Leaderboard

Popular Content

Showing content with the highest reputation on 09/05/16 in Posts

-

Hi, Having seen various recommendations for using bronze tweezers I have looked without success for any UK/European seller. The only seller for watchmaking ones listed on Ebay is in the US and hasn't responded to my requests for information. In the past Sutton Tools, despite mainly dealing in jewellery supplies, have said they will get me any item I'm interested in from the wholesalers. It's a Catch-22 though - how do I know whether I want to go to that expense when I don't know if I want them anyway? Does anyone here use them? They are apparently similar to brass in that they don't leave marks, but are more hard wearing and don't deform as easily. As an experiment I did buy some sold on EBay (photos below). I do actually like these, but as you can see they are slightly large compared to the brass and steel watchmaking tweezers. I am sure I will get plenty of use out of them though. Stephen1 point

-

1 point

-

Here's my start Wake up a comrade, shake him well and ask about misplaced tank keys. As he babbles something remind him/her that tanks have no keys. Laugh.1 point

-

Just completed a cleaning of a watchcase & a Waltham 15j Pocket watch movement. Then I put them together to make a whole watch. Neither came to me as a whole timepiece. I have been looking for an unusual case to put the movement in & I found it at Dave's watch parts. The movement was very dirty and very sluggish & the case was very tarnished with dings and scratches. The crystal was not bad with a lot of small scratches (fixed with cerium oxide) So here are the before & after shots1 point

-

1 point

-

I don't like these case because of that, easy to broke the stem but you can fix it ; drill the stem in the center, make the hole two or three time deeper than the diameter of the hole turn a new square in steel with a round plug, adjust the plug until it enter the hole, a little drop of loctite and voila.1 point

-

1 point

-

1 point

-

1. It ran well before. 2, It started to run erratically. 3. Cleaning didn't help. Assuming that the cleaning was done well, this probably means something else has happened to cause the erratic running. This usually happens when the watch is dropped, resulting in.. a. Mushroomed pivots.. if the watch is dropped dial down, the pivot will mushroom at its tip. Perversely it will run ok dial down but when placed dial up, the mushroomed bit will 'hang' on the hole jewel and the watch will stop. b.Hairspring got caught up on the regulator or the regulator has moved as a result of the drop. c. One problem I encountered was where the screw for the pallet cock was not correct, the head of the screw was too thick so that when the watch was dial down the hairspring touched the screw head and resulted in the watch stopping. Worth checking on this. In your case, the original problem could have been a dirty movement but an oversight during the service may have created a new problem. Go back to basics, assemble the train without the pallet fork and balance. put some wind on the mainspring..see that it winds down smoothly. On a handwind movement, you should see a bit of 'backspin' as the last ounce of energy from the mainspring is dissipated. If you nudge the escape wheel and it continues to spin another few rounds then your escapement needs attention. Once you're satisfied that the escapement is fine, remove the train and fit the pallet-fork and balance (the escapement). At rest the pallet fork should be at the center of its travel with the balance installed. Your watch seems to have a movable stud holder so this is easy to do. On watches with a fixed stud holder the hairspring will need to be adjusted at the collet. Here you would also examine the pivots closely and triple check that the hole jewels are clean and clear. Endshake should be present but not measurable, The balance should move slightly when you move the movement (balance installed). Next re-assemble the train wheel and pallet cock, wind the barrel a turn. using a trimmed down pegwood, manipulate the pallet fork to and fro while observing the interaction of the pallet jewels viz escape wheel. Its hard to explain but one stone should catch immediately as the other releases... no dead space. If after all this and it still doesn't work, put the watch away and start with another.. this will relieve your frustration and allow you to come back with a clearer frame of mind after a decent interval. Anil1 point

-

good info, i agree. my guess its in the balance. let us know what you find.1 point

-

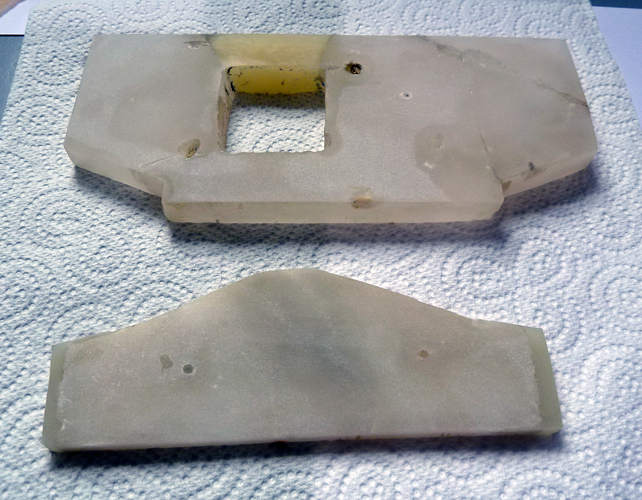

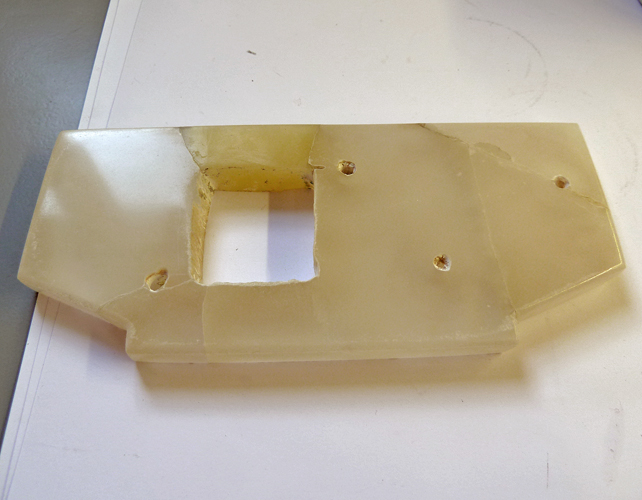

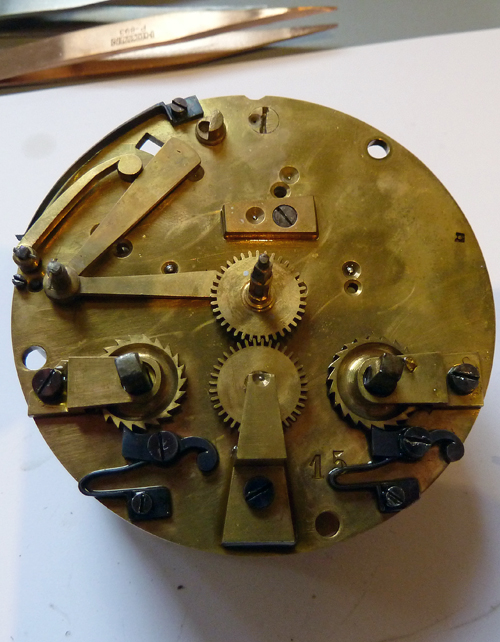

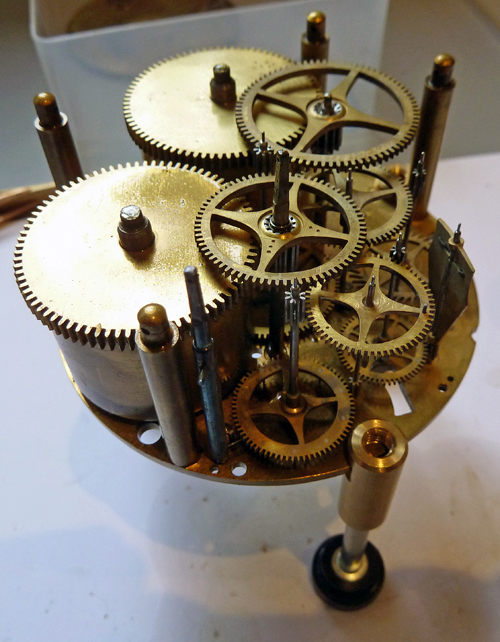

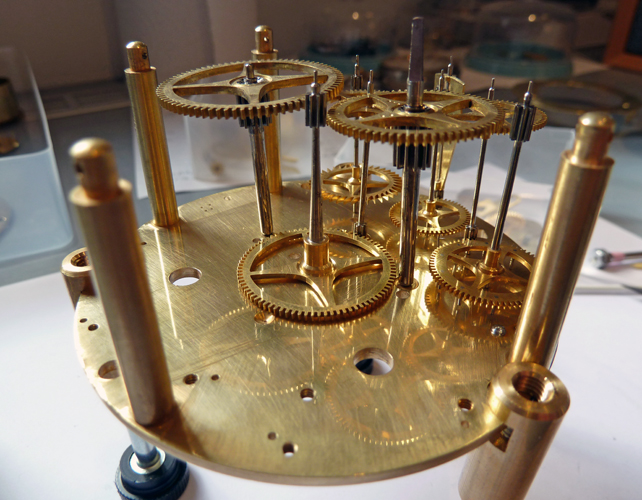

A friend threw this thing at me recently: Bought at a recent car boot sale for the princely sum of £10, it also has a glass dome (not shown) in good condition. The bad points: 1. Lots of thick gold paint. 2. The figure is missing something in her hand (a mirror?). 3. The alabaster base is cracked in several places, with a section missing at the back. 4. The alabaster on the front is cracked, too short on the sides & has had a non original brass plate fixed to the front. 5. Hands are rusting. 6. It looks like it's taken a few heavy knocks in the past. 7. The sub base is very poor, worn gilding, moth eaten velvet & cracked. 8. Very, very dirty. The good points. 1. It runs. 2. err.. 3. that's it. Right, lets see what we can do (a polite request to the conservationists among you- look away now, you may not like what you see!) Movement out and seen from underneath the previous attempts at repair: The studs holding the figure & the clock case to the base have been replaced with various odds & ends. The base has had some interesting repairs with epoxy: Copious amounts of gold paint: The base with the ill fitting stone & brass inserts: After stripping with Nitromors, acetone & an old tooth brush, were back to the original gold plate (what's left of it). The holes in the treasure chest will be filled with epoxy: A new mirror is fashioned out of a piece of scrap alloy & epoxied in place (note the casting detail showing now the paint has gone): The cracked alabaster base is soaked in acetone for about a week to remove the old epoxy then resembled using clear epoxy: The missing section is remoulded by laying the item face down on baking parchment, fashioning a couple of dams out of old Rodico & filling with epoxy (Araldite in this case): Mould removed, more clear epoxy applied to fill the cracks. Also the front stone is extended using the same method: Filled & sanded using wet & dry papers. The colour match on the front piece was adjusted for a better match by adding a little more of the clear Araldite. It looks like it originally had a couple of rosettes fitted: Given a further polishing with diamond impregnated polishing pads it begins to shine, unfortunately alabaster is almost impossible to repair invisibly so we will have to live with the cracks. It is however somewhat more stable: Onto the movement. Stamped S (Samuel) Marti, Medaille de Bronze - this being awarded during 1860 in Paris. The company later received the Medaille d'Argent in 1889, so it would have been produced between these two dates. Nothing major to report, just a bit tarnished, oily & grubby: Duly cleaned in Horolene, checked & showing (amazingly) no discernible wear: The case was originally (very thinly) gold plated, showing the copper base coat & spelter in places. As electroplating is too expensive, gilding using gold leaf was attempted first but the colour was far too bright yellow, so the case was repainted using a couple of thin coats (to preserve the detail) of Rustoleum brilliant gold (Valspars equivalent was also tried but looked to brassy). New screw studs for the clock case & figure closely matched to the original ones still in the figure were sourced from www.ba-bolts.co.uk . The alabaster stone base inserts still looked a little dull, so were given a thick coat of clear acrylic high gloss varnish. The non original brass plate covering the front alabaster insert was replaced with 2 brass rosettes from Cousins & painted to match case. The gilt sub base was sprayed gold & the fabric recovered using purple dressmaking velvet with gold rope trim. The wood main base (not shown in the final pics) was cleaned & french polished. Movement regulated. Dial cleaned. Hands re-blued etc: ..........and this is what it looks like now:1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)

.jpg.be4483543f8e4c029661bac425807a80.jpg)