Leaderboard

Popular Content

Showing content with the highest reputation on 12/27/22 in all areas

-

Recently got this guy from eBay. My first jump-hour watch, it was too cool and inexpensive to pass up. A 1-jewel pin pallet movement was inside and it was not running when I got it. Full service (after losing the one jewel past the edge of the screen in my Fixodrop bottle) and a crystal polish later, and it's ready for the wrist! Before: During: After: Dial down: Dial up:4 points

-

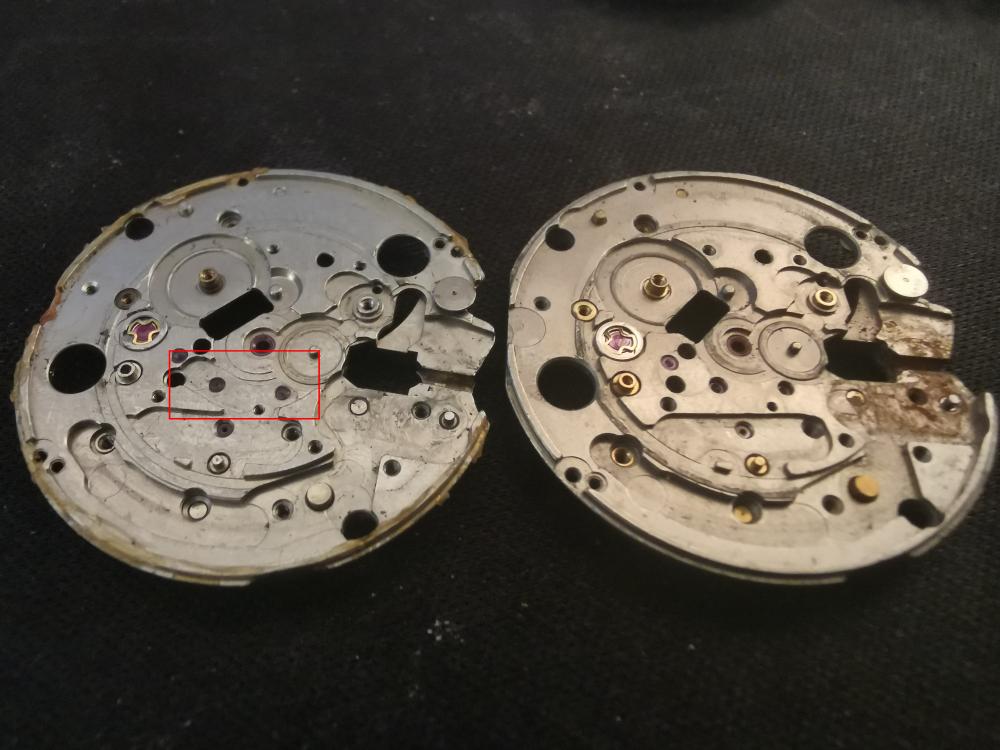

Hey guys! Merry Christmas! It's been a while since the last update. Have been grinding away at end of year work, doing the Christmas thing, and also caught covid a couple weeks back, so there's been a lot going on. Have been waiting on more bits and pieces, tools and such to arrive before making any more headway. I've received my super cheap mainspring winders in the mail and managed to wind a 7009 mainspring and get it back into a barrel, so that's nice! I've also taken delivery of 4x 7009a parts/restoration movements from SpeedTimerKollektion. I got some small ziploc bags and a cheap small parts case, and have very carefully disassembled and catalogued every part of this movement. Here are 5x 7009a movements worth of parts. Interestingly, the unmarked bag in the front of the container has a small cock/bridge and screw that came out of the Mumbai Special that was the original subject of this thread. These parts are not in the 7009a service manual and were not found on any of the other 4x movements that I recently got. Anyone have any idea what these are? I'm gonna have to look through some other seiko movement manuals to figure it out, but I don't think this Mumbai Special was a 7009a. Next steps are to sort through and gather the best looking parts, give them a clean and try and assemble one complete working movement out of this mess. I've got a case and some new dials on the way, and I might look into getting some new hands as the ones I've got are all fairly beat up, but I'm hopeful I can get this all done now I have some spare time for the next week or two. EDIT A COUPLE HOURS LATER. Well, I'm a step closer to unraveling the mystery of the parts. On the left is the main plate they belong to, and on the right is a standard (if rusty) 7009a main plate. It looks like this cock/bridge acts as cap jewels for a couple of pivots. On a regular main plate these are just open jewels that pivots sit in, but for this plate they have this bridge with the two cap jewels to suspend the lubricant and capture the pivots. I'm not entirely sure why, but I'm wondering if this is one of theose Allwyn seiko clones I've heard were manufactured in India.3 points

-

I used an ESP32, but I'm pretty sure something like a Pro Mini would be fine and less overkill. I just started this project so the micro board might change. Basically the cheapest you could find should control a watch cleaning machine I think. Just need PWM and probably 4 or so high/low GPIO Here's a video link showing what I got it to do as of last night. Short video, and still too long: https://youtu.be/gA0I5p6n5yo hmm. I just took a cursory look and evidently the Arduino stuff has gone the way of the Raspberry Pi. Probably the cheap way to go is an ESP of some kind - they are still relatively cheap... so far I guess. The way things are going, next month they might be extinct too I suppose. Remember the good old days?3 points

-

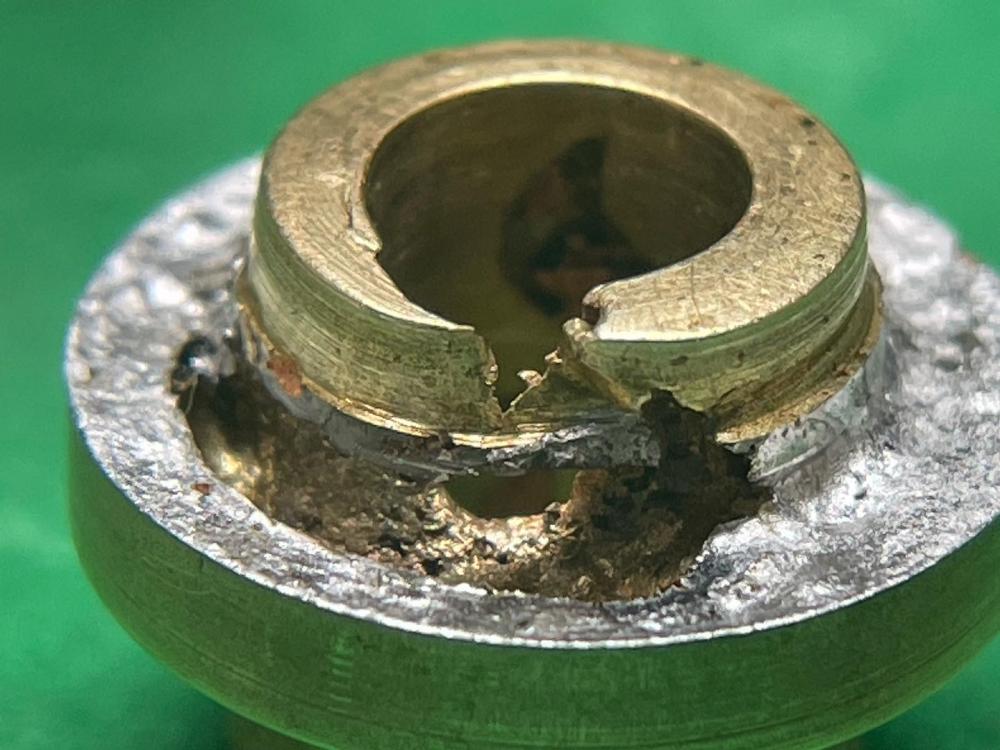

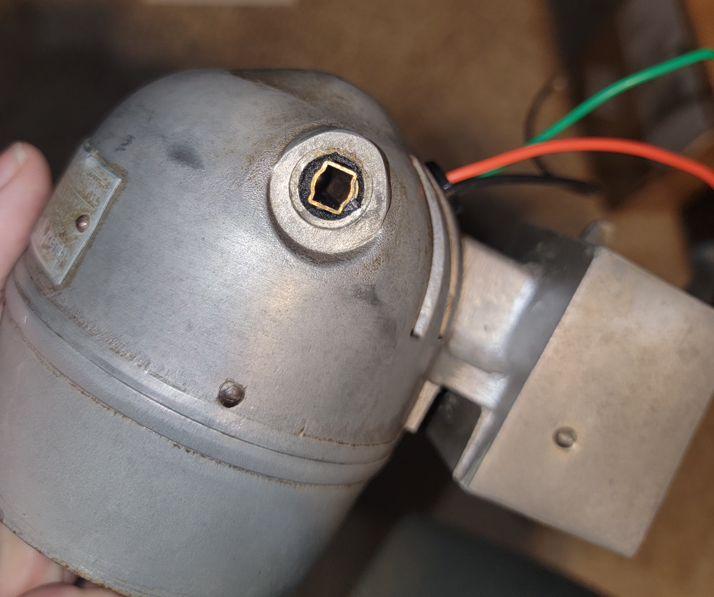

I snagged this Hamilton Beach mixer motor off ebay for a good price...for a backup if needed for future cleaner repairs. It was missing the brushes that are round. I could not find any, but I did find square ones where the dimension of the side was equal to the diameter I needed, so I bought four sets for cheap. Then I turned them on the lathe. I was surprised at how well they turned out. I do not have the cap screws, but I assembled the motor anyway (had to rewire it) and held the brushes in with rodico. The motor works. Now to solve the cap screw issue.2 points

-

Hi folks. I'm new to the forum. I'll post a link to my intro forum once the mods give me the official "okeedokee". Since I'm pretty new to watchmaking but not new to making stuff, I have naturally drifted my thinking toward a DIY project, namely a cleaning machine. I have seen a couple DIY attempts and starts, which are commendable. This got me thinking about an approach which might make a lot of sense, even financially, so that newcomers and maybe even old hands (like a backup machine or whatever) could whip one together for relatively cheap. The approach I speak of is to have interested parties contribute on an Open Source watch cleaning machine project. I'm not sure how these things are typically organized online, but even a forum thread could be the home base if nothing else. Designing and iterating a one-off machine like this is probably not efficient in both time and $$ compared to finding a used one for sale. But if a proven design existed and folks just needed to find, download and make it, then it probably would be worth it. One thing I already did on my own is to pick up a really cheap gear-reduction DC motor, controller and power supply which I have connected up and wrote some code to control it with a microcontroller. The code is just started but I have it oscillating smoothly (reversing back & forth with ramping acceleration). I'll have it working with switches/buttons and have RPM control soon. What I've learned so far is 200rpm (the motor I bought) is not correct like I thought it would be, but rather is too slow (without pulley ratios or something). But it's a start. Parts cost so far: power supply $11, motor $15, microcontroller $3, motor driver $14, total = $33 but could be reduced to maybe half that with better research. Lots of people have 3D printers these days so I figured a lot of the parts could be made that way. The difficult part of 3D printing is modeling the parts, so if files could be made available for download, then that would help folks a ton. You can also make tools to make other parts as well - what I'm thinking is some 2-part dies to shape mesh screen into the desired cup shapes for the parts baskets. Other stuff as well I'm sure. One of the DIY projects I saw was 3D printed parts for the parts cage. The guy said he tested PLA in the solution and it appeared to resist reacting with whatever he had anyway. There are other plastics to choose from too of course, so the "best" one can be determined over time. Anyways, my pipe dream is that there could eventually be a github or something that contained all the pertinent files, parts list & sources and instructions for a newcomer to download and use to whip one of these up. If this existed, I would think a lot of new folks would benefit. Even some experienced watchmakers might benefit from having one too. Let me know what your thoughts are. So the next step is to maybe get started. Here's a short video showing the oscillating motor control:1 point

-

1 point

-

More progress on some custom 3D printed baskets. These are half baskets and the dividers can be customized however I'd like. Seems like the 3D printer is more than capable of making a nice mesh. These baskets are for medium-large size parts so the side hole sizes don't matter that much.1 point

-

1 point

-

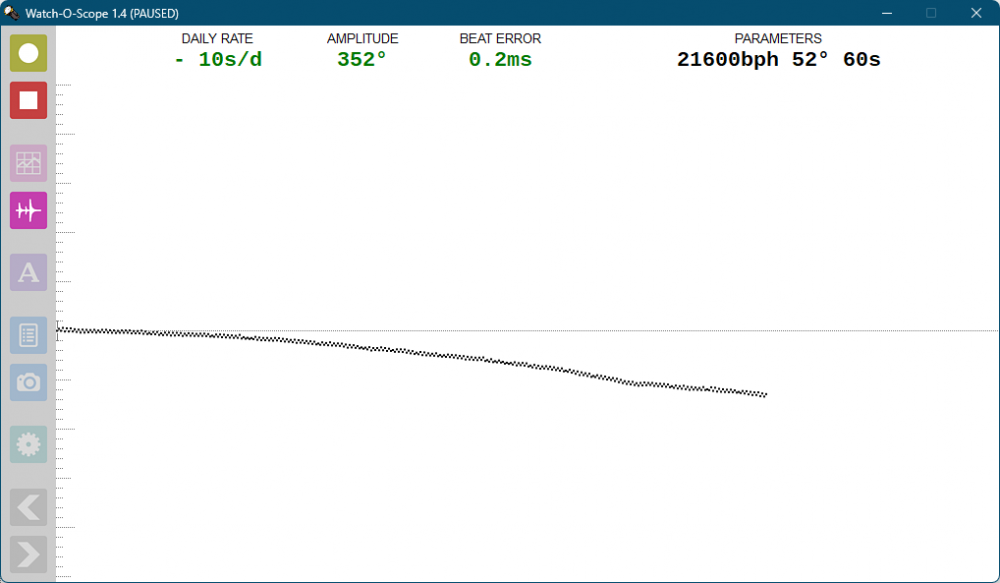

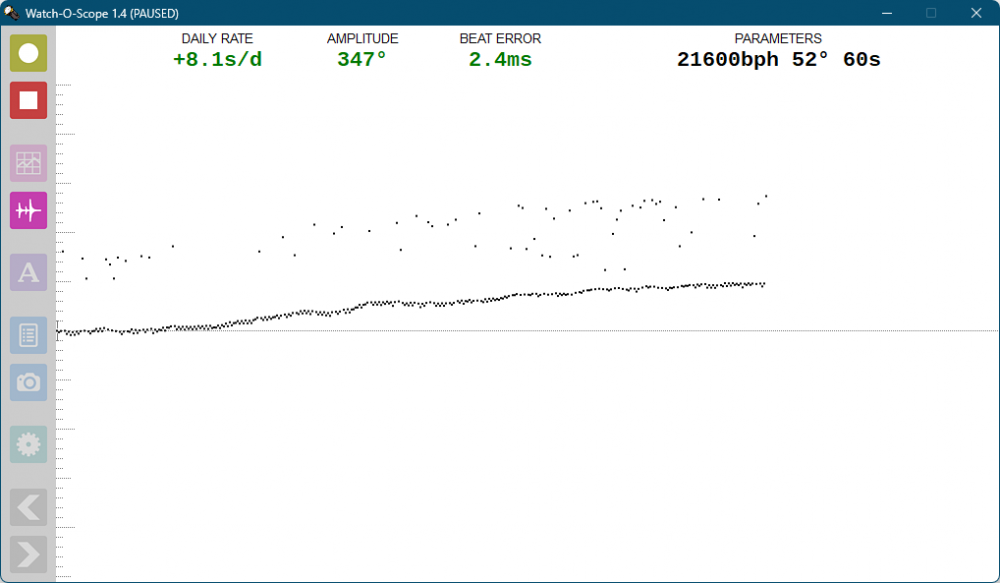

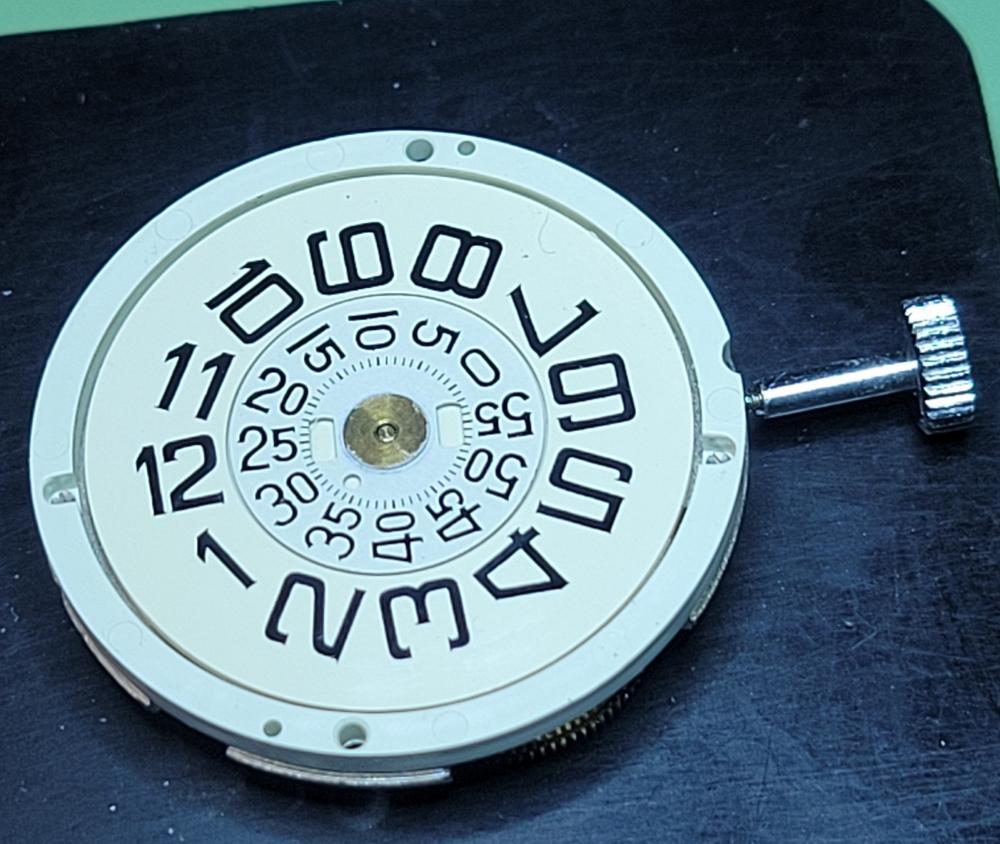

Bentima Star 1940s I think AS1240 £3 Charity Shop find. Needed a new balance staff. Fitted wrong one at first that turned out to be for incabloc (0.1mm too long, staff numbered 724). Eventually got the right staff for non incabloc, numbered 723. Running at 280 degrees DU an hour after full wind. Will see how it keeps time and regulate as needed. Late additional Christmas present for my wife.1 point

-

An update for anyone following...the GR recommended 4585 1.6 height looked lovely in the barrel but did not allow the barrel cover to close...fortunately I purchased both and the 3398 referenced spring, while looking a bit wrong sized in barrel, at least allows for the barel to be closed...1 point

-

@muddttI like your DIY stuff. I've done enough 3D printing that I know why you made teardrop-shaped holes in the sides. @jimzzillaGood on you too for the reversing. I just yesterday did a microcontroller version of something similar. It might apply to a whole different cleaner project thing someday. Some great ideas flowing here.1 point

-

1 point

-

It looks like you've kept your dismantling procedure very organized, well planned-out. And you've taken pictures along the way. All of that is always tremendously important, especially if we ever work on an unfamiliar movement that may have eccentricities in its construction. If it comes apart in that particular order, it will more easily go back together in that order, and less time will be spent staring at some little part trying to recall where in this great mess of parts this little one belongs. Headaches are no fun. My own grandfathers never wore a watch, that we know of, and I still haven't learned what became of the watch my great-grandfather, the tailor, carried hidden in his pocket in every photo we have of him. So you have a greater treasure than I, and I shall be checking back on this and cheering you on. Keep us informed on the progress. Show us pictures at the end. Good luck!1 point

-

\ That spectacular Girard Perregaux Gyromatic and the diminutive Suizo above reminded me a somewhat of this ETA 1080 based 1950s Linaso Candido, so I dug it out and gave it some fresh air too. I'm fascinated by the elegance of these smaller 1950s watches. So much more refined in my opinion than the majority of recent designs.1 point

-

This Suizo 1950s AS1361N 10 micron gold plated Automatic got an outing today. It is a gents watch, but is quite a diminutive piece (as was typical for the time). It is also very well engineered. The plating has a few wear marks, but other than that it is looking pretty good for its age. There is one minor discrepancy though. The dial states 25 jewels but the rotor says 21 jewels. Oh well, I guess nobody's perfect. It got a new crystal as the old one had resisted my best polishing efforts, but still wasn't up to scratch. I also treated it to a period correct 17mm dark green leather band from a job lot of 1950s or 1960s straps I picket up recently. Before you ask, no, I am not responsible for all of those scratches on the rotor, they were there long before I got my hands on it. Suizo is almost certainly a Achille Hirsch brand.1 point

-

1 point

.thumb.jpg.d76a35bbdb71b4cc042f4d60270b2044.jpg)