Leaderboard

Popular Content

Showing content with the highest reputation on 11/27/24 in Posts

-

Yes. In a binary true/false sense, this is 100% possible. It's far from practical though. In a pure energy transmission context, you're not wrong. However, you seem to be neglecting the energy requirements and source thereof. Energy has to come from somewhere. In a clock, that's a spring (typically, and for the sake of simplicity in this context). The energy from the spring is passed through the gear train to oscillate the balance, and en route turns hands to indicate the passage of time. If you have additional complications, a chronograph say, you have to increase the strength of the spring to accommodate the additional work being done moving additional hands or dials or what have you. In this instance, the complication is heat generation. You need a commensurate increase in spring strength. Heat energy is pretty intense, and the energy used to power a clock is, by comparison, infinitesimal. The oven will operate in terms of kilowatt hours (typically 2-3 kWh/hr according to google), where the watch spring will be measured in microjoules; 1 kWh = 3,600,000,000,000 uJ. A quick google says the mainspring in a 2824-2 (an extremely common modern movement) stores 33,000 uJ. By the time you got a spring significant enough (at least 8 orders of magnitude) to make a dent in the heat generation requirements of a stove, it wouldn't be in any way recognizable as a clock (edit: actually, the 2824-2 is a watch movement. I do watches, not clocks, and those are the terms I think/operate in. A clock spring would be bigger/stronger, but not meaningfully so in this context, and I'm not going to go back through and redo the math for this sort of thing). The spring would be easily the size of a small car, and winding it would either take massive mechanical reduction or massive force from the winder. So let's say you did it. You set up a watch with all the gear reduction in the world to some sort of heat generation device. You wind the watch up and... The full wind of a 2824-2 mainspring will get you an increase of .008°C in 1 mL of water. Extrapolate that to a turkey (Thanksgiving is tomorrow in the US). Say a fairly average 15 1/2 lb turkey, which we'll round to 7 kg for simplicity, is 70% water (ignore the rest for these purposes), and you want to raise the temperature from 20°C to 70°C. You've got 7,000 grams X 50°C / .008°C per wind of the mainspring. If you could wind the spring fast enough to keep it in continuous motion, and it wasn't also powering the clockworks (which would use all the stored energy in addition to slowing its release beyond the point of the turkey's decomposition; assuming a 36 hour wind down time for the watch, and all of the energy goes to heat generation instead of clockworks, that's 103,561,644 years), and could release the energy of the spring extremely quickly and without any internal friction, you'd have to wind the mainspring 43,750,000 times to cook your turkey. More googling says to expect 13 minutes per pound of turkey, so you'd be winding your spring 3,365,385 times per minute, or 56,090 times per second. A mainspring barrel typically holds something like 5 full revolutions (I'm picturing a Maltese cross whatever it's called limiting device), so you're looking at 16,826,923 RPM just on the winding side. Double that since you ALSO have to unwind to release the energy... Never mind that the spring would explode, I honestly can't think of anything that's running 34 million RPM for any length of time... In summary, it's POSSIBLE, just not practical, and probably not feasible.3 points

-

Triumph! As many have suggested escapement was the culprit. Despite the pictures looking good, I started to examine each piece independently and when each piece worked separately, I finally got a closer look at the balance wheel and touched the impulse jewel. Although it looked right, it wobbled on me. I have since shellacked it in place and the watch is running nicely again! Thank you for all your help. Lesson learned - examine typical suspsects first and up close.3 points

-

You can use a hotplate like this for melting the shellac in pallet forks as well, so take care not to melt the shellac of the impulse jewel when drying parts.3 points

-

In my time I have repaired many french carriage clocks like this one. Unfortunately this has not had the care I would give it. Just look at the poor condition of the screws and the pins. If it had been me all the screws would have been polished and where needed blued, all new pins fitted and their ends rounded off. I thought this was a good example for budding clockmakers to see what you can face when you are skilled in clockmaking. https://www.ebay.co.uk/itm/395935363872?_trksid=p2332490.c101875.m1851&itmprp=cksum%3A3959353638722f6f1139751c4f74a861cf6c8fe4c1ff|enc%3AAQAJAAABIEK7FTfzsGw0VauxYyX1IOHjsuXJ1NPjVWebvOca%2BJbVzh3VqcrGnLFKHjKk2M42BtfNs8bK1jFneKBZqmubi3LqdL1O3pSAti0ziME15OMATy6%2B0bVJFiKlbAty3RsIjF%2Fur%2BgKabl1a%2F%2Bja3XVQjb%2FuU1ZNH4nMcbW%2BW3okw%2BsWFUjGCsp1OUjOZnh6yCKAhWGMZUij8t3R9IulDLbQ1CnaqFpGWtesqZMfL9ncZ2AD1poo49bO6xICCjiGHd6cIrO%2Fa41JsI3esfxsWQn4B9jWRit%2FQ2qbnbxYmshZQBDUZFduWoCFpZ8Wq%2FPrUHpZBaUHj3fZq55MsX1Rp6htwbVHVM8p3Uj3Nq0byc2oa4Iw3fCkOtCXWbNO031%2ByftQQ%3D%3D|ampid%3APL_CLK|clp%3A2332490&itmmeta=01JDPCYK6KH26EF80AYPD24Q322 points

-

That’s good advice. I can see that putting a watch together once would be amazing; but doing it 10 times without destroying it is where it’s at.2 points

-

I've tried various hot plates for part drying but i have had better results with warm airflow.2 points

-

yes this is exactly what the tool is used for. problem is this is such a specialty tool to do something that commonly isn't done anymore. Which is one of the reasons it's very hard to find any information on such a tool. then when I get a chance I'll see if I can scan the pages from the book I have plus I have another book I need to look at but I need to move some stuff so I can get to it2 points

-

Hey folks! Thanks to your guidance, I was able to resolve the problem on the 1221. I actually cannot believe that I did it myself - I'm really proud! Issue was seemingly simple. I pulled the dial and hands, and noticed that the clutch wheel was askew. I was able to remove it, realign it, and boom the crown went in just fine. Here's a photo pointing to the clutch wheel in question, post-fix.2 points

-

if you go searching for something like the term above in case ranch you will find something like this it's one of the interesting problems of watch companies there are lots and lots and lots of variations of stuff including how back's on. It's like the picture above of all the various case wrenches typically if you require old watchmakers stuff you'll end up with a huge supply of those it typically you'll never use almost because it was a limited for one company and that was the end of it. the alternative to using the wrench on the case back itself is epoxy a large nut to the back and unscrew that. Although the word unscrew is not quite appropriate as it only needs to move a little bit the free the tabs. Then the epoxy is really easy to get off you just dropped the thing of boiling water and usually not that much pressure is required and I will pop off. That's also really nice way of removing glass crystals and have been epoxy into watch cases is you just boil them and they will just push out. Then the other probably may be facing is that a lot of times the gaskets disintegrate and become super sticky like glue which is one of the reasons you may be requiring so much forced unscrew it2 points

-

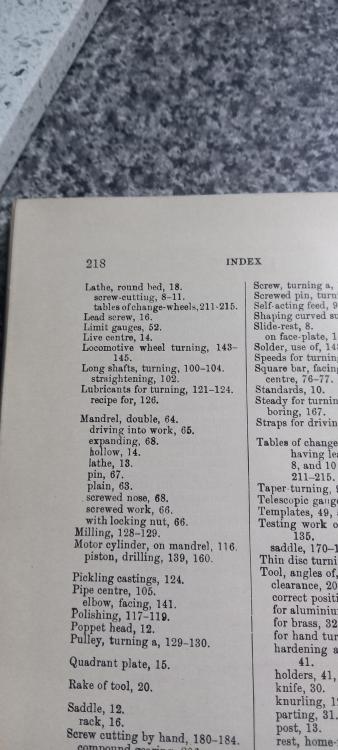

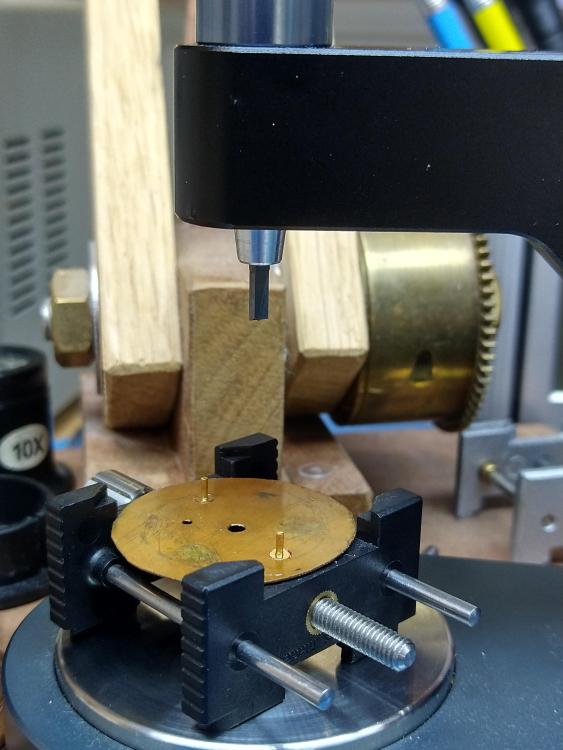

This can be used in conjunction with a faceplate chuck, to either slightly widen an existing hole or just create a new hole. It is also used without the faceplate chuck, such as when cutting a new jewel setting from brass stock. This is used as follows, from my understanding of the books I have: You set the cutter at the center of the workpiece to be cut, but turning the lead screw. Then you adjust the stop to sit flush with where the swing is currently located. Then you screw open the swing arm, and place your jewel, or arbor or setting or whatever it is you want to reference to cut, within the space between the stop you just set, and the swingarm, and adjust it to be flush on both sides. Then remove your jewel, and advance the cutter into the workpiece, then turn the large leadscrew until it bottoms out on the stop you set. This is all my interpretation as I have never seen one of these used before, and my lathe book seems to assume you'll know how to use it. I find it a bit odd that its designed to cut from out to in, whereas I would want to start the cut in the center and then swing it out. This thing basically will just replicated whatever you put between the stops, but at 50% of their diameter, since you'll be turning the piece from center. Its a clever tool, but there does seem to be a bit of mystery surrounding it. I think the mystery, is I'm making it seem more complicated than it is, and the vintage lathe books like stated above seem to believe you'll know how to use it.2 points

-

What I’m on about is a bit different than the Seitz process Rich. The Seitz process is less accurate, if for instance you are replacing a bushing for a Seiko 6139 barrel, it can be done wit the Seitz tool to ream however it is preferable to bore it out as it is more accurate. The Seitz tool cannot correct any misalignment of a hole by reaming, however boring can. To achieve the accuracy for initially making a plate it is normal to bore after drilling as using a drill is inherently inaccurate. Reamers are generally multi point cutting tools, as are drills whereas single point tools are more accurate as you can alter the cut incrementally thereby reducing flexing in the tool whereas you cannot do that with a. Multipoint tool. I’m maybe going too far back towards the manufacture rather than repair. I would suspect that this tool is maybe more rigid and likely cheaper than a crosslide for manufacturing. I’m eager to see what @JohnR725 digs up from his library. There seems to be a wealth of tools in this field to the uninitiated would do the same job unfortunately we don’t yet have the experience or knowledge ourselves to discern the differences which may at first seem nuanced however would be huge gaps seen by expert eyes. and don’t go correcting my atrocious grammar and sentence formation or I’ll get all curmueonly on ya and chase you off my lawn Tom2 points

-

To get the most of my adventures into lathe work , Percy has got on board to give me some extra advice. Wow 3 shillings.... 15 pence, this sale around cost me considerably more but hopefully worth every penny. I know ideas have moved on but the principles remain the same.....I always look to see how many pages a book has before I buy it, Percy did ok with this one though its only a small book.2 points

-

It will not affect the price. There is as much value in the case as there is in the movement. To me it is pure job satisfaction knowing you have done a first class repair and no one can better it.2 points

-

I think we would need some more operating parameters to really properly answer your question. So for instance how much power does the stove that you would like to power consume and then we can work with this and work out how to generate the power.2 points

-

Good evening. Personally, I’ve tried using the service manual for the ETA 6497 on the ST-3601 movement, and there were no significant differences. If it’s a clone of the ETA, you might want to give that manual a try. I found this link, which could be useful for you: https://watchguy.co.uk/cgi-bin/files?showfile=ETA/ETA 6498-2.pdf&filename=ETA 6498-2.pdf&dir=Technical Manuals&action=documents Additionally, there are some videos online about the assembly and disassembly of 6498 caliber. Best regards!2 points

-

With the temperature range it has you should be able to consistently blue steel parts, hands, screws etc. Tom2 points

-

Don’t bother. If you want cheap mainspring winders I’ll sell you mine. They’re all but useless. personally I think mainspring winding is over played in the various youtube channels. I either buy a new one, hand wind, or occasionally wind if the spring fits one of the few Bergeon winders I have (5-8)1 point

-

it's amazing how much air moving past something that you would like to evaporate does such an outstanding job versus pure heat without the airflow. then if you look at Ally express do a quick search for you'll find something like this just have to make sure you get the right voltage for the country you live in. https://www.aliexpress.us/item/3256806608058975.html?spm=a2g0o.productlist.main.5.baf4tt47tt47oU&algo_pvid=edd241ea-6ff5-4c5c-bd18-13d44a4d75a4&algo_exp_id=edd241ea-6ff5-4c5c-bd18-13d44a4d75a4-2&pdp_npi=4%40dis!USD!34.05!34.05!!!246.00!246.00!%402101eac917327396089252470e9d04!12000038325414224!sea!US!0!ABX&curPageLogUid=gRLOsbOihP82&utparam-url=scene%3Asearch|query_from%3A they see everyone else beat me to the answer. I think without a source of air drying watch parts would be problematic. But they would definitely work good for melting shellac and bluing screws hands etc.1 point

-

one of the important thing is to learn when you're starting out yes taking apart is easy. Putting back together successfully is more challenging. Plus practice practice on this watch practice a lot. Often times people want to practice as they go with the only doing things one time and you really should practice for several days of taking apart putting back together looking at the watch seeing how it runs. Looking at the balance wheel and the hairspring and see how they look look at how they operate. In other words you starting off take some time enjoy it study it and understand what you're doing. The effort done here will pay off later on1 point

-

Thank you both. It’s good to know that there is relevant documentation out there to assist when I get around to trying to assemble a movement. I’ve always been good at taking things apart but obviously that’s only half the story!1 point

-

1 point

-

My guess (!) is that the screw slot is not there for aesthetic purposes. I'd take out the balance complete, open/turn the regulator pins to give the hairspring room, hold the stud using the screw slot and turn the balance cock 90 degrees.1 point

-

1 point

-

The very best athletes apparently output around 2 kW for short periods of time: https://sportsmedicine-open.springeropen.com/articles/10.1186/s40798-021-00341-7/figures/1. Unless your wind-up stove comes with a professional cyclist, I think this project might prove challenging.1 point

-

1 point

-

1 point

-

It does look like it should come off with a partial rotation with lugs lining up with the equidistant slots around the edge of the caseback as @AndyGSi suggests. Tom1 point

-

1 point

-

1 point

-

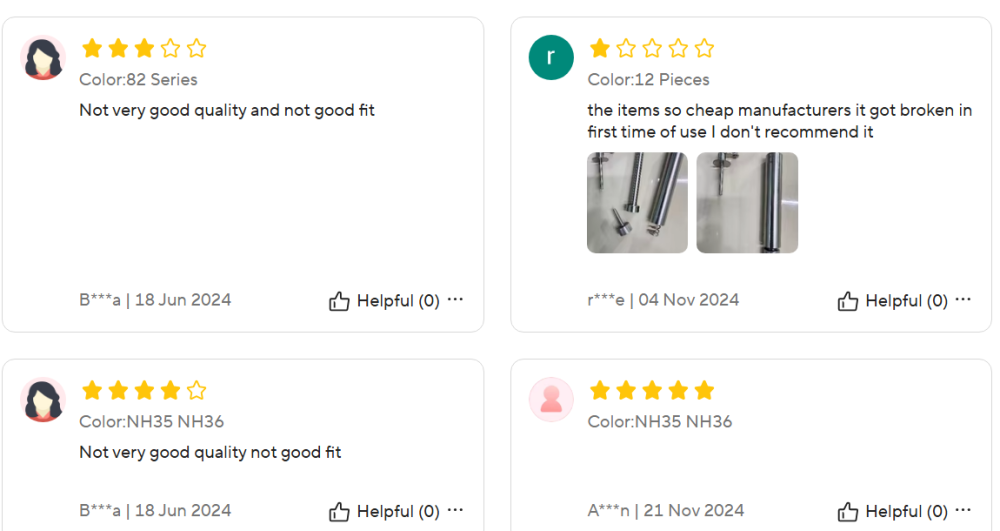

I have a full set of those Chinese winders and none of them fit a 7S26. A better bet is this other Chinese design. 1Pcs Watch Mainspring Winding Winder for ETA Movement 3135 2836 2824 2892 46941 7750 2824-2 NH35 7120 2000-1 8200 8205 2671 8500 https://a.aliexpress.com/_mPVysEr The NH35 model also works for the 7S26 and many other Seiko movements. It's much easier to get the spring on the winding arbor and to release the spring from the arbor after winding.1 point

-

all of these movements are based on the base 6497/6498 I have a link below that comments on all the variations at least the Swiss variations. then I'm attaching a slightly newer version than the above version of the service information seems to have a few more pages. https://ranfft.org/caliber/10349-Unitas-6498 CT_6498-2_FDE_482480_08.pdf1 point

-

A lathe set up will be much more accurate, tighter tolerances and undetectable run out ( the big old lathe I set up earlier this week i can see no run out at all under low magnification ) in comparison with a Seitz Jewelling tool that is wobbly as hell. I was just curious if the same method was used with the reaming process on a lathe and maybe the headstock spindle is not locked off so that the fixed workpiece can semi float around within the spindle's movement.1 point

-

1 point

-

Different techniques for different tools Rich is my thought. With the Seitz tool you are enlarging an original hole to fit a bigger jewel generally. With the lathe you are creating that original jewel position and setting as that will be much more accurate than using a drill press followed by the Seitz tool. As I understand it this would have been the way to make plates and bridges long before the advent of CNC and jig boring. Tom1 point

-

You're going to need to produce a lot of energy to power a stove with any real heat so that is one big clockwork generator. Energy is not free as such, besides harnessing what the planet can provide.....Tesla suggested it...if it can self produce we certainly dont have access to it.....yet ..........in which case who's going to wind up this massive clock ? That would be a chemical to kinetic to thermal energy conversion. Intersting idea that my old boss once put to me....a clockwork generator to power a house. I think you're better to invest in letting nature produce your free energy....wind turbine ?1 point

-

Generally these cheap chines sets are for specific calibres, none of them seiko based. The quality varies a lot from single use till broken to pretty shit. Tom1 point

-

Very little info here on this advert. Do you know if there's one that's the correct size and direction for the 7S26? The other question you need to ask is will the old mainspring but reusable?1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

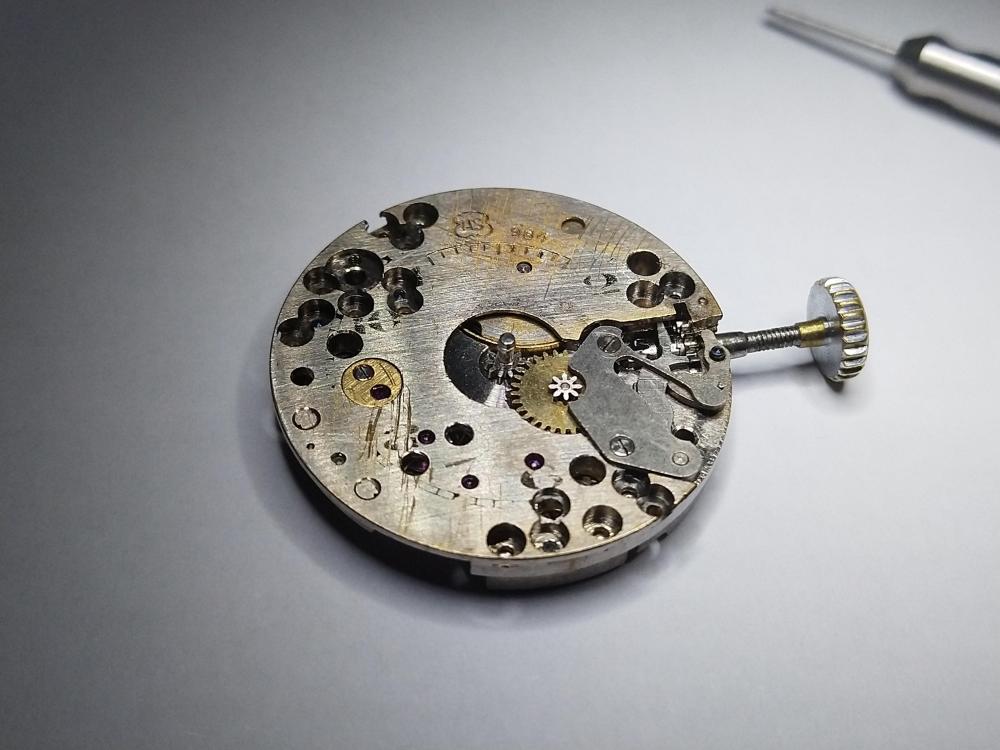

HWGIKE#30 AS 984 Afra Watch One of my most difficult repair. Dial is not made for AS984 so it is not possible to add a second hand, there is no extended pivot for it anyway. The hole should be only 1 or 2 mm be closer to the center. ( i consider to larger the hole and buy a 4th wheel with an extended pivot) New crystal, stem & crown. Holes for the barrel arbor tightened, both upper and lower one. (the second one was tightened after the assembly, with full power the arbor wedged so the movement stopped.) Setting lever did not reach the stem, was worn, ordered another but i knew before the new one arrived that it would not work... i am not sure if the case is original to the movement or not... i had to file the setting lever down a bit so the little thing on the setting lever would catch the stem. This was a very challenging repair/ service and I am very happy how it worked out at the end. Dial was originally big someone cut it around so it would fit and had no legs. I added new legs, but with difficulties, even if I marked their position using the holes on the movement it was not accurate enough had to replace them several time. I also learnt that adding a tiny drop of the oil to the cutting edge of the tool makes an enormous difference. It cuts and does not try to twist the movement holder out from your hand making the hole oval. I made a mistake and went too deep so it is visible on the other side a bit. AFRA stands for Dr Alex Frankel from Vienna, but it also happens that my daughter is also named Afra. I am going to wear it as promised 4 years ago when I bought it.1 point

-

I think it's a boley. Ask the seller for the make and if all the punches and stump are boley.1 point

-

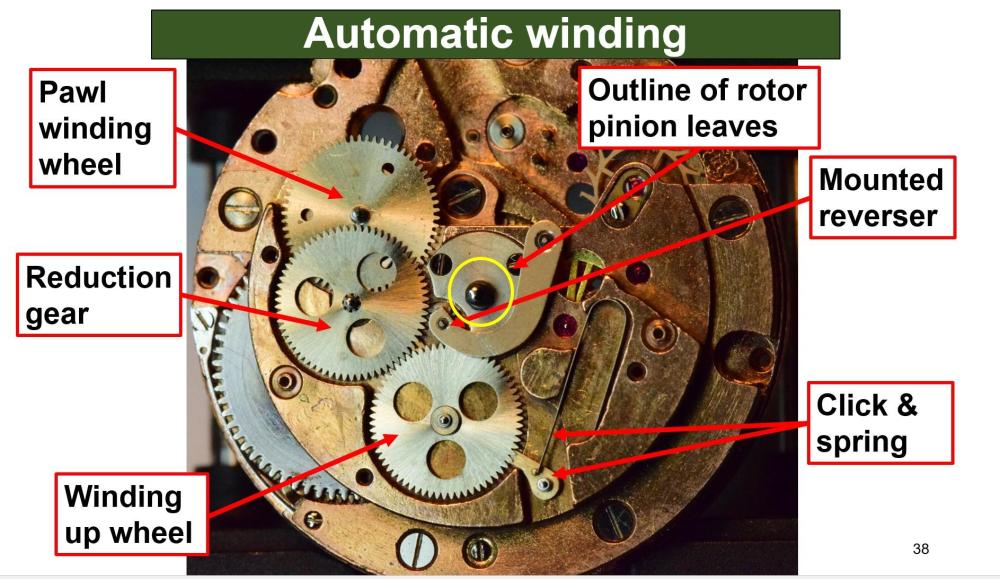

Just lubricate the posts and arbors with HP1300, definitely not the teeth or pinion leaves It's pretty much like a Felsa 690 Bidynator in how the wheel teeth drives wheel teeth in the auto work and the pinion leaves of the mounted reverser drives those teeth in either direction. This was one of the first successful bi-directional winding of the rotor in a watch Low torque high speed of the rotor which ends up at high torque and low speed of the pawl winding wheel to put power into the mainspring1 point

-

Bless you for taking it on the chin fella, i may come across as being harsh sometimes....i try to be diplomatic about it but my philosophy is...to say it as it is...it saves an awful lot of time . Anyways a great way to learn in one respect lol. Micro mechanics eh...If it takes more force to do something than your brain is telling you but your ego isn't...then its time to back it down. As with all mistakes we make in life....we become better people for it, God knows the ones I've made....i should be rocket scientist by now .1 point

-

Here is my haul from the Friday swap meet and 1st Saturday of the month vintage fair. 11 watches for $9.50US (£7.30) each. They all work except the accutron (hopefully just an accucell which is on its way) and the Gruen with a broken staff) the Illinos pocket watch (from 1919) is missing the crystal and the dial is beat but really runs nice and the movement is very nice. It was part of a lot that was $1 and pulled down the average of the other 10! The Tissot rock watch is in the original box and the receipt from a cruise ship in Jamaica from 1991 shows someone paid $110US. Love the hunt, and then the opening and research into the piece. The Ultramar has a Felsa 690 auto with 25 j. The center seconds pinion is broken and seconds hand is missing. Had the correct new acrylic. On the Accutron nice case and original crown. It was a presentation piece for 25 years at Goodyear 1975. 25 years for a rolled gold watch. Oh well better than nothing; hope he got a good pension as well. The Autocrat A new bow is on the way as well as crystal.1 point

-

Had two 8m25 watches, the case on one was scuffed back to brass and the other was missing the battery cover and screw and had a cog floating about inside, made this out of the two, I kinda like it, what do you guys think? Sent from my Pixel 2 using Tapatalk1 point