Leaderboard

Popular Content

Showing content with the highest reputation on 04/08/24 in all areas

-

You don't have power to the escape wheel. May be still jam in the train, but (a silly question) did You wingd the mainspring? When the pallet was removed, then was the time to check if everything in the train is OK. Winding then leads to all wheels spinning fast3 points

-

Well, the vintage-watch bug has been nibbling at me for a good while now, and I have finally given in and got me some tools, and I am working on improving my skills and knowledge on an inexpensive ebay find. I have some older watches (Hamilton, Gruen, Aero Watch) I don't dare touch yet and hope to gain more insight from this forum that I have found invaluable already on many occasions. Looking forward to interact and learn! Have a great day everybody!2 points

-

It's not often you are wrong. But you are both right again. Inexperience rules. Thank you for taking the time to reply and advise. Ross.2 points

-

I'm assuming, bracelet staff is a wrist watch but I could be wrong .2 points

-

No, not serious damage but in some movements the sliding pinion can drop out of place, making the insertion of the stem impossible without removing the dial. I'm not sure which movements this affects, maybe someone could provide a list, until then, I always put the movement in set position.1 point

-

I agree, such spring doesn't behave as normal spring. But, You can try it. It mainly depends on the type of clock and what torque is needed to keep it working. The isochronism is the thing thart will suffer the most.1 point

-

You won't see any obvious movement with it as it is - but if you apply a bit of force, you should find that the small pinion at the top end in the first photo can be turned relative to the large wheel, but with significant friction. All conventional clock and watches must have some friction slip "clutch" mechanism. to allow the hands to be set without breaking the movement; without that clutch, the hands could not be set, other than by stopping and starting the whole movement. These are some other examples, from a box of scrap clock bits I have; the first uses an overgrown cannon pinion style setup, with a sleeve that's been pinched or twisted slightly to make it grip the shaft - you can see the steel shaft through the slot in the brass sleeve. The others are spring loaded, more open variants of the one you have:1 point

-

Leave the ends soft. Two reasons: 1. The harder they are, the easier to break again. 2. No mater how perfect You have hardened the end, next to the hardened place always lefts annealed soft part between the end and the rest of the spring. So it is not possible to achieve uniform hardness unles You harden the whole spring, which is not easy thing to do. Then, hardening a steel needs knowlage about the steel and what is the correct regime for hardening. It is easy to damage a steel by overheating or burning the carbon in it for example.1 point

-

Yes, nice and simple. Move it aside just to get the jewel setting out. This video is very helpful. Start watching at 17:05 to get the answer to your question.1 point

-

Hi. Ithink you will find that it is pivoted and hinges round to cover/hold the jewel setting.1 point

-

Hi. You have received plenty good advice already. Find attached the 2895-2 technical document. ETA_ETA 2895-2.pdf1 point

-

VWatchie, RichardHarris is correct, you wear bracelet watches on your arm [smaller movements], pockets watches, timers etc. is what the other punch would be suited for....1 point

-

7T32 or Y182 should not be your "first introduction to watch repair" projects. But on a positive side, you probably will not need any parts at all. The movement requires cleaning, especially under / around circuit block.1 point

-

see what they need to repair and go from there to justify the cost, learning ain't free sometimes....1 point

-

1 point

-

1 point

-

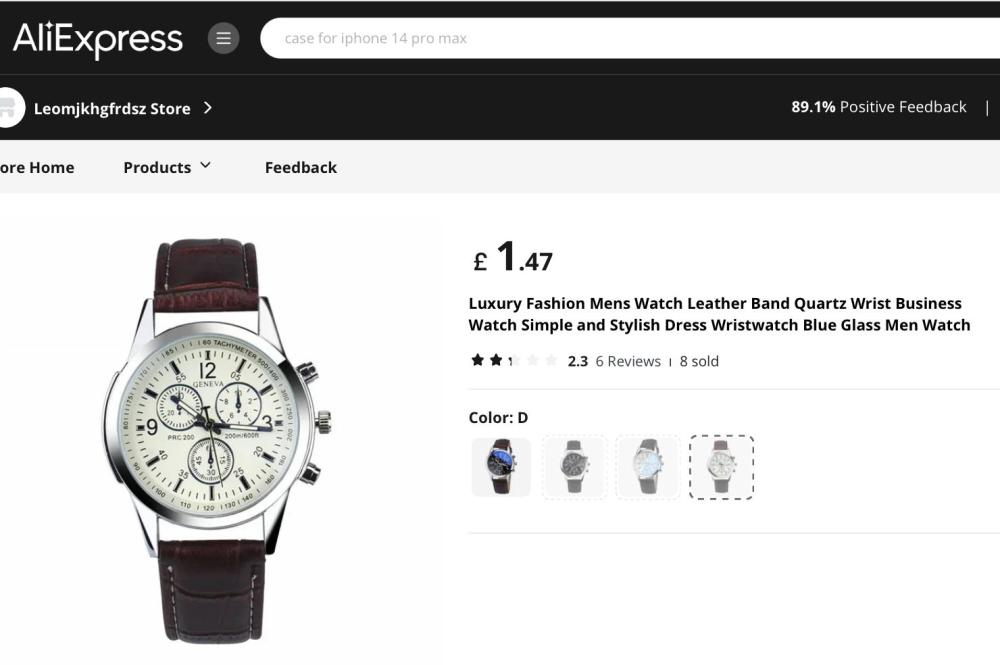

Wow very cheap indeed, worth buying to harvest the parts: strap crystal hands ???1 point

-

1 point

-

That's an excellent idea! I've been doing this for many years now but I still take a lot pictures.1 point

-

yes as we know it's quite a common problem when stems go bad the whole watch just disintegrates it's a very strange thing isn't it? Of course the local watchmaker never expects that anyone else is going to examine his handiwork and contemplate the insanity of this person. I don't suppose you have accessed in a test equipment? then this is a really vintage Rhonda movement and I am attaching the tech sheet. More than likely changing the circuit would solve the problem it's probably the electrical problems someplace. this is because typically slow quartz watches are mechanical issues and the only thing that can make a quartz watch run fast is a circuit issue. Then quartz watches even for regulation can't be regulated for minutes per hour it's usually seconds per day. Or really nice watches seconds per month. But never seconds per hour. Ronda_373-375-377_TECH.pdf1 point

-

Don't forget about the video Jon. No hurry, just a friendly reminder! Your content is always appreciated I guess you'll publish it here!? https://www.youtube.com/@jonthewatch3640/videos1 point

-

An update on the OWA issue: I ordered a new replacement part for the watch and it arrived a few days ago. Thanks to Watchweasol's tech sheet, the installation and lubrication went very smoothly. Had I the attention span of a grapefruit, I would have noted in Watchweasol's tech sheet the sole, but crucial difference between the AS1361 and the AS1361N: the diameter of the oscillating weight axle has been increased on the New version of this movement. Of course, I didn't notice and I ordered a part for the old version. Now I have an attached, albeit very wobbly rotor and it's all going back into the To Do drawer until an inexpensive parts movement turns up. Thank you, Watchweasol for the tech sheet, and thank you MaverickWaz for the advice on using my staking set to remove the old axle, it worked a charm.1 point

-

If the two parts your referring too are in the below image yes, it can be done with a staking set pretty easily. Just tested it now. And that’s coming from a guy who’s first post on here was about breaking something with the same tool!1 point