought I might buy some tester pots to see if I can find a match.1 point

-

Cant see the wood for the trees (idiom)......too fixated on a particular small fact that the big picture problem has become invisible. Thats nice to know......that we have a group that understands, cares and takes the effort to help another member. Unlike some facebook groups that belittle with sarcastic, condescending remarks with gatekeepering tactics. We are literally the best watch forum on the planet1 point

-

Thanks for that clarification. I'm a newspaper journalist in nearby North Platte, NE, and my late father was an electrical engineer specializing in capacitor design for Goodall's successor firms TRW and ASC. I can tell more about Robert Goodall's impact on the world of inventions as well as during World War II if anyone's interested. Good luck to you.1 point