Leaderboard

Popular Content

Showing content with the highest reputation on 06/04/23 in Posts

-

For €51 I couldn't resist this CCCP clock ! It's defect. According to the seller, when winding the key, the hands go fast around and than it all stops. Sounds like somewhere in the escape wheel / anchor era ...... we'll see I would assume that these 8-days movements are of high / robust quality (?) Nice serial-number too3 points

-

The feeling some members here radiate as they talk about a find they found must be nice, unfortunate as it may be I don't have much free time to shop around, instead a watchshop buys for me the watches I collect, and I recently discovered Seiko Lordmatic, acquired four this month I think. heres a most recent acquirement.2 points

-

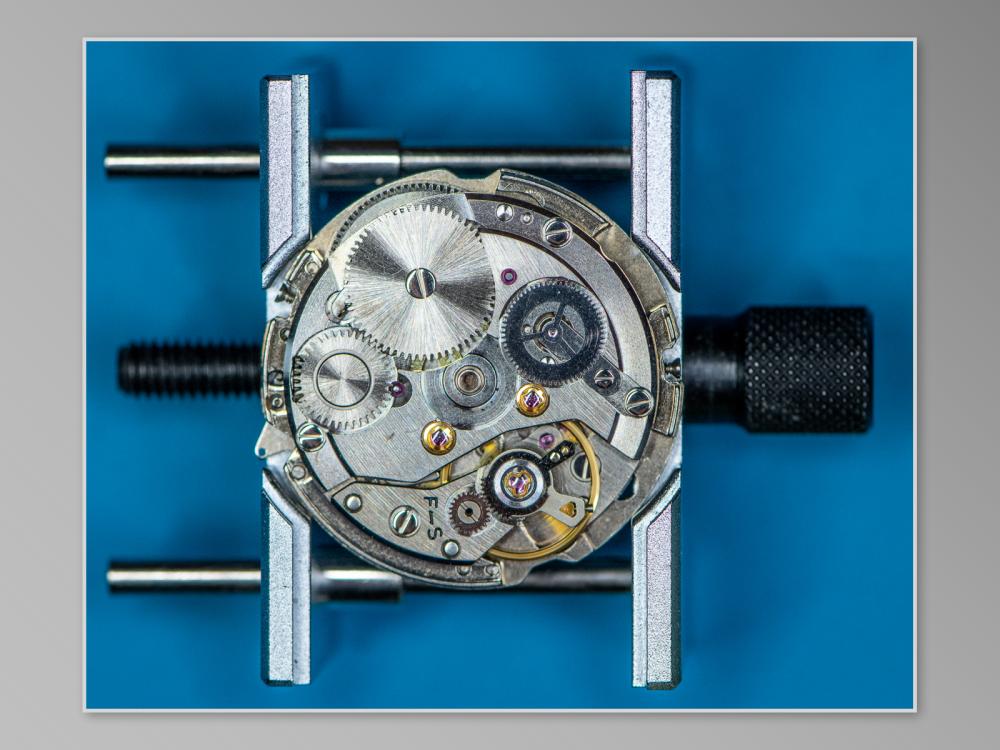

I've got this one coming soon. I saw it on eBay and thought it looked unique. It's got an ETA 2452 in it. There was zero bids with about 12 hours left. I made an offer of about 25% below the starting bid amount, and the seller accepted. Pretty excited to get this one in and on the bench. I think it will look really good with a dark brown or black leather strap.2 points

-

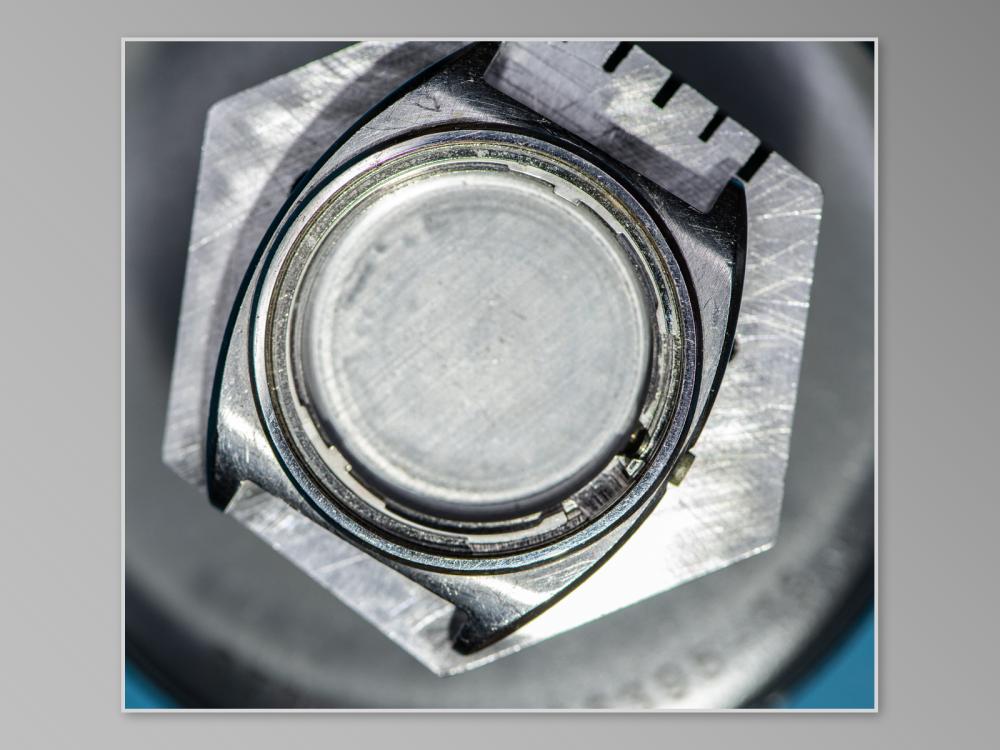

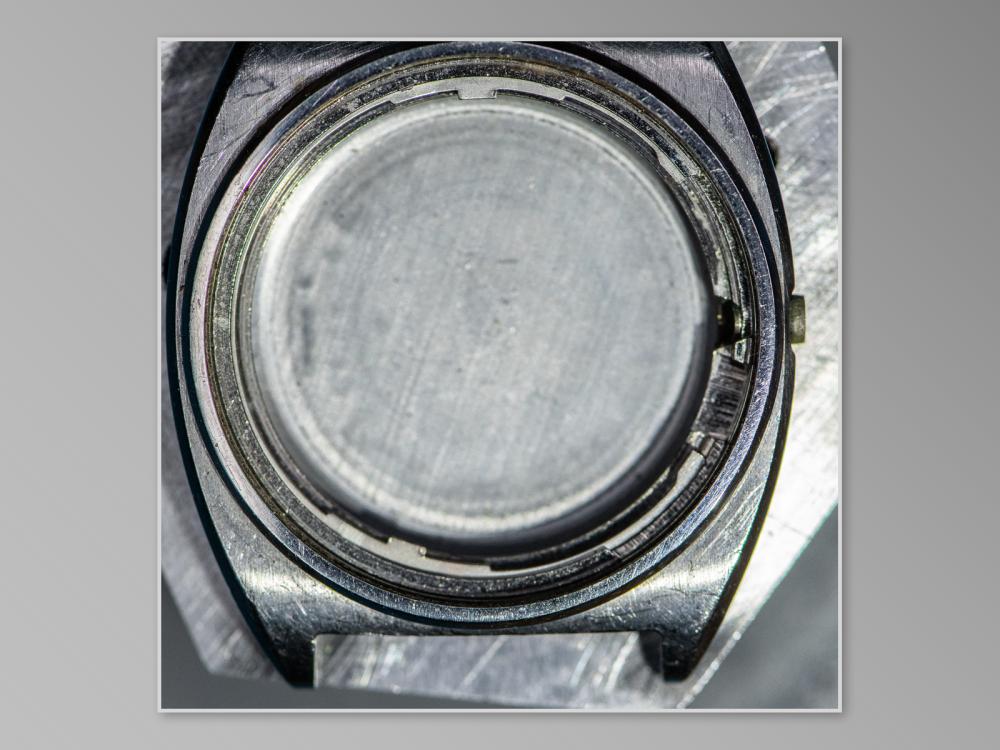

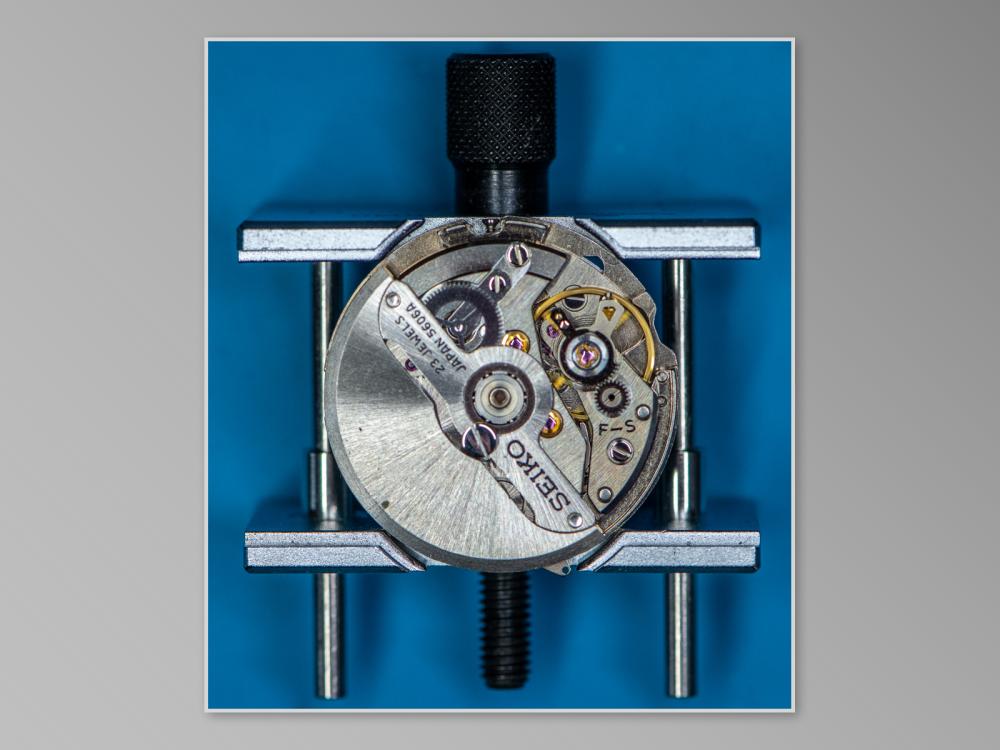

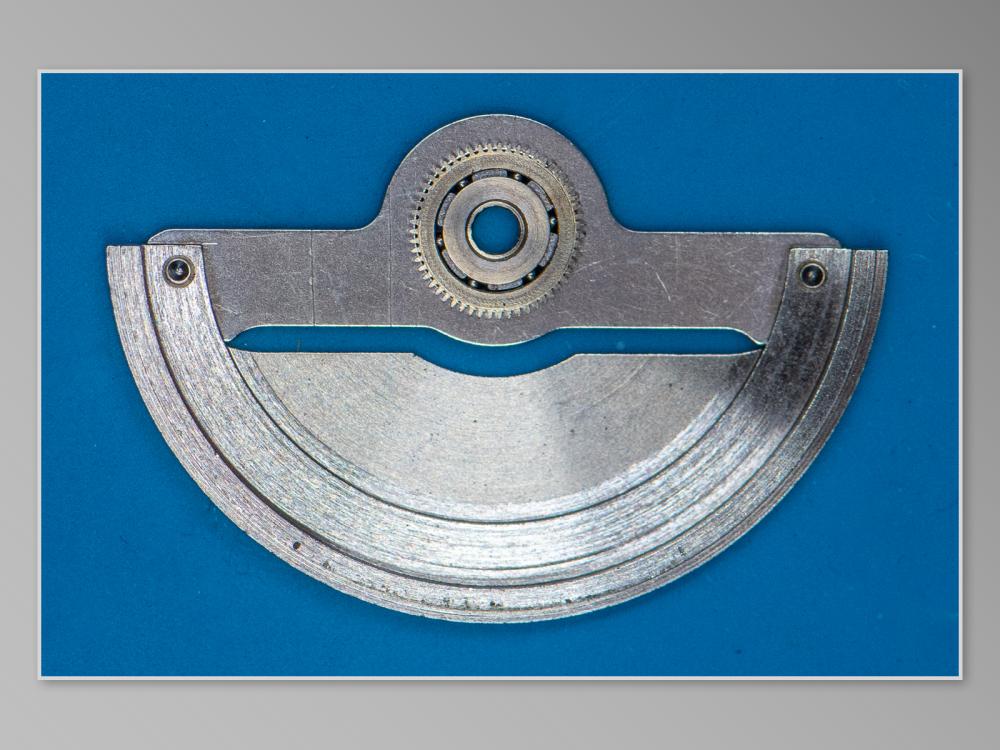

I don't know why I was limited to a 3DPrinting forum, but oh well. I managed to grab a much coveted Meyer's No.58 Movement holder off ebay, but it only came with the second to smallest jaw inserts. Not to be detered I reverse engineered how to machine the jaw inserts. Here is the Flickr Album. https://flic.kr/s/aHBqjAGuFJ I made a small insert set as a test and then made a set for size 16s pocket watches. I'll make a few more to fill out the set. I made these from Aluminum, but might try glass-filled Delrin as an experiment The drawing could easily be used to design the jaw inserts for 3D printing in Nylon or a hard Urethane1 point

-

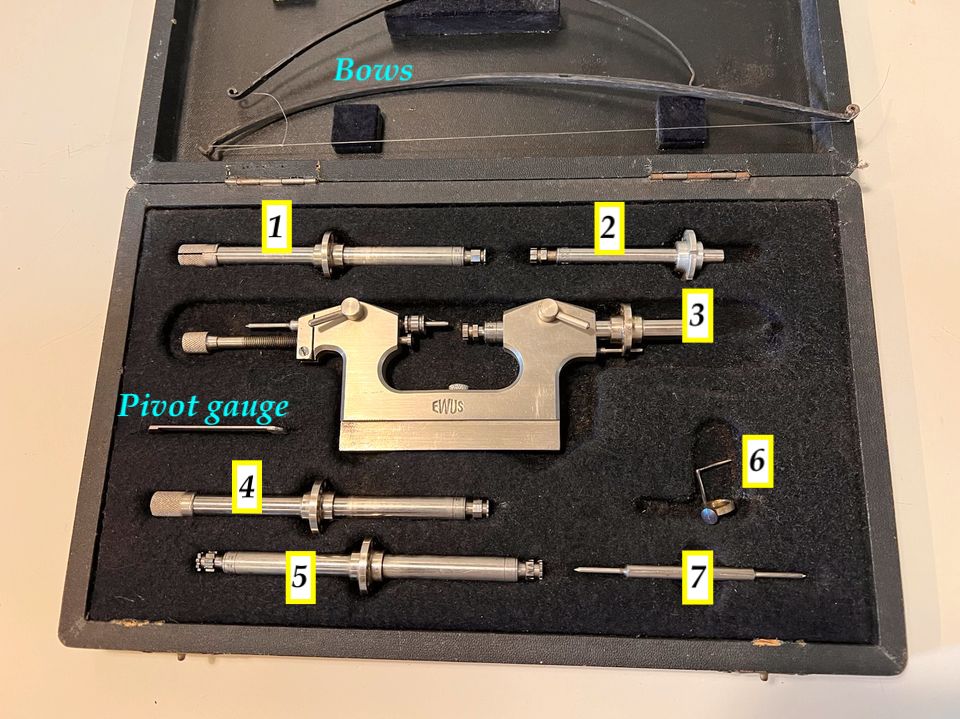

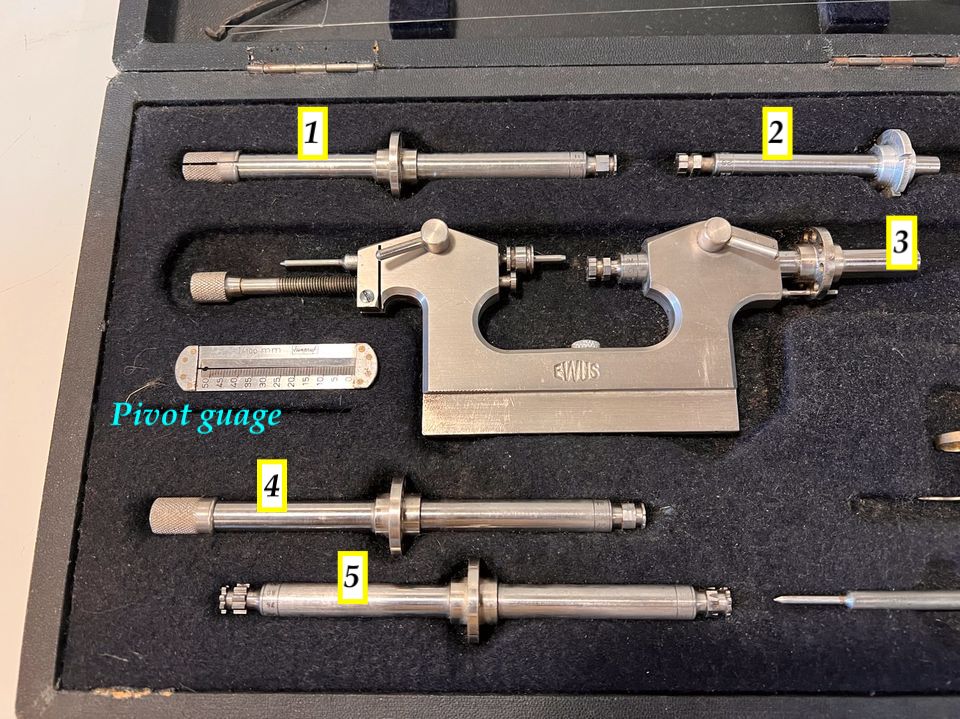

Hello All; I've read some of the recent replies of @JohnR725 and @nickelsilver regarding @VWatchie new Steiner Jacot tool, but it would be nice to get all the names of the parts, and their exact uses, in one place. Seeing VWatchie's new shiny Steiner, I couldn't resist to search and stumbled over this Jacot tool, no it's not a Steiner, but it looks good none the less. It has quite a few runners and some additional parts. The covered lanterns should be in good condition. Could our experts on this forum be so kind to explain what the different runners are, why and when to use and what the parts 6 (?) & 7 (center broach) are / used for? Thank you in advance1 point

-

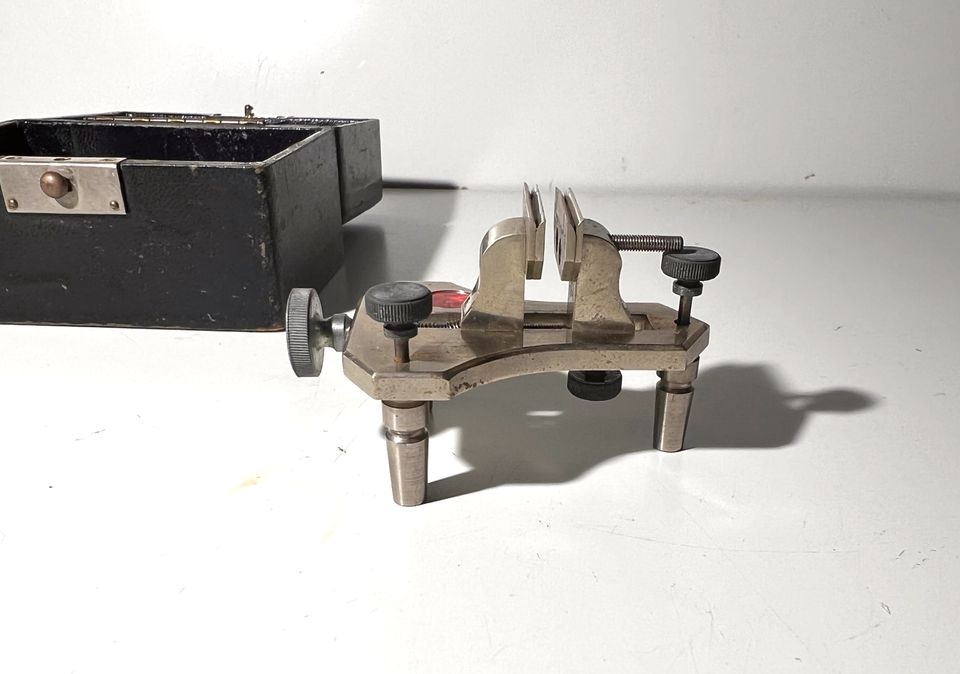

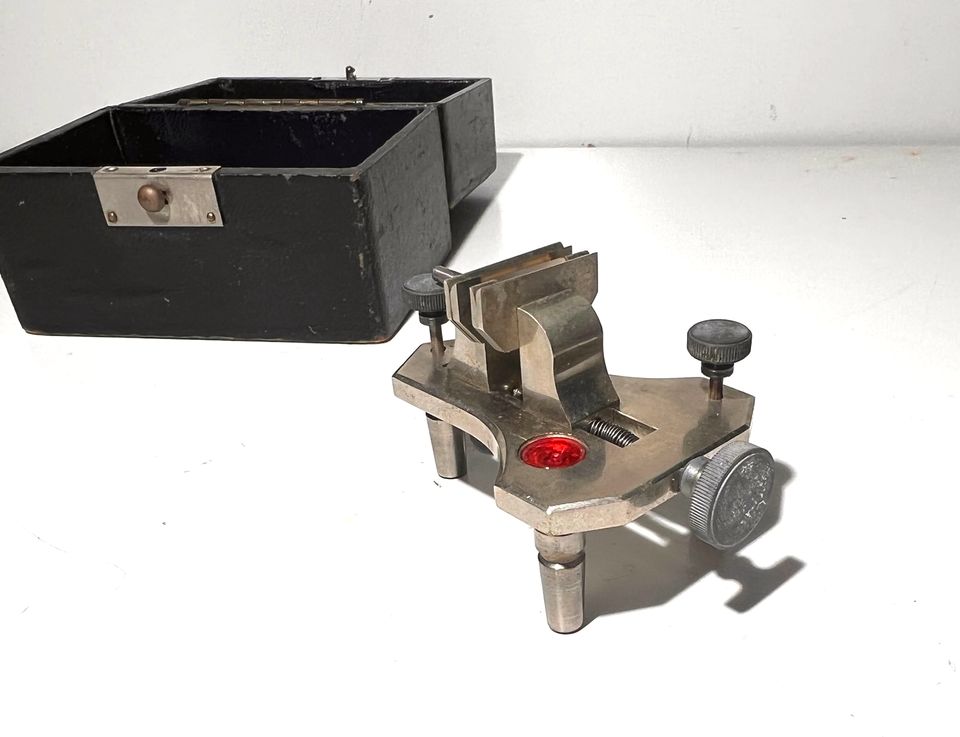

Hello All; bought this poising tool which has ruby jaws (according to the seller in perfect shape), but it seems to have "double jaws"; one side ruby and the other side steel ?? Also, on top it has a weird long piece of threaded rod sticking out, which could possible interfere with the front adjustment knob ; a DIY modification and what could its function be ? Anybody?1 point

-

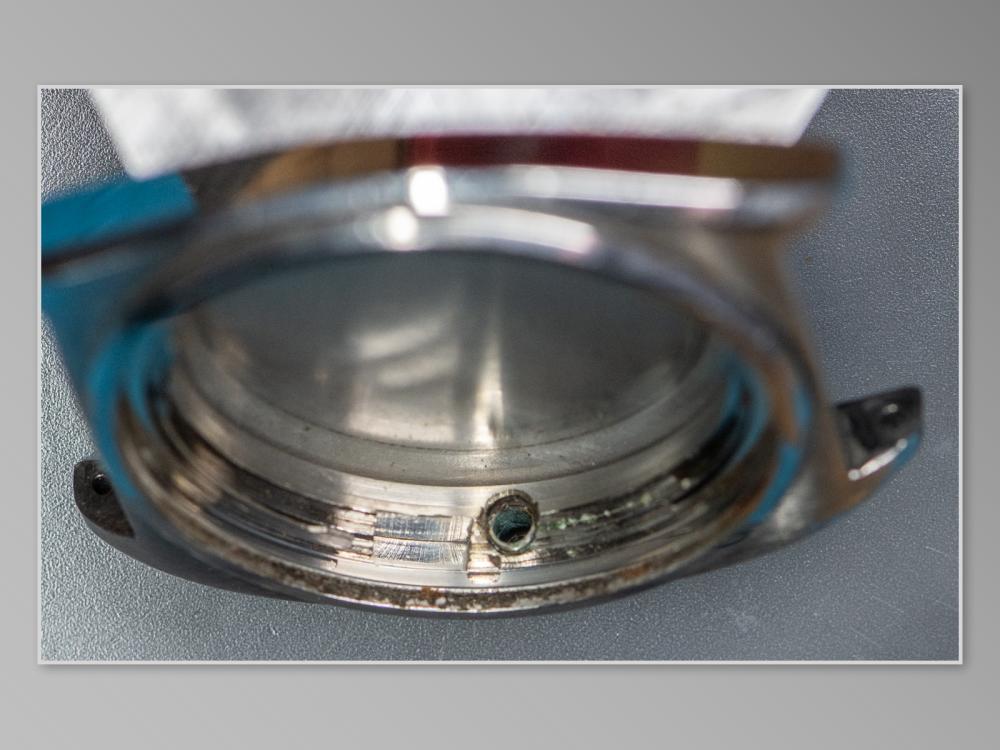

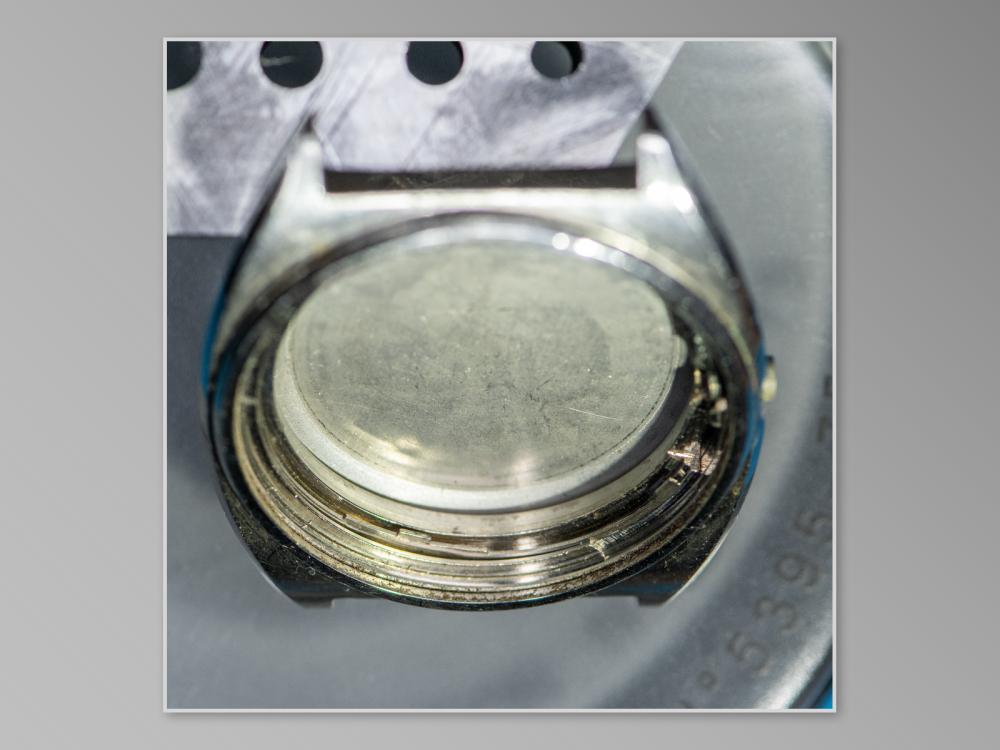

Just when you thought they couldn't get any more scruffy, I present the latest ebay horological detritus. That was the only picture in the listing, so I have no clue what (if anything) is in it. I'm not into this for much, though, just 0.99p plus shipping, so its not a major issue if it turns out to be scrap metal. The second find of the day has a little more chance of actually working when it arrives. It also looks considerably less scruffy. A USSR era Raketa 2609 HA based pocket watch with a missing bow.1 point

-

This thread was originally posted in 2021 in that time most of the issues have been covered. The Platax tool is no longer manufactured so only used platax tools are available and for extortionate prices. I own one purchased new and it is a great tool for removing balance staffs etc. However there are other tools available that do an excellent job such as attachments for a staking tool. The traditional way of removing a balance staff was to remove its rivet using a lathe. This method with care is faultless. As I have highlighted during this thread punching out a balance staff has to be approached with caution. It’s very easy distort a balance if too much force his applied.1 point

-

1 point

-

Yeah, it looks like it was finished on a whetstone. I don't think more recent ones have improved much either.1 point

-

I just looked at the link and I can see the movement has a typical rough and ready finish which you expect to find with most Russian movement from bygone years. The design of the platform gives you plenty of scope to achieve the correct depth for the escape wheel to engage with the contrite wheel.1 point

-

Yes, in the past I've seen these platforms but they are slowly drying up. Buying from the Ukraine is a no-go, as the EU has become in all regards the Soviet-Unions replacement; any EU-import and you pay through your nose. I've seen a platform on German eBay, but it's expensive (€140). However, I've been looking for these clocks for a long time and the starting price is low Would this clock have a VOSTOK 5-ChM movement?1 point

-

The russian submarine clocks are of a very nice quality. It uses a separate escapement platform which contains the escape wheel, pallet fork and balance. And these are all jewelled. If there is anything wrong with the escapement platform, spares are still available. But the seller is in Ukraine. Hope he's ok. I have one which is accurate to about 30 seconds a week. There's another one out there that has been tempting me this week.1 point

-

Common wrong approach even by pros is how you proceeded detaching cock-balance assembly. Best to loosen cock screw , not entirely and not remove it, then pry the cock to loosen/ disengage it from the locating pins. Under the remarks subtitle, Dr ranfft list many calibers which practicaly are the same as AS324, the balance complete of any fits your watch. Good luck pal.1 point

-

Impressive brisk date change on these. Spidel made bracelets which resembles the original ones on this, check pics online to see how original braceletes looked. SS case but later in chrome plated case. You also like how noiseless it winds. Wear it in good health.1 point

-

1 point

-

@nickelsilver; Thank you very much I'll print it out and stick it, once the set arrives, in the box Indeed, I have had one of those (killer) pivot gauges before (throw it away, but now I'll receive another one ) and they are ideal for ruining pivots, hence my DIY pivot-gauge:1 point

-

The parts 1,2,3,4, and 5 are what Bergeon and Horia (Steiner) call broaches, or broche in French. In my schooling they were called runners, and most English speakers I know call them that. The main body of the tool is usually called the frame. Number 7 is also called a runner in English (Horia just calls it a cylinder, also in French), but specified as the headstock runner- the headstock being the end of the frame with the pulley. The different runners are for different sizes and types of pivots. In the above (and most sets), the runners with caps on one end are for smaller pivots, up perhaps 0.36mm. The caps cover the fragile lanterns, which allow working on the pivot ends. The short runner, with no lantern (#2 above) is for long pivots on 4th wheels that carry a second hand. They have longer beds and naturally make a tapered pivot. In the above set it looks like #3 could be an additional 4th wheel runner. The runner with beds on both ends is for center wheels i.e. larger pivots. You would choose between headstock runner #7 or the one currently in the tool according to pivot size, usually one will do the normal range up to 0.30-40, the other up to the limit of the center wheel runner. Finally, #6 is a limiter for the burnisher. It clamps onto the runner (tailstock runner, with beds), and can be positioned so that the burnisher can't ride up easily over a shoulder on conical pivots for example. They aren't very common, and I have to say I've never used one, even on teeny tiny ladies sized balance staffs. But I would say a useful thing to have! The pivot gage is something that has always terrified me, and I've never used one of that style. It seems like a good way to mark or break a pivot. But it was a standard accessory for most Jacot tools. I much prefer a jeweled hole gage.1 point

-

In my old Seitz catalog it says the jewels are accurate to 1/4 of 100th of a mm, or 0.0025. Not sure if that's +- or total; I recall seeing the same claim on one of the jewel assortments but not sure? I definitely have jewels in my stock (from other makers) with in-between sizes, like 0.095mm. I use the Seitz pivot straightener as a gage, and it's in 0.0025mm steps, so I would imagine those jewels are indeed held to a tighter tolerance. I think it's pretty standard practice to hold the jewel hole size to within 0.0025mm, it was 20 years ago but I visited the Robellaz jewel factory in Ste-Croix and remember being shocked how precise the jewels were- and also had a new respect for them!1 point

-

The extra metal next to the jaws is just there as added protection for the fragile ruby. The screw thread would be to stroke your tweezers over to induce some vibration and help the balance settle into position.1 point

-

Another little bit of a gamble. This is a "Catorex" pocket watch. The brand appears to have produced mainly midrange or high quality watches, with a fair few having Unitas UT 6310 or similar quality movements. I have no idea what is in this, but then again, that is reflected in the price. It may be white gold, it may be made of old soup cans. Time will tell.1 point

-

1 point

-

You need to take off the screw at the end of the shaft as well. There’s one that goes into the rod.1 point

-

1 point

-

Correct, it's just like WAS (watch acquisition syndrome) where you need "just one" more mechanical watch and your heart will be at peace... but then you see something else, and then you have this difficult issue of how do you keep all of the mechanical's running at one time because you can't wear them fast enough in rotation to keep them all running without spending more money on a winder. Or at least makes your wallet feel like you own a genuine Rolex Maybe stir the tea with a Bergeon piece of pegwood... it will taste so much better with Bergeon pegwood than generic pegwood.1 point

-

Yes- I use my jewel press much more for other things than for jewel-pressing, and for many things that would normally be seen as tasks for the staking tool. It's a truly useful tool! And becomes more so if you can turn up various pushers and stumps on the lathe.1 point

-

I am German, but this word made my laugh so hard By the way, I'm thoroughly enjoying my Seitz press. I haven't used it for any jewels, but for as many other applications as possible It gives me much pleasure - putting the hairspring collet back on the balance staff safely and evenly: - putting a mainspring into the barrel - closing the barrel:1 point

-

1 point

-

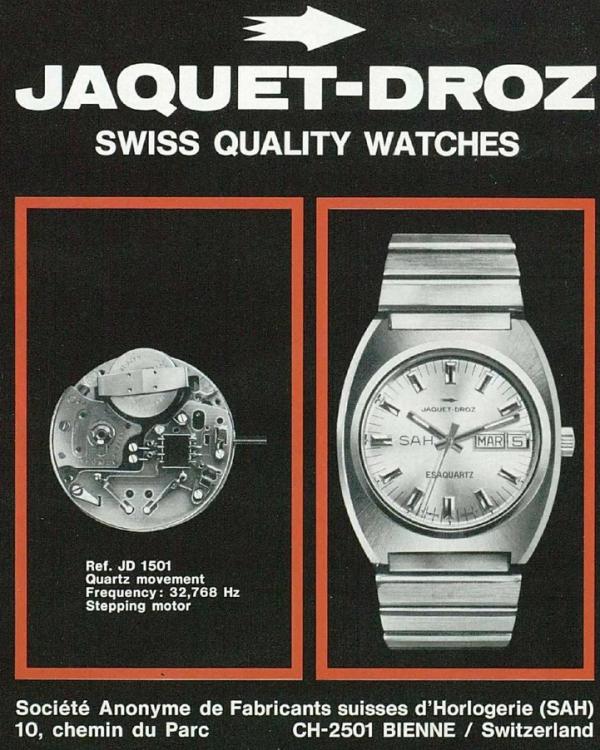

Not for the purists perhaps, as its quartz, but it does have a blue dial. An Esaquartz 1501 based "Verity" SAH with more than a hint of a connection to Jaquet-Droz https://grail-watch.com/2021/04/22/the-forgotten-history-of-jaquet-droz-switzerlands-shared-watch-brand/ I have a soft spot for early stepper motor quartz mechanisms, so this looks pretty interesting.1 point

-

1 point

-

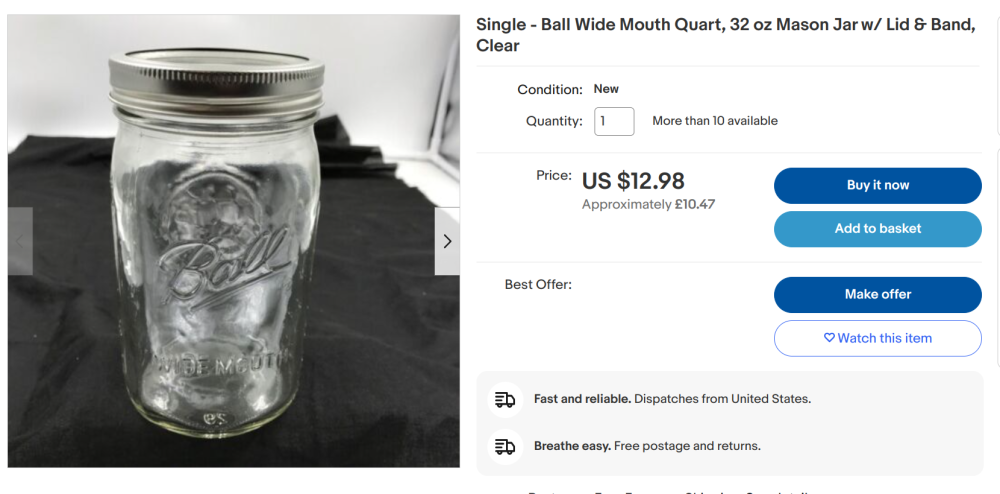

I have a pearl machine and use these Ball jars: Make sure you get the 'wide mouth'" version and not the standard version. As you can see from the below they fit well on the machine: A little tighter on the jar opening, but still goes in no problem with room to spare: Substitute Ball jar on the left and original Pearl jar on the right: Also as you can see from my pictures I took @jimzzillareccommendation and use the plumbers 3" test caps which fit the pearl and Ball jars. Hope this helps1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)