Leaderboard

Popular Content

Showing content with the highest reputation on 11/13/24 in all areas

-

Hi everyone, been a while since I posted, but just moved house and then getting ready to move back to the UK to start a whole new career, so my watch shenanigans have had to take a back seat. Anyhow, I recently managed to sneak in a Seiko 7005, I think it was made in April 1969. Here are the before and after shots. Here is the front, I had to replace the cracked crystal, but it was hiding a nice dial, not 100% convinced it's original, but suits the watch: Here is the back of the watch, with a generous helping of arm cheese: And here is the finished watch, I managed to save the bracelet and everything else is original, apart from the crystal and mainspring , and bearing on the rotor.4 points

-

There's no problem removing laser welded collets. I do. You just need to close the hole up top and bottom with an inverto staking set with 2 domed stakes before refitting. Use some scalpels to lever the collet off the balance staff. Here's a video of me doing just that in my cloud storage https://drive.google.com/file/d/11S-CURADm81ZdZaaZfEF-sts9g0oXgci/view?usp=sharing Here's a pic of me closing the hole up before fitting back onto the staff4 points

-

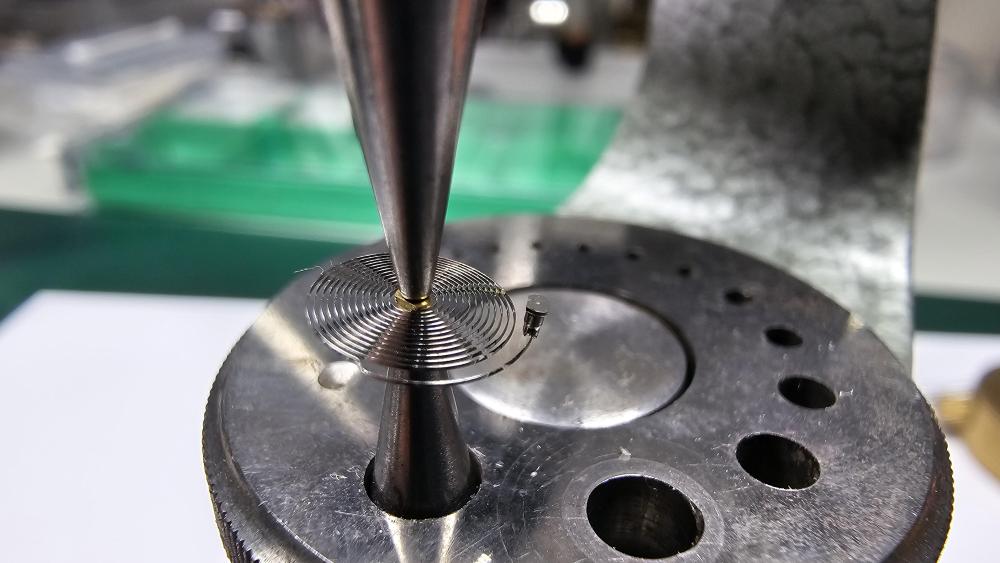

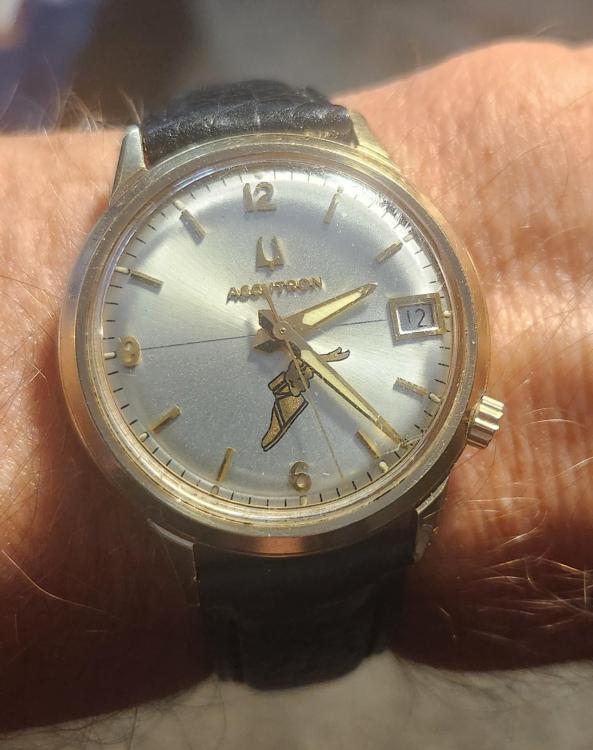

I showed this one as part of a lot in the 10:10 club thread. Was not working and one a speidel flex bracelet A 218 1 from 1975. Presentation piece from Goodyear. Could use a crystal. Sourced an accucell. Put on a decent band. It was a bugger to get going. Will need a full service but could feel the buzz but just would not move. Finally after reading the chapter and going back 2 or 3 times to the book realized it was probably just gunked up. Can't find one dip so used a slight bit of carburetor cleaner and a fine oiler to clean the debris off the pawl stones and micro adjust them on the index wheel Since I got it running about 4 hours ago it has not lost or gain 1 second. It is as smooth a sweep second hand I have ever seen in person. Very mesmerizing...2 points

-

Sounds like the rotor is fouling something. Could be that the rotor bearing is loose which your watchmaker should have picked up on. Alternatively, it might be that your watchmaker swapped some screws and the rotor is fouling on the screw heads (I did that with the case clamp screws on an ETA 2472, so I know it's possible). In either case, you don't want the rotor scraping against anything and potentially shedding metal shards into the movement. I'd suggest going back to your watchmaker and asking him/her to take another look.2 points

-

Hi all, I've been looking for a watch cleaning machine for a while. At the moment, I'm using a three-jar setup in a cheap ultrasonic cleaner. It works well, but I have a lot of cross-contamination between the jars because I can't properly spin of excess liquid after each stage. In my quest to find a machine, I've basically wanted to buy a Elma Super Elite, but despite looking for months, I've not found one below 750 EUR. Last night, one was sold in an eBay auction (!) for 1000 (incl shipping within Europe). And I got scammed and lost 500 EUR when trying to buy one that seemed a good deal.... very painful. I've also looked a various other machines, such as the Indian Pearl machines, Glashütte machines, and "Vibrasonic" models. Long story short: I've not yet found my luck. NOW: there's a new super-compact machine on the market. Basically a guy in Germany that created his own DIY machine and is now selling it. Compared to all the DIY machines that we've discussed on the forum, this one is very compact and without a big stand. It sits directly on the jar. Well, just have a look yourselves: https://nestromo.com/products/compact-watch-cleaning-machine Make sure to scroll down to see the video (it's a bit hidden among the pictures). My idea of using it is the following: get the machine with 5 jars (the jars are cheap and generic). - 1 glass for washing + 1 for spinning washing fluid - 2 glasses for rinsing + 1 for spinning rinsing fluid = total of 5 jars. Thoughts: pros: + savings of a few hundred compared to Elma Super Elite on the current market + bidirectional spinning!! + small size cons: - seems very expensive for what it is (but the engineer insists that most parts are Made in Germany and that about 10h of handwork goes into finishing the product). But well, still much cheaper than the Elma. - biggest con is the absence of a heater for drying! but that's where a DIY solution could be figure out (silicone heating pads with adjustable temperature can be bought on AliX for 20 EUR. Add a tube of some sort and let the machine rest on it. - spinning off liquid isn't as "elegant" as on the Elma (instead of a "plunger" within the same jar, one has to move to a dedicated spinning jar). What are your thoughts!!??1 point

-

1 point

-

1 point

-

Can you remove the back and see what's on it and also the movement.1 point

-

Just had a quick search, on some other forums similar question asked, possibily SIS indicates Indian Army 1930s1 point

-

1 point

-

1 point

-

From what you just posted it was stated that this is a version 2 of this watch with no black infill on the bezel. So basically you want to mod a Timex watch. If not you need to take your complaints to Timex and/or the trading standards organisation of your country. Don’t hold your breath for the outcome though. Tom1 point

-

That was not what I was expecting I've seen another one on the eBay not as compact as this. Then yes the price seems disturbing except usually on DIY people forget about what the time is worth in their quest to do whatever it is they're trying to do and if you're making a limited quantity of things then the price will be high. The manual moving of a watch basket from container to container is not a new thing. Various cleaning machines the past employed a process of moving from container to container typically without spinning between baths like for instance here's a brand-new machine with ultrasonic. https://www.lititzpp.com/matador.html Yes a common amusement on this group is everything is easy. The other day someone had concerns about rewiring a cleaning machine was pointed out it's easy. So yes everything on this group is easy rewiring a cleaning machine with no prior experience no tools no wire no supplies how badly could that go wrong? Oh and then nowadays you need a 3-D printer or for that matter a lot of tools as their places you can send you design files and they will manufacture for you. Of course you do need to have design files how hard would it be to make those? From what I can tell the Swiss like oil especially on the keyless they're just going to a heavier and heavier oil. But if you look at some of the newest tech sheets you will find 9504 usually recommended on some of the highest pressure components on the keyless. Not as nice as spinning was something that I did. Instead a separate jars I had one beaker and used ultrasonic with that. So when I remove the baskets the parts strung on a wire I would Place it on a paper towel Which would absorb a lot of fluids. This would allow me the opportunity to pour the fluids back into the jars that I Them in and then fill up the beaker with the next solution.1 point

-

Thanks guys for the quick reply. Especially you Caseback. The movement come out the front, but the back also comes off to release the stem. I'll order that stem now.1 point

-

30 secs for the reversing auto timer is better than the initially reported 3 minutes, which was not really useful since that’s about what a cycle should be. But getting closer to 10 secs would better reflect what traditional units provide for most effective cleaning.1 point

-

I am not sure if its lazer welded, but might not friction refit tight enough as it is not adjustable. If you intend to attach another hairspring to it, you'd be better off using a fresh old type collet. Rgds1 point

-

The placement of the numeral 5 had me thinking the cowboy was incongruously riding a racehorse. Use care with all that radium, by the way.1 point

-

1 point

-

1 point

-

Happy that it's working but getting it right and it being safe are different things. Each metal part should have its own earth as currently if there's a short at the motor for example and the case becomes live the only path to earth would be you when you touch it.1 point

-

1 point

-

If he makes regular updates on this mineral oil filled Casio, I'll keep posting them. This is after 3 months. But forget about the oil filling... THE LUME mod is amazing. I'm totally gonna do this.1 point

-

After trying a mainspring that has slightly less strength (0.10 vs 0.11), that rebanking issue went away. I still get a healthy amplitude. So, I was finally able to finish up my grandfather's watch.1 point

-

In the spirit of the general destruction of perfectly good time pieces that this thread embodies, I would like to point out that DOT5 brake fluid is mainly silicone oil with a few herbs and spices for rust inhibition and improved lubrication. Make of that what you will. A note of caution for anybody daft enough to be interested in this observation, DOT3, DOT4 and DOT5.1 brake fluids probably would not be suitable for this game, as they contain glycol ethers, and may well dissolve some plastics. Always check the label before filling your perfectly serviceable watch with bizarre fluids. I take absolutely no responsibility whatsoever for anybody dissolving their watch/arm/cat/beloved family member when conducting said experiments.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)