Search the Community

Showing results for 'accutron' in topics.

-

Nice. Impressive boom. I have been playing around with different configurations for magnification and for now am using a Bulova Accutron microscope (30x). For awhile, I had a setup similar to yours (different style boom) but I never got the viewing angle and body position right. Probably should revisit that someday. Using stereo magnification just cannot be beat.

-

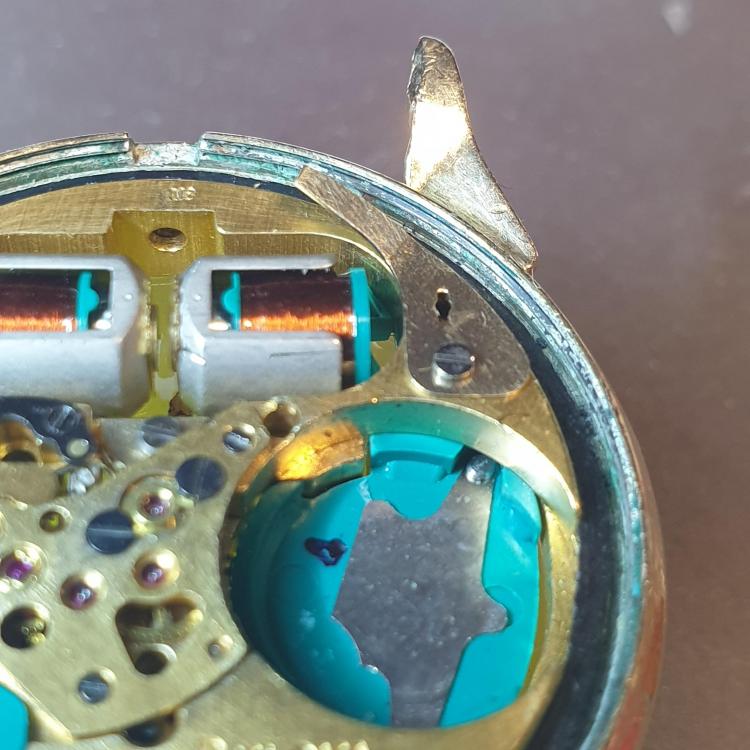

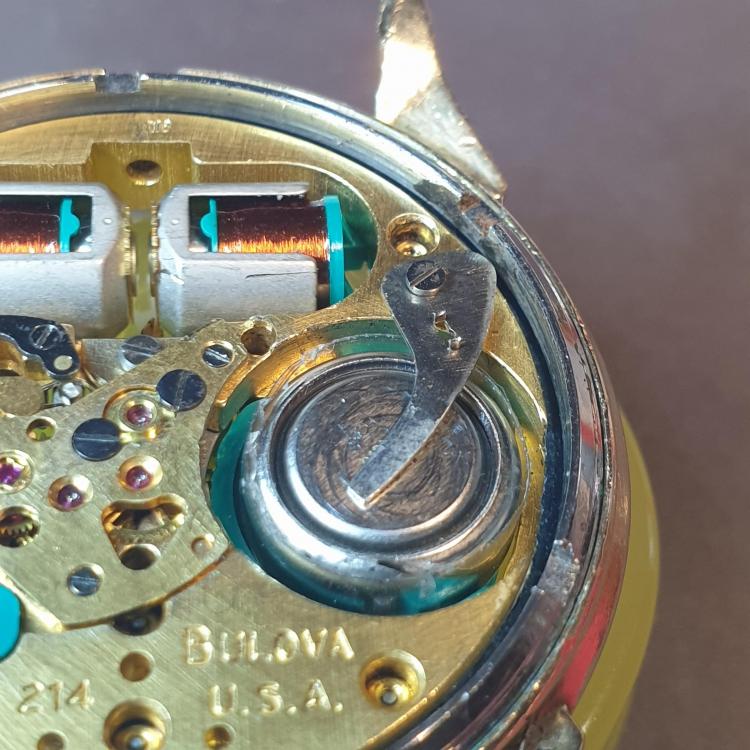

A 344 has the same dimensions as a 343. That's what I use in my Accutron 214s. Is this an electromechanical balance watch or a tuning fork watch?

- 56 replies

-

- 1

-

-

- benrus

- electronic

-

(and 2 more)

Tagged with:

-

I've been servicing Accutrons for some time now. But yesterday I just had an AHA! moment. When phasing the 214, I had been using the power from my Accutron 700 test meter to supply voltage to the watch. I would clip one lead to the ground strap and used one hand to press the positive lead to the battery terminal. This leaves only one hand to adjust the pawl finger. I was thinking of a way to make a battery clip hold the battery in place to make this procedure easier. Then it hit me.... All I needed to do was to flip the ground strap upside-down and use it as a battery clip!

-

Hi and greetings I have been given the instrument shown below. It was the property of a deceased watchmaker who like myself was also a radio ham. The donor believed it might be an item of radio equipment. The instrument says VEGAL made in England. No other marks or serial numbers. When plugged in the unit hums, I don't think it's mains hum as the frequency sounds too high, the loudness being controlled by the volume knowb. The switch is marked WATCHES, CLOCKS CLOCKS + 10 and T. FORK plus various numbers. The display ("Nixie tubes" ) displays numbers, could be frequency, time etc. The jack socket is simply marked INPUT I recall back in the 60's (yes I'm that old) an acquaintance had a Bulova accutron watch who's mechanism was controlled by a vibrating tuning fork, which could be heard humming if held near the ear. SO!! flash of inspiration. 1) The insrument was owned by a watchmaker and the switch positions obviously relate to timepieces 2) It has a setting marked T Fork 3) It hums Is it some sort of frequenct standard/calibration device/diagnostic aid for tuning fork watches ? Can anyone help Many thanks in advance Geoff

-

Assembling the Bulova Astronaut 214 bezel

clockboy replied to Blubarb's topic in Watch Repairs Help & Advice

Found this showing assembly sequence https://www.thewatchforum.co.uk/index.php?/topic/115197-accutron-astronaut-variant-guide-and-reference-info/ -

Hi i would be interested in this accutron spaceview but i have some doubt that it has not been converted. Could someone help me to understand if the glass, case, spheres and minute circle are contemporary with this spaceview? I have attached some photos Thank you in advance

-

Library of Horology DVD...any good?

HectorLooi replied to LittleWatchShop's topic in Chat About Watches & The Industry Here

I have something similar bought off eBay. Except for the Accutron service manuals, I've not really explored the contents of the rest of my disc. But at $15.... you can't really complain much. -

Tuning fork/analog electronic clock idea

spectre6000 replied to spectre6000's topic in All Things Clocks

Current thoughts: Power supply will be 170VDC tube rectified. The heater supply will be split off and rectified (solid state) for 5V and/or 12V depending on how things shake out. Tuning fork pickup/stimulator will be amplified via a dual triode. Preferably something readily available and in current production (though with current events...). Likely a 12AX7 of similar if I can make that work with the 170VDC (preferred by most nixie tubes). I don't know that I'll be able to handle the counter logic work and be tunable without a microcontroller... I have a handful of Arduinos, and another similar microcontroller board or two, so that should be easy. I had a neat idea to control the nixies from the microcontroller: an array of reed relays! They'll click quietly, but for different reasons than your typical clock. Additionally, there will be more information in the ticking, as there will be extra ticks every 10 seconds, minute, ten minutes, etc. It would take a total of 40-something relays (one for each number that is used, plus a few for some neon lamps) if I want to keep it simple. I might be able to figure out a way to multiplex them, but I'm not sure it really gives me any benefits. Enclosing the whole thing will bump up the temp and keep it stable to keep the tuning fork thermally stable. The point of the microcontroller counter is to be able to reduce the frequency being counted to account for this AND any manufacturing variances. Both of these factors will be unknown until it's done and in service, so the ability to control it on the fly is necessary for any accuracy. I'm hoping to be able to figure out how to suspend the tuning fork, pickup, and stimulator magnetically. I know it can be done actively, but I'm not sure it can't be done passively. If it can't be done passively, I'll use a series of springs or something. Total mechanical isolation, so the only way the hum can get out is through the air. Similarly/convesely, if I want the ticking relays to be audible, I'll need to mount them/that assembly (however it works out) either to a soundboard of sorts, or I might be able to get away with just mounting them to the side of the case somehow. So... The big question is accuracy... I'm pretty sure I'll be able to get the accuracy to within half a Hz of whatever frequency the tuning fork oscillates at. 440Hz is sort of the standard tuning fork frequency, but higher frequencies obviously decrease the potential error rate. It needs to be big enough to fit the look I'm going for (I don't know exactly how it's going to work proportionally), and it needs to be magnetic (apparently, a lot of tuning forks are made of aluminum these days). Assuming 400Hz (decreasing the 440Hz for temperature and to make a round number) and spherical chickens in a vacuum, I should be able to just barely edge out an Accutron at +/-1 minute per month. I'll have a higher frequency, more stable temperature, and no motion to account for. If it is close enough that it's not meaningfully out (~+/-5 minutes) over the course of 6 months, I'll be thrilled. I'm 99% sure this is my next big project. I've got another similar project currently in the works that I need to finish to make room though, and there will be some learning curve to this. I intend to prototype a subsystem at a time, probably starting with the tuning fork pickup/stimulator. I'll copy an existing transistor based circuit to start. It's a semi-known quantity, and I'll use it as a baseline. -

https://hackaday.com/2021/02/13/tuning-fork-keeps-this-throwback-digital-clock-ticking/ https://www.secretbatcave.co.uk/projects/electromechanical-clock/ I stumbled on these in one of my newsfeeds the other day. Macro scale Accutron clock project. A third clock project popped up at the same time, but it's not exactly a time based clock. I guess these are cool all of a sudden maybe? Meanwhile, back at the lab, I've been learning about analog electronics. Building a 100% analog phono preamp on the side of my desk not occupied by work related detritus (watchmaking, unfortunately, commands nearly entirety of my desk surface, so it's been playing 3rd fiddle at best lately). Anyway, digging into the first one got me thinking. He mentions at the end of the video that accuracy varies according to ambient temperature, and there's some conversation in the comments about ways of compensating for that. My knee jerk reaction to an image of the final project was that the 7 segment displays could be replaced with nixies. The schematic for the tuning fork regulator part of the clock could easily be done with a simple and readily available dual triode. I'm not sure about the rest of the circuit yet, but those are bridges that can be crossed. The interesting thought involved the intersection of the analog electronics, the heat they produce, and the regulation of the tuning fork. The heating elements in the tubes put off a lot of heat. Especially if the entire thing were to be executed in analog circuitry (rectification, amplification, display, and I haven't figured out the totalizing/counting aspect of it yet). If all of that could be crammed under a double walled glass bell, there'd be some serious heat in there. Possibly enough to cause problems. BUT I think it might be self regulating.... As the heating coils get hotter, resistance drops. If the ambient temperature is higher, they consume less power, yadda, yadda, and I think you'd end up with a pretty stable, albeit high, temperature to keep the fork humming along at a pretty steady rate. That rate would NOT be the rate stamped into the side of the fork though, so there'd need to be some means of tuning that regulation... Not really sure about that yet. Not sure I'm going to do this yet. It's a pretty tall leap to get from basic AC rectification and signal amplification to a totalizer circuit of some sort, but I haven't had time to do anything more than read that article/watch the video. I recall having seen another guy on youtube (handle has to do with rabbits in Japanese or something) that might have done something along the lines of a counter/timer. Might be worth looking into that. Videos require less eye strain and concentration than reading, and my toddler likes videos on daddy's computer, meaning I stand a chance at being able to do such a thing. Anyway. Thought I'd drop this here to see what the horological hive mind thinks on the subject.

-

Which Watch Have You Got Coming In The Mail ? Show Us !!!

Jimg1969 replied to SCOTTY's topic in Your Watch Collection

Bought a lot for 16.00, looks to have a vintage bulova, a small accutron and one that looks to be a vintage mido multifort with a rectangle case. Should be here Thursday, can't wait. -

My first fix, almost, Timex, calendar stuck

HectorLooi replied to nickynoodles's topic in Watch Repairs Help & Advice

If you are really looking for a challenge, try an Accutron 214. You already have all the necessary tools for the job. I know you'll eventually succumb to it. -

Technique for pinion alignment for reassembly

HectorLooi replied to MrWhippy's topic in Watch Repairs Help & Advice

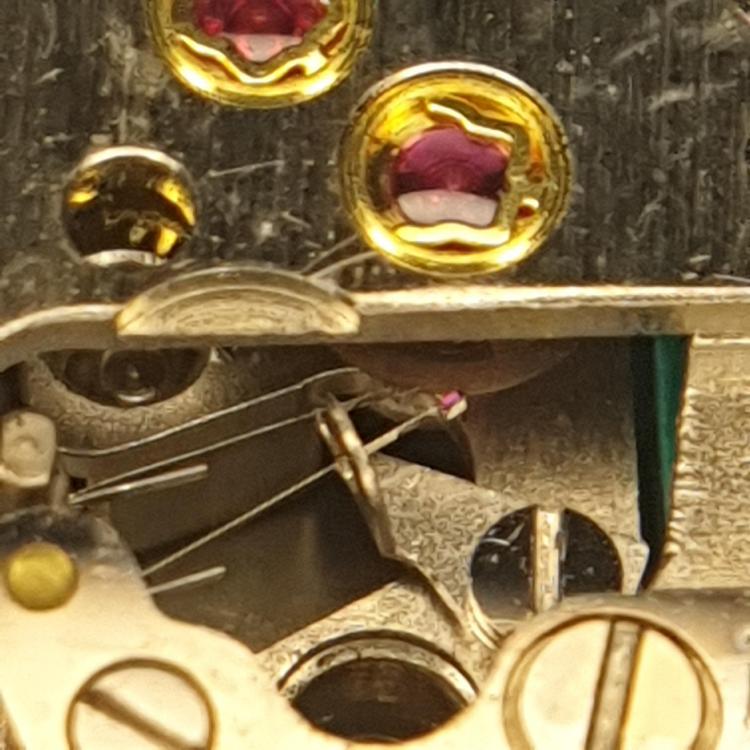

I used to use the technique described above by Nucejoe. It was also the technique taught to me by my mentor. But in recent years, I switched to using a technique which I learnt from YouTube. Basically, you put all the wheels into the holes of the bottom plate, stand them as upright as possible, then hover the upper plate over the wheels, trying to align the holes to the pivot and drop it on. There is a chance that you'll get a "hole-in-one" and all the pivots would go home into their respective holes. Failing which, you use the back end of your tweezer and tap lightly on the movement holder while observing the upper plate. The tapping will jar the wheels and when they are all aligned you'll be able to see the upper plate drop home. Sound ridiculously ludicrous, right? But I've been using this technique for the past 2 years, with only an occasional stubborn movement which will require the poke and pray method. And for Accutron movements, mastering this technique is essential to avoid damaging the delicate index wheel. Oh yes! May I add that with this method, I can get most top plates on in under 30 seconds. -

Looks like you've got your hands full. But Accutrons are really interesting. They are the only watches with true burnt coils, unlike quartz watches. Quartz coils normally break when someone slips with a screwdriver and scratch the surface. Accutrons have open coils with absolutely no visible physical damage. If one can repair the burnt coils, Accutron owners will beat a path to his front door.

-

Bulova Accutron 2180 2181

markr replied to markr's topic in Quartz and Tuning Fork Battery Operated Watches

I bought a Accutron 600 tester. Now I need to learn how to use it. -

I am in the process of building a custom tester based on the Accutron 600 test set. I choose the 600 because I have a pristine 700 and dont mind hacking the 600. I like the test set because of the huge 25ua meter! I am designing a variable battery source using a miniature digital volt meter mounted on a 3D printed module that plugs into the hole in the 600 test set (where the leads are stored). This is not a "does everything" tester either. It will let me test for low and high battery voltages, and also test pulse current. The picture shows the current state of the module--basically got the 3D print done. The electronics will be trivial.

-

Bulova Accutron 2180 2181

JohnR725 replied to markr's topic in Quartz and Tuning Fork Battery Operated Watches

No need to scan the manual somebody else did it for us. I've attached the service manual a specification sheet and the bonus parts list. The reason I use the word bonus is that the parts list came with the boxes of the material. Siege to the various watches at least the tuning fork watches would have a box with a lot of envelopes and due to have these cards that showed you the parts. So here is where someone scanned in all the cards and made a nice PDF for us. I'm probably being nitpicky here but when I think multimeter I'm thinking analogue and if somebody use the word digital multimeter then the fluke would qualify. Accutron 218 --Manual.pdf Accutron Parts 214 218.pdf Accutron_Specifications.pdf -

Bulova Accutron 2180 2181

LittleWatchShop replied to markr's topic in Quartz and Tuning Fork Battery Operated Watches

Regarding meters...it is not easy to find a 25ua analog meter. That is why I recently bought two accutron test sets because they use a rather large 25ua FS meter. I am planning on building a test platform using one of them. I know nothing about servicing accutron and don't plan to head that way...just hijacking this thread to add my thoughts on meters -

Bulova Accutron 2180 2181

HectorLooi replied to markr's topic in Quartz and Tuning Fork Battery Operated Watches

https://www.ebay.com.sg/itm/VINTAGE-ACCUTRON-MODEL-700-WRIST-WATCH-REPAIR-TEST-TOOL-SERVICE-KIT-/384557962006?mkcid=16&mkevt=1&_trksid=p2349624.m2548.l6249&mkrid=711-127632-2357-0 If you place a battery in the test clip, it will provide power at the test leads to power up the watch under test. The meter gives a reading of 25 microamps FSD. I guess you could use an analog multimeter on the 50 microamp range but then the needle would hardly move. -

Bulova Accutron 2180 2181

HectorLooi replied to markr's topic in Quartz and Tuning Fork Battery Operated Watches

Go download a copy of the manual. You can find it on the internet. Also, read up on the theory of how a tuning fork watch works and how to index the watch correctly. There are some videos on YouTube on servicing tuning fork watches too. I remember I read everything I could find on the internet on the subject and watched every video on servicing tuning fork watches too. Then I put in on the back burner and let it stew for a few months. A tuning fork watch is totally different from mechanical and quartz watches, although background experience on working on other components like keyless works, motion works and calendar works would be a great help. A microscope of at least 20X magnification is essential. If you have an Accutron model 700 test meter, you won't need a variable power supply. But a normal multimeter isn't going to work. As for the watch that is humming, if the hands are not moving, it's better to remove the battery before the index wheel gets damaged. I'm no expert on Accutrons, but I'm here to help if you need it. Good luck. -

Bulova Accutron 2180 2181

HectorLooi replied to markr's topic in Quartz and Tuning Fork Battery Operated Watches

Be very careful with the index and pawl fingers. And don't hold the index wheel anywhere except by the arbor. Do you have an Accutron test meter? -

I have a 2180 that hums and a 2181 that does not. I'm about to start these two projects. Besides lots of photos any advice?

-

I was asked to look at an Accutron 214 that could hum but doesn't move. I removed the safety bridge and immediately noticed that the index jewel was missing. I searched the movement and also the watch case but couldn't find the missing jewel. Has anyone tried replacing a missing index jewel before? What bonding agent would be good for bonding to a ruby surface. Or is replacing the entire tuning fork the best way to go. TIA