Leaderboard

Popular Content

Showing content with the highest reputation on 01/02/23 in Posts

-

7 points

-

... though it's not "complete" yet. I realized a couple days ago that for just kinda getting used to working on the size scale of watches and getting a bit of a feel for using the hand tools (tweezers, etc.) that trying to bring to life some of my old "junk" dial indicators might be a good way to go. The movements are dead simple compared to any watch but it's about on par with the size of pocket watch gears & such. Well I bungled up my first attempt - a DTI. But I want to follow through on it just for the practice, so I'm going to get a couple parts (indicator hand mainly) and finish it. The second one, another DTI, I realized that it had a shattered jewel so I decided to jump right in and order one of those import Horia clone jeweling tools - baptism of fire. I'll measure and buy the jewel soon, but I have a month to wait so no burning rush. But today I dove into a Federal .0001" indicator (6 jewels). It's a nice one but it was gummy like you wouldn't believe. Well I'm sure you'd believe it and indeed run into worse yourself, but still. So I just took it apart & cleaned it, polished the badly scratched up crystal, put it back together with new lubrication, and I'll be darned if it ain't working again just like new! I did have to remove the crystal to clean things properly and I'm going to need a press to get it back in, so I'll get an import cheap version of that for now. But even though it's not all buttoned up yet, I feel a little joy that I was able to revive an old tool which was worthless otherwise. I'll wade into actual watches pretty soon. I kinda needed a little gratification of success after those first two dead ends. It makes me feel like maybe I can learn how to do some of this after all.5 points

-

If this was an over coil hairspring then the rule is as tight as possible as long as they hairspring can still slide between the pins. On a flat hairspring you have to have a tiny bit of breathing room but not very much. I think the suggestion might have been if you had a another piece of hairspring and shoved it in so basically at half of the new hairspring on either side that would be the most but I suspect that this number can vary. And yes you definitely need to follow the terminal curve that was last week's fun at work. My boss likes to have a service of regulating watches to being just like Rolex watches at least to please the timing machine. So he had played with the Seiko hairspring everything was perfect except the raids and then when he move the regulator it was all screwed up because? This is what happens when you don't follow and have a terminal curve Then I've attached an image the importance of things being right. So yes if you open up the pins too much in the amplitude drops at some point in time you get some really bizarre timekeeping. This also becomes very obvious on an over quill watch for that spacing is even more critical you'll see the watch being really slow as the amplitude drops you might even think you have some other problem and it's just a regulator pin problem.4 points

-

Ok. I didn't get any answers here but i solved the problem or problems so if you get these readings maybe i can help. 1. The big positional variation was due to my hairspring not being centered in the regulator pins on my balance, they were rubbing against the inner pin even with the etachron regulator stud/pins set to all the way open. I opened it, adjusted the etachron stud so my hairspring was centered and then slowly closed it till there was the tiniest bit of movement in the hairspring. This corrected the positional variance in my rate. This was a new movement and it had this problem. 2. I noticed a weird look to the oil bubble under my top balance jewel. THe bubble i had before had now gaps in it and was no longer round. I removed the shock spring, reversed it because that helped once cleaned and relubed it to a perfect bubble and that drastically increased my rate in all positions but was still not good enough. 3. Then i remembered since i was going off a seiko service sheet and for some insane reason they do not tell you to lubricate the barrel arbor, OR the jewel it sits in! Insane! I went back and relubricated the barrel arbor with hp1300 and WOW, my amplitude in dial down jumped to 303 and in dial down 298 (briefly). Those things fixed all the issues. my amplitude is INSANE and my positional delta is fantastic now.4 points

-

3 points

-

Well ain't this always the way it goes? I'm an old man and new to watchmaking. I'm a machinist by trade so somewhat adjacently familiar to the subject, but never actually tried to learn anything about actual watchmaking until recently. With the advice of starting with a pocket watch or import ST36/6497 movement, I picked up some inexpensive examples of those to start with. But I also have some sticky or broken dial indicators too so I thought if I want to start simple, then the dial indicators might be a great way to dip my toe in and score some quick gratification points. Well, yes and no. I found a Starrett back-plunger indicator that was gummy so I thought I'd start with that. Keep in mind that the thing was already not being used because of its performance and if I totaled it, I don't use these much at all so it wouldn't be a big loss. Well disassembly went fine, and talk about a simple movement! You can maybe find something simpler, but it would take serious digging. Anyway, long story longer... after cleaning it up I started putting it back together and realized that the solitary jewel is all busted up. I guess I found the other forgotten reason I tossed in the junk pile years ago. Anyway, I figured I'd just punt and pick another something to work on. But giving up started to bug me, so I started looking into what it takes to replace jewels. I'm pretty sure I can pull this off well enough. So now what about the tools? A search reveals that I can pick up one of those chinese jewelling presses and pressers/dies for about $160. I pulled the trigger in hopes that it will work out. I'll measure the set and polish them to size if necessary. If I'm lucky, it will all be within spec and I can just use it. Not sure if I have to mess with reamers and such, but I guess I'll find out. So out of the gate, about my second task is jumping in and replacing jewels. Baptism of fire I guess. And if it doesn't go well, the worst that can happen is I'll trash an indicator that was in the junk pile anyway. I'm learning stuff I guess. edit to add: I haven't seen much talk about machinist dial indicator repair. If you haven't thought of this, you should look into it. There are tons of problem indicators in junk boxes in every shop in the world (I personally have about two dozen). These things are frequently getting splashed with coolant, oil and dirt and it seems like if a guy wanted to, he could maybe make a little beer money going through and bringing these things back to life. Like I said, the movements in these things are WAY simple compared to the most basic watch.2 points

-

Luckily it comes with a tiny candle to wax the relevant parts. I'm not sure if it's made of solid 9010 or what I have to say, overall I'm very impressed. The instructions were very good and easy to follow. Having a knowledge of how a Swiss lever escapement works definitely helped when putting together and tuning the tourbillon though. Getting the mainspring in and wound properly took several tries, and was probably the most frustrating part. Once it's all together, the parts do need to be lapped in. The instructions say to turn the tourbillon for 10 minutes by hand, but I found mine needed a lot more running time once it was assembled. You just have to wind it and keep giving the balance a nudge when it gets stuck on the pallet fork. The real issue I had was with part of the tourbillon coming apart while running. I'm still not sure if it damaged anything, but I did use a little superglue on some of the more important parts when I rebuilt it. It's far from a Swiss timepiece, but it does have beat and rate adjustments, and it really looks cool spinning around on my desk.2 points

-

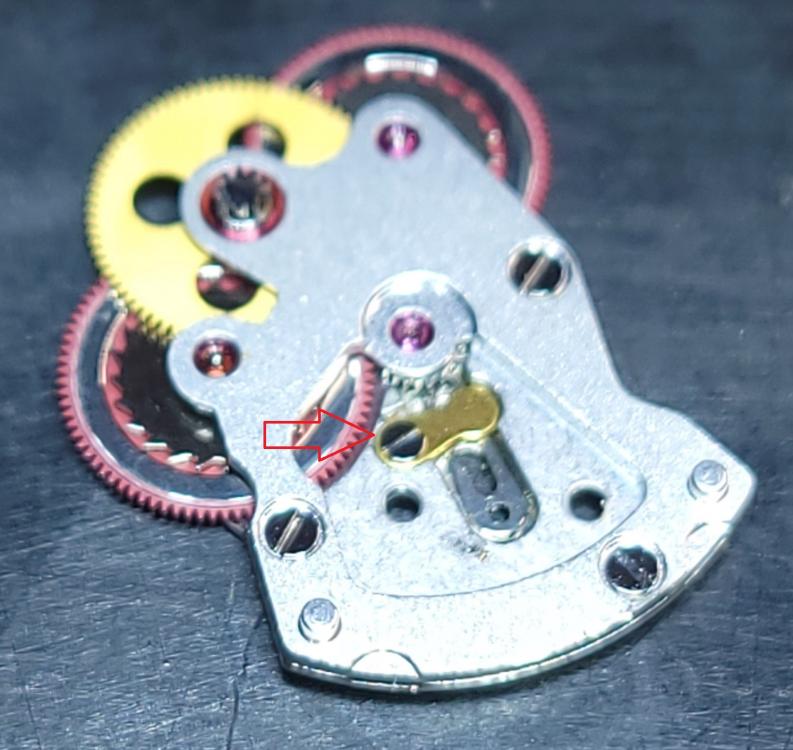

Since I know you're all on the edge of your seat: I found it, thanks to the many pictures I (thankfully!) took during disassembly. I was looking at this image, and realized I had seen that brass stem retaining screw somewhere: I thought it was to hold the brass cover on the underside of the automatic works. When I took a look at my disassembly photo, it was pretty clear that screw was the countersunk screw I couldn't find. Moral of the story: take tons of pictures during disassembly! Since this has been together and apart a few times, since I've got some L&R #566 and #3 coming in the mail, and since it was first cleaned with only lighter fluid, I'm going to clean the parts again before tackling reassembly. I figure it can't hurt to start with extra pristine parts.2 points

-

I don't think I can afford the 9010 for that.2 points

-

There are several YouTube videos showing the use of tweezers to remove the stud. The method I learnt from my mentor is to modify a cheap screwdriver blade and sharpen it into a spear point, with a rhomboid cross section. This will allow it to work on stud holders of different sizes. Just wedge it into the gap behind the stud and rotate it gentle to pop out the stud. You might want to put some rodico to prevent the stud from shooting out and distorting the hairspring any further.2 points

-

Another piece of (translated) horological poetry, berating time and its measurement. This one from Plautus in Roman times. Source - https://en.wikipedia.org/wiki/History_of_timekeeping_devices2 points

-

Here's a guy in Arkansas putting an estate he acquired on ebay. Curious I was. He shows you the stuff with a series of terrible videos. This kind of stuff intrigues me, but this guy is whistling Dixie, IMHO. I tried to find a reason to go buy it but failed.1 point

-

1 point

-

That Chinese Horia clone is really nice for the price. There's some variation how the stumps fit. I think my set has one stump that's a bit too tight fit. You could also consider getting a used Seitz tool. The pushers are a lot higher quality (and very expensive if bought as individuals). Just try to find one that uses 4mm pushers (3mm is the other version) so you can buy replacements new. The Horia clone is 4mm for both the pushers and stumps. I have the clone and also a Seitz that I bought without any spindles, pushers or stumps. I bought a reaming spindle and bits for it. I don't know if reaming accessories are available for Horia. Nice thing is you can use new Seitz pushers with a 4mm Horia. I use the Seitz cannon pinion tightening bits.1 point

-

1 point

-

That would help centering of the hairspring if it did. Can you post a close up of it.1 point

-

1 point

-

There is no getting around hairspring work, so you might as well bite the bullet and start now. A stereo microscope really helps. Start with some scrap hairsprings first. Start simple, don't try to disentangle a ball of noodles. I find that most hairspring work is on the endcurve part, which might be the most important and most critical part of the spring. Good luck.1 point

-

1 point

-

Hi Hector. Do yo have a picture of the tool so that others may be able to create one for themselves. A picture is worth a thousand words. Thanks.1 point

-

Have a read of this thread messed-up-a-seiko-6r35-regulation There's a video which explains removal and adjustment https://youtu.be/ExfFlYFAffg1 point

-

Woohoo! It's get's easier the longer you go at it, and the more of them you do. It becomes a trifle addictive after a bit too (if it hasn't already become so for you).1 point

-

A couple of concerns from your description 1. You wound the mainspring until it stopped taking any more wind, if I read that correctly that's not right, with an automatic wind mainspring you should be able to wind it untill the cows come home and it will still not stop taking a wind, the spring is designed to just slip around the barrel and not get fully wound. 2. The pallet cock screw is missing, unless it been missing for some time and the back has been off before it must be in there somewhere. Have you fully stripped the watch or just removed the Ballance and pallet. The may be stuck somewhere causing your problem and a full strip will be needed to find it.1 point

-

Taking Back Control: The Cousins/Swatch Case and Why the Government and the Courts Should Reject Participation in the Lugano Convention Julian Maitland-Walker (Maitland Walker LLP)/September 23, 2022/Leave a comment The Lugano Convention 2007 is an international treaty negotiated by the EU on behalf of its Member States with Iceland, Norway and Switzerland. It seeks to clarify (inter alia) which courts have jurisdiction in cross-border civil and commercial disputes. The UK ceased to be a Member of the Convention upon Brexit and its attempt to rejoin the Convention has so far been rejected by the EU largely on political grounds relating to the ongoing dispute with the UK over the Northern Ireland Protocol. A recent cross-border dispute relating to alleged breaches of UK and EU competition law currently before the Swiss Federal Supreme Court (FSC) offers a stark lesson on the shortcomings of the Lugano Convention. It suggests that the UK Government and the English Courts should think twice before contemplating rejoining the Lugano Convention, at least while these jurisdictional deficiencies remain. Cousins Material House Limited (“Cousins”) is a family-owned business acting as a Business to Business wholesaler of parts, consumables and tools for the watch repair and jewellery trades. It employs 60 staff and has a turnover of £11 million. Cousins has in excess of 12 million items across 130,000 product lines in stock and offers a unique one-stop shop supply service across all watch brands to independent repairers across the UK. Swatch Group is the largest manufacturer of Swiss-branded watches which it sells all over the world owning dozens of major watch brands including Omega, Tissot and Longines. It employs around 35,000 people worldwide and has an annual turnover in the region of £6 billion. In 2014, Swatch Group announced that with effect from 31 December 2015, it would no longer supply independent wholesalers or independent watch repairers with watch spare parts or movements in the UK. This included Cousins, a long-standing Swatch customer for many years. The supply of Swatch Group watch spare parts represented a significant proportion of Cousins’ turnover and Cousins was the main source of spare parts for independent repairers in the UK. Swatch’s stated objective was to improve the quality of the servicing and repairs of its watches. From a competition law perspective, the concern must be that such a strategy would extend Swatch Group’s market power downstream into the repair and maintenance of Swatch brand watches which (self-evidently) could no longer be carried out by independent repairers if they had no access to spare parts. It is settled law that it is an abuse of a dominant position for a manufacturer of raw materials to refuse to supply those raw materials to an existing customer for reprocessing into a downstream product where the manufacturer has decided to supply the product itself, thereby extending its dominance into the downstream market. [1] Cousins issued a letter before action to Swatch in March 2016. Swatch’s reaction was to request additional time to respond to the claim. Extra time was granted but rather than using the time to examine the merits of the English proceedings, Swatch, without notifying Cousins in advance, went ahead and launched parallel proceedings in the Berne Commercial Court in Switzerland seeking a Declaration of non-infringement in relation to its decision to refuse supplies of spare parts to Cousins. This litigation “torpedo” was presumably launched to remove the risk of proceedings in the English Courts and to secure a trial of the issue in the Swiss Courts where no doubt Swatch was confident that it would receive a more ‘sympathetic’ hearing. The infamous “Italian torpedo” tactic exploits the “Court first seized” rule under the Lugano Convention which would require any English Court proceedings to be stayed pending the Swiss Court’s ruling on the Declaration. Had the UK not been a party to the Lugano Convention by virtue of its EU membership at the time that the Application was made, the English High Court would not have been prevented from proceeding with Cousin’s Application. Cousins’ attempts to challenge the admissibility of the case in the Swiss Court and the jurisdiction of the Swiss Courts were unsuccessful and in December 2021 the Berne Court delivered its judgment six years after the Swiss proceedings were first issued. This judgment is currently on appeal to the Swiss Federal Supreme Court. In essence, the Berne Court found as follows: That the EU Case Law established that spare parts for each branded product is a market in its own right and that there is no substitutability of parts between brands and consumers require the use of original parts to maintain the value of their watches. The relevant market comprised (inter alia) the UK market for the supply of original spare parts for prestige watches of the respective Swatch brands; Swatch is the sole source for the purchase of these spare parts; Swatch had eliminated all competitors in the relevant UK market and now enjoys a 100% monopoly for the supply of Swatch spare parts to repairers. Despite these findings, and notwithstanding the prior case law of the Courts of Justice of the European Union and the English Courts, the Berne Court concluded that this conduct by Swatch was “objectively justified” under EU and UK competition law. In reaching these findings, the Berne Court made several fundamental errors in EU and UK competition law summarised below. First, in assessing the question of “objective justification,” the Berne Court chose to ignore the fact that under the case law an essential legal prerequisite to allow a termination of supply by a dominant undertaking was that it should not, thereby, eliminate effective downstream competition, which was the clear and inevitable result of its actions in this case. This error was all the more glaring given that, as noted above, the Berne Court also accepted that Swatch was a monopolist in the supply of spare parts for its own brands of watches. Second, the Berne Court failed to carry out any assessment as to the effect that Swatch’s decision had had on the UK market. It was for Swatch to prove that its actions did not have a detrimental effect on competition and consumers and yet Swatch produced no evidence in support of its case based on the actual impact of the refusal to supply in the UK. Not a single English witness was called in the proceedings and yet the Berne Court delivered a judgment in favour of Swatch having major implications for the UK, its wholesalers and final consumers without any reference to the local market conditions. Indeed, the evidence produced by Cousins shows that withholding supplies of watch parts had led directly to a serious reduction in the number of independent watch repairers and a very substantial increase in the cost of repairing Swatch watches through Swatch’s approved repairers. This evidence was simply ignored. The Berne Court could have called for market evidence to establish the facts but failed to do so. Third, contrary to more than 50 years of EU and UK jurisprudence, the Berne Court reached the untenable conclusion that the degree of Swatch’s market power in the supply of spare parts (i.e., its monopoly position) is irrelevant to the assessment of the objective justification for the refusal to supply. In reaching its decision, the Berne Court wrongly claimed that it has not yet been decided under European Competition law whether reorganising a dominant company’s distribution arrangements could constitute justification for a refusal to supply. In fact, the ECJ case law has consistently condemned the refusal to supply existing customers by dominant undertakings. The Berne Court argued that the EU Courts had, however, “tentatively” suggested that an internal reorganisation by a dominant supplier of the distribution of goods could constitute a justification for a refusal to supply existing customers and cited the EU Court Judgments in BP v Commission [2] and the Opinion of Advocate General Colomer in Sot. Lélos kai Sia. [3] in support of that contention. Neither of these cases in fact supports the Berne Court’s claim. Although it is the case that BP had carried out a reorganisation of its activities in the Netherlands in 1972 when a large part of its production facilities were nationalised, the issue before the Court, in that case, had nothing to do with the reorganisation. The central question was whether BP was entitled to apply different supply conditions to regular customers as opposed to occasional customers as a result of the 1973 oil crisis. Not surprisingly it held, on the facts, that BP was entitled to offer different conditions of supply to non-regular customers. But here, as noted, Cousins was a long-standing customer of Swatch and was therefore entitled to continuity of supply. In relation to the Advocate General’s Opinion in Lelos, the first point to make is that it was not a Judgment of the ECJ and represents no more than the personal opinion of the Advocate General. The second point to make is that the Case was concerned with the special features of the regulated medicines market and concerned the extent to which supply restrictions imposed to prevent parallel exports might be justified as a means of preventing shortages in the domestic market. Contrary to the Berne Court’s suggestion that the Advocate General was seeking to justify a refusal to supply, he in fact states the opposite at para 115 that it would be abusive to apply a practice which eliminates competition in distribution within Europe by suppressing exports from Greece. The contrary interpretation applied by the Berne Court is plainly wrong. Cousins has appealed the judgment of the Berne Court to the Swiss Federal Supreme Court. The risk is that the Federal Supreme Court will simply endorse the Berne Court’s decision on the facts. The case illustrates that it is both unjust and impractical for cases to be heard in a foreign court where they concern an infringement of local law with which the foreign court concerned may be unfamiliar and may be keen to support an important local industry. The risks of injustice are increased in such circumstances by the aggrieved party having to cope with foreign law, a foreign language in a foreign Court. In addition, it is both unfair and unjust for prospective defendants in matters properly brought before the English Courts to fall victim to such “torpedo claims” whose sole purpose is to deprive claimants of access to justice in the appropriate forum, to delay proceedings and in some cases secure the wrong decision through the pursuit of national interest in a foreign court. In particular, in the Cousins case, all of the key market effects on Cousins, other wholesalers, wholesalers’ customers, and final consumers arose in the UK and, yet, as noted, the Swiss court heard no evidence from UK witnesses. On a wider level, the facts of the Cousins case raise questions as to the apparent enthusiasm of the UK Government to rejoin the Lugano Convention. One may reasonably ask why it is that those advocates of Brexit with their call to arms of “bringing back control” and who are now in control of government should be promoting a cause which will give foreign courts once more the right to rule on matters of English law directly affecting the UK producers and consumers. If and when the EU agrees to allow the UK to rejoin Lugano – and given the current French opposition, it is likely to be a long wait – rejoining must surely be subject to changes in the current Convention which allowed the use of the Swiss torpedo in the Cousins case. The Brussels (Recast) Regulation, which also covers issues of competing for jurisdictional claims, provides at Article 31(2) an attempt to restrict the use of torpedo-tactics. It would be desirable to introduce similar constraints on torpedo-tactics if Lugano is to be acceptable to the UK post-Brexit. _________________ [1] See Commercial Solvents v Commission (1974) ECR 223; also Napier Brown/British Sugar OJ1988 L284/1; Upton Cash Registers/Hugin OJ1978 L22/23. [2] Case 77/77 ECR (1978) 141. [3] Delivered 1/4/2008 ECR (2008) 180. _________________ Maitland Walker LLP advises Cousins Material House Limited in these proceedings. Any opinions or conclusions provided in this blog entry shall not be ascribed to Maitland Walker LLP or any clients of the firm.1 point

-

Thank you for your kind words @RickTock and glad my Vostok cal. 2409 walkthrough could be of help! I somewhat recently serviced a Vostok 2431 and it uses the exact same type of calendar complication as the Vostok cal. 2414. You'll find my service walkthrough of it here. Anyway, I'll include the assembly pictures for the calendar works in this post for your and any future Watch Repair Talker's convenience. The only difference is that the cal. 2414 doesn't have what I call the "1st intermediate date indicator wheel" so you can simply ignore that part. I include the picture where the "1st intermediate date indicator wheel" is assembled anyway since it shows lubricating the upper section of the cannon pinion. Unfortunately, it has become increasingly difficult to source parts for Russian movements as Russian sellers have been banned on eBay. Good luck with your reassembly!1 point