Leaderboard

Popular Content

Showing content with the highest reputation on 03/10/22 in Posts

-

For 14.4 mm barrel a spring 0.17 - 430 ... 470 (thickness / length) will be ok. not that Frank2 points

-

Have you ever worked on a watch mov.t before? To be blunt, adding or modifying , 'flipping gears' and the like as if they were hamburgers, is maybe 100 times above the reach and the possibilities of not only a beginner without knowledge, tools and experience, but also surpasses most accomplished watchmakers.2 points

-

2 points

-

That's because there is no problem I wish all of my hairsprings looked as good as this. I have a question for everybody what is the problem if it's not the hairspring? Have you figured out the question yet the problem is faulty diagnostic skills much farther down I'm going to explain the problems of that but for right now let's look at the hairspring problem? It's a big problem if you have faulty diagnostic skills otherwise it's not a problem. To understand the hairspring crisis I snipped out an image. Notice I circled two separate things horrible looking hairspring and shiny stud screw? In case you can't see the shiny steel studs screw like you typically find on watches it's because it's not there never had one which is typical of watches of this type. The hairspring stud is friction into the bridge it can usually be pushed out with some force. Otherwise the easiest way to deal with this is just removing the pin and sliding the hairspring out. For manufacturing purposes which works out good for us the hairspring always sticks out beyond the Stud. The part that sticking out just has to stay out a way of everything else that can't be bumping into the hairspring or balance wheel it doesn't have to look pretty it just has to be there. If you go to the top look at the original pictures that's what were seeing is the offending hairspring sticking out doing exactly what it's supposed to be doing it's just fine. A question for Ross does the watch have any sentimental value for you or your family? If the answer is yes wrap the watch up continue reading the discussion and don't touch it again for some time you're not ready for it. If the answer is no you don't care about this watch and then will continue but were really continue anyway is just a suggestion of it be better if you were working on this watch right now. Faulty diagnostics leads to faulty questions. On the other hand we've answered all the questions you really don't want to replace they hairspring it looks nice and replacing would be a nightmare. Second question you're not going to get another balance wheel I'm a talk about spare parts farther below why you're not. Third question yes it can be fixed but not by you not right now and I'll also explained that down below. Sometimes I think of learning watch repair is similar to learning to become a doctor? Both require similar things like knowledge skills and a heck of a lot of practice. Both have similarity in that patients are like watches their all the little different they have similarities but they have a lot of differences. Unfortunately the biggest difference is doctors typically don't work on living patients until a half enough skills. Then they have a lot of supervision. It's very bad if you're patient dies could be a heck of a big lawsuit. What's the worst that happens if you break the family heirloom watch? Although sometimes painful lessons are what is needed to perhaps go down a better path. Practicing for watch repair is not to practice on live watches. Practice on watches they don't care about that you have zero intention of fixing. Practice until you can put the watch together without breaking the pivots on. Hopefully your practice watches have balance wheels with hairsprings. Look at your hairspring see what a good hairspring is supposed to look like that's why purchasing a brand-new Chinese 6497 clone is nice. Look at how they hairspring is opening and closing and see how nice it looks. Then look at your practice watches do they look similar? In practice bending your hair Springs bended at the stud how does it look try to bend it back the only way to get good with hairspring and watches is to practice lots of practice. Then don't worry no one ever learns watch repair were all still practicing. Now back to movement identification you're probably not going to find an identification but here's how we would do it if there is no name anywhere to be found? You can remove the dial some times there is a makers Mark on the older watches its typically on this side. But even if you figure out who makes it doesn't mean you're going to get components at all. The other reason for taking a dial off there's another way to identify the watch? We need the diameter the movement always measured from the dial side because what were going to look up is categorized by the movement size. I've heard it referred to as the fingerprint system it might have an official name I don't know what it is. Up until relatively modern times the setting components in a watch for all unique. Her books that you to look at and see the pictures of the setting components you can attempt to find pictures of your components to figure out which watch you have. But most of the books are relatively moderate Mike may be the 60s and I got have won the 50s I don't know if I've really seen anything before that so if you're looking at more vintage you're probably not going get an identification. Even the older book I have a lot of times ill just have a name with no other references at all.2 points

-

As you are from Holland you should watch Chronoglide Watchmaking on Youtube he is Dutch and he is excellent. Here is his link. https://www.youtube.com/c/ChronoglideWatchmaking1 point

-

I think that there is too much excess spring sticking out beyond the stud and touching the rim of the balance. Try straightening the excess get it away from the balance wheel. I think the hairspring might have been replaced before as no watchmaker would leave so much spring sticking out. So I'm not sure if the hairspring has been vibrated for this balance wheel. As Ross says, and what my practice philosophy is.... Leave it till your skills catch up with the problem.1 point

-

I've got to ask. ???? The answer is probably so simple. But I am, so it isn't Ross.1 point

-

Thank you for the request. However as suggested I will stop the disassemble and come back to the repair when I have more experience. Sorry to disappoint. Regards Ross1 point

-

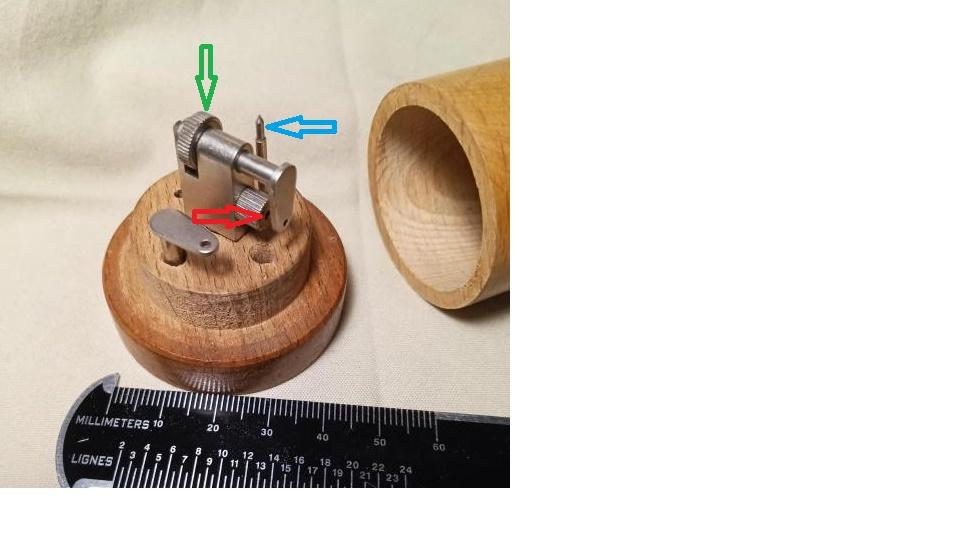

I was on the fence here, to start. Without the spring in front of me, it's a tough thing to really diagnose well. As Nickelsilber stated, in the picture it doesn't *look* too bad. I think it could have expanded a bit larger in the unwound state, judging by its barrel next to it, but it doesn't seem all that tired. Yet, as we all know, how the spring makes the watch *perform* is the important issue, not how it looks. Not knowing what its performance was before makes me want to give my default advice: if you can get an alloy replacement, I'd go for it. An NOS alloy replacement is probably the ideal situation here. Fewer worries for the future, and the performance of the watch will likely improve.1 point

-

Alloy springs are less likely to break, and generally (not always) have a very slight increase in power for the same thickness. If you find an old stock Elgin alloy spring that's great- they pretty much invented the alloy and it's still produced and used for high tech stuff: Elgiloy. To be honest that spring looks ok to me. An old rule of thumb is if it opens up bigger than twice the size of the barrel when taken out it's ok. But an alloy spring will be safer; if a mainspring breaks at full wind it can damage other parts of the gearing.1 point

-

That spring needs to be replaced. If I could imagine myself as a mainspring that is me at the end of each day bloody knackered and ready for bed.1 point

-

With the exception of something that the American watch and clockmakers Institute once did of assigning numbers to its members everything else is unique to whoever did it. So one time AWCI assigned a number so if I remember right it's a number which corresponds to the state the Delta symbol which is kind of a pyramid shape and the your unique number. That's because they were getting requests from police trying to track down the owner or wherever watch her anything and they had the same problem we did. But otherwise everything is a code number. The code could range from actually telling whoever what exactly they did. Or other times its references to their book like basically a page number go to page whatever and that's where it will tell about the watch. Occasionally might be lucky the watch was serviced a whole bunch of times and then you can figure out that may be those are date codes in addition to service stuff. But anything beyond that you're just darned lucky or really clever at figuring out how to read a short cipher that's unbreakable1 point

-

1 point

-

I decided not to read anything below the pictures because we have a problem? As a reminder this is an American pocket watch and there's a problem? When the movement is out of the case there is no stem. Why is that a problem the stem is found in the case the position of the stem is controlled by the sleeve in the case. When an American pocket watch comes out of the case it goes into setting. Like my picture isn't that wheel in the setting position? As everybody should grasp if you run a watch while in setting your driving the entire setting mechanism and simplistically that is bad. American watch companies grasping that their movements might have to run out of the case usually have a procedure to put it into the winding position or running position. I can't see enough of the movement to see what I need to see. Sometimes they'll be a screw that you turn other times they'll be a little lever like thing that's near where the stem would go in that you pull out. To basically look at how the setting components work and there should be something in there to allow it to go back in the winding position. That hopefully will improve things then if you ever seen any of my windings and fussing is about hairsprings now you know why hairsprings are typically vibrated to each balance wheel. But if you have an over a coil of the over coil has to be made very exacting position. So what they do is they match the balance wheel to the hairspring. The factory had all the different timing screws and then they also undercut the balance screws themselves to bring each one into the right timing to match the hairspring. This is why mixing and matching hairsprings will result in dramatic timing issues. So I would put the original hairspring back on the balance wheel and try to deal with the hot otherwise you're going to have to be playing with the screws quite a bit and you may still have to do it if somebody did a mix-and-match of not grasping that one hairspring is not identical to another.1 point

-

I had to look that up, turns out it is a USA luxury car leather thing, and not, as I feared when I hit the Google enter button, a "specialist club" in London's Soho.1 point

-

Outstanding? You've learned an important lesson that the problem might be just you or perhaps you adding to the problem. So many newbies failed to grasp that they very likely are the major problem with why there watches not running. Problem is it could be just about anything? Basically if you get the watch to run with more pressure it still could be about anything. It just says that the power from the mainspring isn't getting to the balance wheel or if it's getting there the balance wheel is having a problem. Look in at the balance wheel look at the hairspring make sure it's flat make sure it's not touching the balance arms. You can lose a lot of energy if that hairspring isn't where it's supposed to be. Out of curiosity how did you lubricate the escapement? With power on remove the balance wheel gently push on the fork Doesn't snap nicely as you push in one direction unsnapped the other way when you push it the other way? In other words you can simulate the balance wheel and just gently push on the fork see if it snaps back and forth? The reason I asked about lubricating the escapement is normally do that with a little power on and you should've observed whether the fork was moving freely when you are lubricating. A lot of the things you look at you do it before you get the watch assembled so you have less surprises of oh dear my watch doesn't run. Not that that doesn't happen sometimes. Let all the power off remove the pallet fork gently start to wind the watch does the gear train start up and spin or does it seem to not spin at all? Worst-case if you wind the watch up quite a bit before the train spins that would be undesirable. Then if you wind it and it just starts to spin effortlessly that would be good look in and make sure the wheels look like they're reasonably flat though. In other words are not wobbling up and down or other undesirable things. Then what happens if you don't touch the mainspring? If the prior lubrication has gone really really bad it can act as a glue and glue the mainspring together. This means if you're lucky the watch will run fully wound up but it definitely won't run overnight. At the minimum you can take the Off and look at the mainspring and see how it looks. So if it's blue in color the old blued steel tends to set with time. But I sent mainspring will run the watch where it's fully wound up and just won't run it overnight. So not ideal you could leave the mainspring in but you should at least check to see how good or bad it looks. Then at least you could clean and oil the arbor. As you've commented balance wheels and hairsprings nice place for new people have problems. You could put the balance wheel back in without the pallet fork give the balance wheel puff of air and see how moves does oscillate back-and-forth nicely or does it come to a screeching halt really fast. Typically when they hairspring is touching the balance arms The balance wheels not colossally nicely. It seems the oscillating fine turn it upside down make sure it still is oscillating nicely. then who made your watch? As a reminder the name on the dial possibly name on the case name on the back of the movement doesn't mean that they made the watch at all. Elgin and their very later years started to purchase overseas movement save and had an overseas factory. Later on they were just a name. So to epically whoever made the movement you'll find usually under the balance wheel at least in later watch is sometimes a manufacturer hides that it could be on the dial side. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&FHF_721 point